Novel winding type lithium ionic cell and manufacturing method thereof

A lithium-ion battery and a manufacturing method technology, which are applied in the field of a new type of winding lithium-ion battery and its manufacturing, can solve the problems of increased failure factors, inconsistent current density, and high internal resistance, and achieve the effects of increasing capacity and increasing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

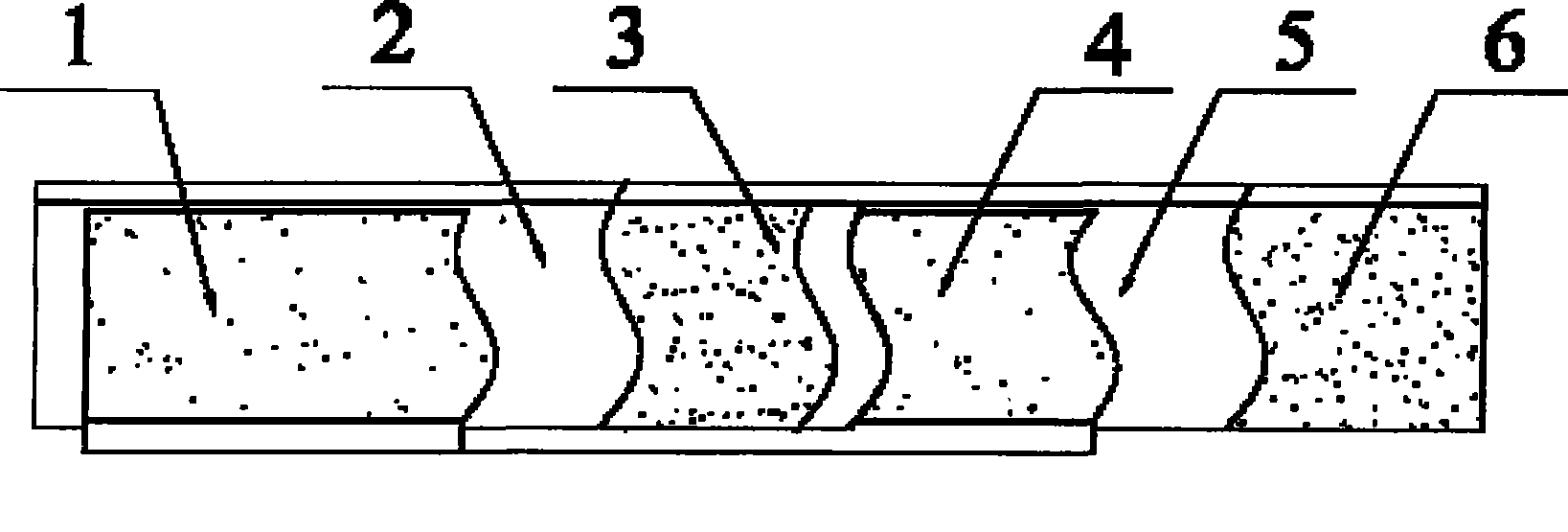

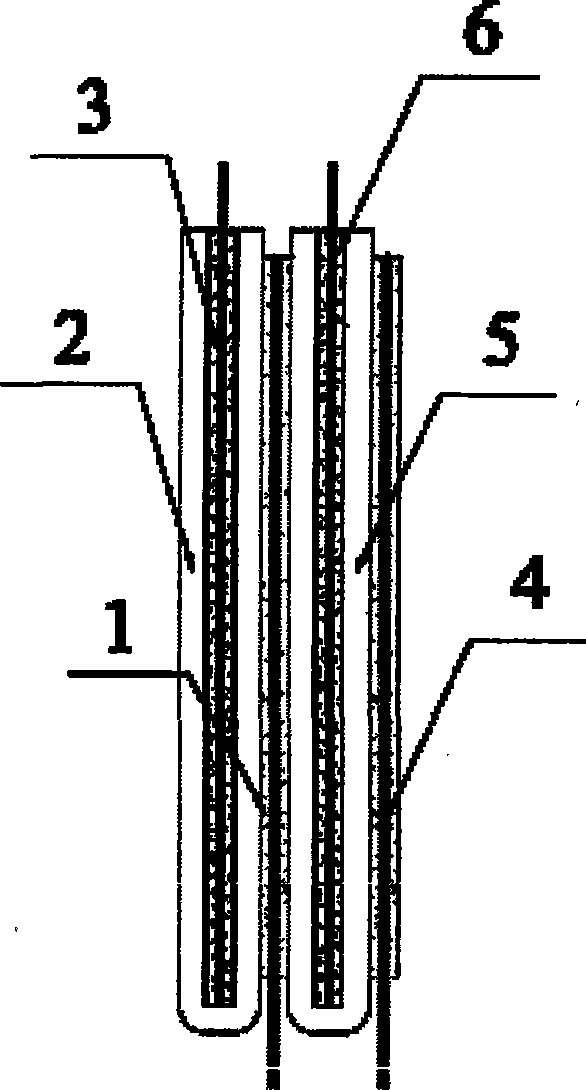

[0015] The present invention is a lithium-ion battery with a novel winding method. The pole group is wound, such as figure 1 As shown, the electrode group is composed of negative electrode sheets 3 and 6, separators 2 and 5, and positive electrode sheets 1 and 4 stacked in sequence. The separator covers the negative electrode sheet from the bottom, and the end faces of the positive electrode and the negative electrode of the electrode group are welded with the positive electrode lugs. And negative ears.

[0016] The present invention is a method for manufacturing a lithium ion battery in a novel winding manner. Both the positive and negative electrodes adopt a constant-width continuous coating method. Before winding, the positive and negative electrodes are figure 1 Laminated in the order shown in the figure, the number of positive and negative plates is N (N≥2), in this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com