System and method for testing performance of large-area flat-plate SOFC single battery

A test system and single-cell technology, which is applied in the application of electric devices to test fluid tightness, measure electricity, and measure devices. It can solve problems such as low reliability, small effective area of test objects, and large high-temperature contact resistance, so as to reduce high temperature. Contact resistance and wire resistance, effective test area increase, and the effect of improving current collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

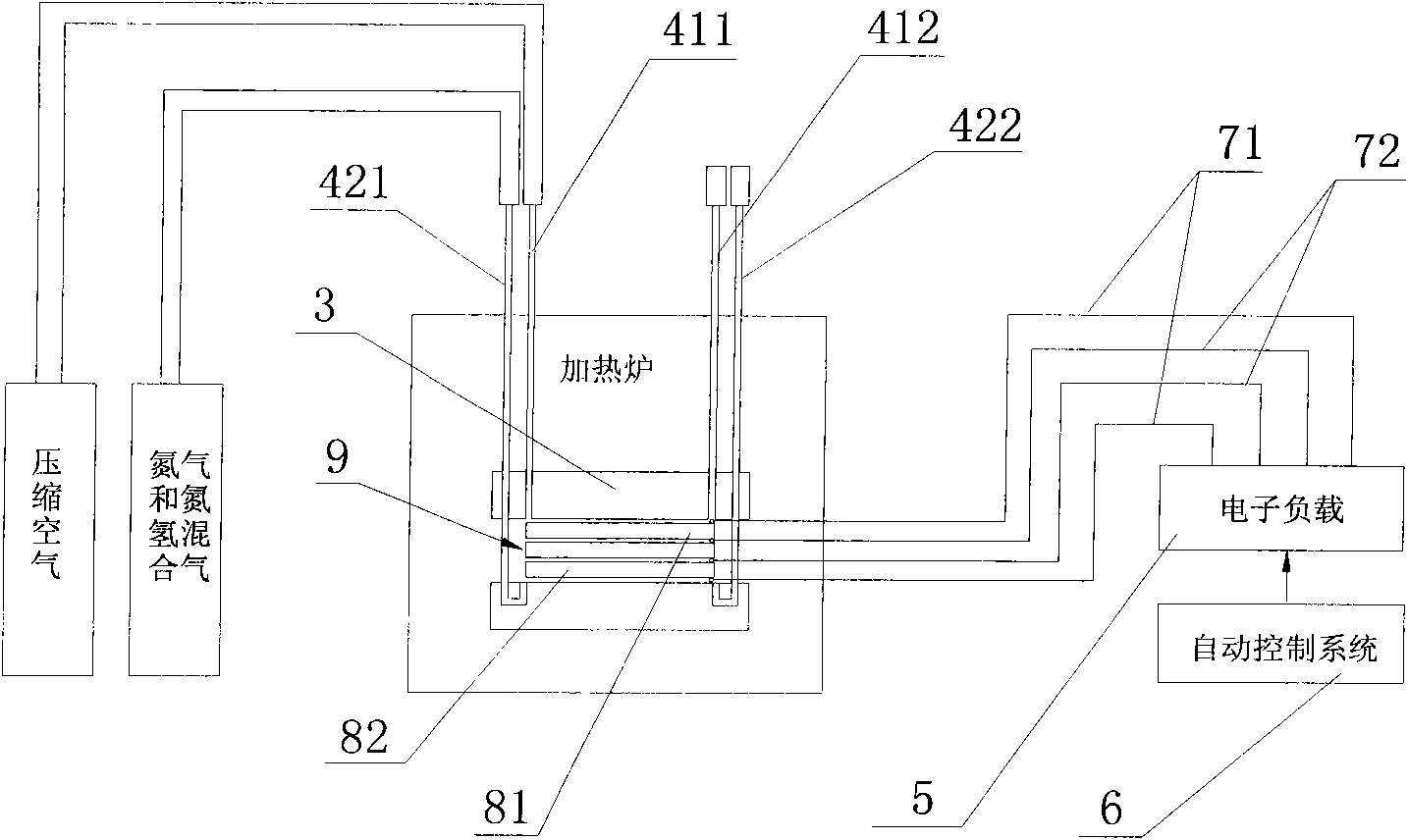

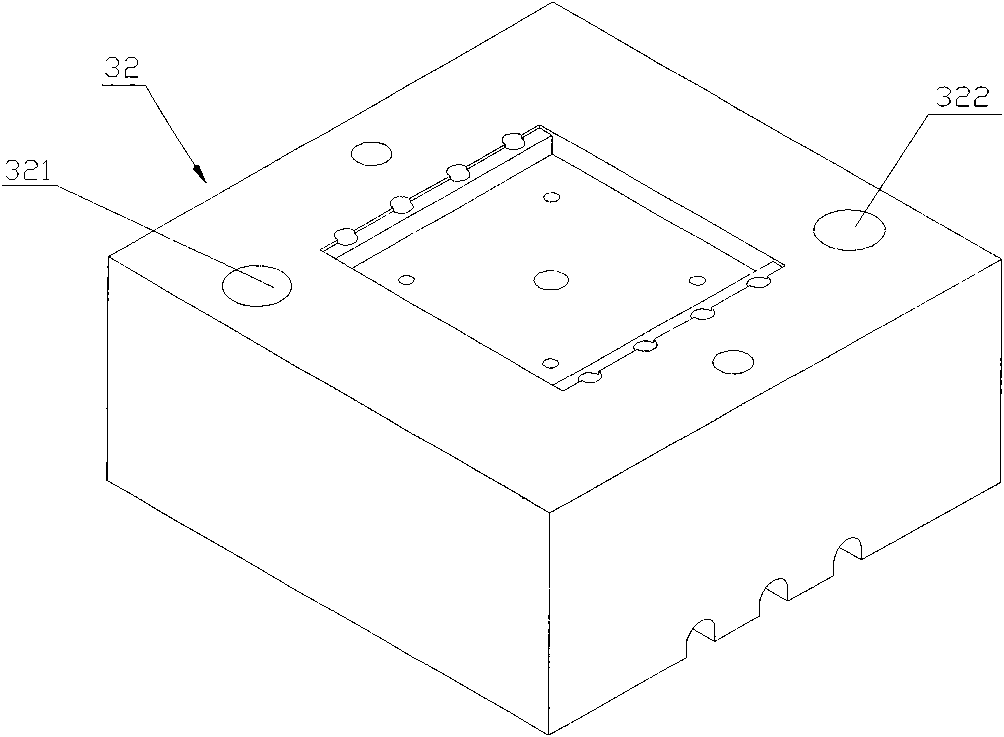

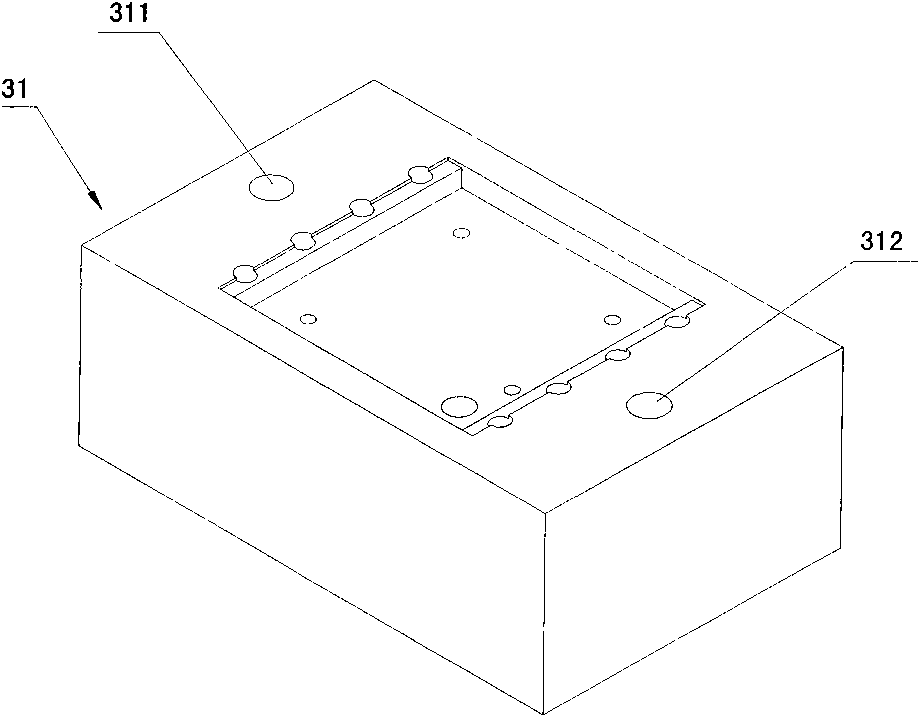

[0033] Such as Figure 1~6 As shown, a large-area flat SOFC single cell performance test system, the test system includes an electronic load 5, a test room 3 and a single cell sealing body 9 installed in the test room 3 (the specific structure is as follows: Figure 5 As shown), the Pt sheet collector layer 81 and the Ni sheet collector layer 82, the electronic load 5 is used for single-cell DC discharge, and the electronic load 5 is connected to the external automatic control system 6. The Pt (platinum) sheet collector layer 81 and the Ni (foam nickel) sheet collector layer 82 are respectively connected to the electronic load 5 through the first high temperature resistant wire 71, and the single cell sealing body is connected to the electronic load 5 through the second high temperature resistant wire 72 , a cathode gas flow channel 14 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com