Anode lug bending and sealing body press-in device for cylindrical lithium battery

A press-in device, lithium battery technology, applied in battery pack parts, non-aqueous electrolyte batteries, electrolyte battery manufacturing and other directions, can solve the problems of positive electrode tabs, sealing ring sealing body damage, low efficiency, battery leakage, etc. Achieve the effect of ensuring discharge capacity, good current collection effect and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

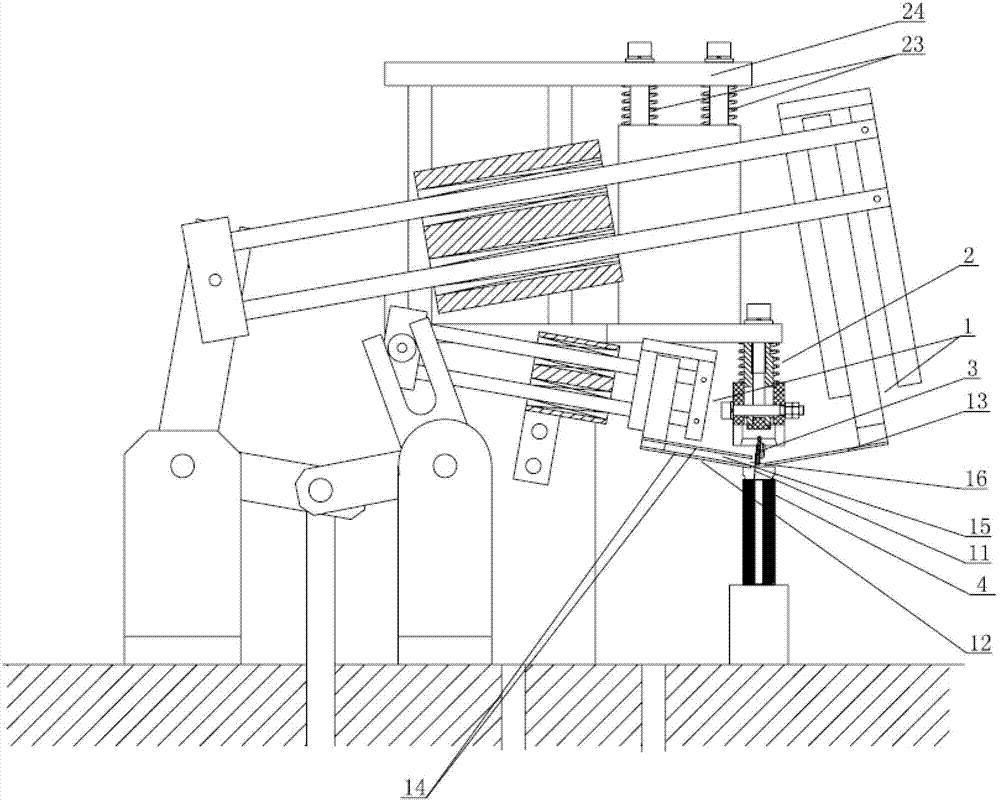

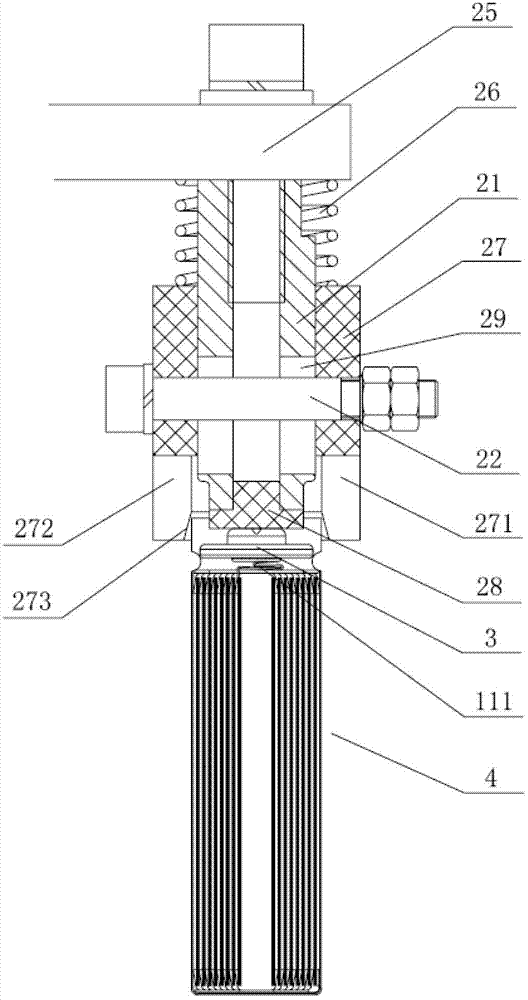

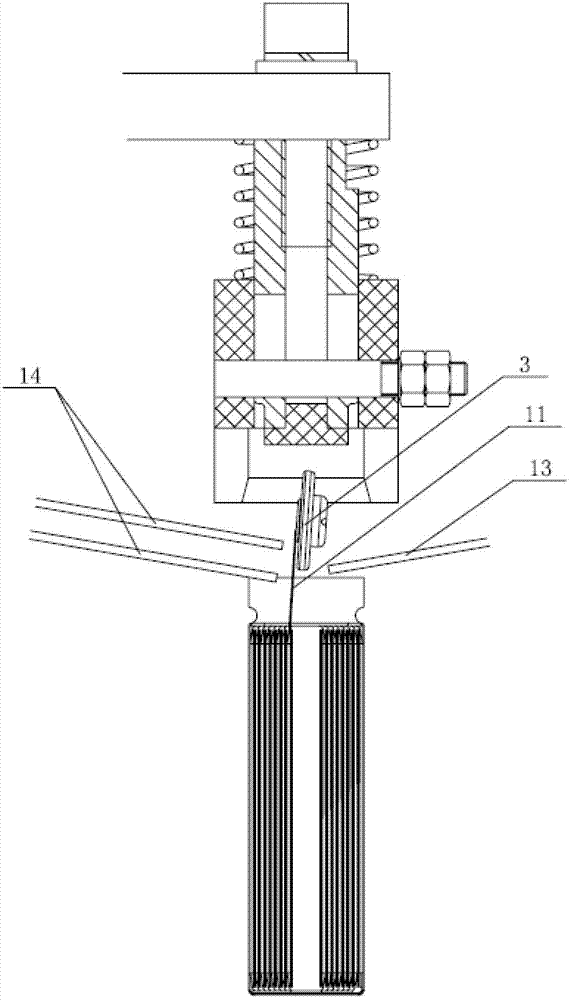

[0018] As shown in the figure, a cylindrical lithium battery positive tab bending and sealing body pressing device includes a positive tab bending mechanism 1 and a pressing mechanism 2 located directly above the sealing body 3 to be pressed into; The ear bending mechanism 1 includes a stop assembly 12 located on one side of the positive tab 11 and a pressing rod 13 located on the other side of the positive tab 11; The two parallel bent pieces 14 enclose a space 15 for accommodating the bent positive pole tab 111. The space 15 has an opening 16 facing the positive pole tab 11. When bending, the pressing rod 13 is aligned with the horizontal direction The included angle is 10°, the positive pole lug 11 is pressed by the pressing rod 13 to produce bending deformation, and the bent positive pole lug 111 enters the space 15 from the opening; the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com