Patents

Literature

220results about How to "Good charge and discharge cycle performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

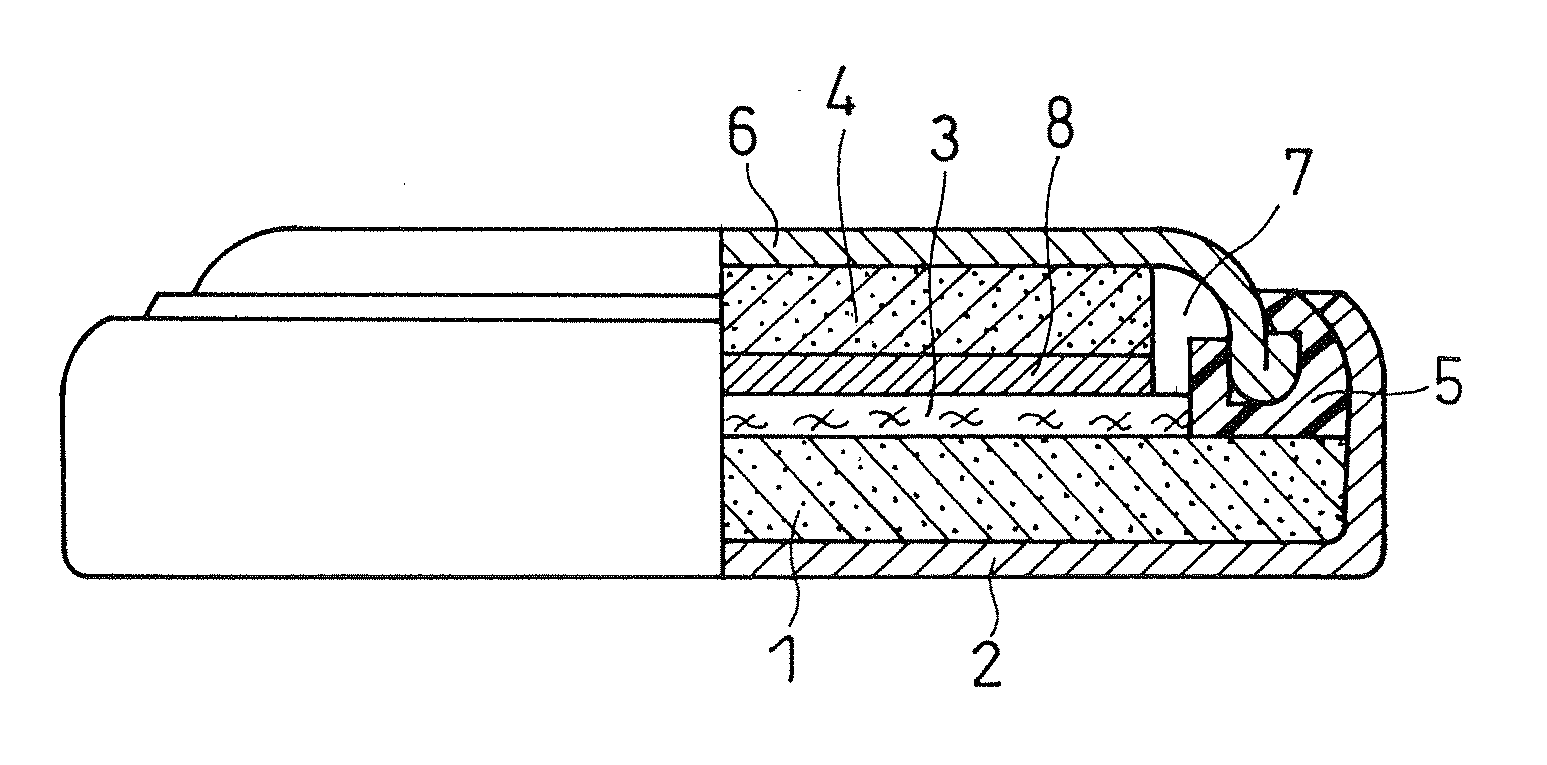

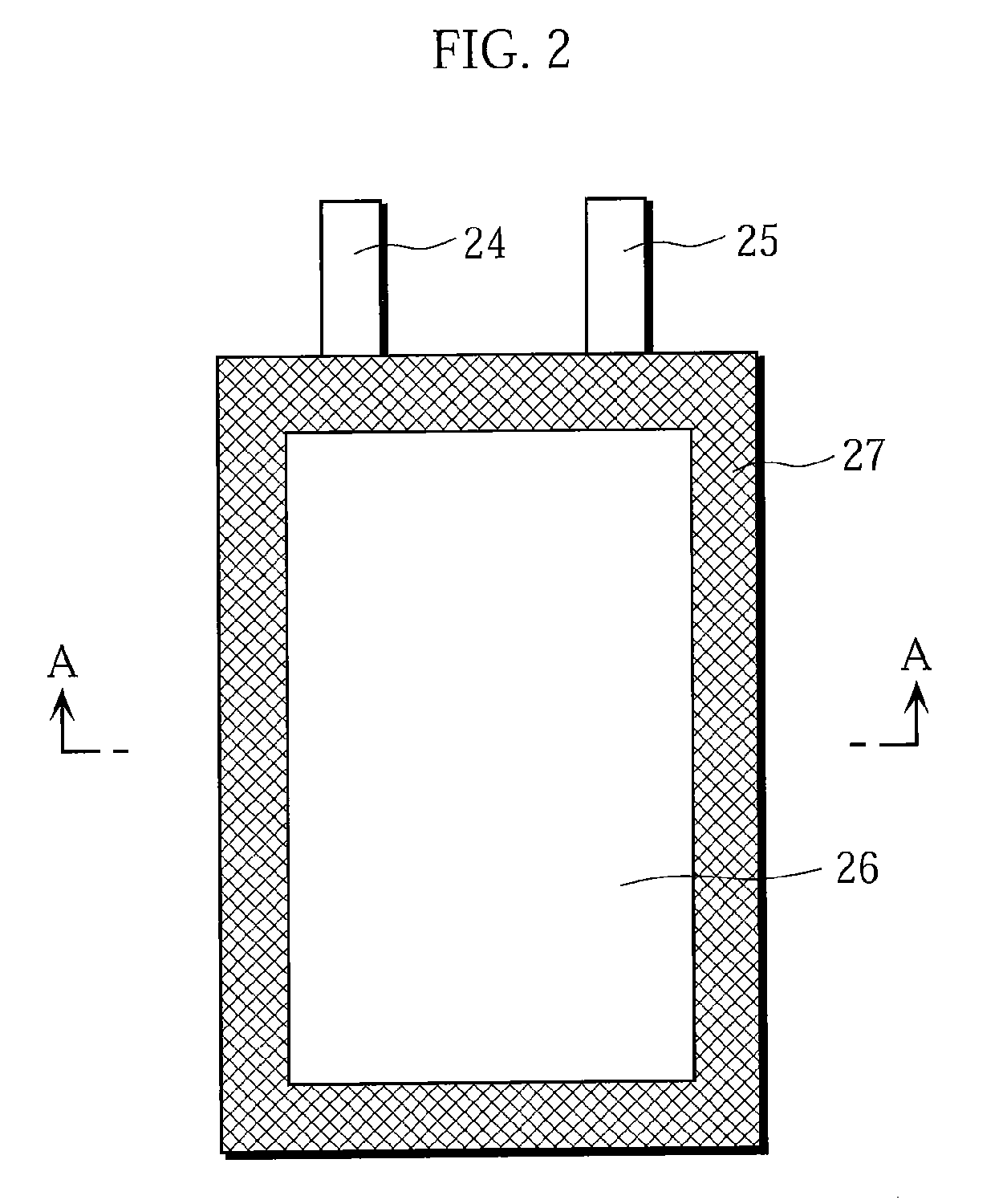

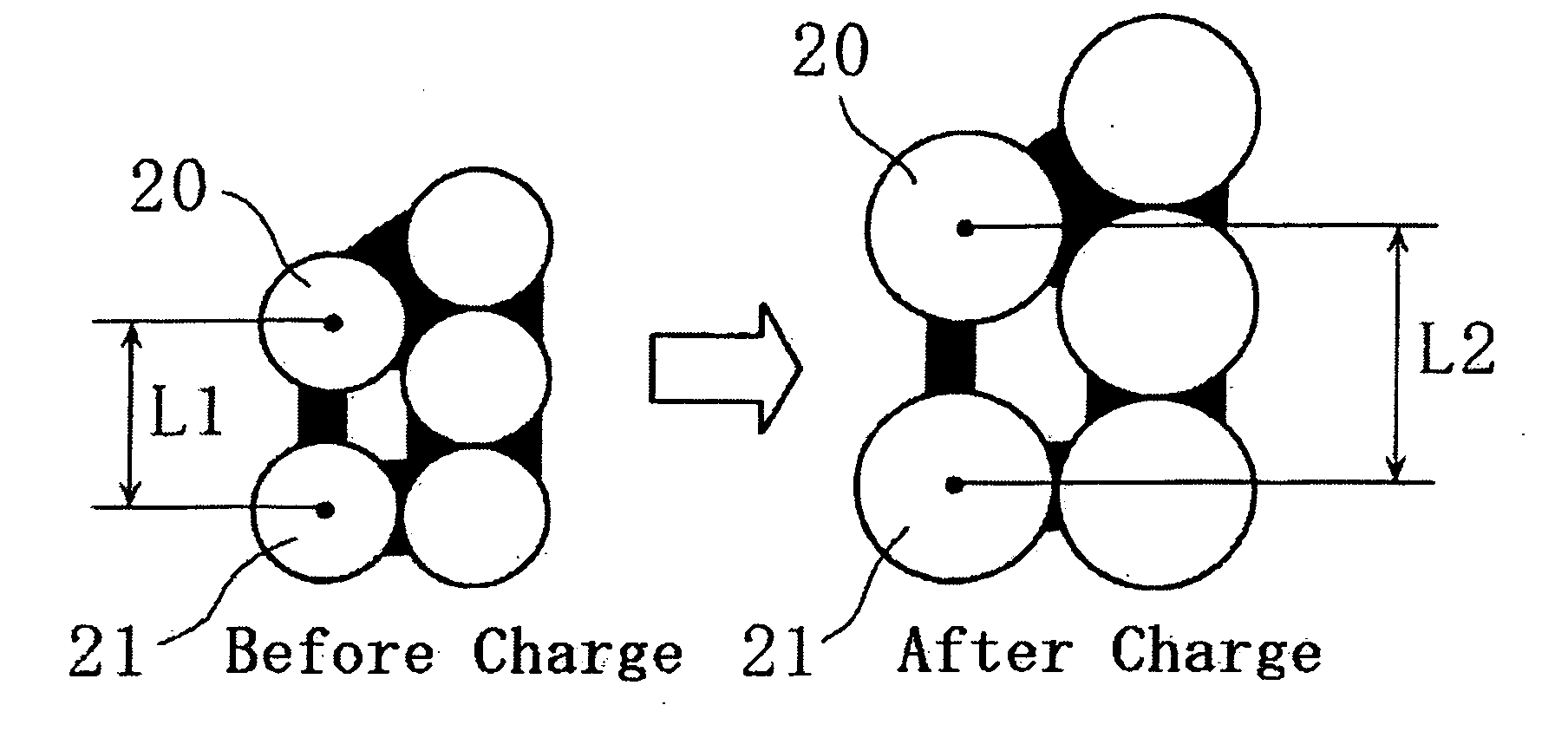

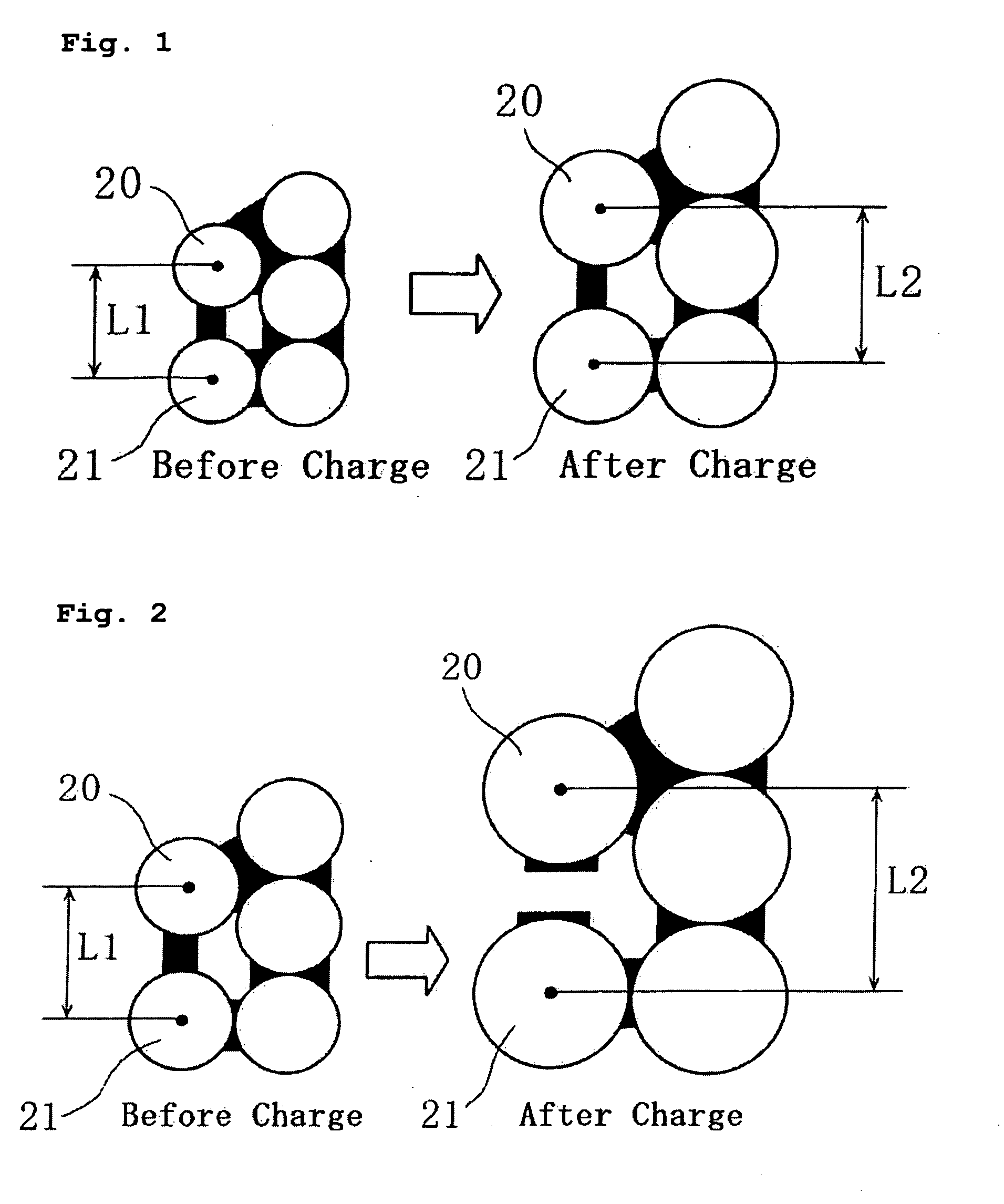

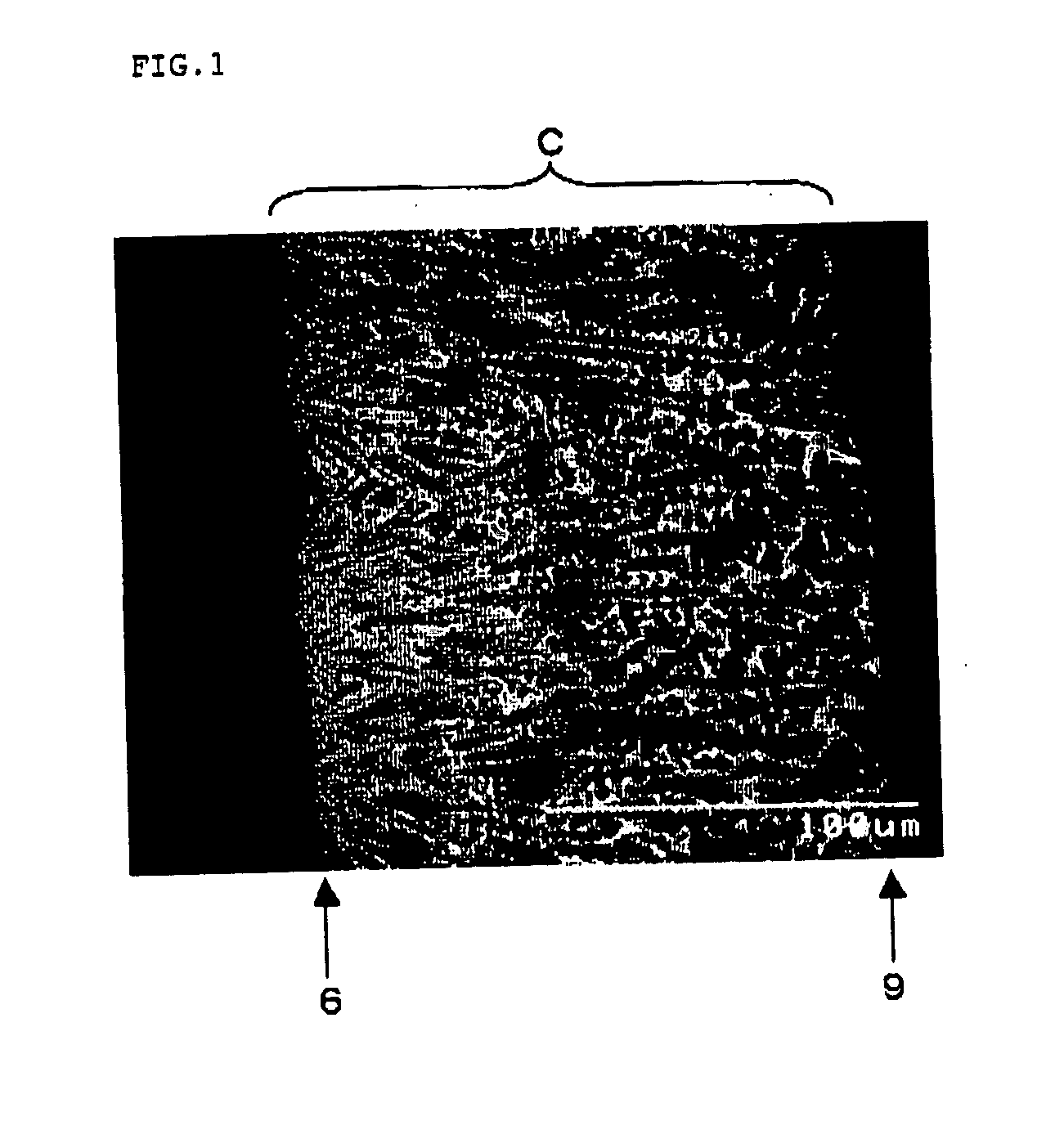

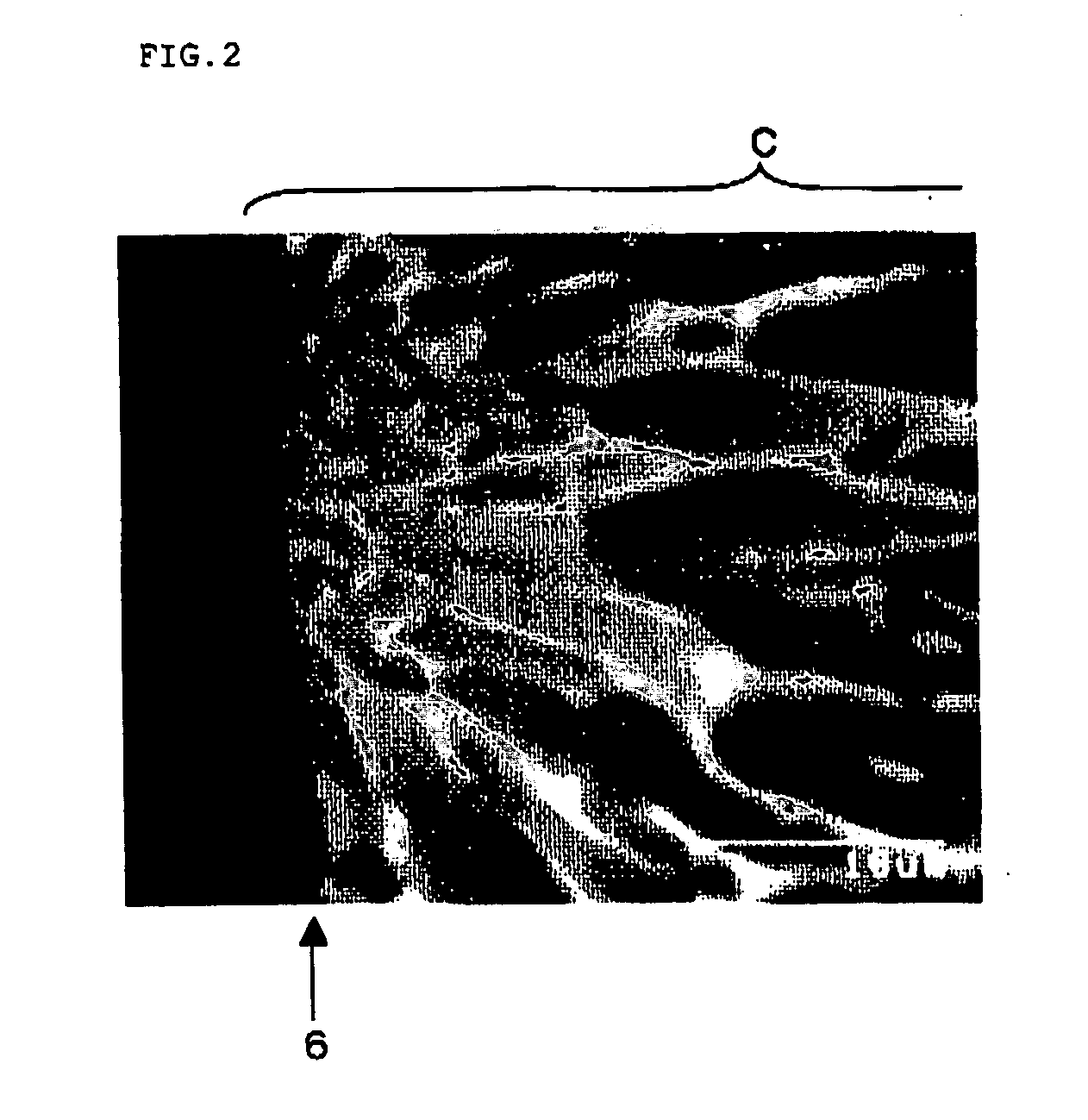

Negative electrode and non-aqueous electrolyte secondary battery using the same

InactiveUS20080096110A1Good charge and discharge cycle performanceImprove cycle performanceNon-aqueous electrolyte accumulatorsElectrode carriers/collectorsPorous substrateConductive materials

