Lead-type anode post lithium battery

A positive pole and lithium battery technology, applied in the field of lithium battery structure improvement, can solve the problems of easy bending, deformation, difficult tinning, high manufacturing cost, etc., to achieve increased current output capability, good soldering tin performance, and good current collection effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

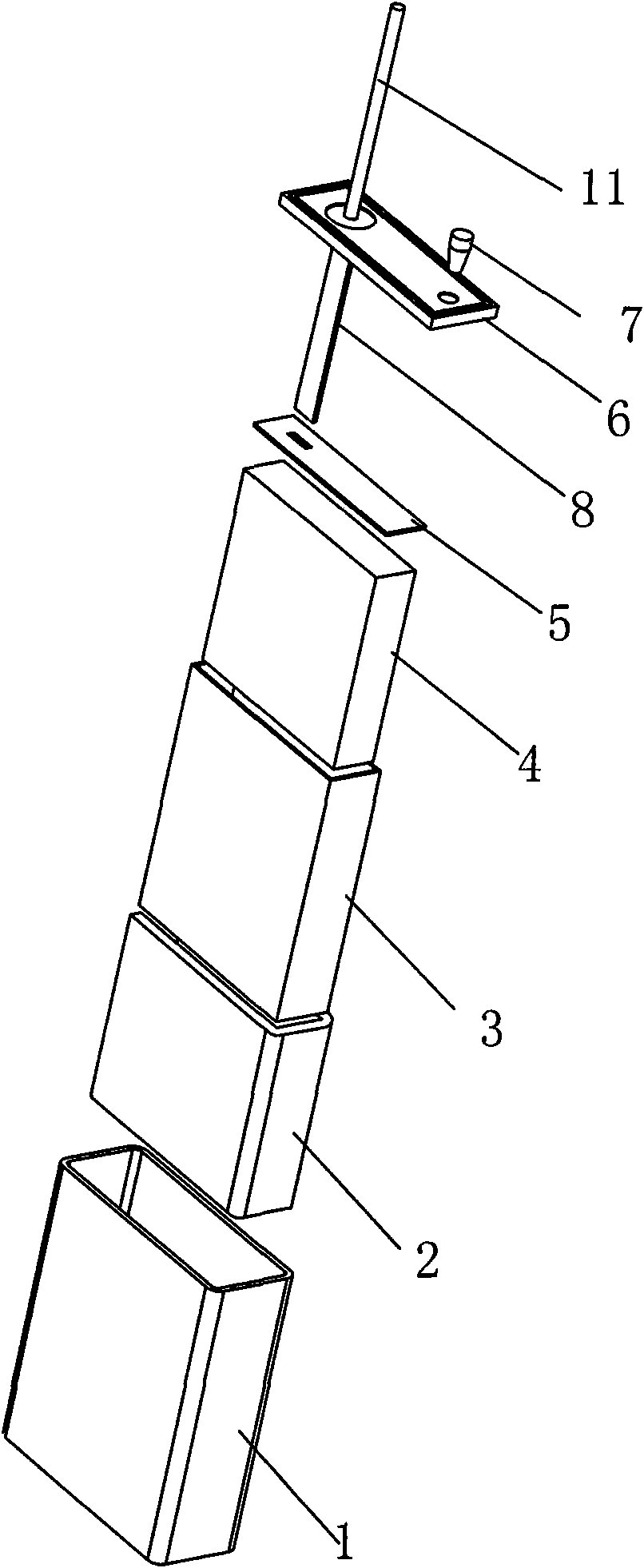

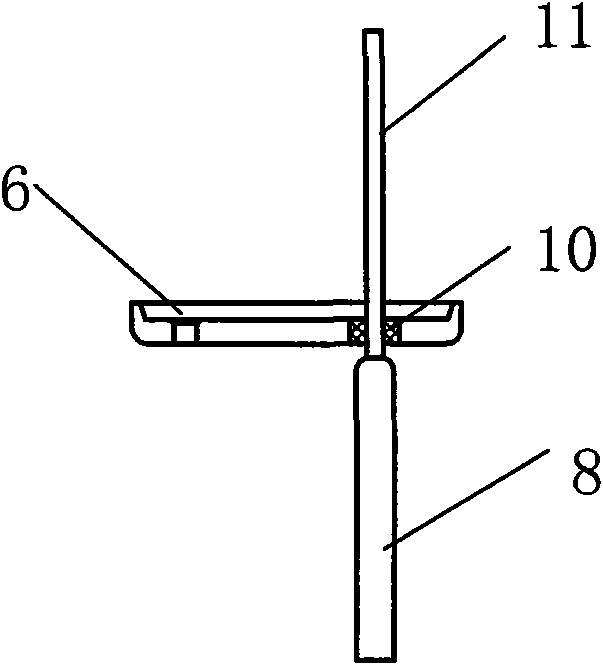

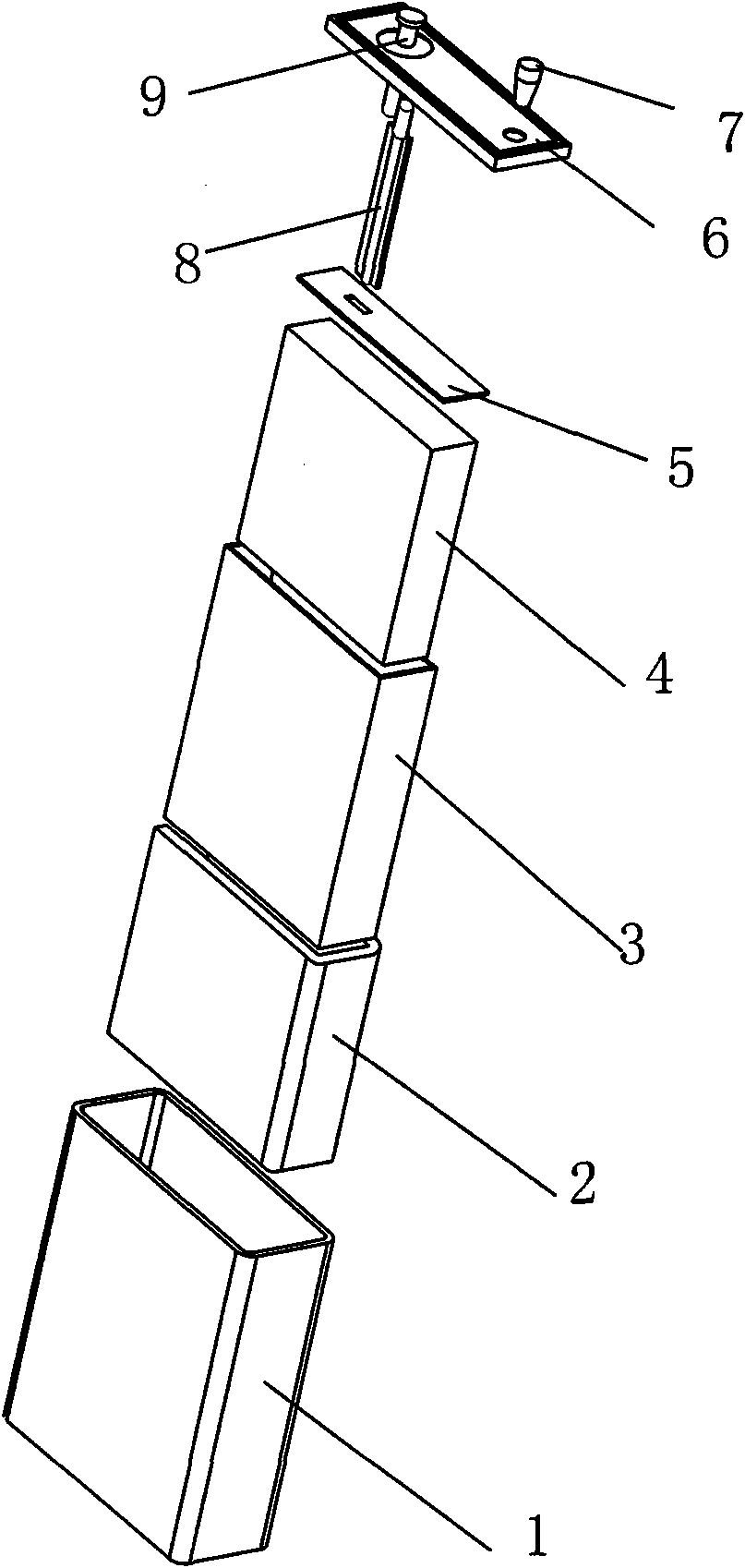

[0025] In order to facilitate the understanding of those skilled in the art, the structural principle of the present invention will be further described in detail below in conjunction with specific embodiments and drawings:

[0026] See Figure 3~7 In combination with a carbon-packed square lithium / thionyl chloride battery, the structure improvement of the lead-type positive pole lithium battery of the present invention is explained.

[0027] The main structure of the carbon-packed prismatic lithium / thionyl chloride battery includes a battery casing 1 and a lithium sheet 2, a side film 3, and a carbon pack 4 sequentially sleeved in the battery casing. A cover film 5 is provided at the edge of the battery casing 1, and a cap assembly is provided on the cover film. The cap assembly includes a cap body 6, a sealing body 7 provided on the cap body, and a positive electrode lead structure. The positive lead structure includes a current collector 8 located in the battery case, a positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com