Building construction environment-friendly waste collecting device and using method thereof

A waste collection and environmental protection technology, applied in chemical instruments and methods, solid separation, grain processing, etc., can solve problems affecting the service life of crushing equipment, unfavorable metal recycling, and affecting the quality of aggregates, so as to increase the storage effect, Convenient for nesting and ensuring the effect of nesting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

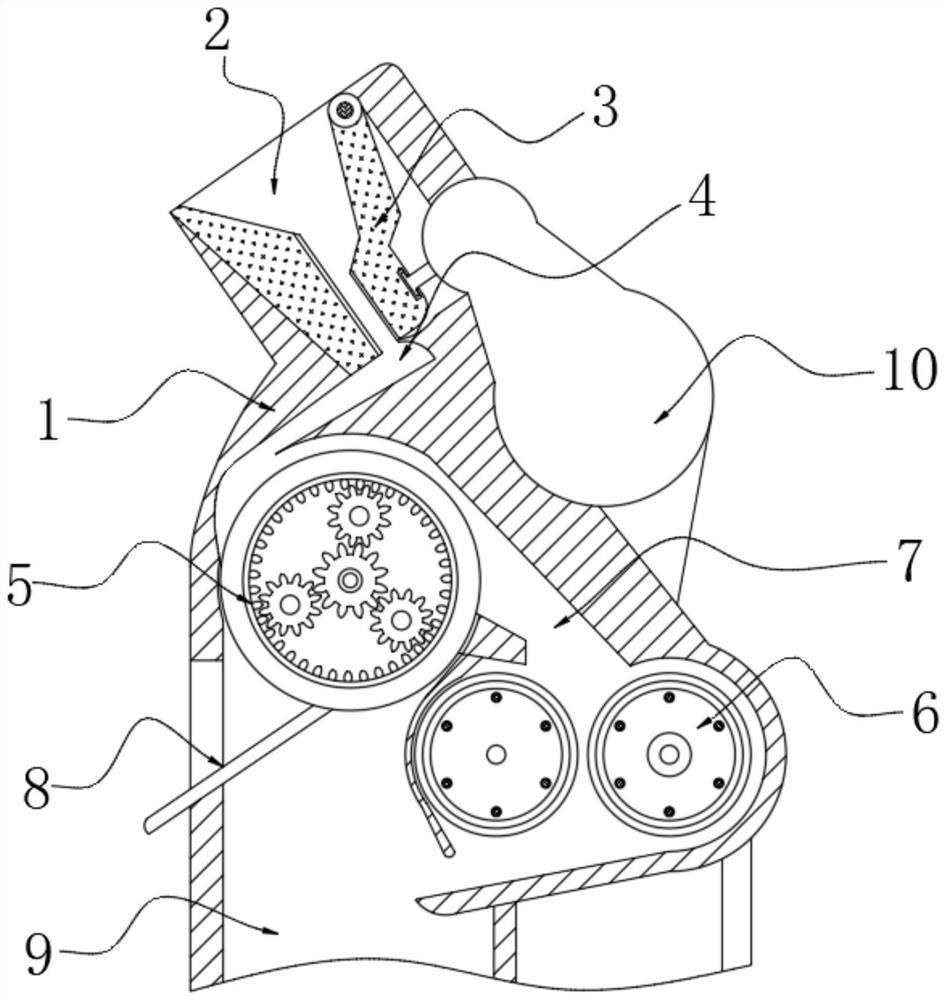

[0035] see Figure 1-6 , a construction and construction environment-friendly waste collection device, comprising a frame 1, the inside of the frame 1 is movably connected with a crushing jaw plate 3, the frame 1 is located on the top of the crushing jaw plate 3 and has a feed inlet 2, and the frame 1 is located at the crushing jaw plate 3 The bottom of the jaw plate 3 is provided with a material guide port 4, the frame 1 is located at the bottom of the material guide port 4 and is movably connected with a material guide mechanism 5, and the frame 1 is located at the bottom of the material guide mechanism 5, and a metal discharge port 8 and a thin A material discharge port 9, and a power mechanism 10 is fixedly installed on the outside of the frame 1;