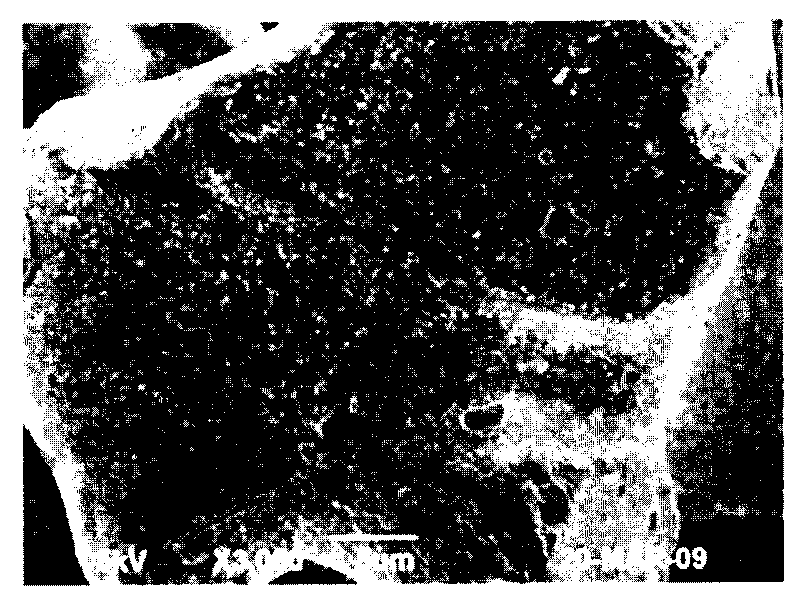

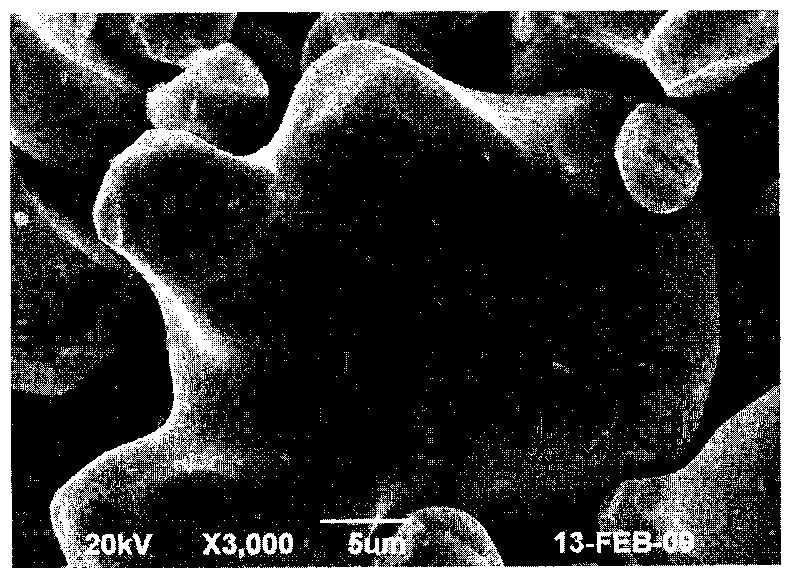

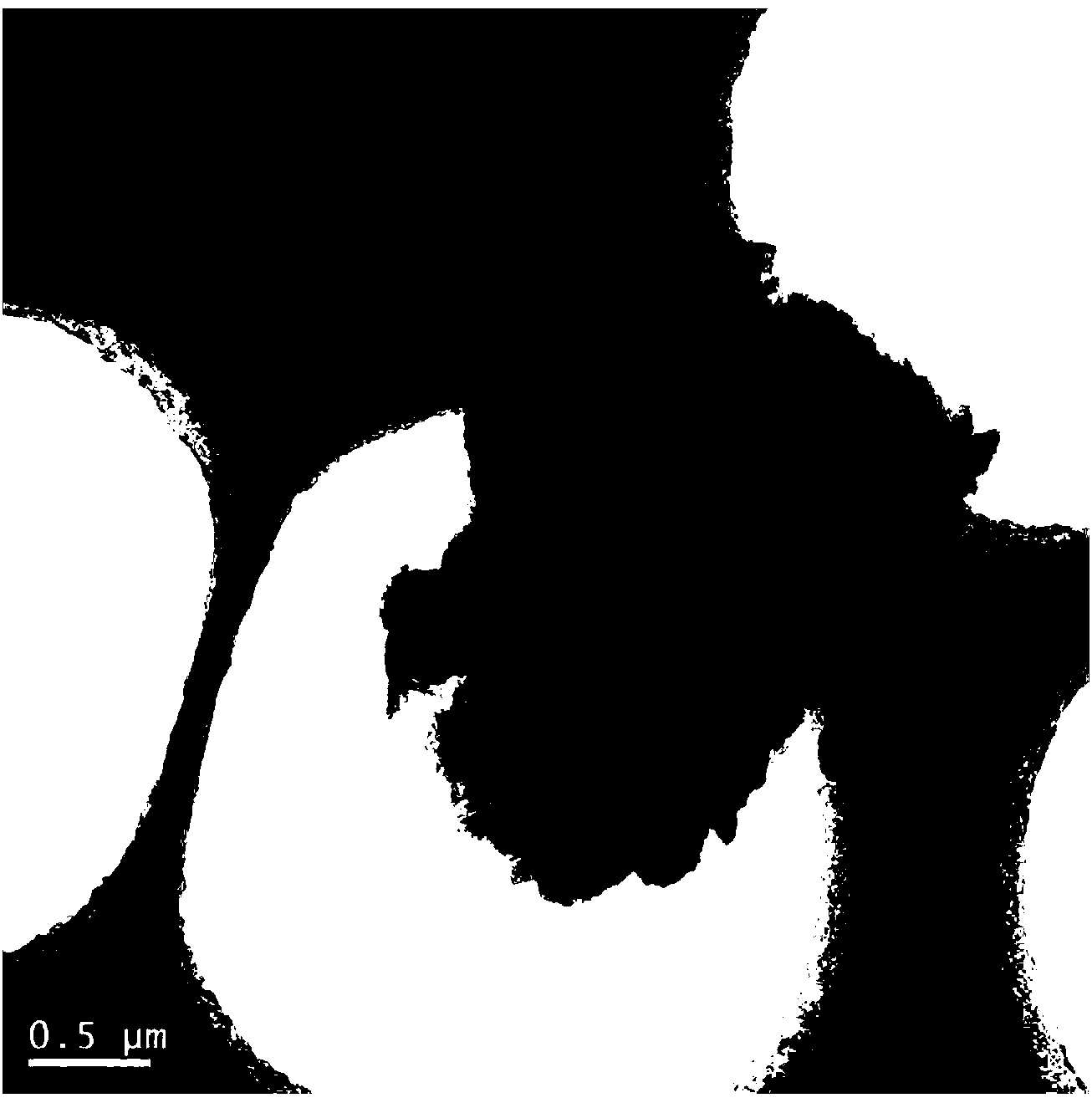

The negative electrode for a non-aqueous electrolyte secondary battery of the present invention includes a conductive porous substrate, and a conductive material and an active material filled in pores of the porous substrate. The active material contains at least one of a metal element and a semi-metal element capable of reversibly absorbing and desorbing lithium.

