A 48v system lithium battery power cooling method

A technology of lithium battery packs and heat dissipation methods, applied in batteries, secondary batteries, circuits, etc., can solve the problems of reducing the stable operation of 48V systems, affecting the discharge capacity of battery packs, increasing fires, explosions, etc., to improve work safety, Ensure the discharge capacity and solve the effect of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

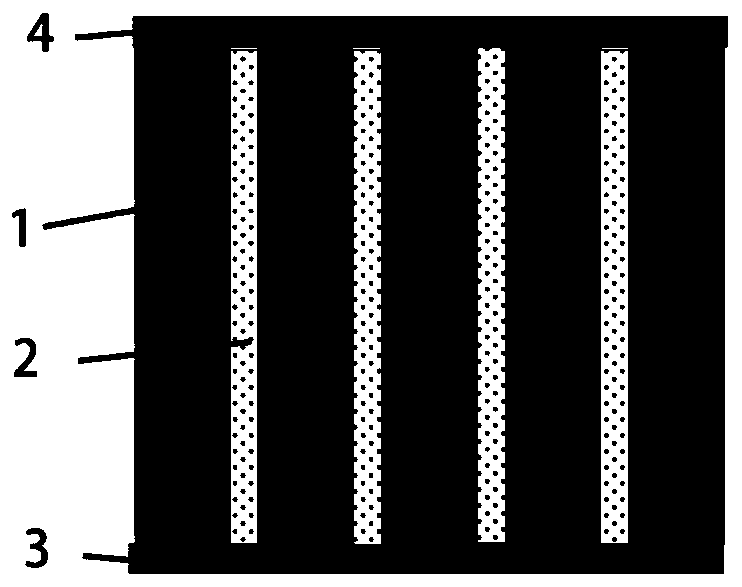

Image

Examples

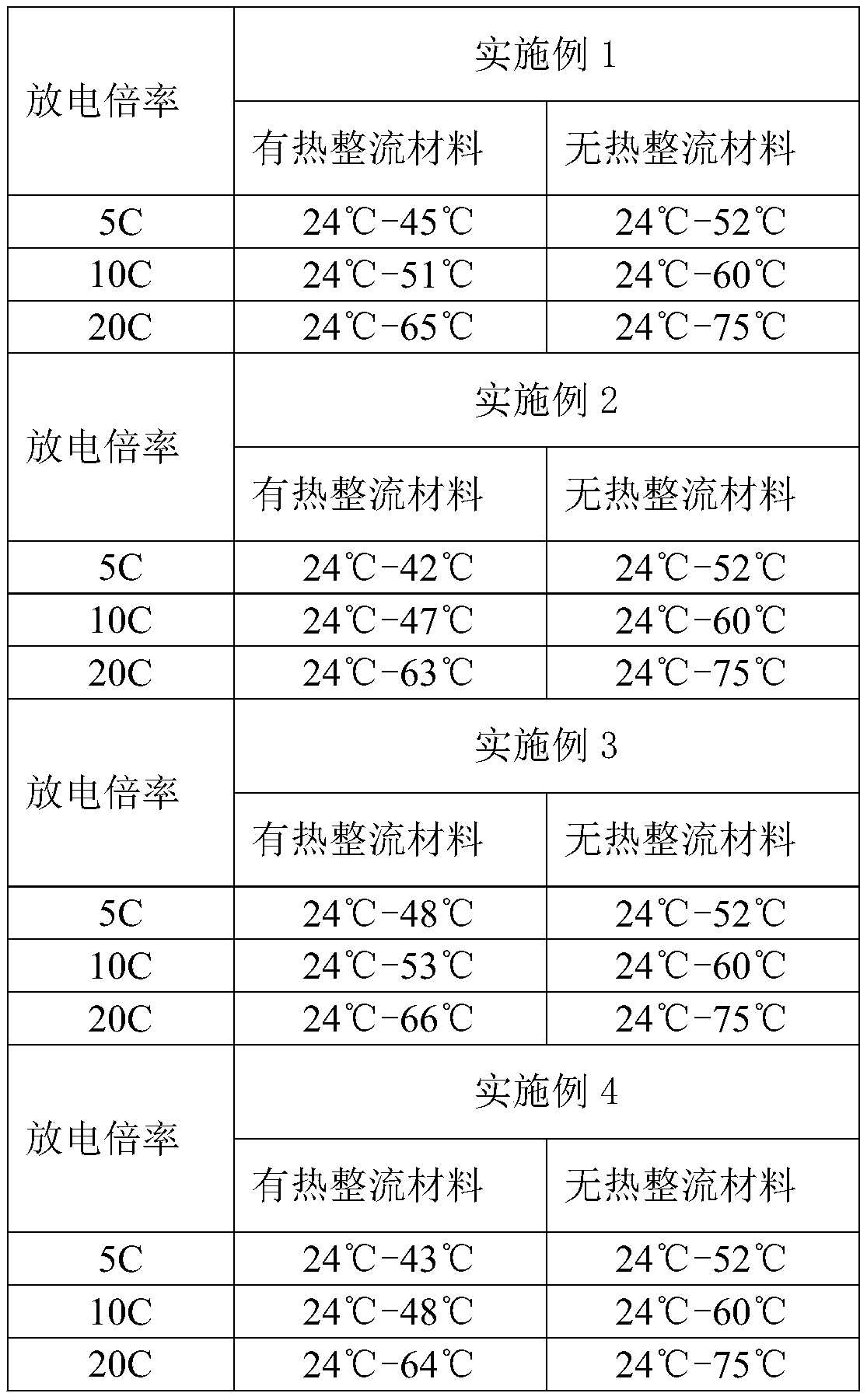

Embodiment 1

[0020] The light / moisture cured heat rectifying material is prepared by the following steps:

[0021] (1) Stir and compound 10 parts of silicon dioxide and 40 parts of paraffin to prepare a composite phase change material.

[0022] (2) In the pass there is N 2 Add 1 part of tetrahydrofuran and butyl butyrate mixed solution (the mass ratio of tetrahydrofuran and butyl butyrate is 1:1) into the stirred tank, stir evenly, then add 30 parts of hexamethylene diisocyanate (HDI) trimer , slowly heat up to 40°C while stirring, then add 0.5 parts of 1,4-hydroquinone, 0.3 parts of dibutyltin dilaurate and 80 parts of composite phase change material powder obtained in step (1), and react while stirring About 3 hours, slowly add 10 parts of hydroxyethyl acrylate (HEA) dropwise, continue the reaction at constant temperature for 15 minutes, slowly raise the temperature to 50°C, continue the reaction for 3 hours, then add 0.5 parts of photoinitiator IRGACURE 184 (CAS No.: 947 -19-3), conti...

Embodiment 2

[0025] The light / moisture cured heat rectifying material is prepared by the following steps:

[0026] (1) Stir and compound 50 parts of silicon dioxide and 100 parts of paraffin to prepare a composite phase change material.