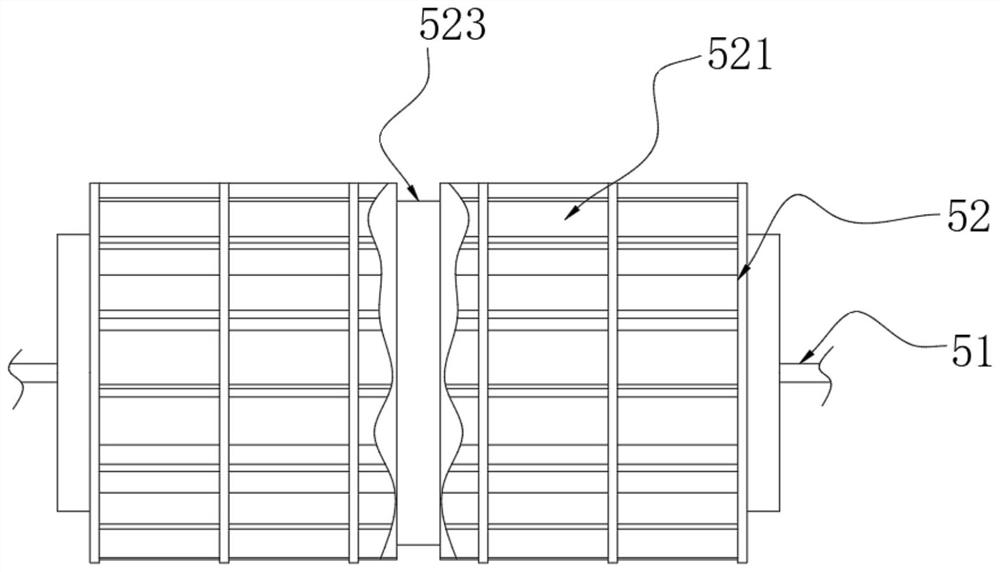

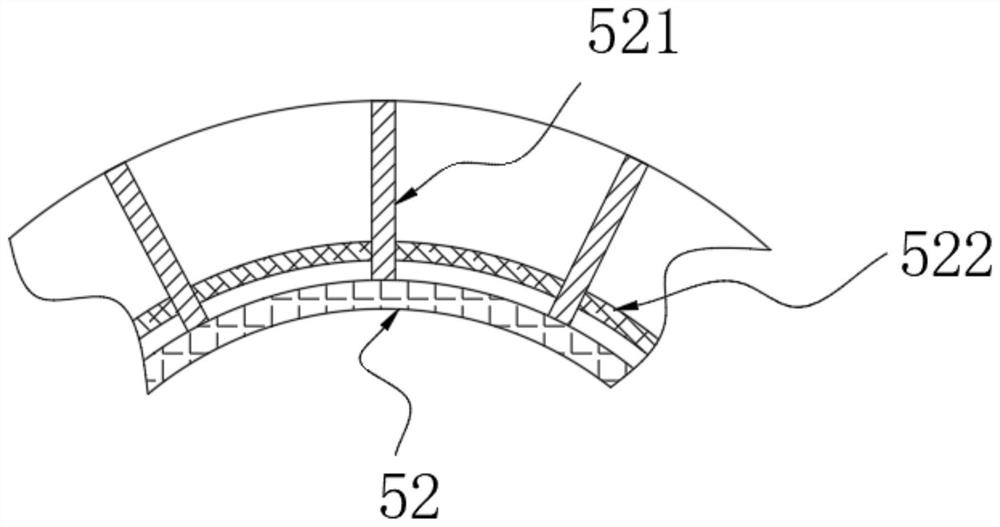

[0036] The material guiding mechanism 5 includes a driving mechanism 51 , a material guiding frame 52 is arranged on the outside of the driving mechanism 51 , and a vibrating mechanism 53 is movably connected inside the materia...

Embodiment 2

[0047] see Figure 1-6 , a construction and construction environment-friendly waste collection device, comprising a frame 1, the inside of the frame 1 is movably connected with a crushing jaw plate 3, the frame 1 is located on the top of the crushing jaw plate 3 and has a feed inlet 2, and the frame 1 is located at the crushing jaw plate 3 The bottom of the jaw plate 3 is provided with a material guide port 4, the frame 1 is located at the bottom of the material guide port 4 and is movably connected with a material guide mechanism 5, and the frame 1 is located at the bottom of the material guide mechanism 5, and a metal discharge port 8 and a thin A material discharge port 9, and a power mechanism 10 is fixedly installed on the outside of the frame 1;

[0048] The material guiding mechanism 5 includes a driving mechanism 51 , a material guiding frame 52 is arranged on the outside of the driving mechanism 51 , and a vibrating mechanism 53 is movably connected inside the materia...

Embodiment 3

[0057] A method for using a construction and construction environmental protection waste collection device, which is realized by the construction and construction environmental protection waste collection device of Embodiment 2, the steps are:

[0058] S1, adding construction waste through the feed port 2, the power mechanism 10 drives the movable jaw of the crushing jaw plate 3 to reciprocate, and the crushing jaw plate 3 performs jaw-type primary crushing of the construction waste;

[0059] S2. The primary crushed waste enters the material guide mechanism 5 through the material guide port 4, and the material guide mechanism 5 conducts material guide and classification;

[0060] S3. The internal drive mechanism 51 of the material guide mechanism 5 drives the material guide frame 52 to rotate, and the material guide frame 52 transmits materials through a number of grids, and the drive mechanism 51 drives the vibration mechanism 53 to vibrate the material guide frame 52;

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com