Owner:PANASONIC CORP

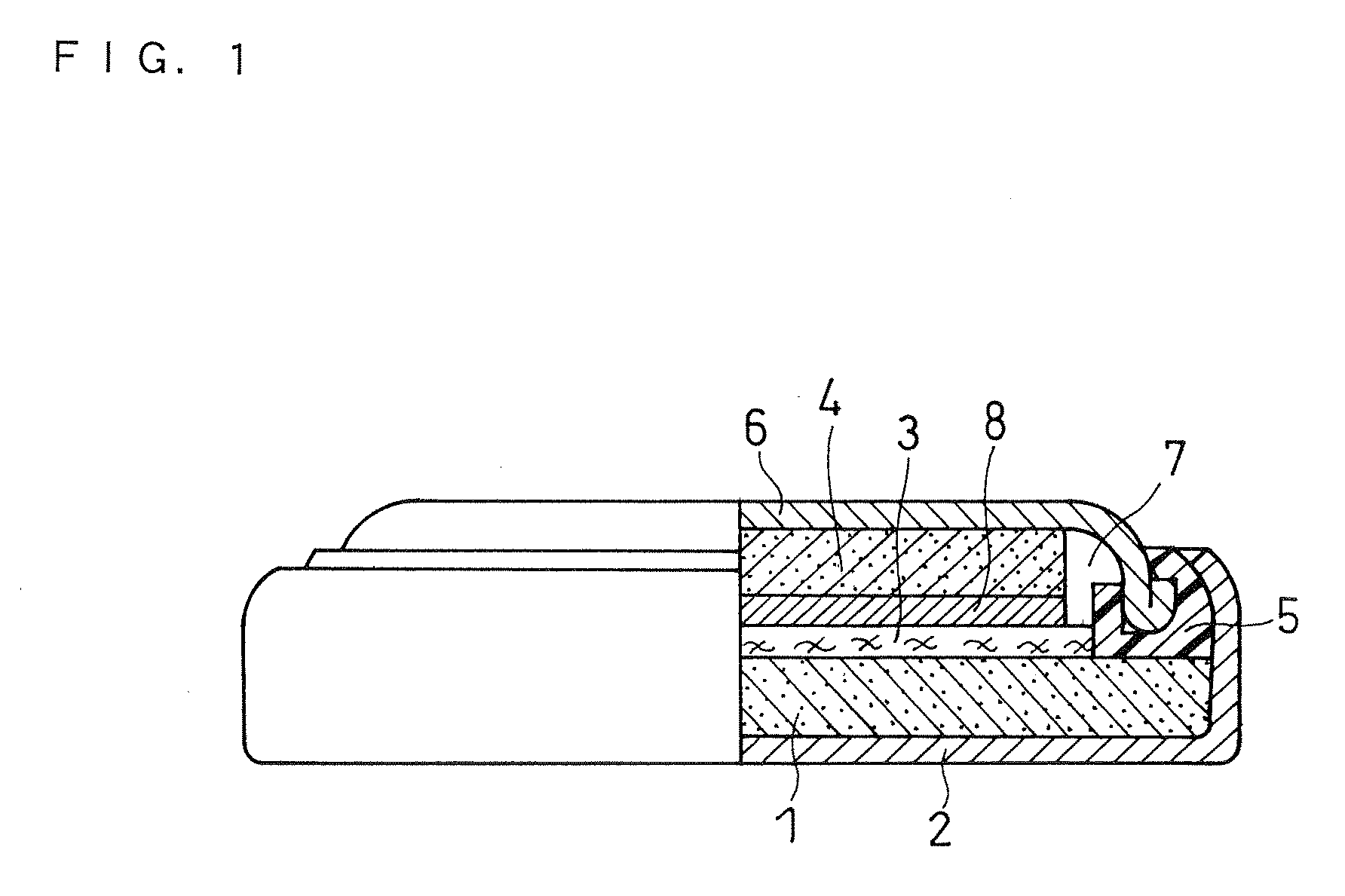

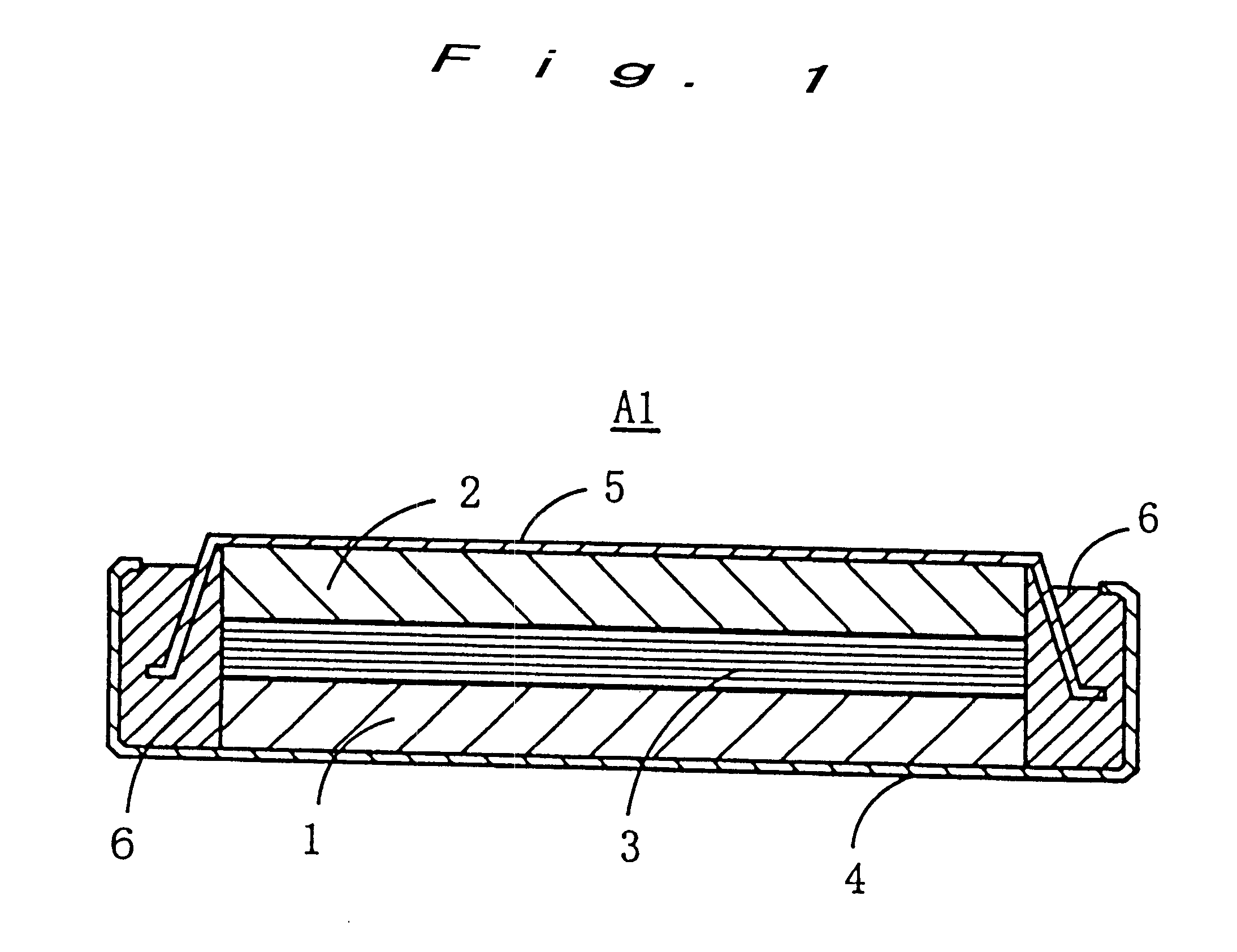

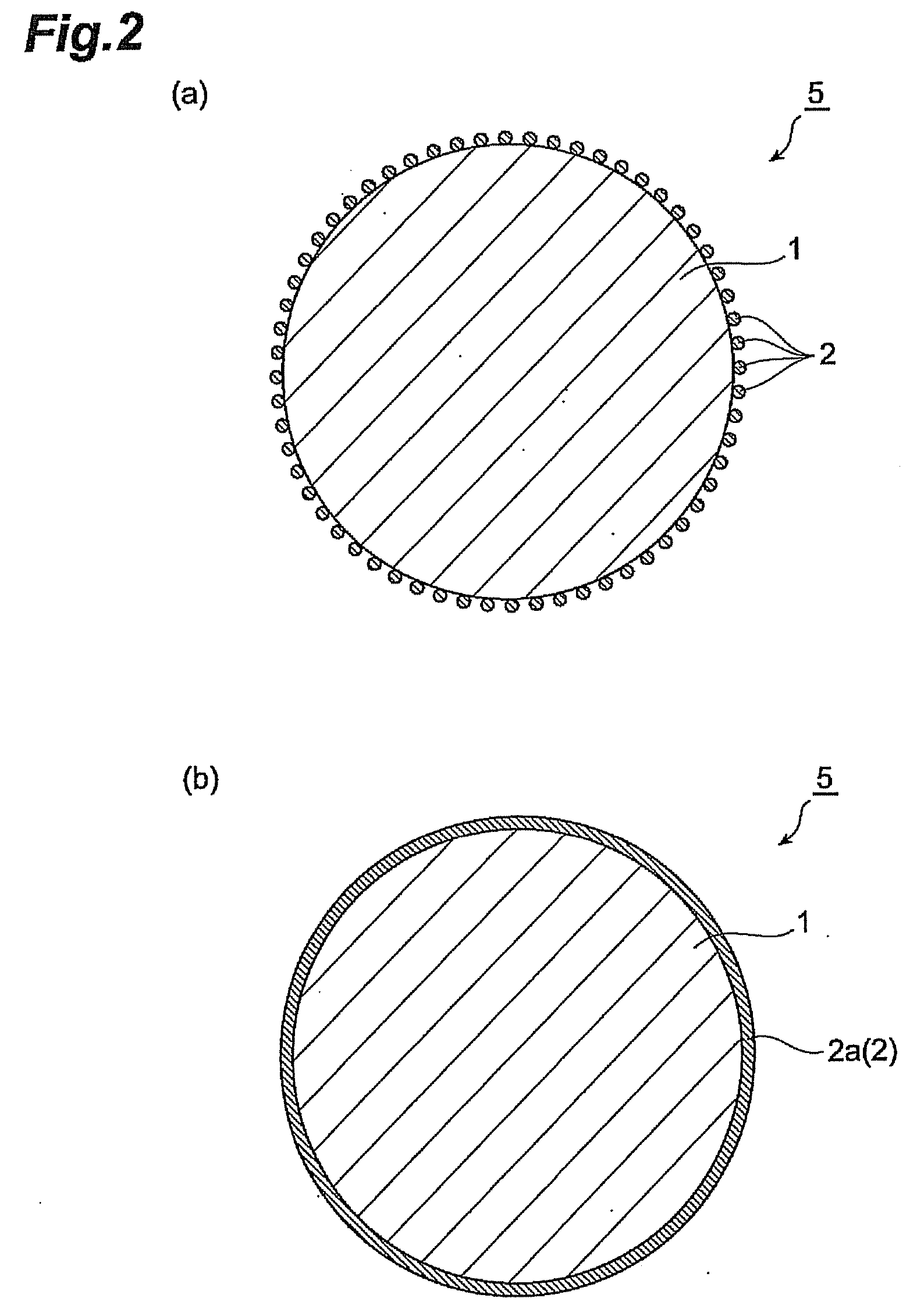

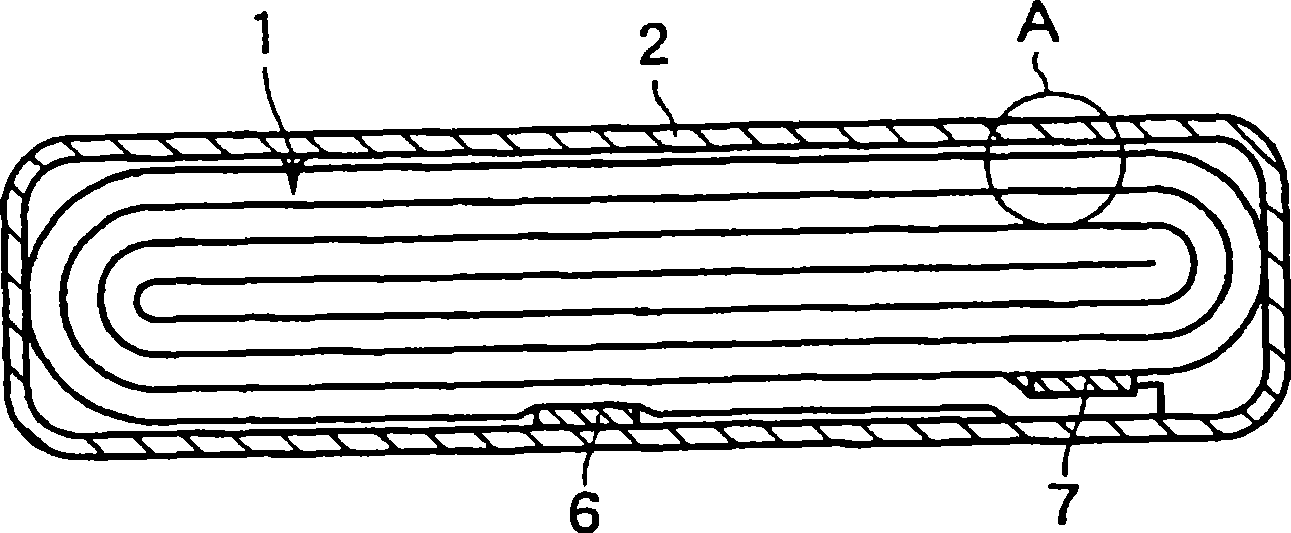

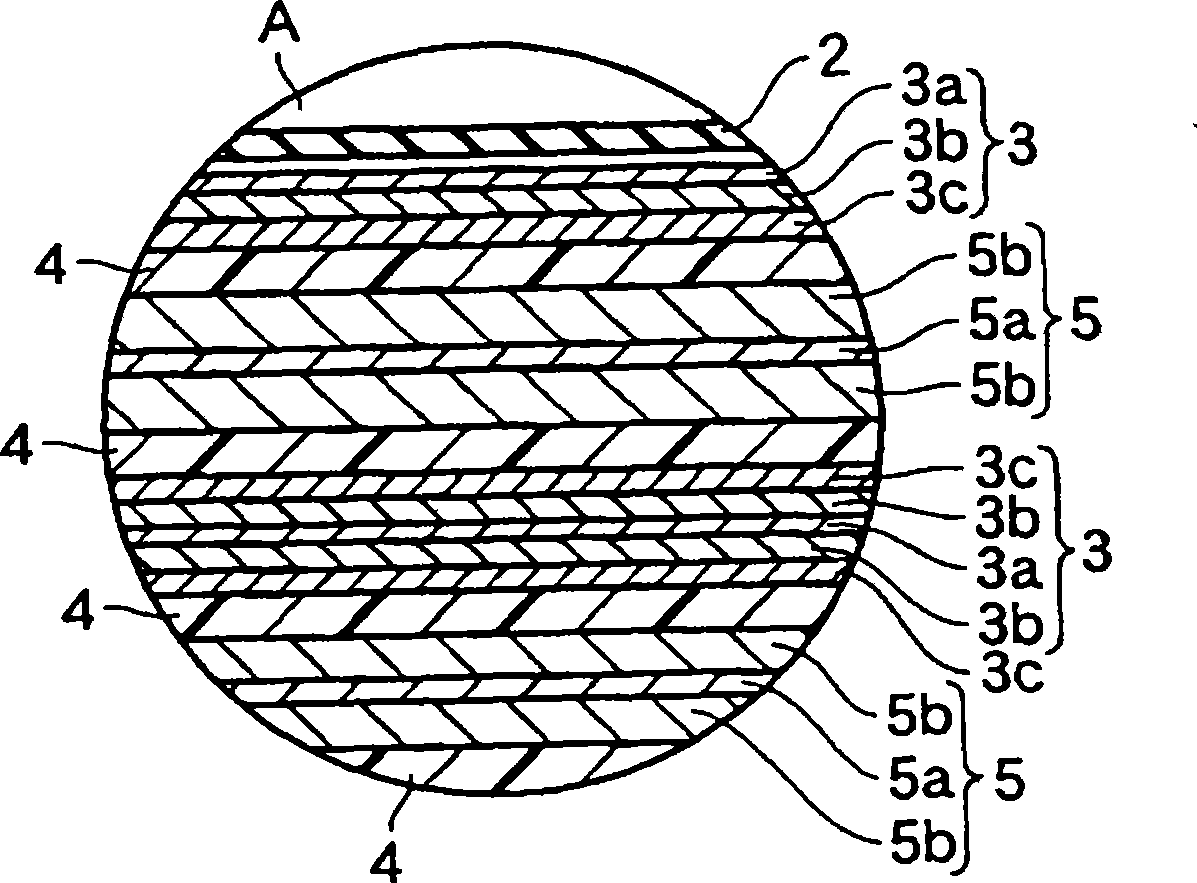

Cylindrical lithium secondary battery

InactiveUS20080241647A1Increase energy densityHigh mechanical strengthFinal product manufactureElectrode carriers/collectorsLithiumMetal foil

A cylindrical lithium secondary battery includes a positive electrode (1) having a positive electrode mixture layer disposed on a surface of a positive electrode current collector made of a conductive metal foil and containing a positive electrode active material, and a negative electrode (2) having a negative electrode mixture layer disposed on a surface of a negative electrode current collector made of a conductive metal foil and having a negative electrode active material containing silicon particles and / or silicon alloy particles. The amount of the positive electrode active material is 50 mg or less per 1 cm2 of the positive electrode, the average particle size of the silicon particles and / or silicon alloy particles is from 5 μm to 15 μm, and the theoretical electrical capacity ratio of the negative electrode to the positive electrode is 1.2 or greater.

Owner:SANYO ELECTRIC CO LTD

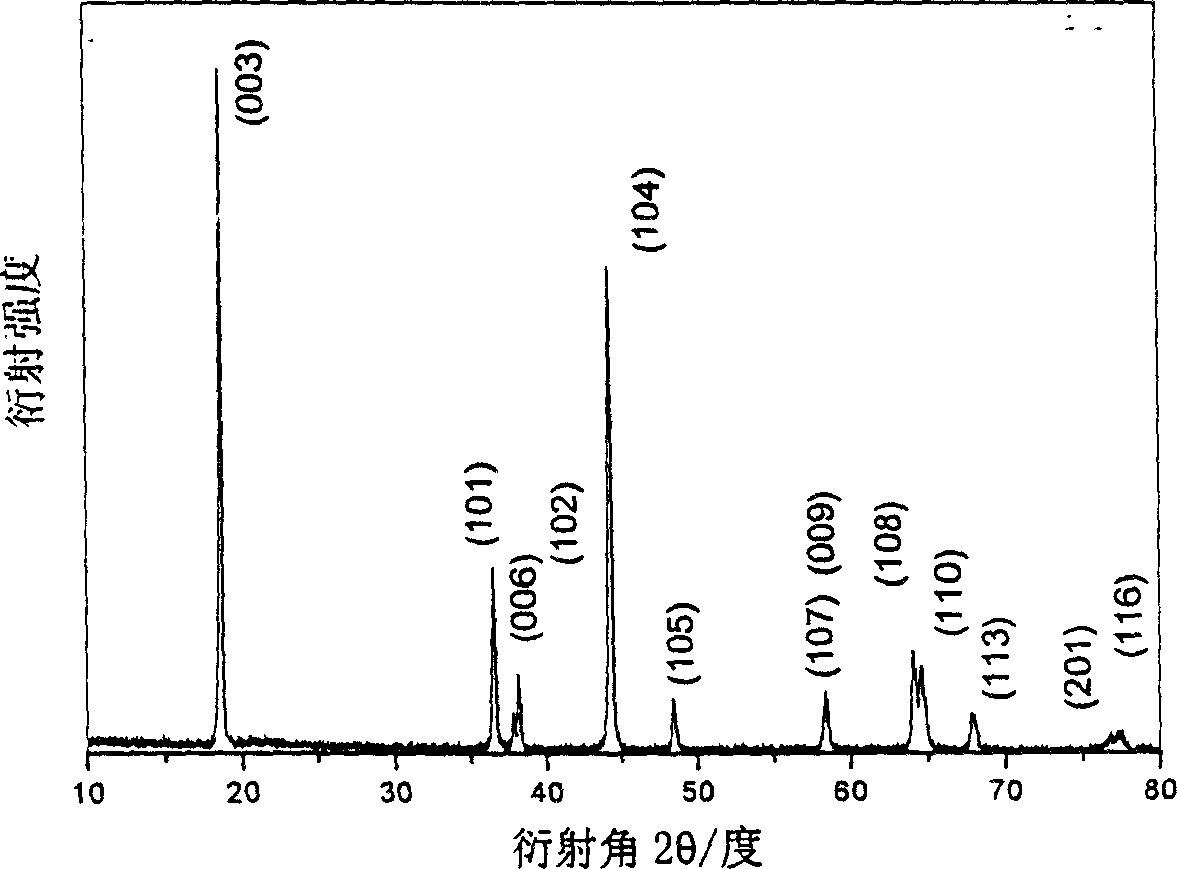

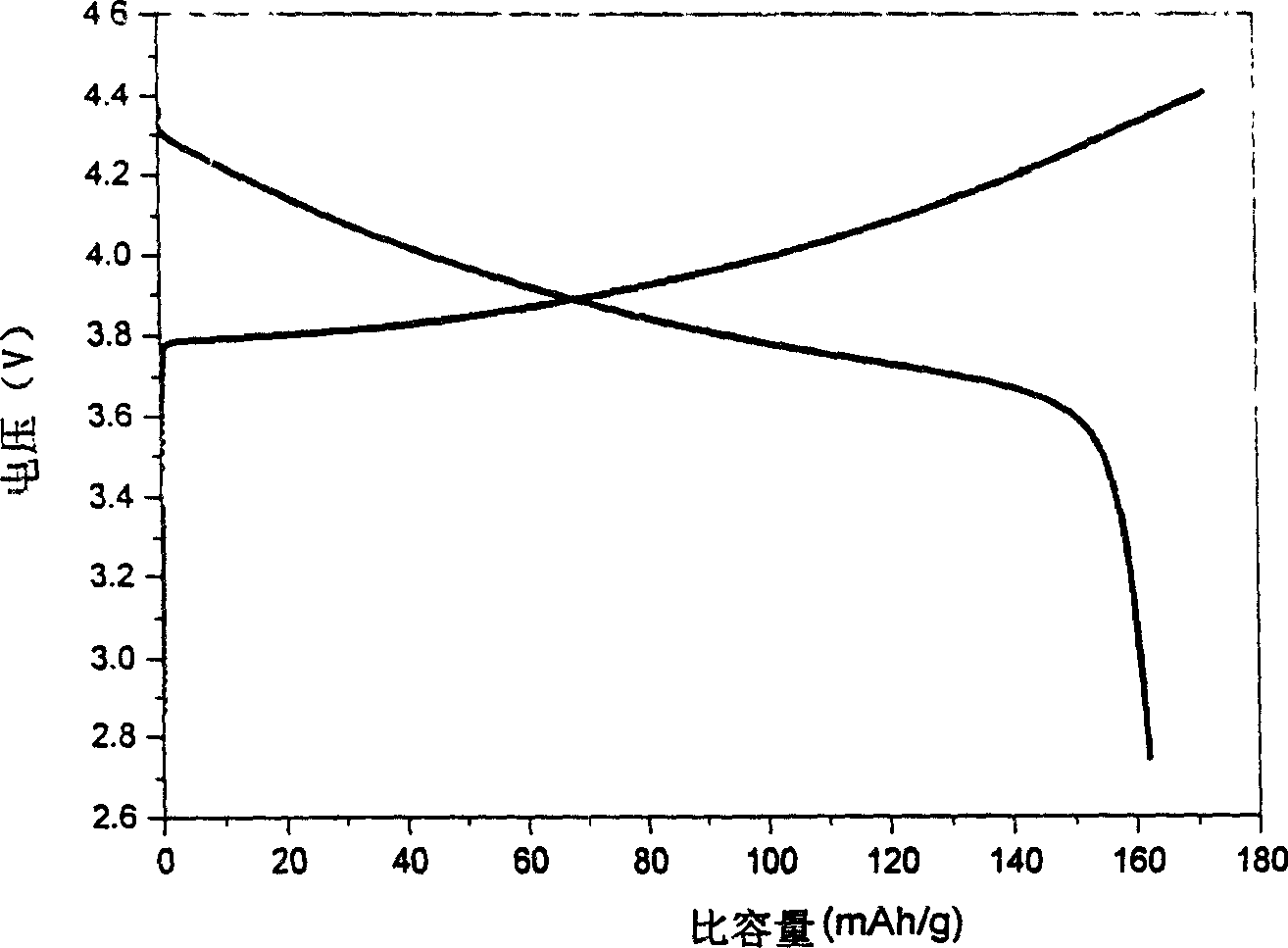

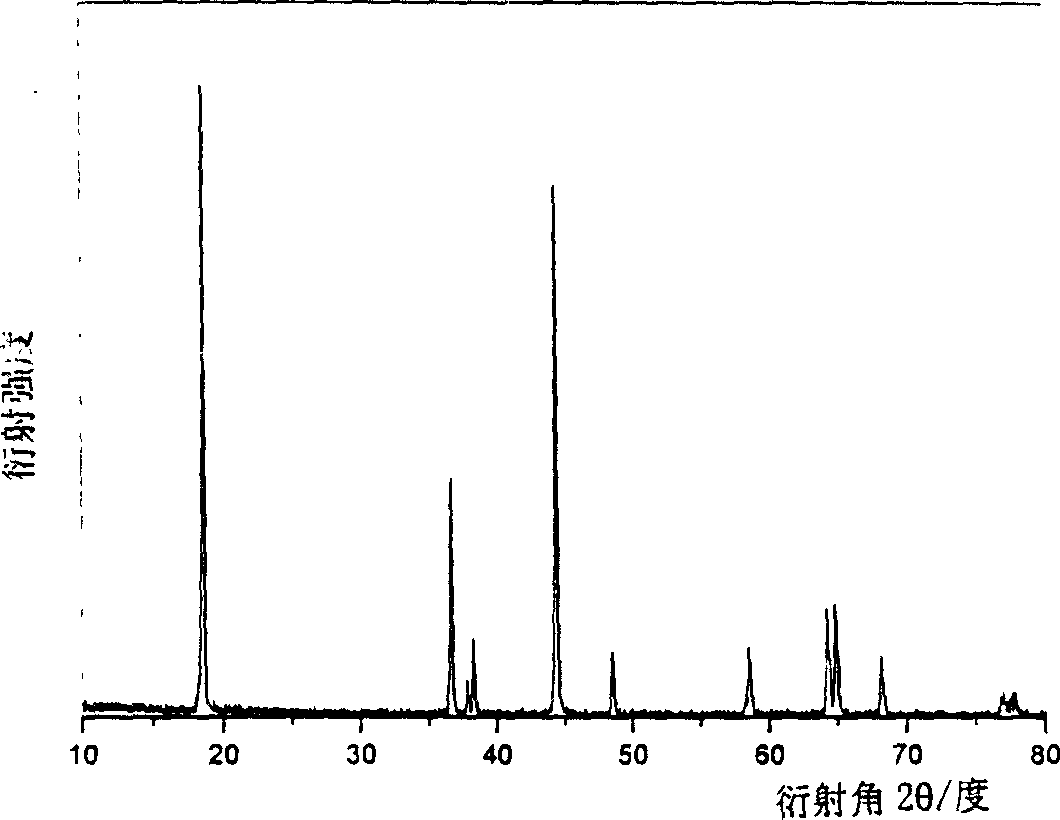

Positive electrode active material and its manufacturing method, positive electrode for lithium secondary cell using same, and lithium secondary cell

InactiveUS20060177739A1Deteriorated in battery performanceGood charge and discharge cycle performanceActive material electrodesNon-aqueous electrolyte accumulator electrodesLithiumEngineering

A positive active material is provided which can inhibit side reactions between the positive electrode and an electrolyte even at a high potential and which, when applied to a battery, can improve charge / discharge cycle performance without impairing battery performances even in storage in a charged state. Also provided are: a process for producing the active material; a positive electrode for lithium secondary batteries which employs the active material; and a lithium secondary battery which has improved charge / discharge cycle performance while retaining intact battery performances even after storage in a charged state and which can exhibit excellent charge / discharge cycle performance even when used at a high upper-limit voltage. The positive active material comprises: base particles able to dope and release lithium ions; and an element in Group 3 of the periodic table present on at least part of that part of the base particles which is able to come into contact with an electrolyte. It is produced by, e.g., a process which comprises: producing base particles containing lithium and able to dope and release lithium ions; and then imparting an element in Group 3 of the periodic table to the base particles so that the element can be present on at least part of that part of the base particles which is able to come into contact with an electrolyte.

