Lithium battery negative electrode current collecting method

A technology of lithium battery and negative electrode, which is applied in the field of lithium battery negative electrode and its current collection, can solve the problems of unable to exert the energy density of lithium battery, restrict the development of lithium metal battery, reduce the energy density of battery, etc., and achieve good current collection effect, Large industrial and commercial application value, the effect of increasing energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0020] Example 1:

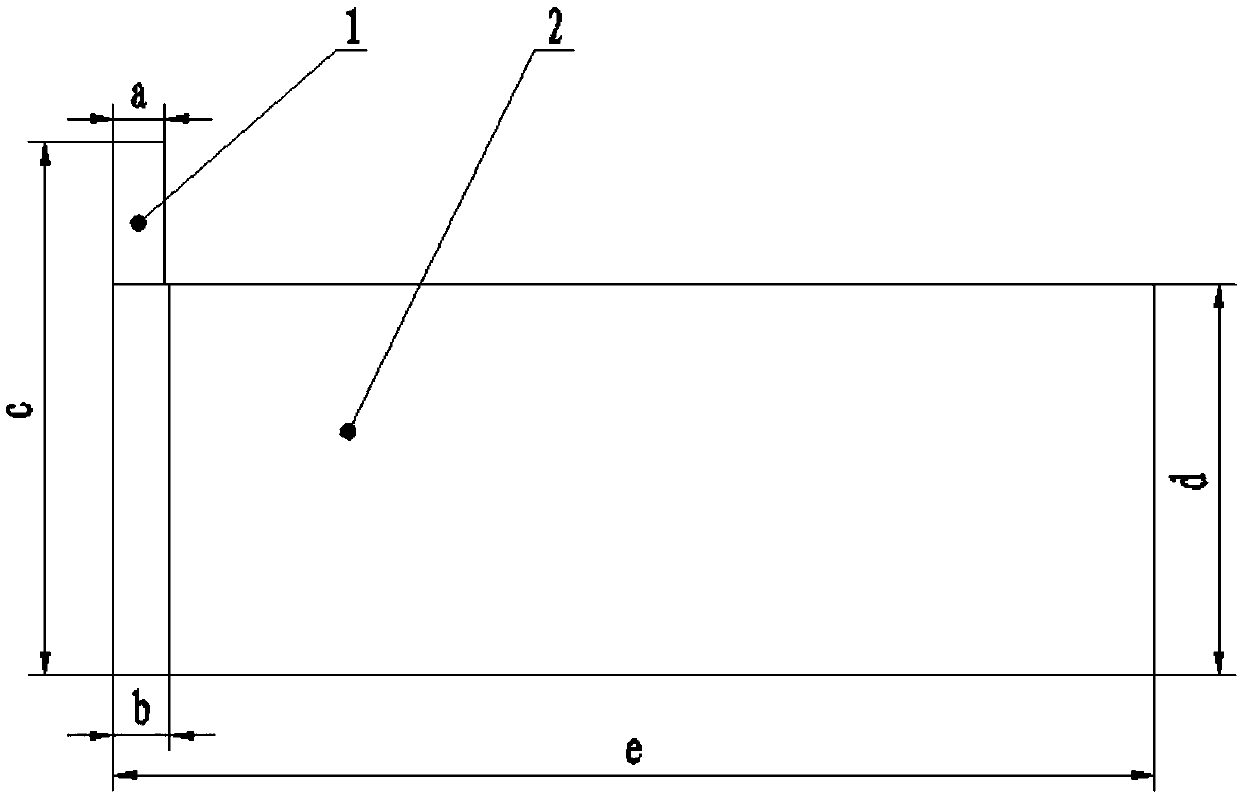

[0021] Such as figure 1 As shown, a nickel strip with a thickness of 0.08mm is selected as the tab, a width a of 10mm, and a length c of 75mm; a metal lithium tape with a thickness of 0.1mm is selected as the negative electrode, the width d is 58mm, and the length e is 450mm, which wraps the tab The part length b is 12mm. Use a hydraulic press to flatten the wrapped part under a pressure of 10 MPa, so that the lithium belt and the nickel strip are tightly combined to obtain a negative electrode with good current collection effect.

[0022] A sulfur-carbon composite material with a sulfur content of 70% is used as the positive electrode, Celgard2325 film is used as the diaphragm, and the aluminum-plastic packaging film is used to inject bistrifluoromethyl xanthimide lithium-based organic electrolyte to form a battery after sealing.

