Small-sized sealing nickel hydride charging button cell and preparation method thereof

A button battery and Ni-MH technology, which is applied in the field of small sealed Ni-MH rechargeable button batteries for medical equipment and its preparation, can solve the problems of easy falling off of the active material of the negative electrode, affecting the service life of the battery, and poor conductivity of the positive electrode. Achieve the effects of increasing the amount of negative electrode added, long service life, and excellent conductive current collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

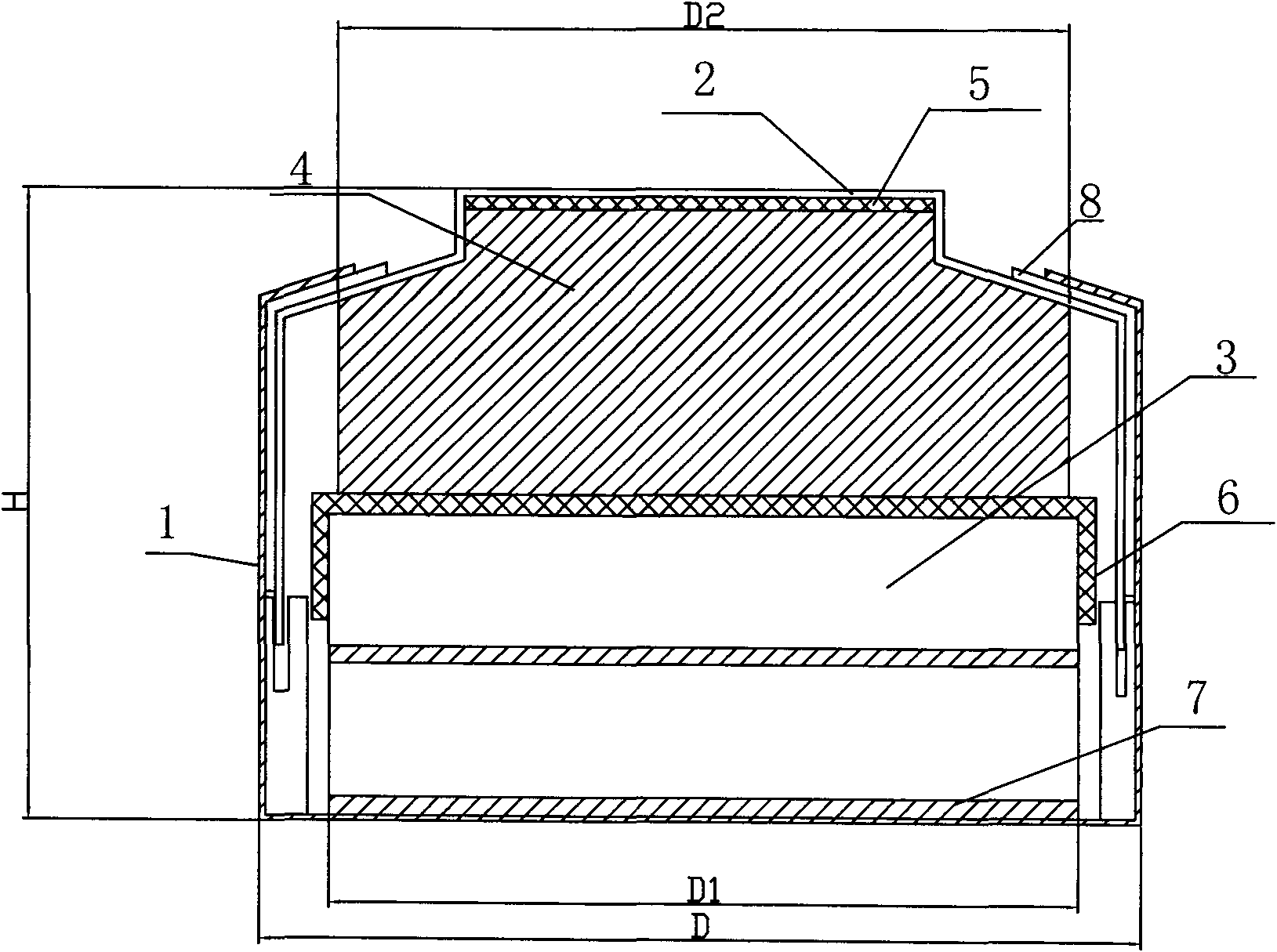

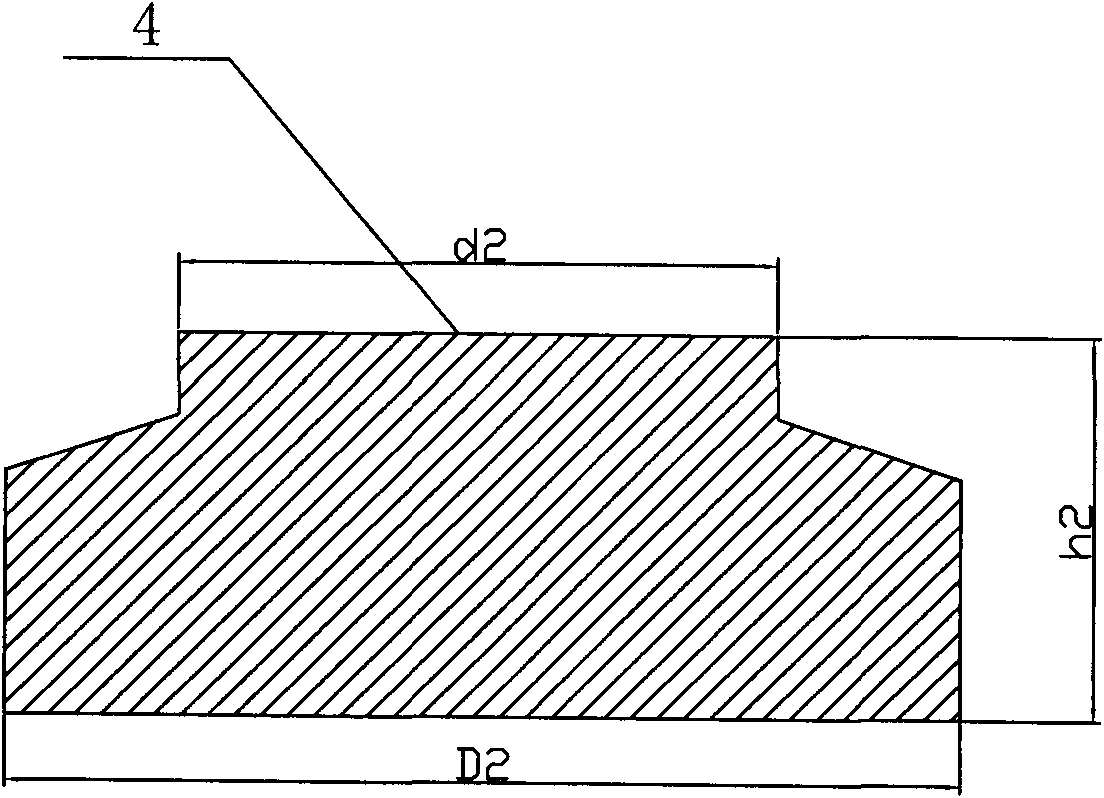

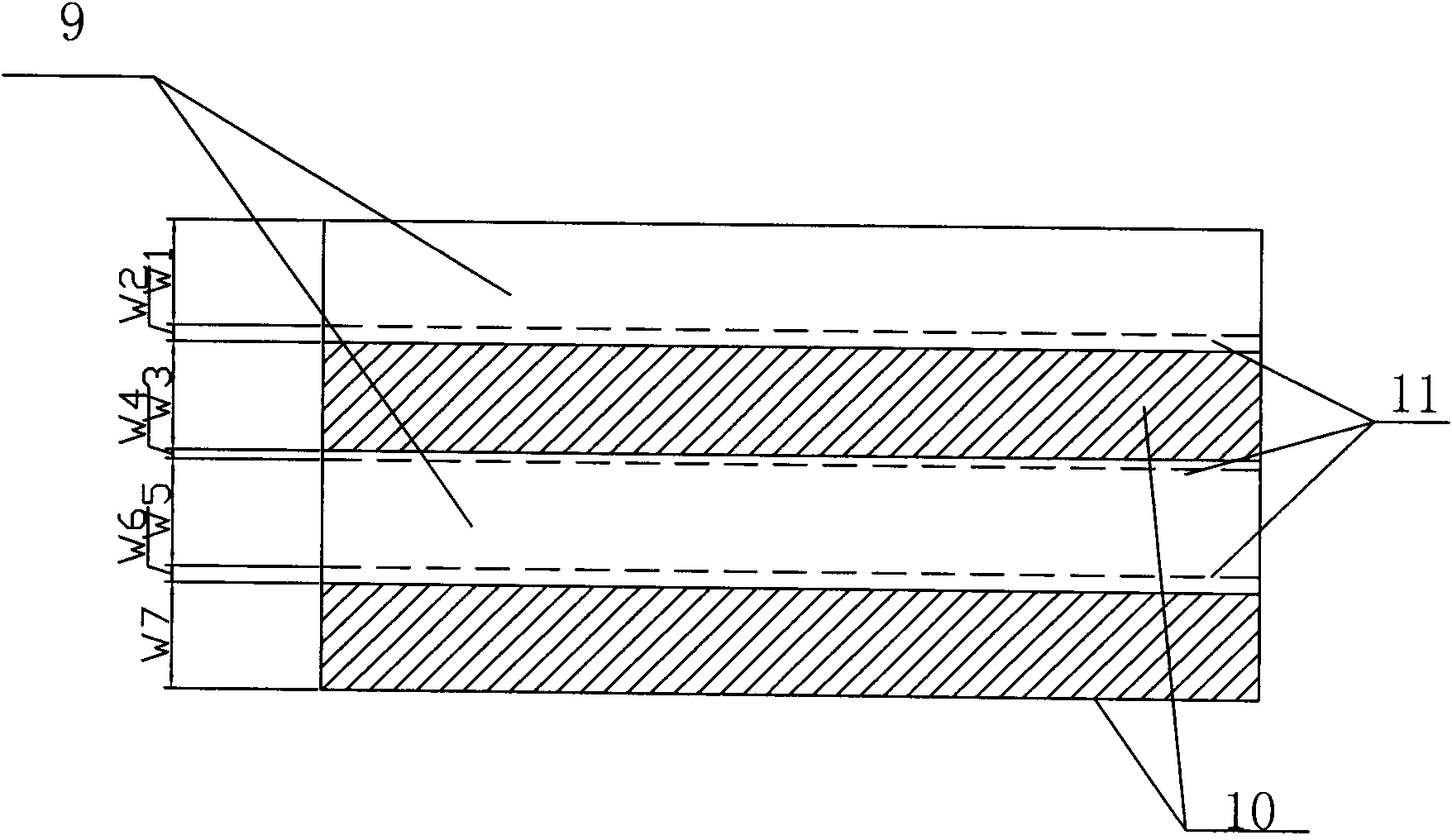

[0014] Small-sized sealed Ni-MH rechargeable button cell, the preparation method is as follows: such as image 3 As shown, the positive electrode conductive substrate 7 is evenly divided into equal parts, and the positive electrode conductive substrate 7 is first compacted to a certain thickness δ1 before coating the active material, and then the positive electrode active material is coated on the spaced positive electrode conductive substrate 7, The coating width is equal to the diameter of the positive electrode of the button battery, and the conductive substrate in the non-coating area is sealed and compacted to 0.2mm with adhesive tape. The thickness of the active material after coating and compacting is δ2, and there is a crease 11 between the coating area 9 and the non-coating area 10, the width of the crease is the same as the thickness of the rolling film in the coating area, and the positive electrode is punched out with a mold. Substrate 7, punching positive electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com