Owner:GS YUASA INT LTD

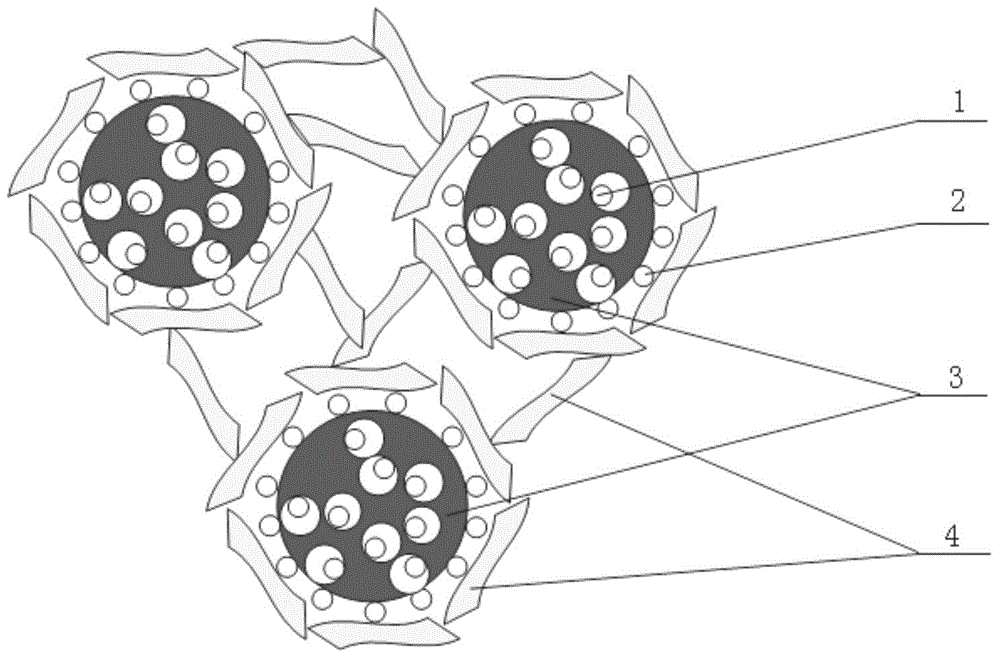

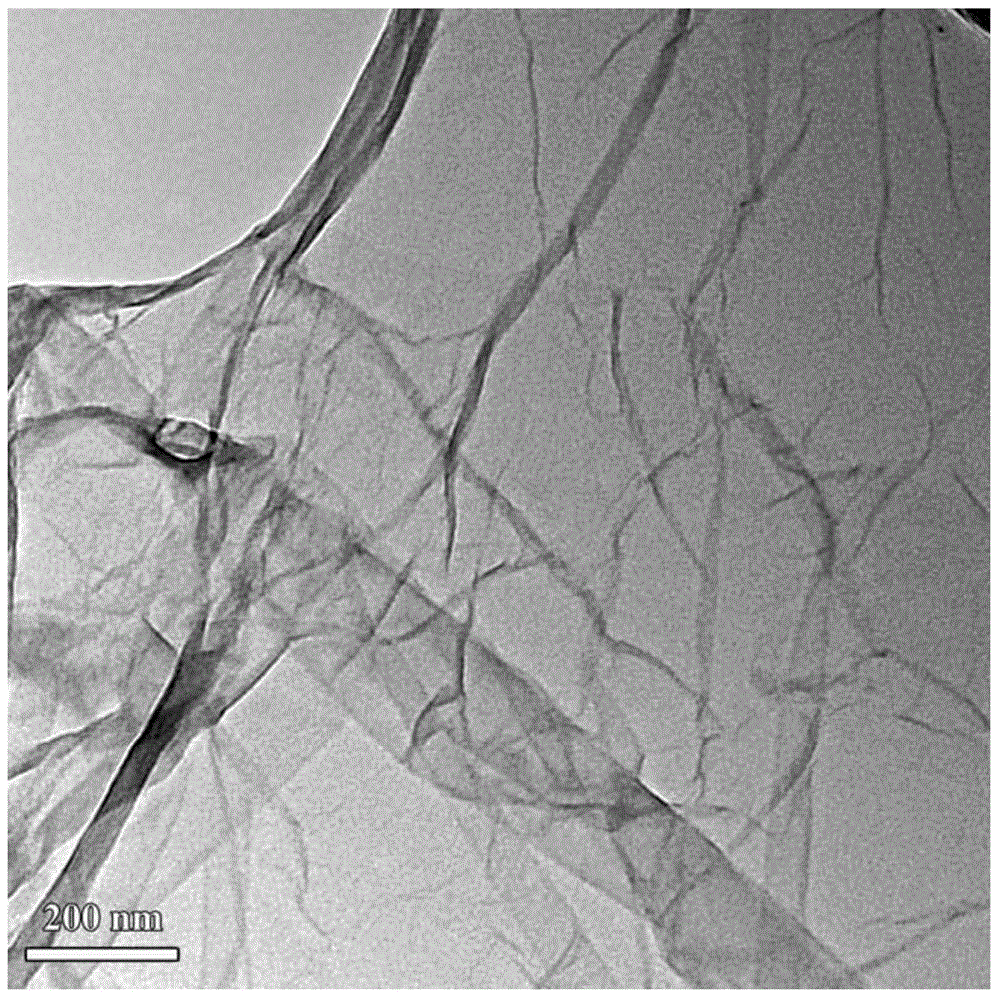

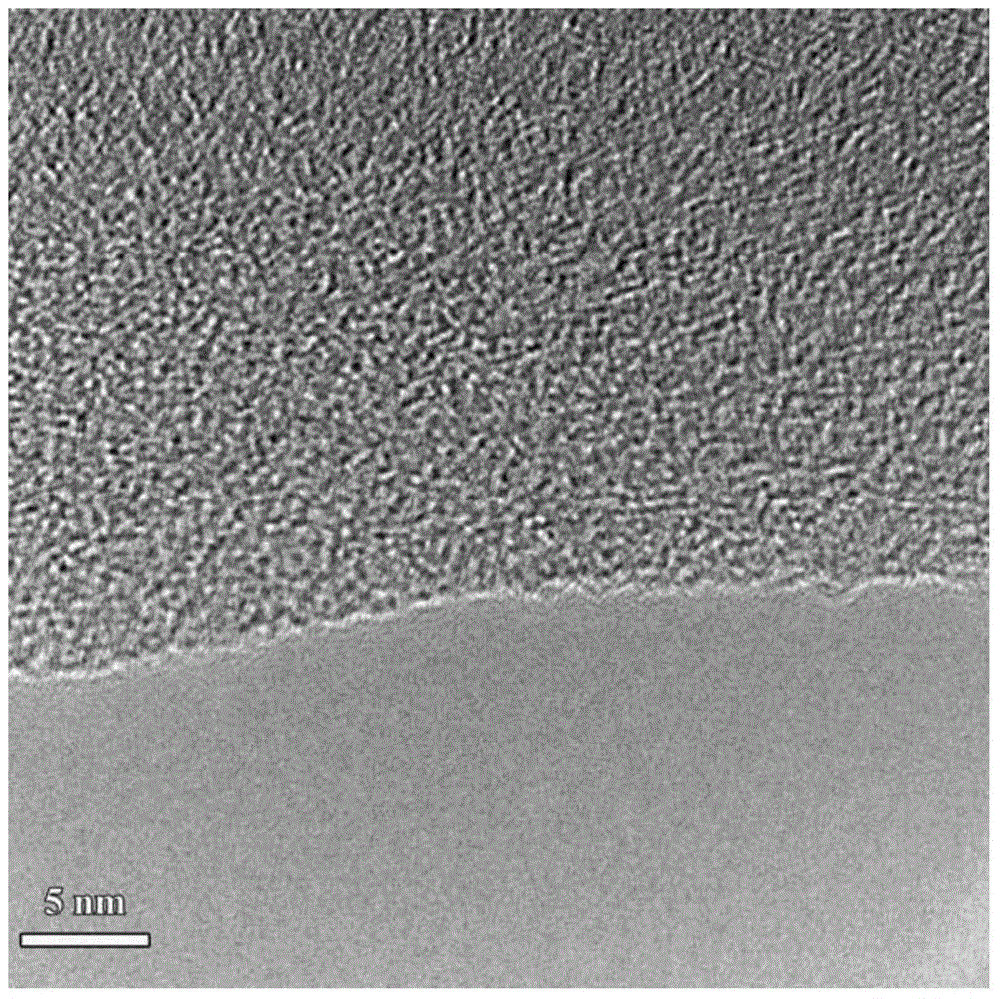

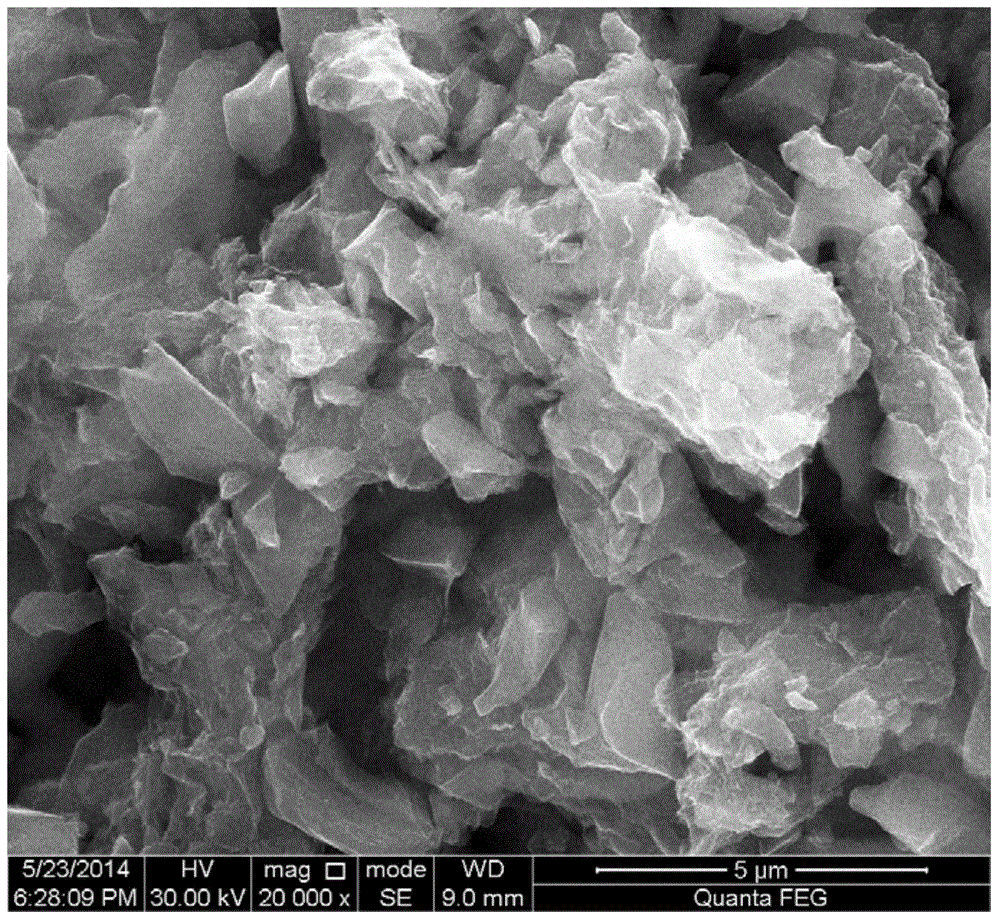

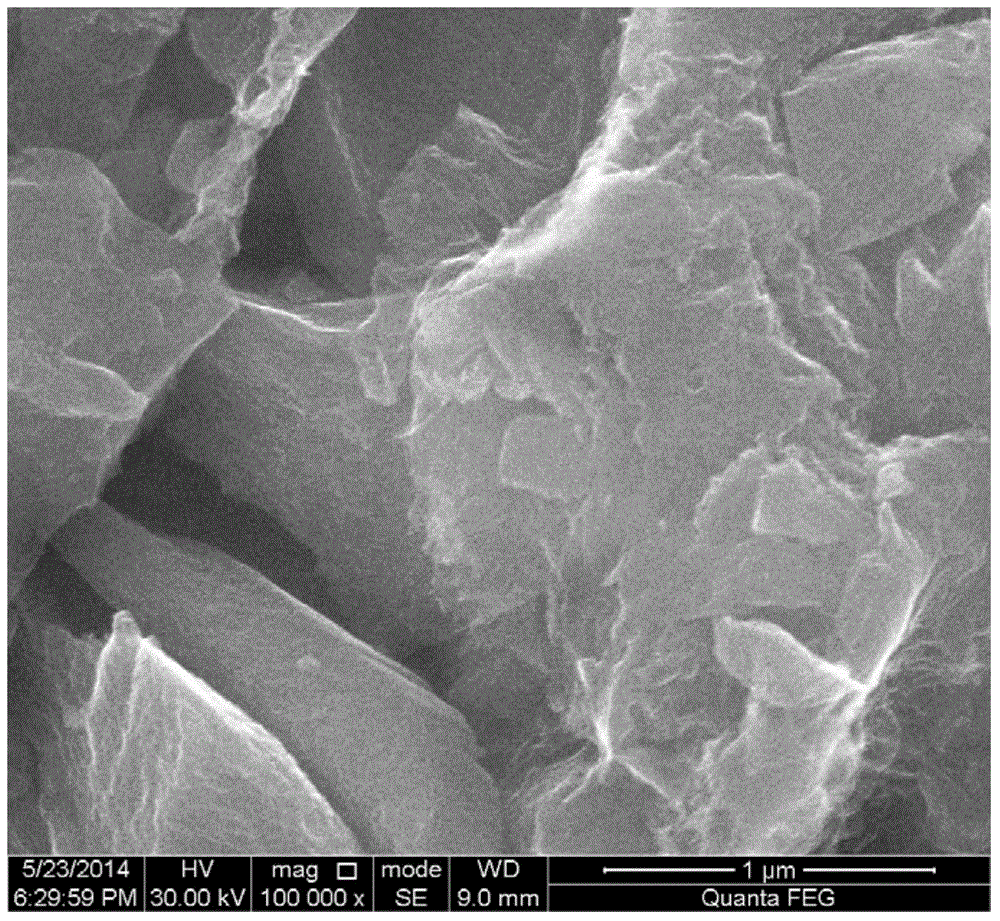

Graphene-coated sulfur/porous carbon composite positive electrode material and preparation method thereof

ActiveCN103560235AUnique hierarchical core-shell structureIncrease contentCell electrodesHigh ratePorous carbon

The invention provides a grapheme-coated sulfur / porous carbon composite material and a preparation method thereof, and relates to a grapheme-coated sulfur / porous carbon composite material used as the positive electrode material of a lithium-sulfur secondary battery and a preparation method thereof. The grapheme-coated sulfur / porous carbon composite positive electrode material provided by the invention can be used for solving the technical problem that the existing grapheme-coated sulfur-containing composite material used as the positive electrode material of a lithium-sulfur battery is low in electrochemical properties. The external surface of each of the particles of the grapheme-coated sulfur / porous carbon composite material provided by the invention is evenly covered with a graphene sheet, and a graphene conductive network is formed between the particles; the obtained grapheme-coated sulfur / porous carbon composite material has a hierarchical core-shell structure. The preparation method of the grapheme-coated sulfur / porous carbon composite material is obtained by adding a sulfur / porous carbon composite material to graphene slurry which is stable for a long time and in which graphene sheets are highly dispersed in water for mixing and coating. The positive electrode material has high specific capacity, long cycle life and excellent high-rate performance. Besides, the grapheme-coated sulfur / porous carbon composite material can be used as the positive electrode material of a lithium secondary battery.

Owner:HARBIN INST OF TECH

Lithium secondary battery

InactiveUS20070054190A1Improve initial performanceImprove adhesionElectrode thermal treatmentFinal product manufactureGraphiteSilicon

A lithium secondary battery has a positive electrode, a negative electrode, and a non-aqueous electrolyte. The negative electrode has a negative electrode current collector and a negative electrode mixture layer containing a negative electrode conductive agent, a negative electrode binder, and negative electrode active material particles made of a material containing silicon. The negative electrode mixture layer is sintered and disposed on the negative electrode current collector. The negative electrode active material particles have an average particle size of from 5.0-15.0 μm before being charged. The negative electrode conductive agent is made of a graphite material having an average particle size of from 2.5-15.0 μm. The amount of the graphite material added is from 3-20 mass % with respect to the negative electrode active material. The theoretical electrical capacity ratio of the positive electrode to the negative electrode is 1.0 or less.

Owner:SANYO ELECTRIC CO LTD

Lithium secondary battery

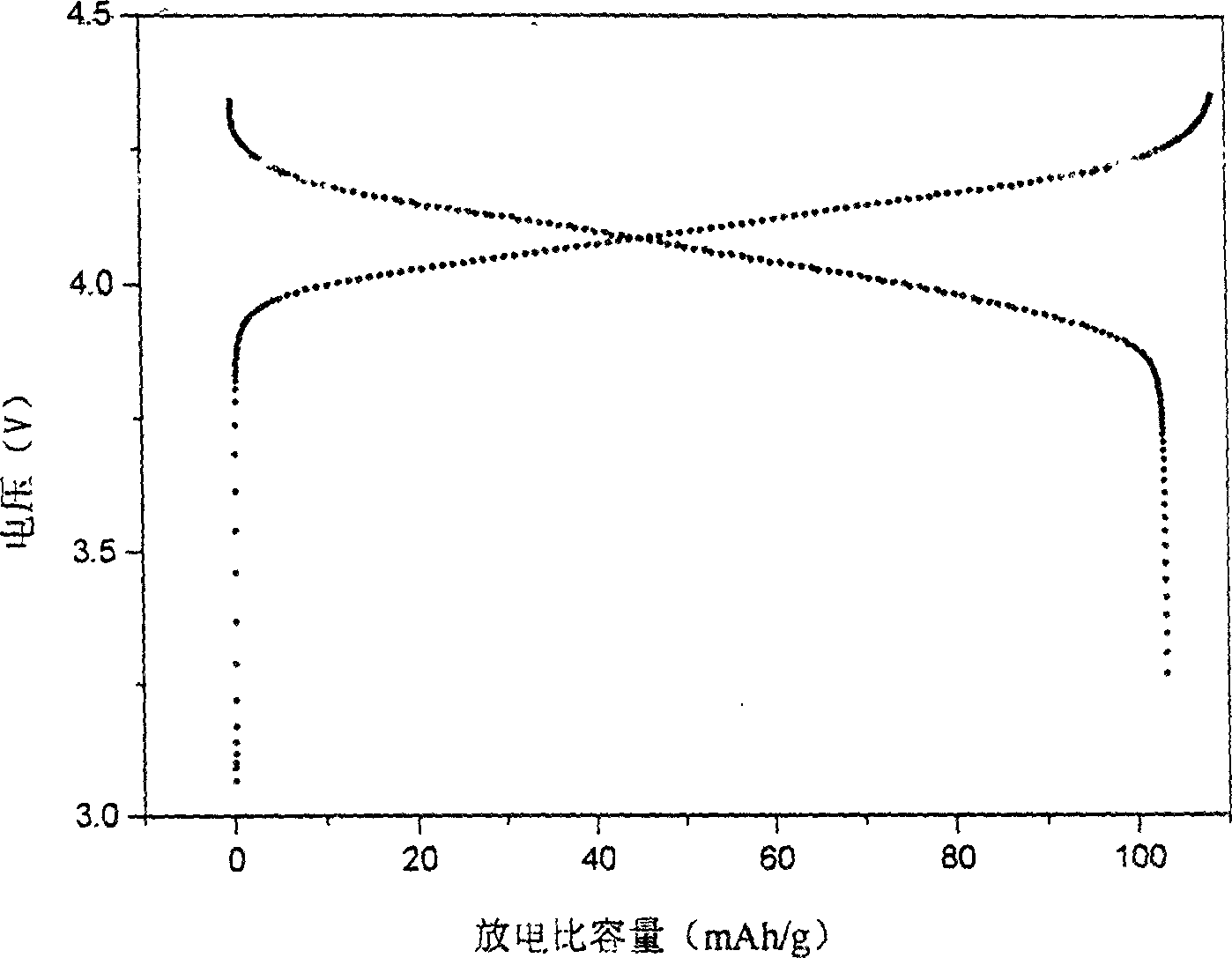

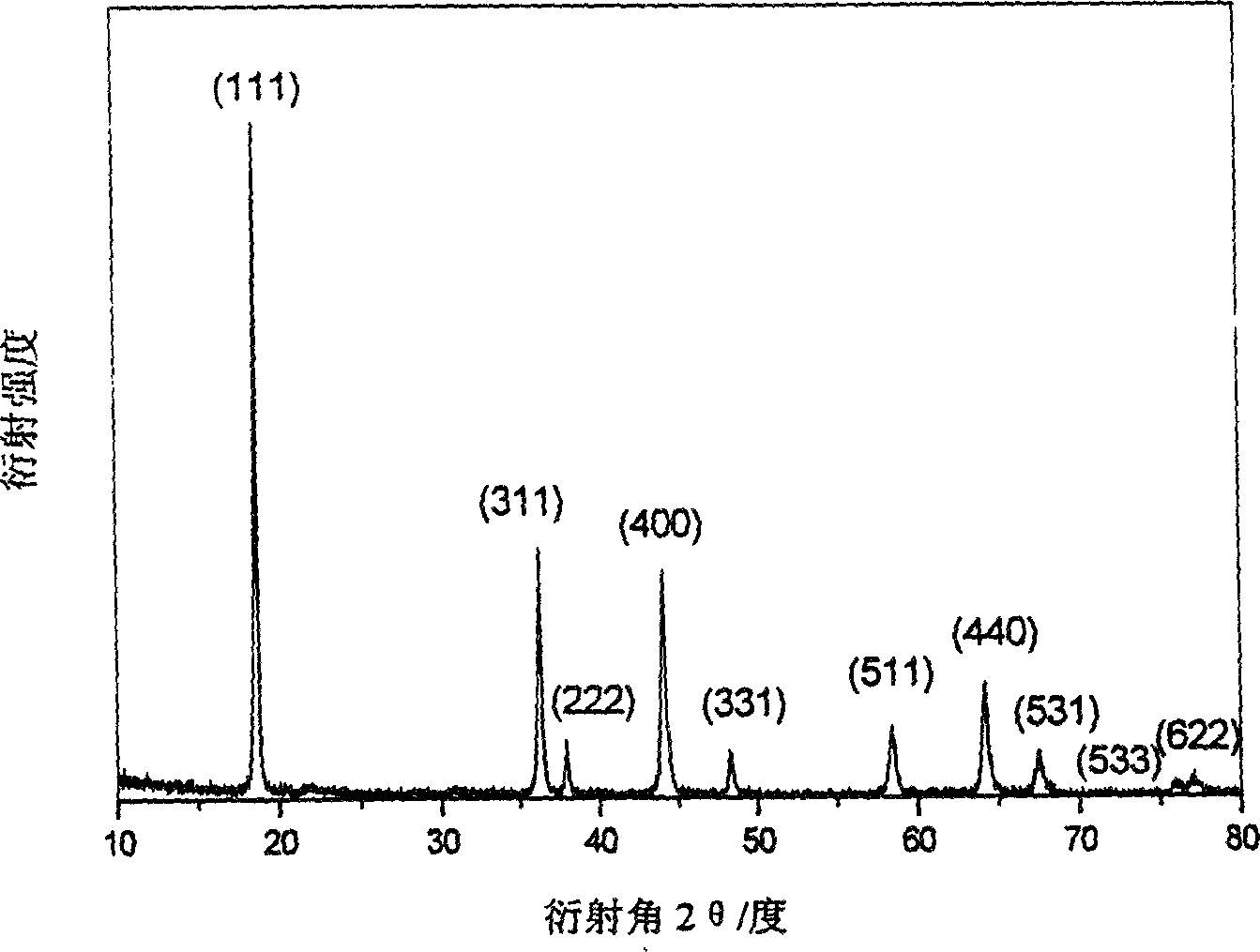

InactiveUS6337158B1Stable crystal structureRelieve pressureFuel cell auxillariesActive material electrodesCharge dischargeLithium-ion battery

A lithium secondary battery of this invention includes a positive electrode using, as an active material, a lithium-containing manganese composite oxide with a spinel structure having a composition, during charge and discharge, represented by a formula, Li.sub.x Mn.sub.2-y-z Ni.sub.y M.sub.z O.sub.4, in which M is at least one element selected from the group consisting of Fe, Co, Ti, V, Mg, Zn, Ga, Nb, Mo and Cu; 0.02.ltoreq..times..ltoreq.1.10, whereas x changes in accordance with occlusion and discharge of lithium ions during charge and discharge; 0.25.ltoreq.y.ltoreq.0.60; and 0<z.ltoreq.0.10. Thus, the invention provides a high-voltage lithium secondary battery exhibiting good charge-discharge cycle performance.

