Flexible film photovoltaic solar cell component and manufacturing method thereof

A technology of solar cells and flexible thin films, applied in the field of solar cells, can solve problems such as complicated process operation and difficult realization of ohmic contact, and achieve the effects of safe ohmic connection, good current collection effect, and tight contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

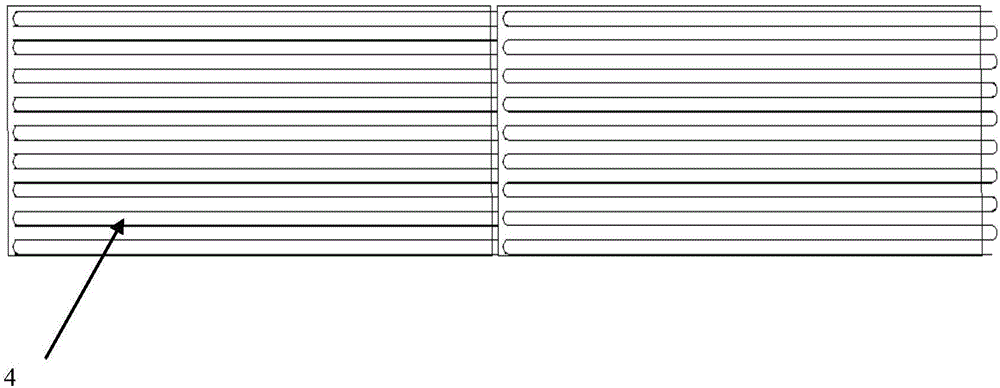

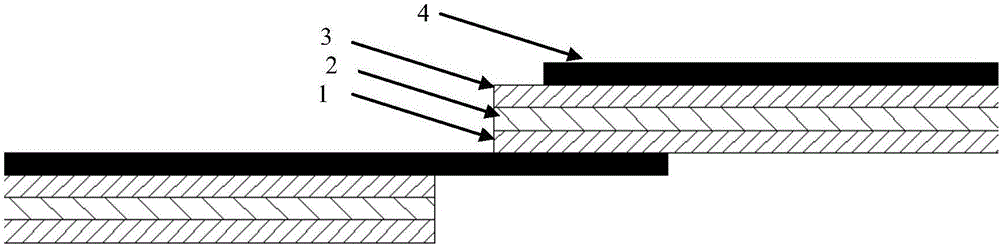

[0032] Example 1, see figure 1 , figure 2 , a flexible photovoltaic solar cell, including two flexible photovoltaic solar cell units, the flexible solar cell unit includes a flexible battery substrate 1, a semiconductor material layer 2 and a light-receiving layer 3, and a conductive bus bar 4 is arranged on the light-receiving layer In two adjacent flexible photovoltaic solar cell units, the conductive bus bar of the light-receiving layer of one flexible solar cell unit overlaps with the edge of the flexible battery substrate of the other flexible solar cell unit, and realizes ohmic connection to the overlapped part.

[0033] The preparation method is as follows: firstly, a flexible thin-film photovoltaic solar cell unit is prepared, and the flexible thin-film photovoltaic solar cell unit includes a flexible battery substrate 1, a semiconductor material layer 2 and a light-receiving layer 3 sequentially stacked from bottom to top; Conductive bus bars 4 are formed by bonding...

Embodiment 2

[0037] Embodiment 2, the same or similar technical content as in Embodiment 1 will not be described one by one in this embodiment. In this example, the material 4 of the conductive bus bar is copper with a diameter of 0.1 mm. The conductive bus bar is directly bonded to the light-receiving layer after being infiltrated by the transparent conductive adhesive, and the ohmic connection method of the overlapping part of the bus bar and another battery unit is conductive adhesive catch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com