[0027] (2) In the pass there is N 2 Add 2 parts of tetrahydrofuran and butyl butyrate mixed solution (the mass ratio of tetrahydrofuran and butyl butyrate is 9:1) in the stirred tank, stir evenly, then add 80 parts of hexamethylene diisocyanate (HDI) trimer , slowly heated up to 60°C while stirring, then added 2 parts of 1,4-hydroquinone, 1.6 parts of dibutyltin dilaurate and 500 parts of the composite phase change material powder obtained in step (1), and reacted while stirring About 6 hours, slowly add 35 parts of hydroxyethyl acrylate (HEA) dropwise, continue the reaction at constant temperature for 45 minutes, slowly raise the temperature to 90°C, continue the reaction for 6 hours, then add 2 parts of photoinitiator DAROCUR 1173 (CAS No.: 7473 -98-5...

Embodiment 3

[0030] The light / moisture cured heat rectifying material is prepared by the following steps:

[0031] (1) Stir and compound 30 parts of alumina and 80 parts of stearic acid to prepare a composite phase change material.

[0032] (2) In the pass there is N 2 Add 1.5 parts of tetrahydrofuran and butyl butyrate mixed solution (the mass ratio of tetrahydrofuran and butyl butyrate is 5:1) into the stirred tank, stir evenly, then add 55 parts of hexamethylene diisocyanate (HDI) trimer , slowly heat up to 50°C while stirring, then add 1 part of 1,4-hydroquinone, 1 part of dibutyltin dilaurate and 290 parts of composite phase change material powder obtained in step (1), and react while stirring About 4 hours, slowly add 20 parts of hydroxyethyl acrylate (HEA) dropwise, continue the reaction at constant temperature for 30 minutes, slowly raise the temperature to 70°C, continue the reaction for 4 hours, then add 1 part of photoinitiator IRGACURE 127 (CAS No.: 474510 -57-1), continue to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com