Owner:SANYO ELECTRIC CO LTD

A positive electrode material for lithium secondary cell, and preparation and usage thereof

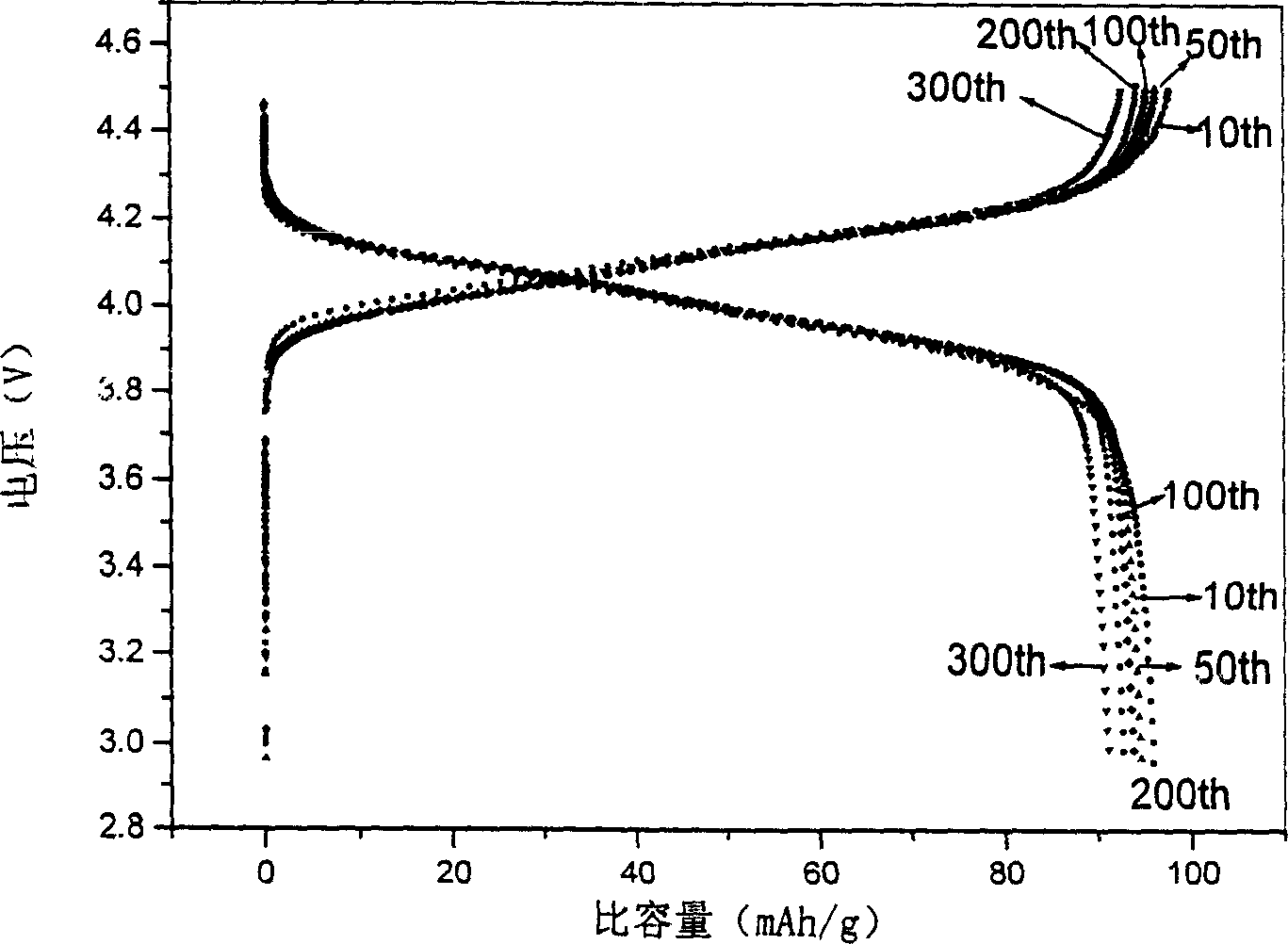

InactiveCN1595687AIncrease energy densityGood charge and discharge cycle performanceElectrode manufacturing processesIron compoundsLithiumManganese

The invention relates to positive electrode material of a lithium secondary battery, which can combine with electrolyte solution or solid electrolyte, and negative electrode active material to form lithium secondary battery. Its characteristics are: the positive electrode material of lithium secondary battery is LiMn2-zMzO4 (0<=z<=0.5.), M is chosen from Li, Mg, Co, Ni, Fe, Al, Sr, Cr, Ga, Cu and Zn. The manufacturing method for positive electrode material of the lithium 1 secondary battery, includes preparation of usher containing Mn; decorate to the covering of usher particle containing Mn; mix with lithium salt and prepare particle; sintering and other steps. By decoration of the surface of particle to usher of positive electrode containing Mn or active material itself, state of material or apparent condition of material can be changed and its capacity of powerful charge and discharge, cycle performance and thermal stability can be raised. The invention has notable advantages including low cost, capacity of powerful charge and discharge, super-long cycle performance, excellent safety, super-long circulation property and resistance to overcharge.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

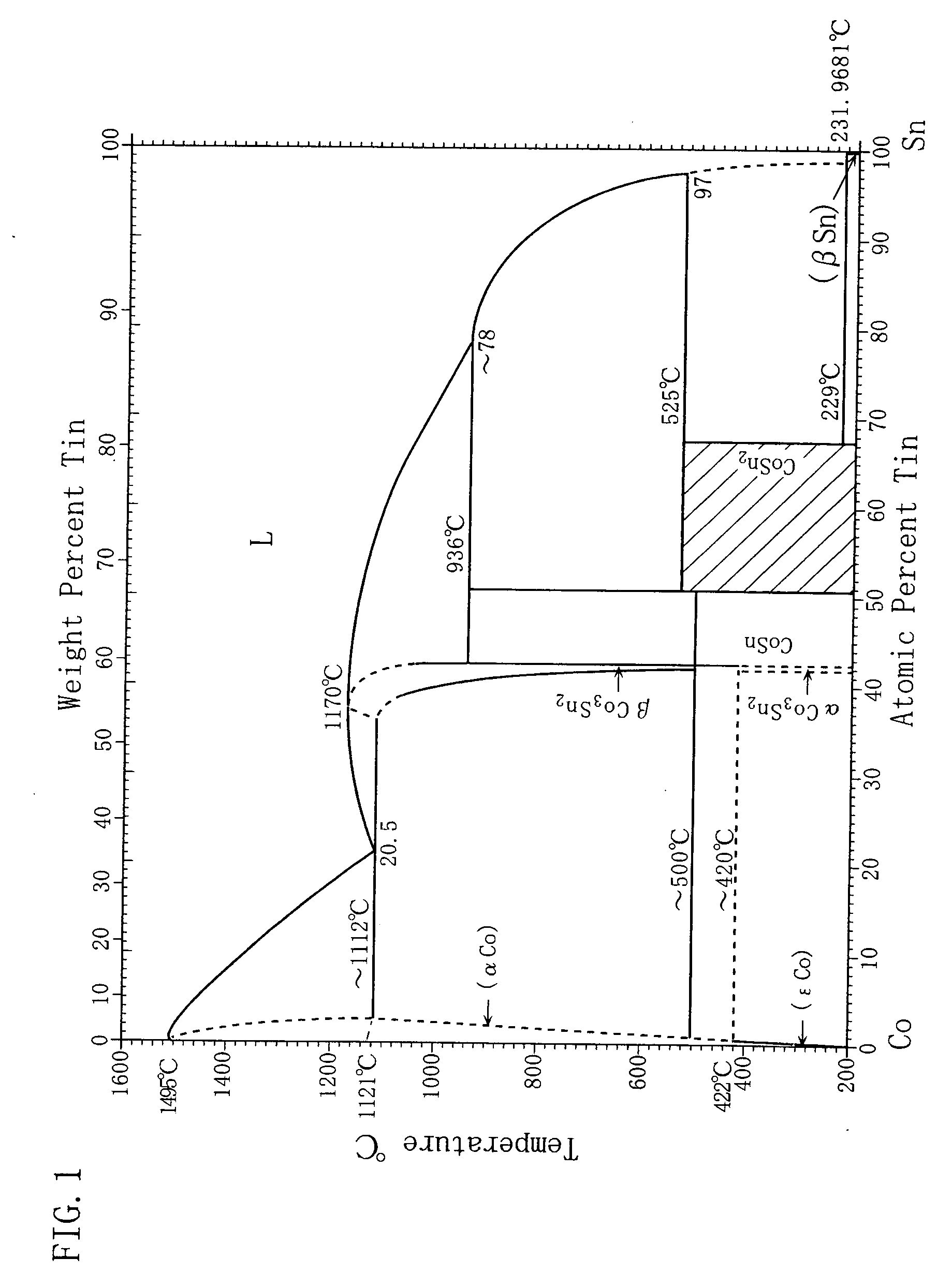

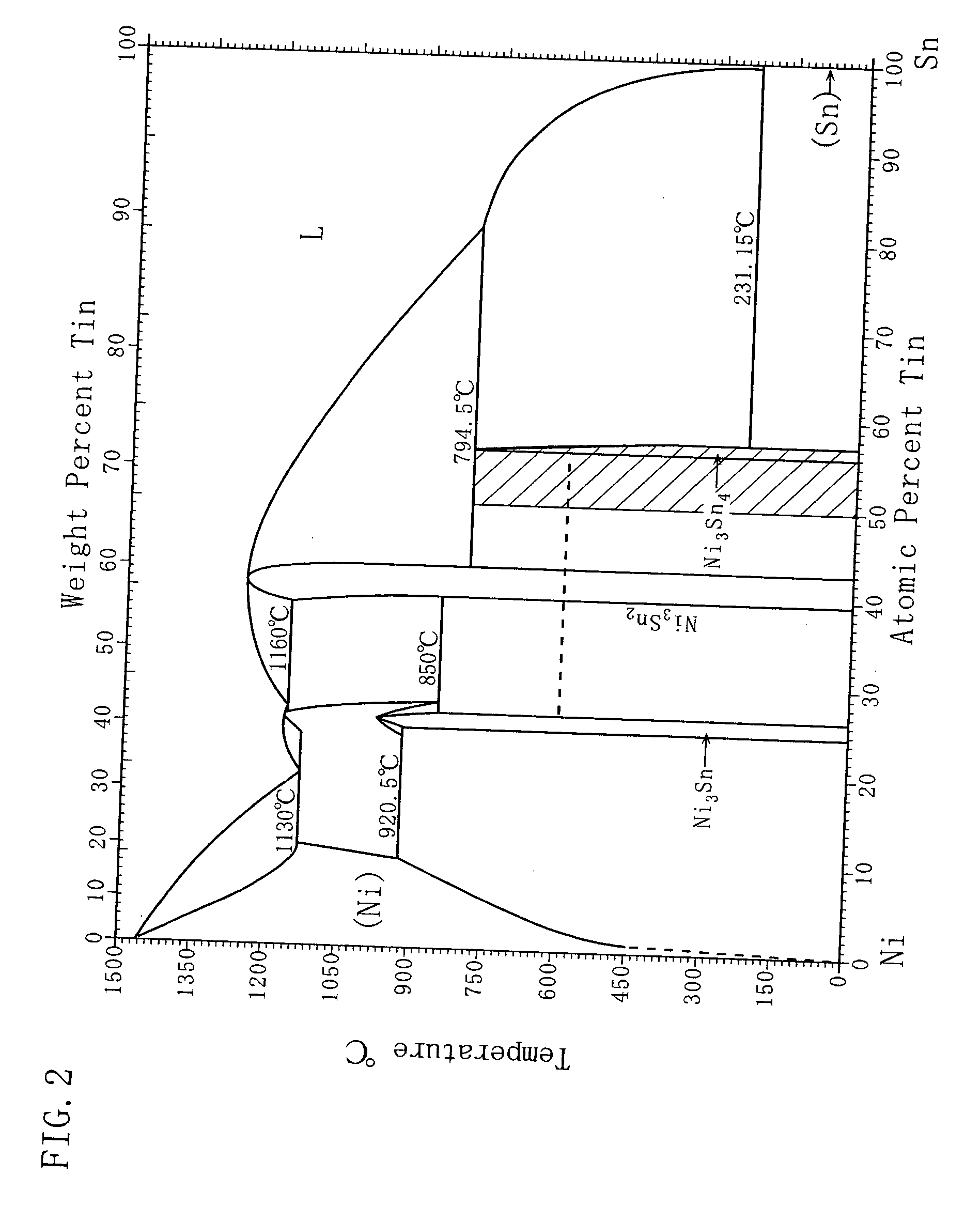

Alloy for negative electrode of lithium secondary battery

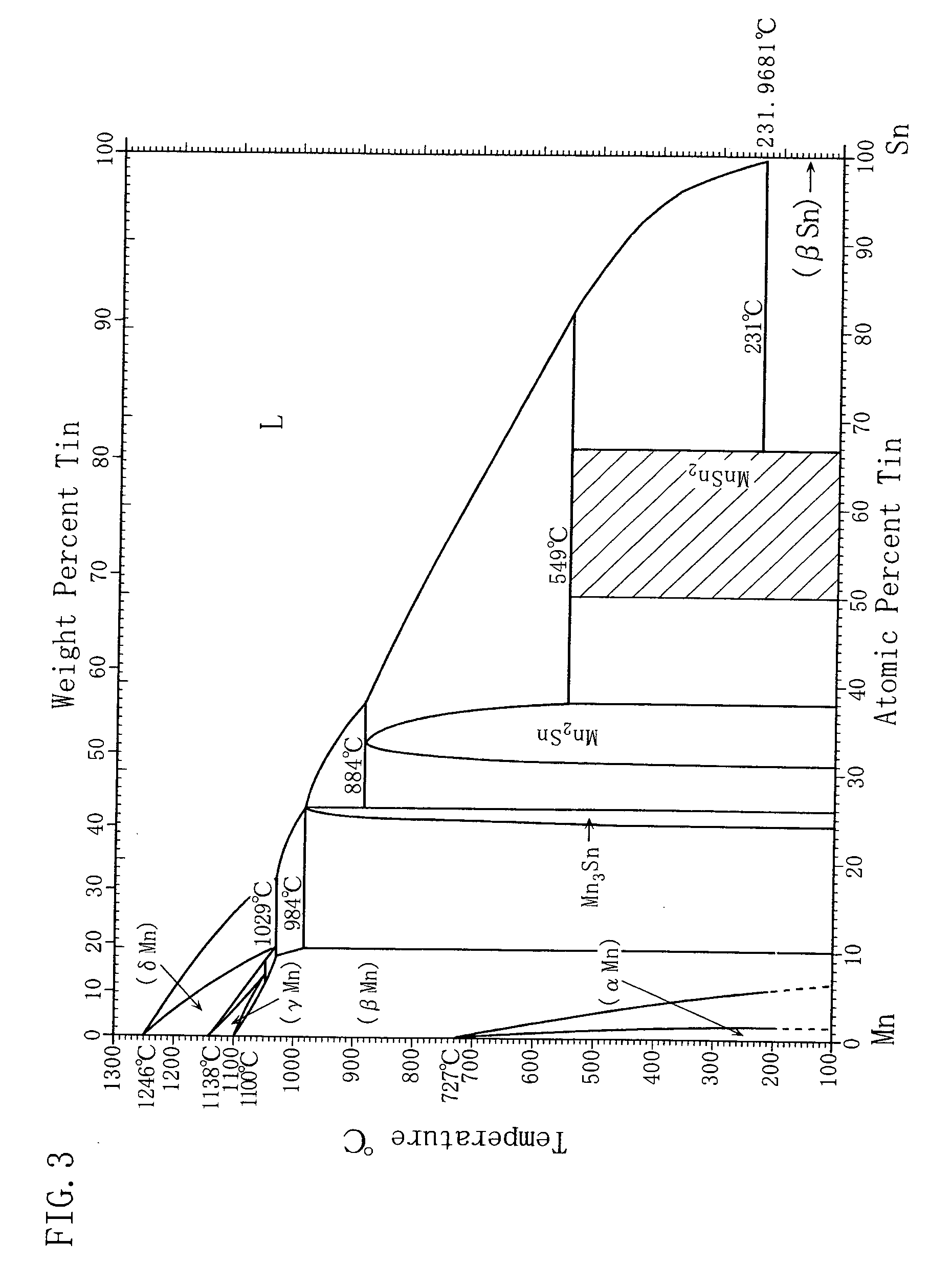

InactiveUS20070048612A1Large discharge capacityLarge electric chargeTransportation and packagingMetal-working apparatusLithiumMetallic materials

At least two metallic materials containing element such as silicon and tin, which has ability of insertion and desertion of lithium element, and optionally another metallic material containing element such as copper are molten to prepare a melt. The melt is rapidly cooled by strip-cast method at a cooling rate of more than 2×103 ° C. / sec and no more than 104 ° C. / sec to be cast. Further, the cast is milled and classified into alloy powder having an average particle size of 0.1 μm to 50 μm. The alloy powder and conductive agent are laminated with binder onto a collector to obtain a negative electrode for a secondary battery. The negative electrode is employed to obtain a lithium secondary battery having high electric charge and discharge capacity, and good property of charge and discharge cycle.

Owner:SHOWA DENKO KK

Positive electrode material of manganese series, and preparation and usage thereof

InactiveCN1595689AIncrease energy densityIncrease powerElectrode manufacturing processesSecondary cellsManganeseThermal stability

The invention relates to manganese department positive electrode material of a lithium secondary battery, which can combine with electrolyte solution or solid electrolyte, and negative electrode active material to form lithium secondary battery. Its characteristics are: the positive electrode material of lithium secondary battery is LiMn1-x-y NixMyO2(x is not less than 0.2 and not larger than 0.8, y is not less than 0 and not larger than 0.6, and x+y is not larger than 1.), M is chosen from Li, Mg, Co, Ni, Fe, Al, Cr. The manufacturing method for manganese department positive electrode material of the lithium secondary battery, includes preparation of usher containing Mn; decorate to the covering of usher particle containing Mn; mix with lithium salt and prepare particle; sintering and other steps. By decoration of the surface of particle to usher 6 of positive electrode containing Mn or active material itself, state of material or apparent condition of material can be changed and its capacity of powerful charge and discharge, cycle performance and thermal stability can be raised. The invention has notable advantages including low cost, capacity of powerful charge and discharge, super-long cycle performance, excellent safety, super-long circulation property and resistance to overcharge .