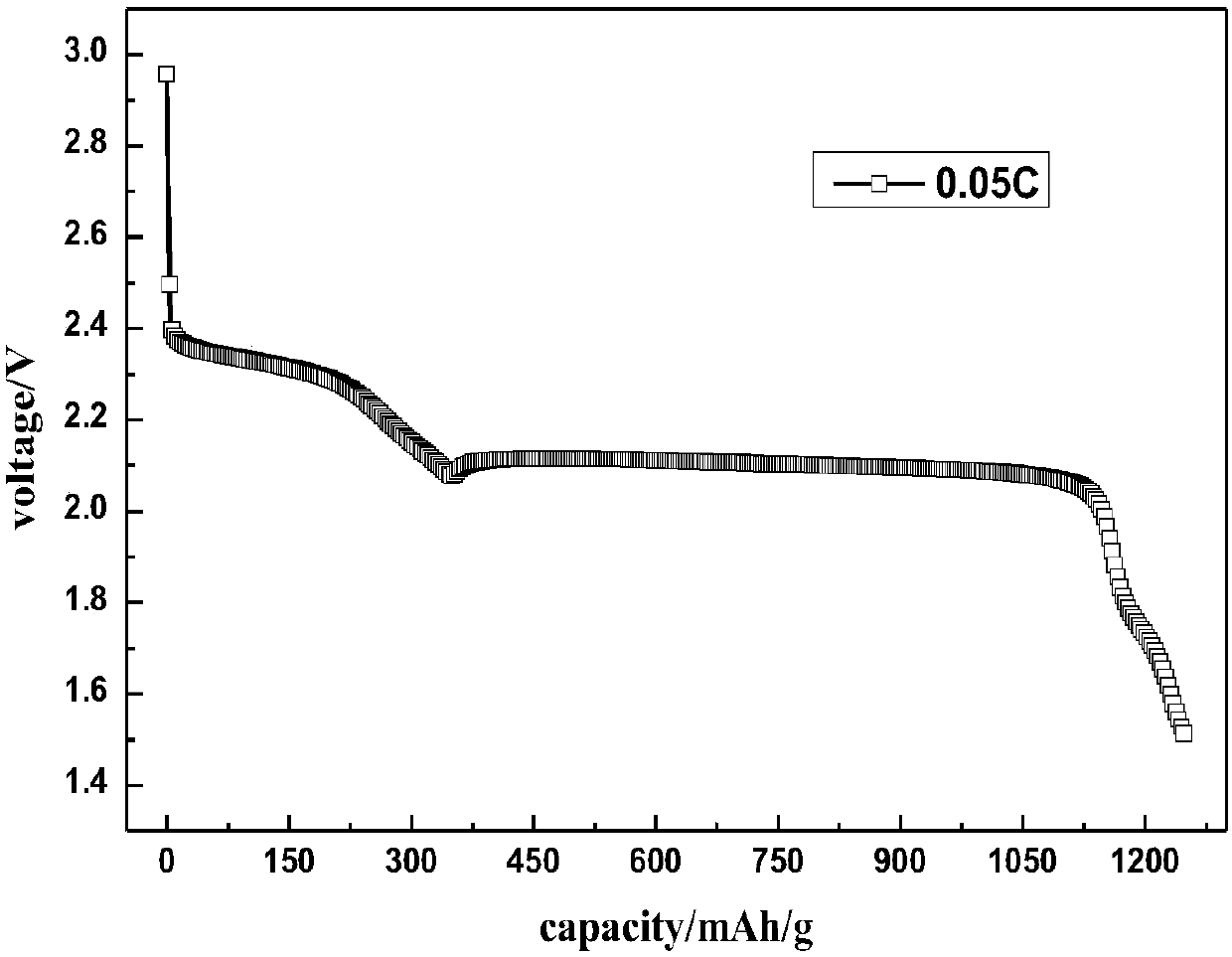

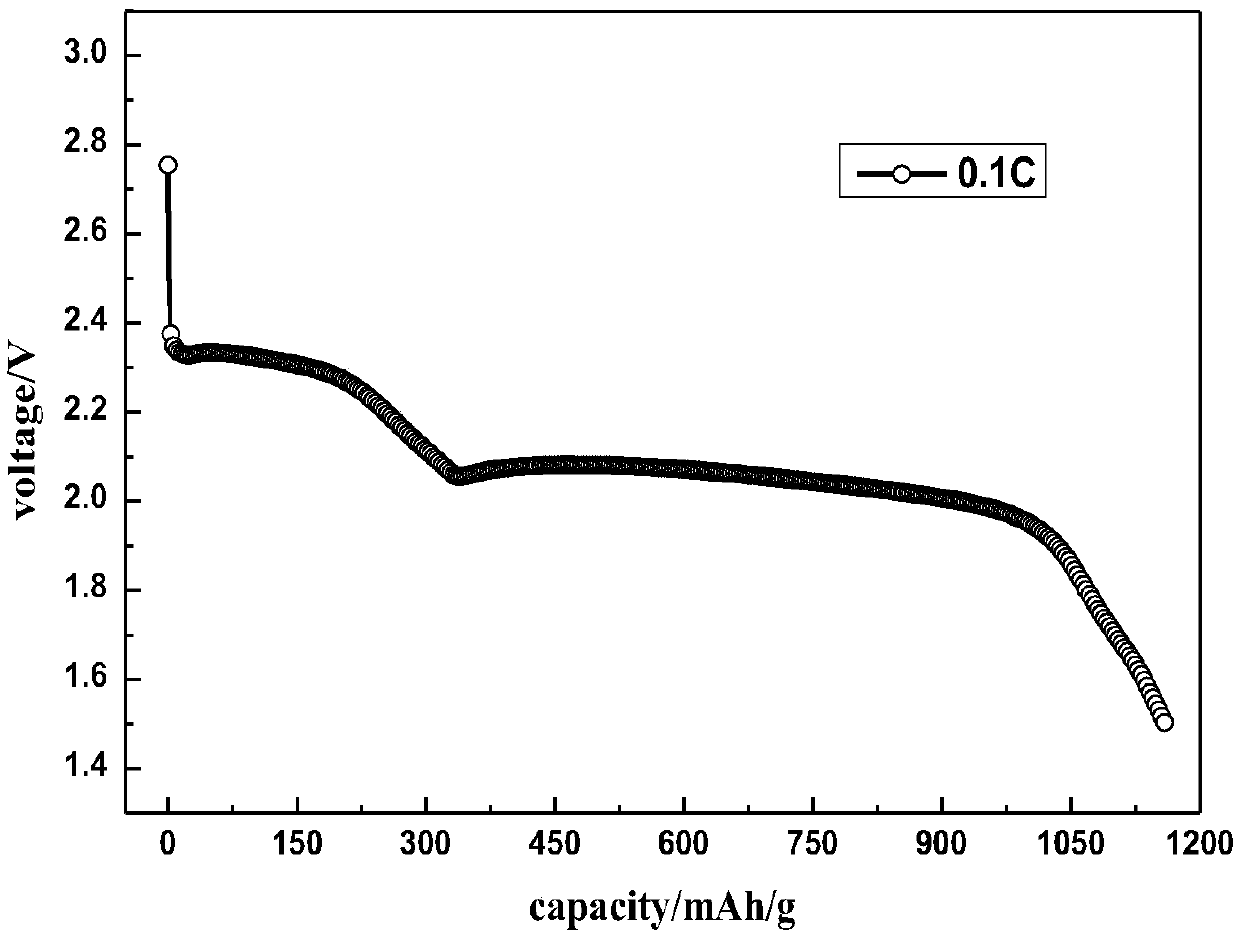

[0023] The assembled battery is discharged at a rate of 0.05C and 0.1C, the discharge cut-off voltage is 1.5V, and the discharge cur...

Example Embodiment

[0025] Example 2:

[0026] Such as figure 1 As shown, a nickel strip with a thickness of 0.1mm is selected as the tab, the width a is 6mm, and the length c is 60mm; a metal lithium tape with a thickness of 0.12mm is selected as the negative electrode, the width d is 45mm, and the length e is 450mm, which wraps the tab The part length b is 8mm. Use a hydraulic press to flatten the wrapped part under a pressure of 8MPa, so that the lithium belt and the nickel strip are tightly combined to obtain a negative electrode with good current collection effect.

[0027] A sulfur-carbon composite material with 80% sulfur content is used as the positive electrode, Celgard2325 film is used as the diaphragm, and the aluminum-plastic packaging film is used to inject bistrifluoromethylxanthimide lithium-based organic electrolyte, and the battery is formed after sealing. The specific discharge capacity of the battery is 1327.5mAh / g at a rate of 0.05C, and the specific energy of the battery is calcu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com