End surface welding current collector of lithium battery

A technology of end face welding and current collector, which is applied to the component structure of lithium batteries and the field of lithium battery end face welding current collectors. It can solve the problems that alkaline battery end face welding current collectors cannot be used, and achieve simple manufacturing process, reduce ohmic resistance and current collection effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In the following, the current collector for lithium battery end face welding according to the present invention will be further described in detail in combination with the accompanying drawings and specific embodiments.

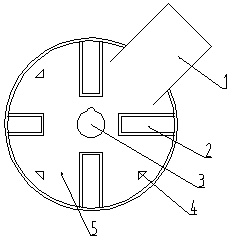

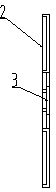

[0015] Such as figure 1 As shown, the present invention is a lithium battery end face welding collector, including a guide plate 5, a central hole 3 is opened on the guide plate 5, and four welding grooves 2 are radially provided on the surface of the guide plate 5, so that The welding groove 2 divides the surface of the guide plate 5 into four quadrants, one of which is provided with a conductive ear 1, and the conductive ear 1 is integrally connected with the guide plate 5, and the remaining three quadrants are provided with Liquid guide hole 4.

[0016] The liquid guide hole 4 is in the shape of an isosceles right triangle, and the fixed point of the right angle of the triangle points to the center of the guide plate 5 .

[0017] The conductive ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com