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

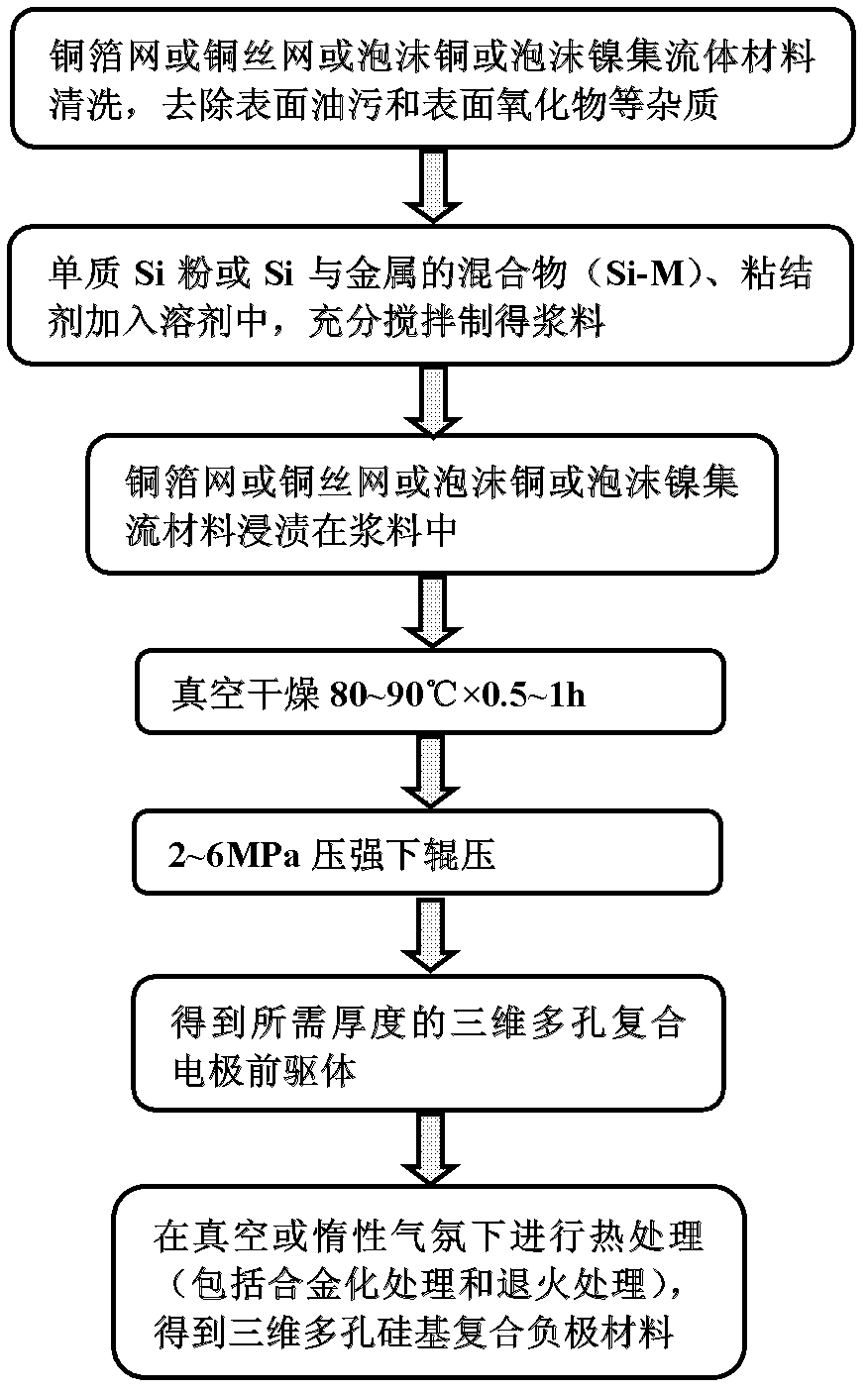

Three-dimensional porous silicon-based composite negative electrode material of lithium ion cell and preparation method thereof

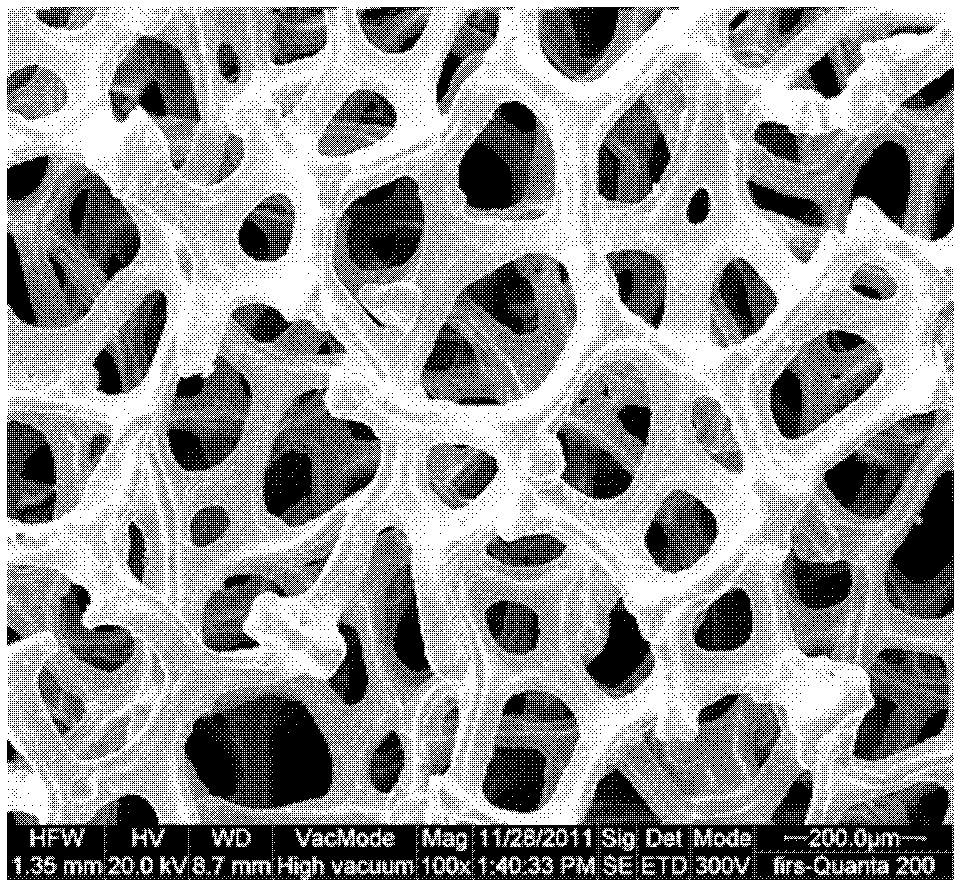

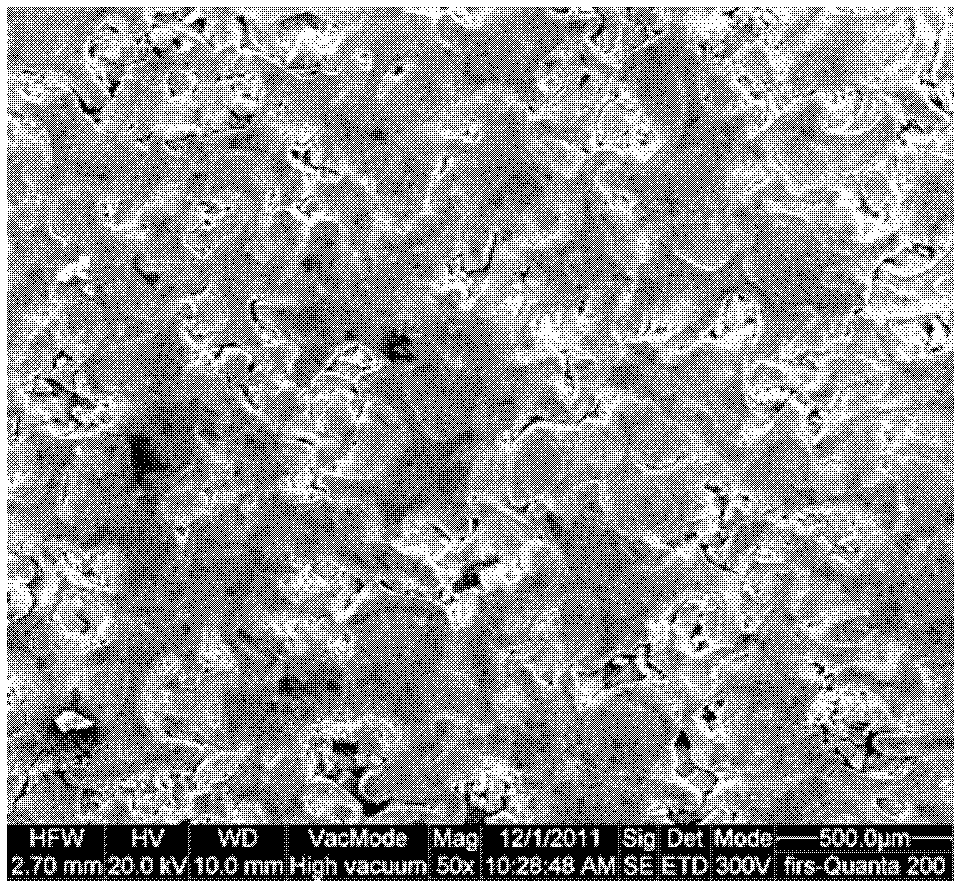

ActiveCN102683655AEasy to operateReduce processing costsElectrode carriers/collectorsSecondary cellsCopper wireCopper foil

The invention discloses a three-dimensional porous silicon-based composite negative electrode material of a lithium ion cell and a preparation method thereof. A collection body material, such as a copper foil net or a copper wire net or foam copper or foam nickel, which has a three-dimensional net structure, enables electrode active substances to be uniformly dispersed in the material and the surface of the material, and has high temperature resistant characteristic and excellent conductivity, is adopted; and a sizing material containing simple substance silicon or a mixture of simple substance silicon and metal M is combined with the copper foil net or copper wire net or foam copper or foam nickel by a dipping method, and then the three-dimensional porous silicon-based composite negative electrode material is formed by a heat treatment (alloying and annealing treatment) manner. According to the invention, based on the three-dimensional porous structure, the forming of silicon metal alloy as well as excellent binding force between the negative electrode material and the three-dimensional porous collection body material, the cell prepared from the porous silicon-based composite negative electrode material has higher discharge specific capacity and first charge-discharge efficiency and excellent cycle performance.

Owner:SHANGHAI SHANSHAN TECH CO LTD

Active material, electrode, and methods of manufacture thereof

InactiveUS20090200509A1Good charge and discharge cycle performanceImprove featuresPositive electrodesNanotechnologyAqueous solutionMetal

An active material having a good cycle performance is produced by bringing a metal-fluoro complex-containing aqueous solution into contact with particles of a first metal oxide so as to form, on surfaces of the first metal oxide particles, particles of a second metal oxide that is an oxide of the metal in the metal-fluoro complex. The active material is composed of particles of the first metal oxide and particles of the second metal oxide which coat the first metal oxide particles and have an average diameter of 50 nm or less. The second metal oxide particles have an adhesive force to the first metal oxide particles of at least 0.1 μN.

Owner:TDK CORPARATION

Hydrothermal preparation method of graphene-coated sulfur/porous carbon composite positive electrode material

ActiveCN104064738AInhibition of dissolution lossPromote wettingCell electrodesSecondary cellsCvd grapheneGraphite oxide

The invention provides a hydrothermal preparation method of a graphene-coated sulfur / porous carbon composite material and relates to a preparation method of the graphene-coated sulfur / porous carbon composite material for a positive electrode material of a lithium-sulfur storage battery. The hydrothermal preparation method is used for solving the technical problem that the electrochemical property of the positive electrode material of an existing lithium-sulfur battery, namely a graphene-coated sulfur-containing composite material, is low. The hydrothermal preparation method comprises the steps of mixing and scattering the sulfur / porous carbon composite material with graphene slurry or oxidized graphene slurry, carrying out hydrothermal synthesis to prepare a hydrogel column, and drying to obtain the graphene-coated sulfur / porous carbon composite material. According to the graphene-coated sulfur / porous carbon composite material prepared by utilizing the hydrothermal preparation method, the outer surfaces of the graphene sheet layers are coated with sulfur / porous carbon composite material particles, a graphene conduction network is generated among the particles, and the obtained graphene-coated sulfur / porous carbon composite material is in a hierarchical core-shell structure; the positive electrode material has the high specific capacity, the long cycle life and the good rate capability; the composite positive electrode material can be used as a positive electrode material in a lithium secondary battery.

Owner:HARBIN INST OF TECH

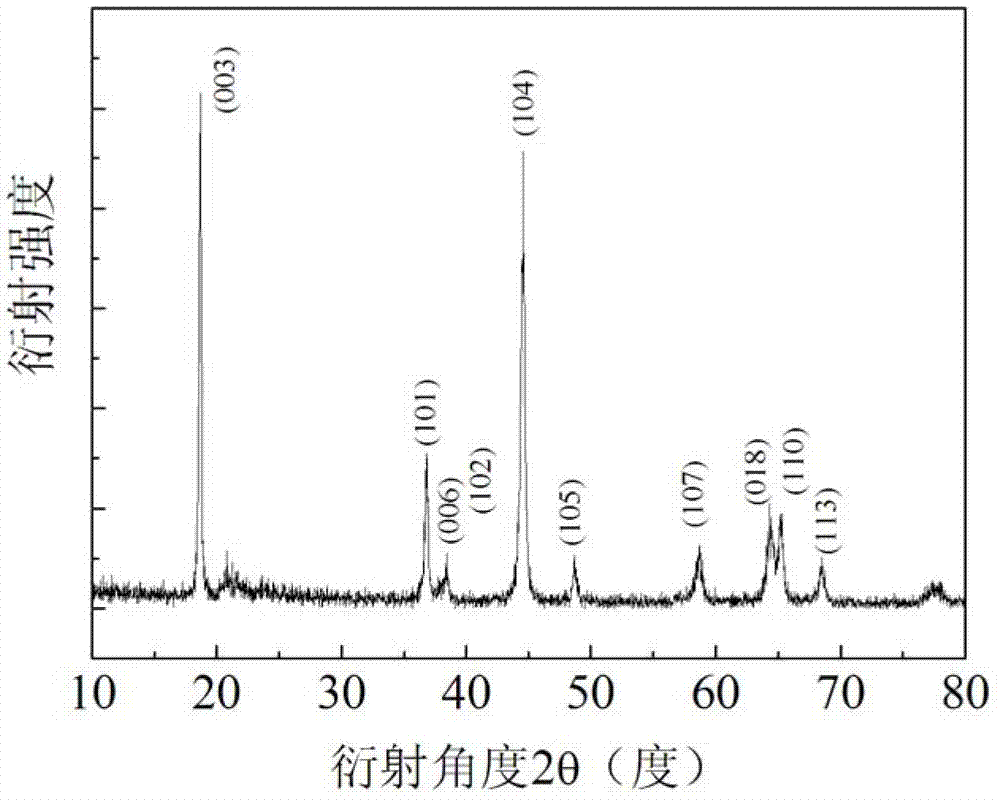

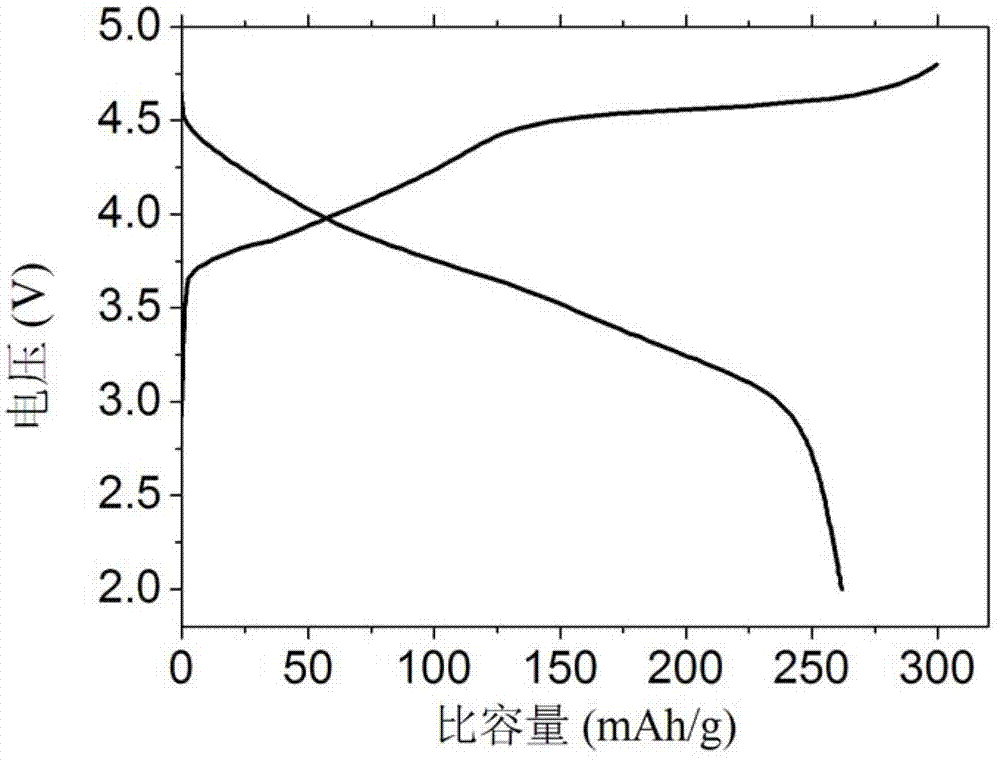

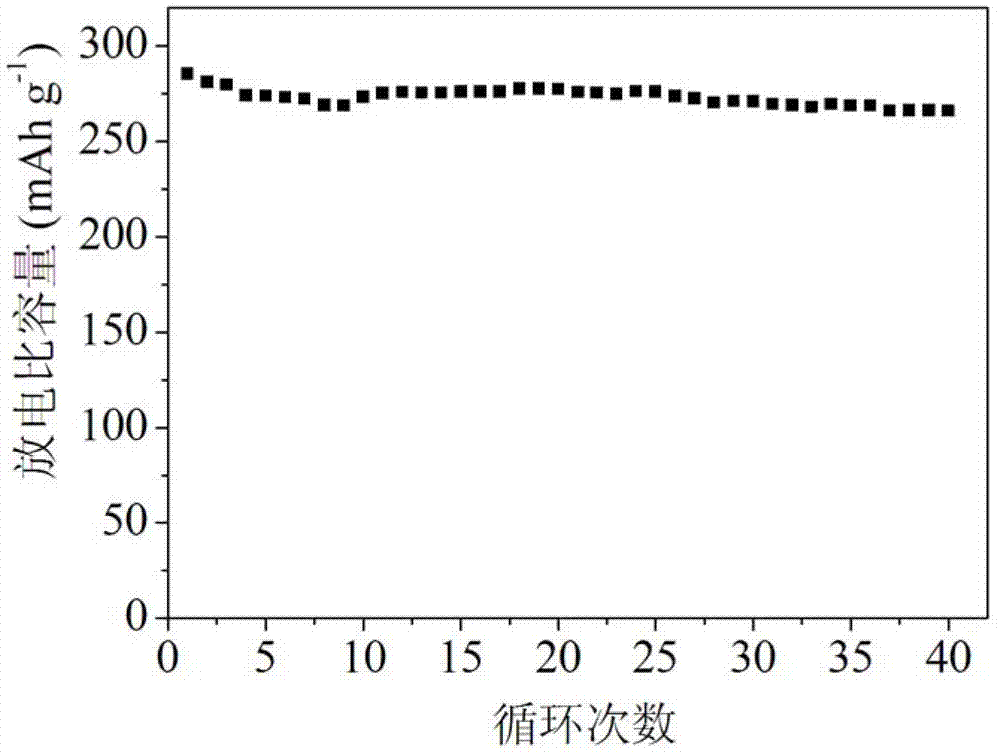

Process for preparing lithium cobalt oxide of lithium-ion secondary battery cathode materials

ActiveCN101694874AImprove featuresImprove discharge capacityCell electrodesSecondary cellsLaser scatteringOxygen

The invention provides a process for preparing lithium cobalt oxide of lithium-ion secondary battery cathode materials. The process includes that cobalt oxide or hydroxyl cobalt oxide powders and lithium carbonate powders are mixed according to a lithium / cobalt molar ratio of 1.0-1.1 and calcined in an atmosphere containing oxygen at the temperature of 850-1100 DEG C; obtained mixture is calcined for 5-55 hours in the atmosphere containing oxygen at the temperature of 850-1100 DEG C; calcined products are naturally cooled to reach room temperature and then grinded; laser scattered grain size distribution measuring device is used for classifying; lithium cobalt oxide semi-finished products are obtained by selecting an average grain diameter D50 of 8-20 micrometers; and a device with high-speed shear strength function is used for conducting coating composition treatment process on the surfaces of the lithium cobalt oxide semi-finished products. The process has the advantages of low raw material cost, high volume energy density, good safety, fine charge-discharge cycle performance, high pressurizing density and superior productivity.

Owner:NANTONG RESHINE NEW MATERIAL

Lithium secondary battery, negative electrode therefor, and method of their manufacture

InactiveUS20070072077A1Increase capacityLess electrical resistancePrimary cellsElectrode carriers/collectorsParticulatesLithium

A practical lithium secondary battery is provided having a greater battery capacity than in the case of using particulate graphite as its negative electrode active material but a less electrical resistance of its negative electrode mixture layer than in the case of using particulate Si as the negative electrode active material. The lithium secondary battery also exhibits good charge-discharge cycle performance. The lithium secondary battery is furnished with a negative electrode having negative electrode current collector and a negative electrode mixture layer that contains a Sn-based particulate negative electrode active material and a negative electrode binder. The negative electrode binder is melt-bonded to the Sn-based particulate negative electrode active material and / or the negative electrode current collector, and the Sn-based particulate negative electrode active material is made of an intermetallic compound represented as SnXM1-X, where 1>X≧1 / 2 and M is Mn, Fe, Co, or Ni.

