Current collector and lithium ion battery containing current collector

A current collector and organic technology, applied in the direction of battery electrodes, secondary batteries, electrode carriers/current collectors, etc., can solve problems such as poor product consistency, breakage, broken edges, burrs, battery short circuits, etc., to improve conductivity and concentration Effect of flow, increase of volume energy density, effect of increase of mass energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

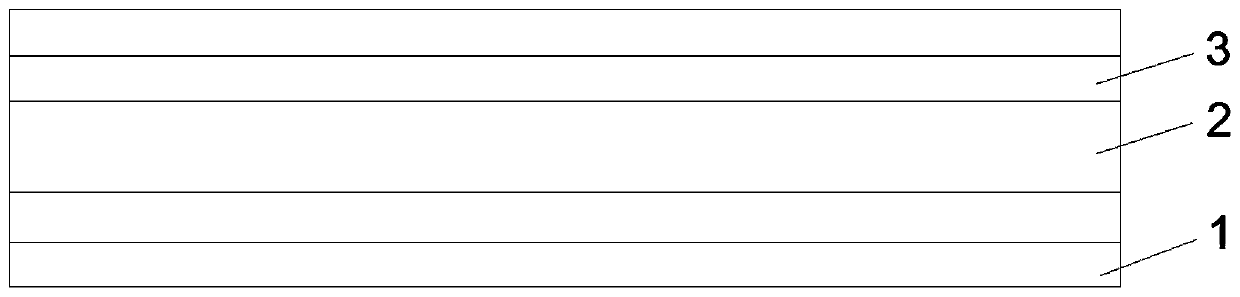

[0033] This embodiment provides a current collector, including a conductive layer 1, an insulating layer 2 and a reinforcing layer 3, the conductive layer 1 is two, and an insulating layer 2 is arranged between the two conductive layers 1, and the conductive layer 1 and the insulating layer 2 are also provided with the reinforcing layer 3 for enhancing the conductivity; specifically, the current collector is composed of conductive layer 1, reinforcing layer 3, insulating layer 2, reinforcing layer 3 and Conductive layer 1, the conductive layer 1, the reinforcing layer 3, and the insulating layer 2 are combined by sputtering;

[0034] The conductive layer 1 is aluminum foil with a thickness of 0.6 μm, and the aluminum foil is surface treated by one or more combinations of hot air blowing, pickling, corona, plasma, sandblasting, and grinding;

[0035] The insulating layer 2 is polyethylene terephthalate, and the thickness of the insulating layer 2 is 2 μm;

[0036] The reinforc...

Embodiment 2

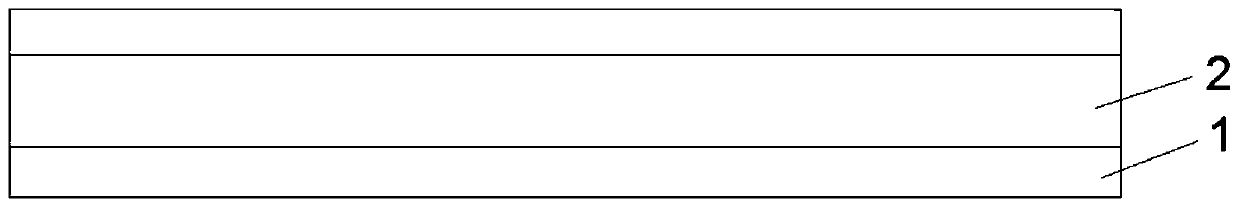

[0038] This embodiment provides a current collector, including a conductive layer 1, an insulating layer 2 and a reinforcing layer 3, the conductive layer 1 is two, and an insulating layer 2 is arranged between the two conductive layers 1, and the conductive layer 1 and the insulating layer 2 are also provided with the reinforcing layer 3 for enhancing the conductivity; specifically, the current collector is composed of conductive layer 1, reinforcing layer 3, insulating layer 2, reinforcing layer 3 and Conductive layer 1, the conductive layer 1, the reinforcing layer 3, and the insulating layer 2 are composited by vacuum evaporation;

[0039] The conductive layer 1 is aluminum foil with a thickness of 0.8 μm, and the aluminum foil is surface treated by one or more combinations of hot air blowing, pickling, corona, plasma, sandblasting, and grinding;

[0040] The insulating layer 2 is epoxy resin, and the thickness of the insulating layer 2 is 4 μm;

[0041] The reinforcement...

Embodiment 3

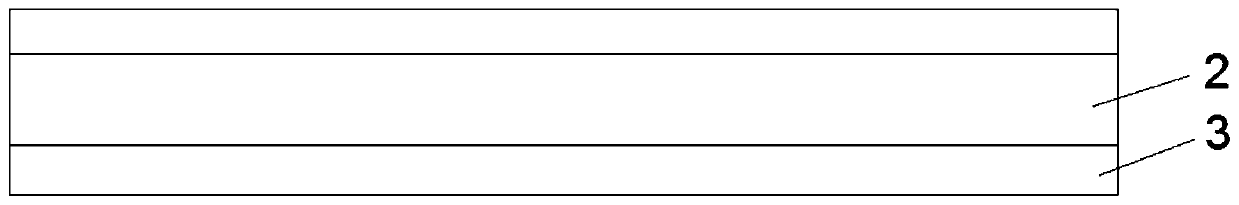

[0043] This embodiment provides a current collector, including a conductive layer 1, an insulating layer 2 and a reinforcing layer 3, the conductive layer 1 is two, and an insulating layer 2 is arranged between the two conductive layers 1, and the conductive layer 1 and the insulating layer 2 are also provided with the reinforcing layer 3 for enhancing the conductivity; specifically, the current collector is composed of conductive layer 1, reinforcing layer 3, insulating layer 2, reinforcing layer 3 and Conductive layer 1, the conductive layer 1, the reinforcing layer 3, and the insulating layer 2 are composited by ion plating;

[0044] The conductive layer 1 is aluminum foil with a thickness of 1 μm, and the aluminum foil is surface treated by one or more combinations of hot air blowing, pickling, corona, plasma, sandblasting, and grinding;

[0045] The insulating layer 2 is polyimide, and the thickness of the insulating layer 2 is 5 μm;

[0046] The reinforcing layer 3 is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com