Owner:SANYO ELECTRIC CO LTD

Polyvinylpyrrolidone modified graphene coated sulfur/porous carbon composite anode material and preparation method thereof

ActiveCN104078685AIncrease contentImprove the utilization rate of active substancesCell electrodesLi-accumulatorsCvd grapheneHigh rate

The invention relates to a polyvinylpyrrolidone modified graphene coated sulfur / porous carbon composite anode material and a preparation method thereof, which relates to a sulfur / carbon composite material applied to a lithium-sulfur secondary battery anode material and a preparation method of the composite material, and solves the technical problem of the existing lithium-sulfur battery anode material graphene-coated sulfur-containing composite material that the electrochemical property is low. The polyvinylpyrrolidone modified graphene coated sulfur / porous carbon composite material is characterized in that the outer surface of a sulfur / porous carbon composite material particle is uniformly coated with a polyvinylpyrrolidone modified graphene slab layer, a graphene conductive network is formed between every two adjacent particles, and a grading core-shell structure is formed. The preparation method comprises the steps of adding the sulfur / porous carbon composite material into graphene slurry modified by the polyvinylpyrrolidone, and mixing the sulfur / porous carbon composite material with the graphene slurry, and coating the sulfur / porous carbon composite material with the graphene slurry modified by the polyvinylpyrrolidone. The anode material is high in specific capacity, long in cycle life and good in high-rate performance.

Owner:HARBIN INST OF TECH

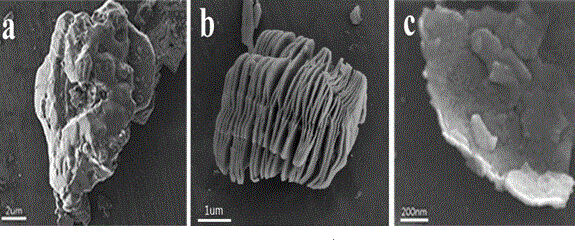

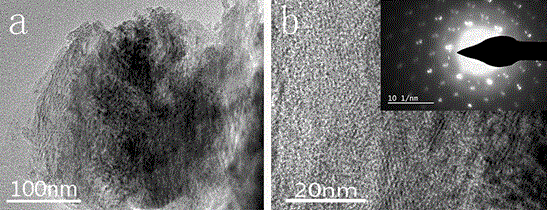

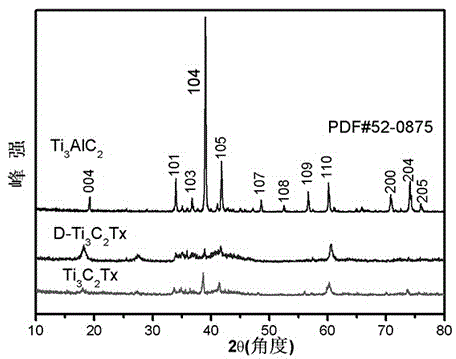

Flaky titanium carbide-loaded manganese dioxide composite material for super capacitor electrode material and preparation of flaky titanium carbide-loaded manganese dioxide composite material

InactiveCN105609319AGood charge and discharge cycle performanceImprove securityHybrid capacitor electrodesHybrid/EDL manufactureSupercapacitorTitanium carbide

The invention provides a flaky titanium carbide-loaded manganese dioxide composite material, which is mainly applied to a super capacitor electrode material, and belongs to the field of composite materials and the technical field of super capacitors. With Ti<3>AlC<2> powder as a raw material, Ti<3>C<2>T<x> with a two-dimensional flaky structure is formed after Al is etched away through HF; and in-situ growth is carried out on a two-dimensional layered titanium carbide surface by potassium permanganate and the Ti<3>C<2>T<x>, thereby obtaining the composite material loaded with a manganese dioxide thin film and a few of manganese dioxide particles on the flaky titanium carbide surface. The composite material is excellent in capacitive performance; the measured specific capacity can reach 256F / g in 0.5M K<2>SO<4> electrolyte; the specific capacity retention rate reaches 92% after 1,000 cycles; and meanwhile, an AC impedance test demonstrates that the material is extremely low in impedance, has the advantages of good safety, high reliability, sufficient energy and the like and has a broad commercial application prospect.

Owner:WANJING ELECTRONICS TECH

Rechargeable battery with nonaqueous electrolyte and process for producing negative electrode

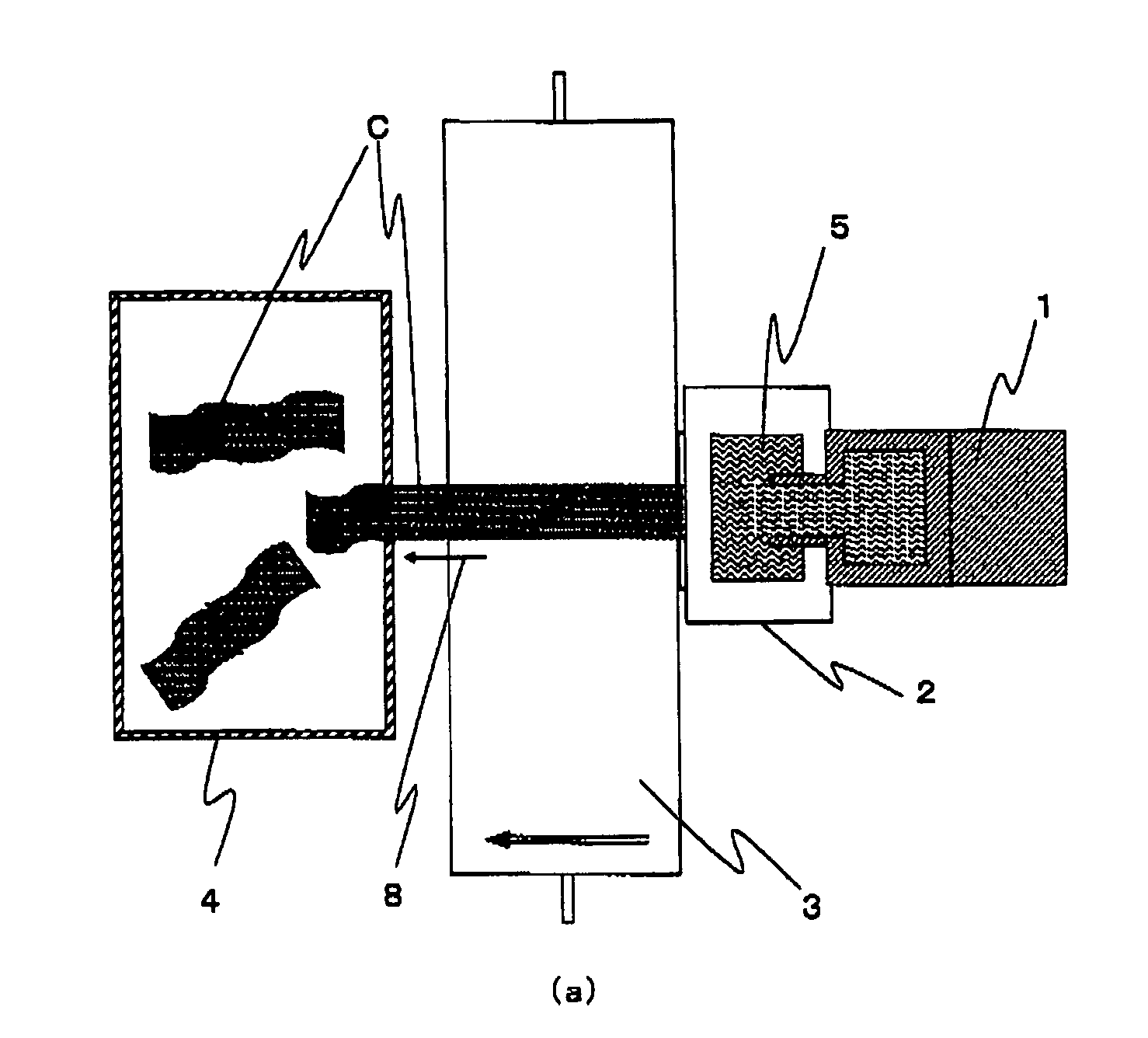

InactiveCN101107734AIncrease energy densityImprove reliabilityElectrode manufacturing processesActive material electrodesMagnetic fluxElectromagnetic induction

An image heating apparatus of electromagnetic induction heating-type capable of providing a proper relative heat-generation distance with a magnetic flux generation member even when the magnetic flux generation member is bent by its own weight or thermally deformed includes at least an exciting coil, a holder for holding the exciting coil, and a rotatable fixation roller for generating heat by magnetic flux from the exciting coil to heat a material to be heated. The holder has an outer diameter phid 1 at a central portion and an outer diameter phid 2 at an end portion in a longitudinal direction of the holder perpendicular to a conveyance direction of the material to be heated. The outer diameters phid 1 and phid 2 satisfies: phid 1 <phid 2.

Owner:PANASONIC CORP

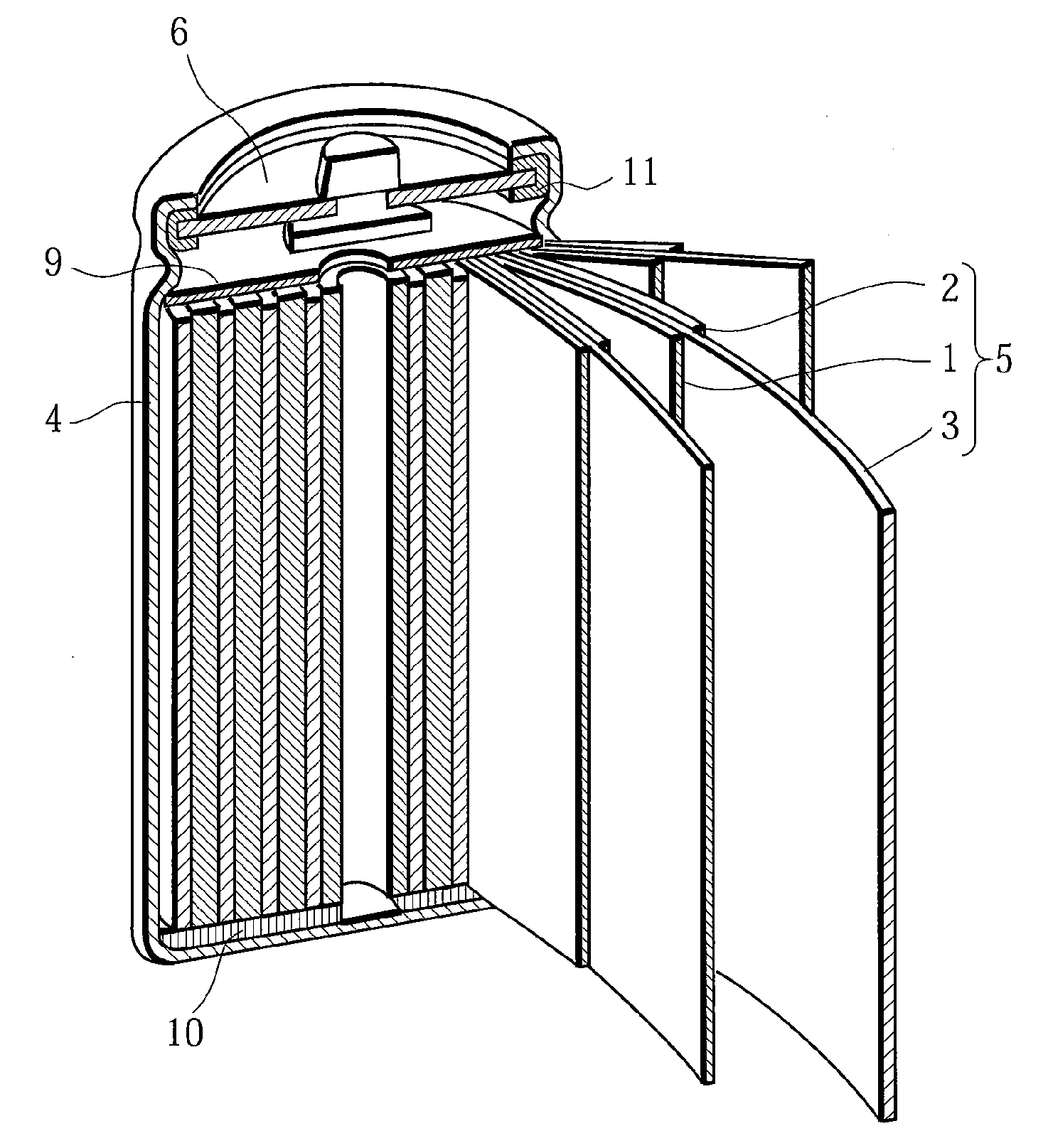

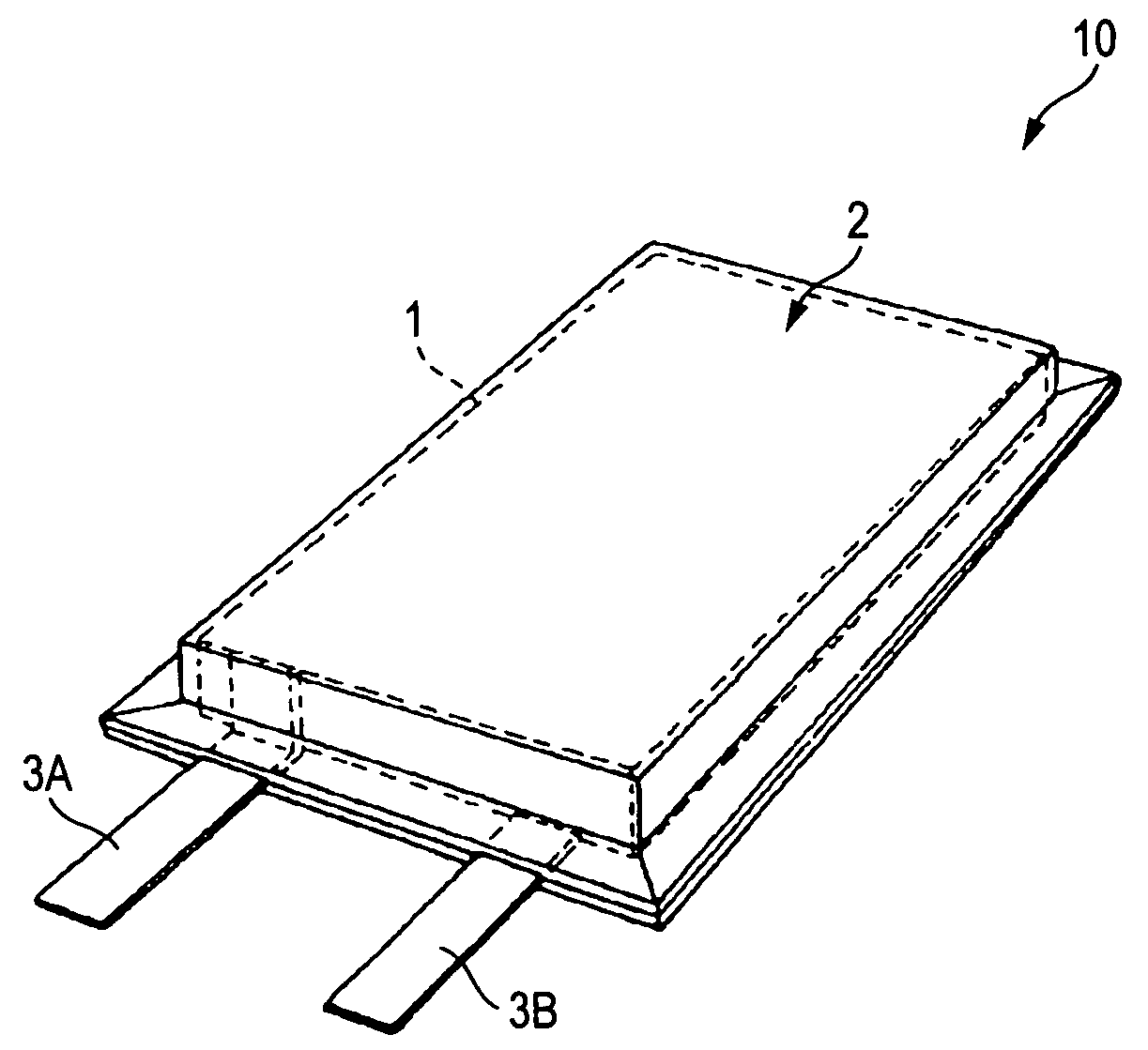

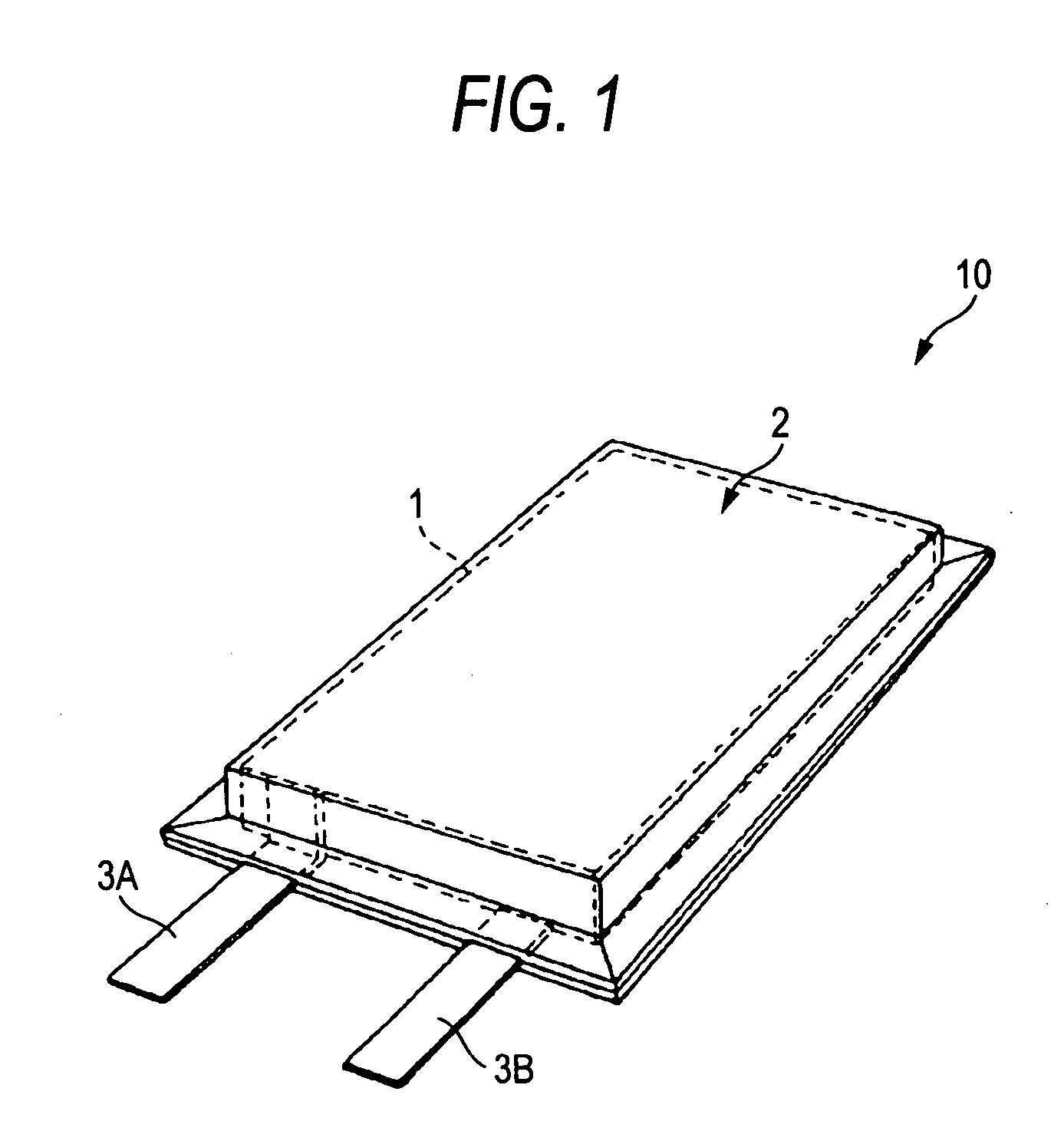

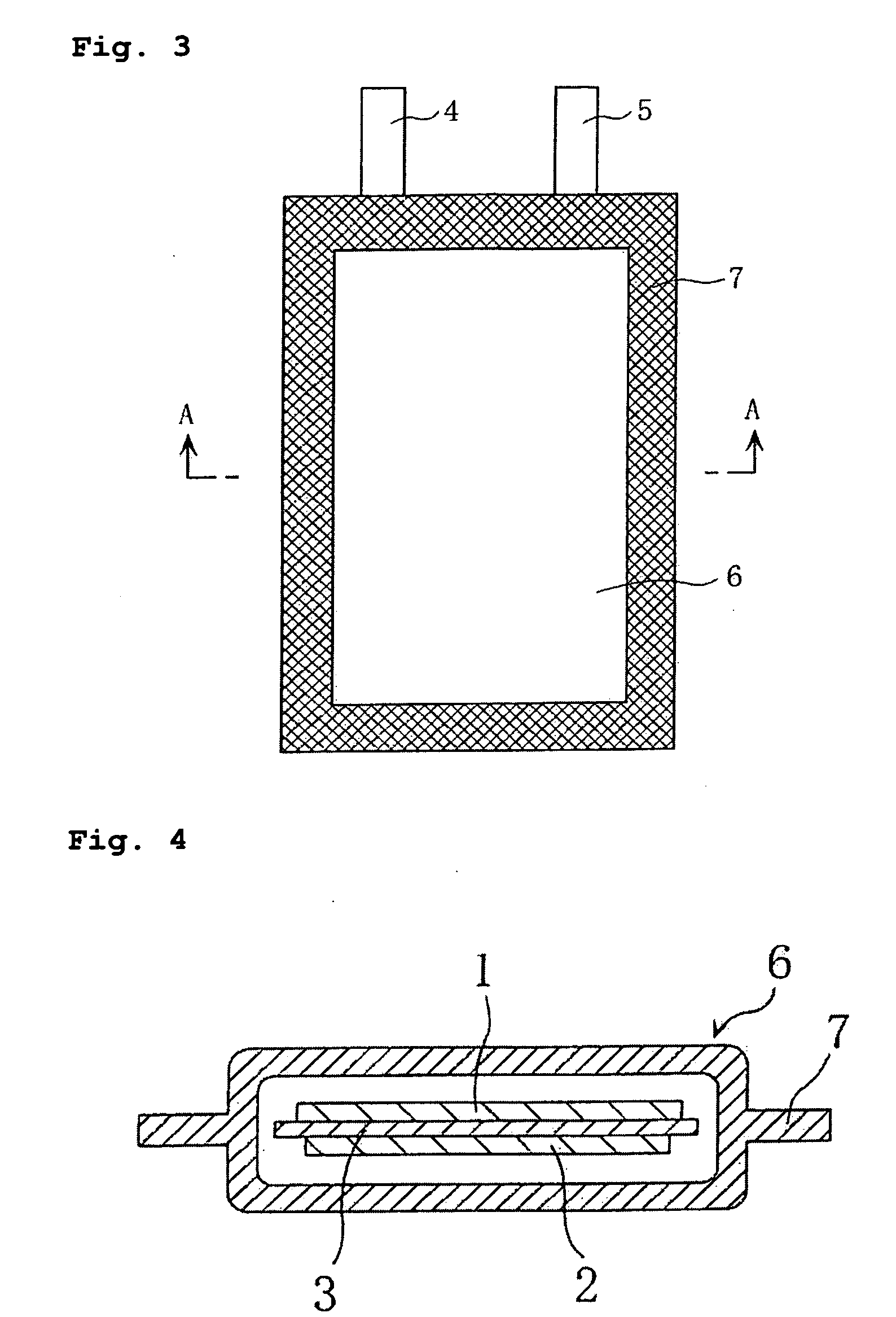

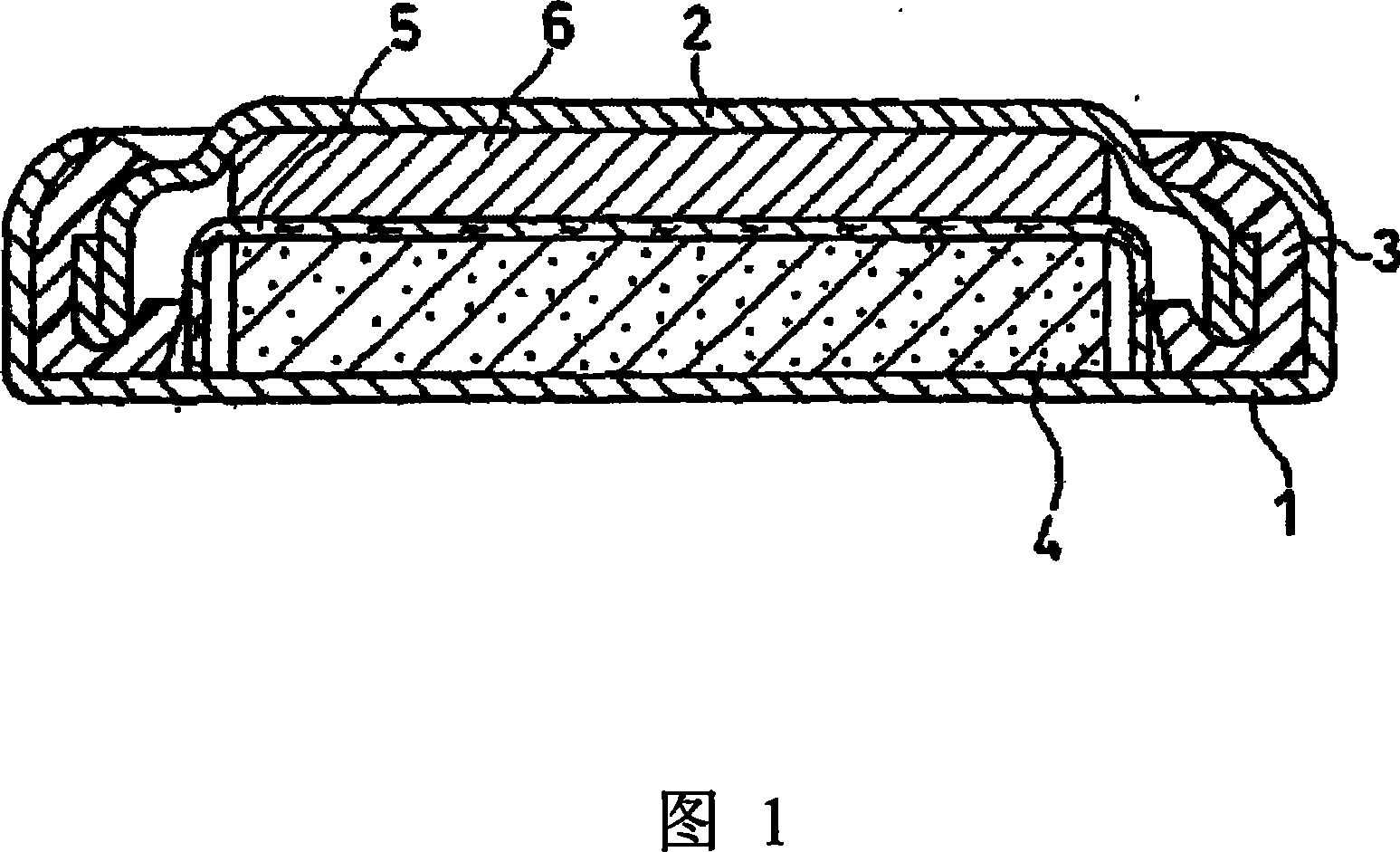

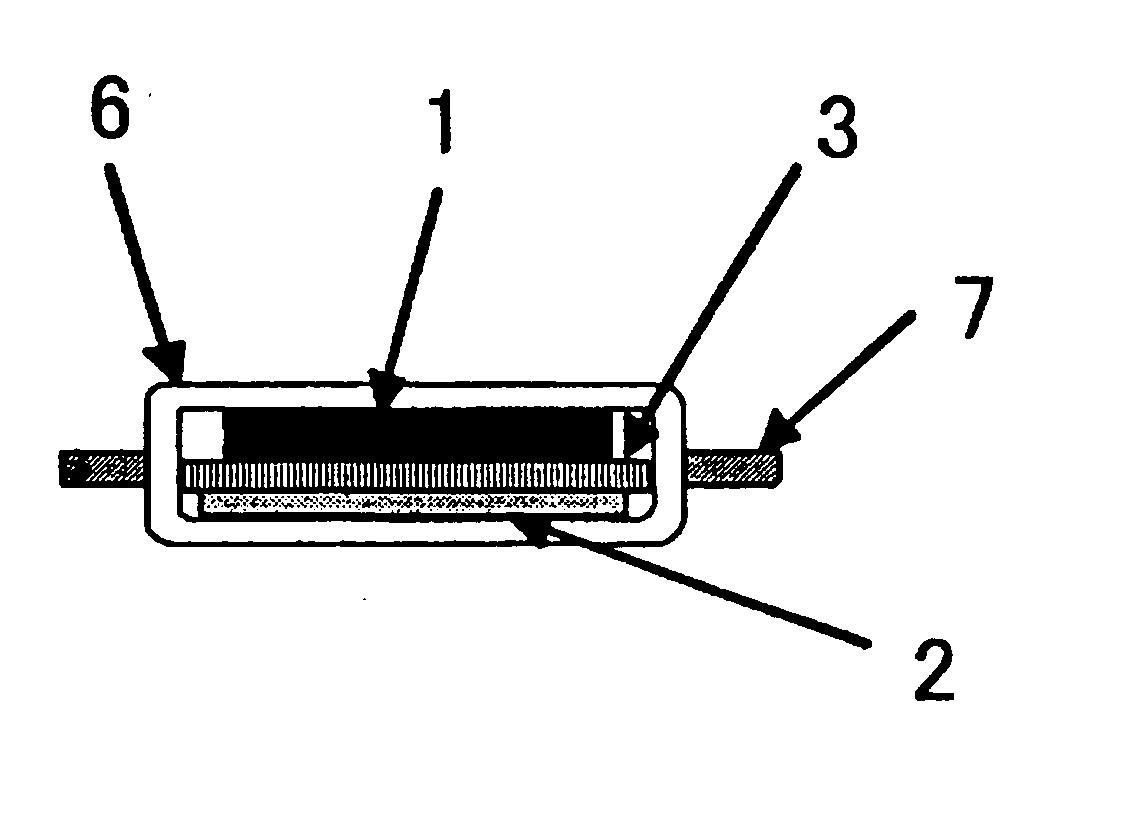

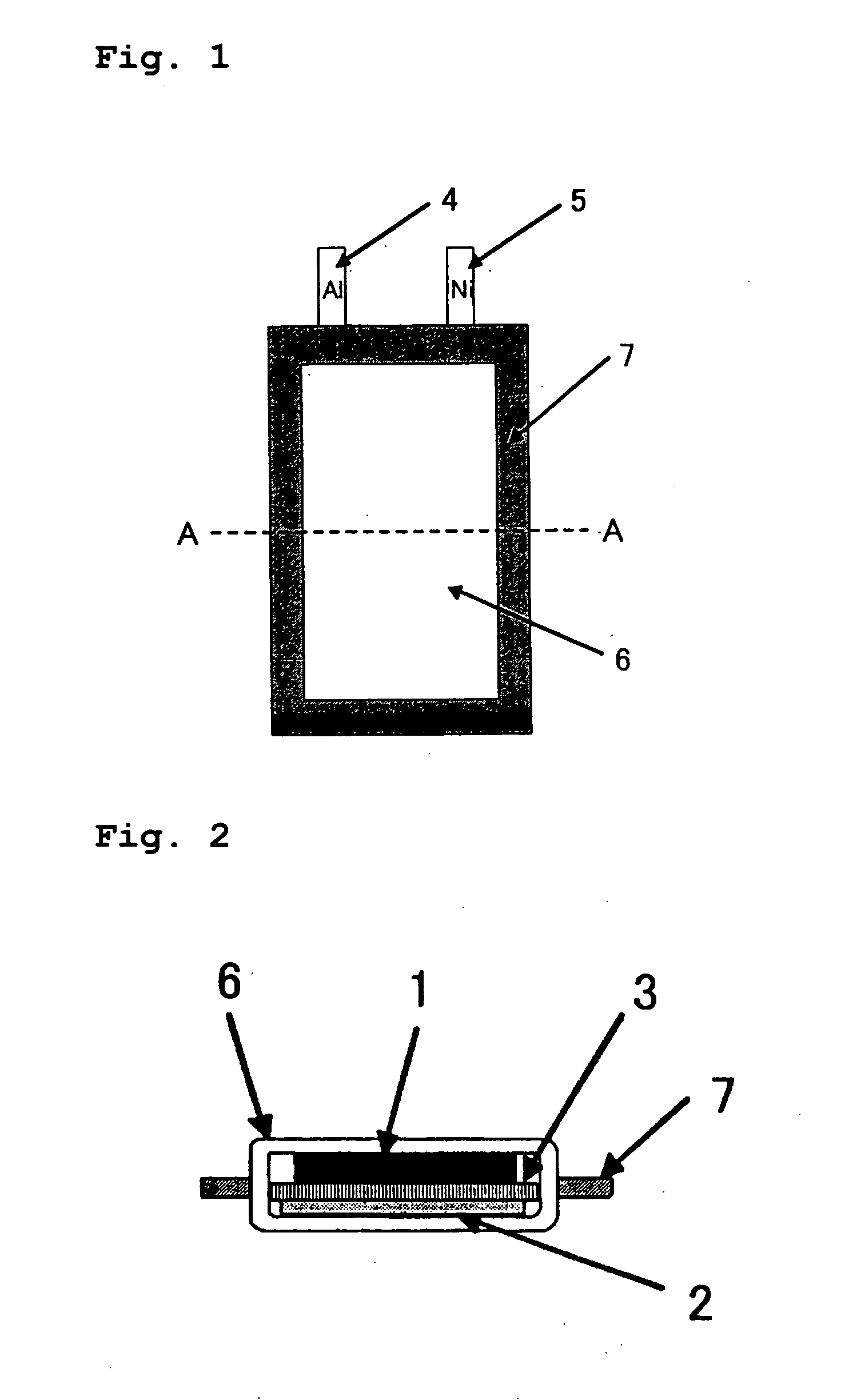

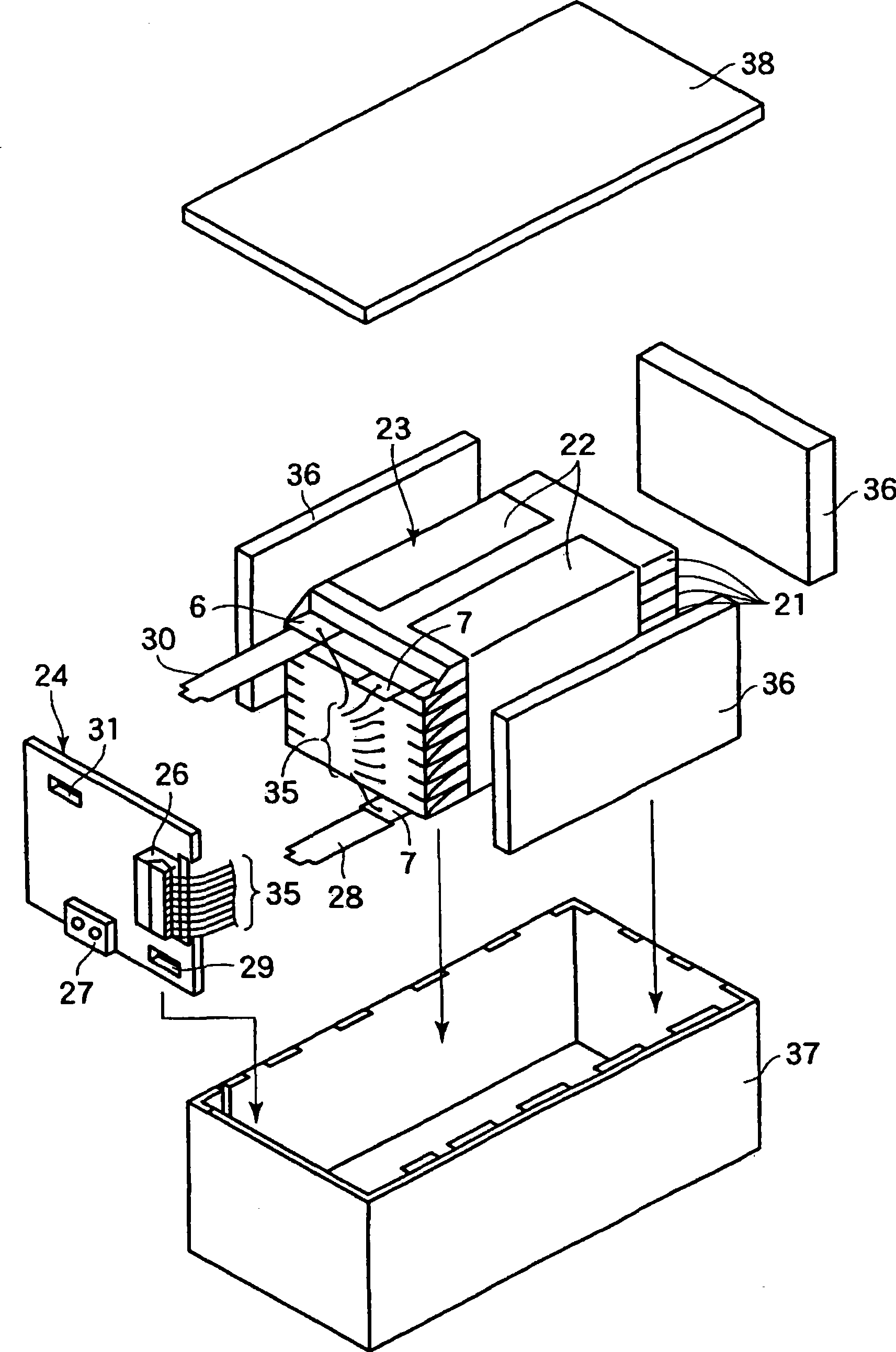

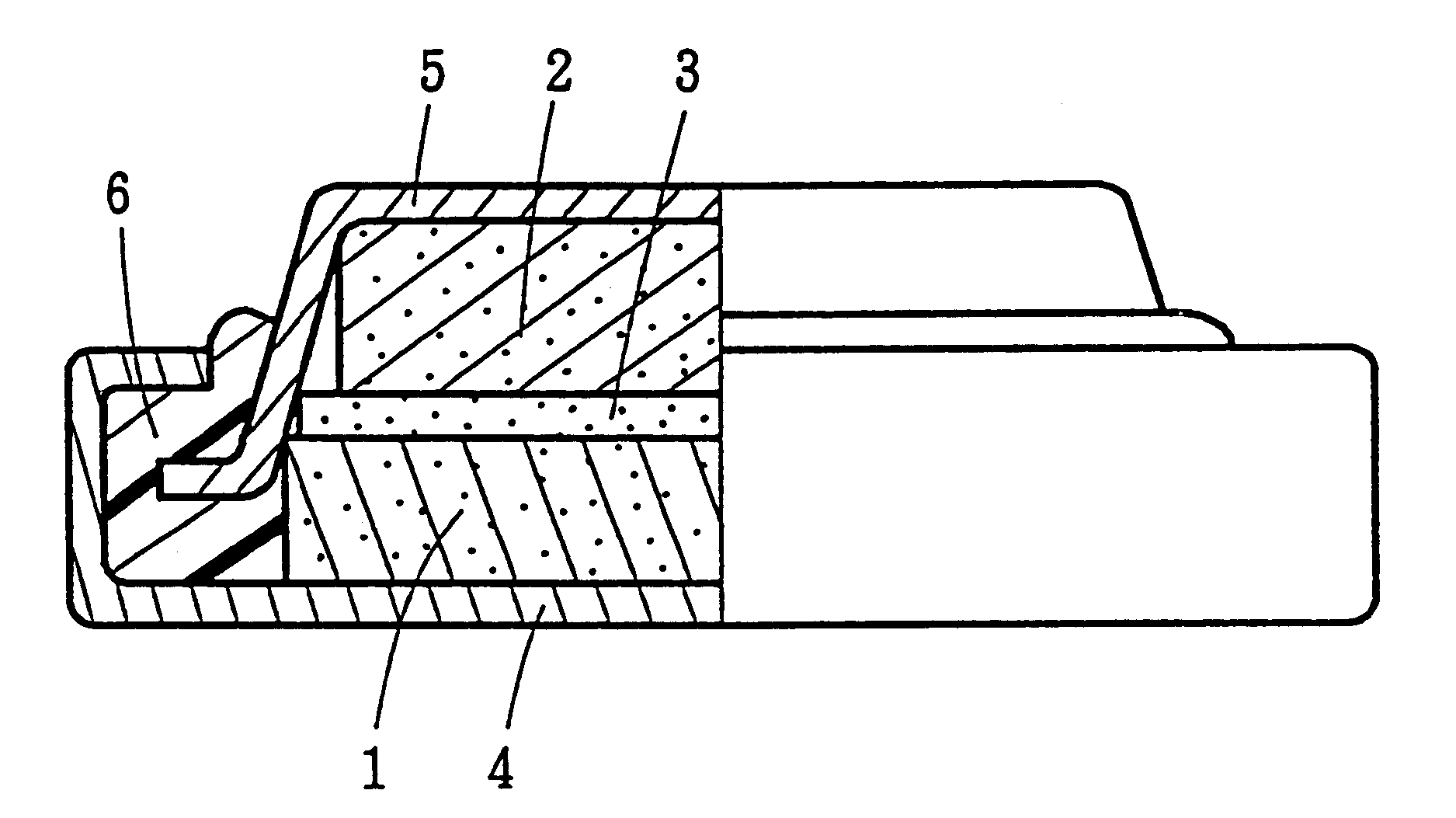

Lithium secondary battery

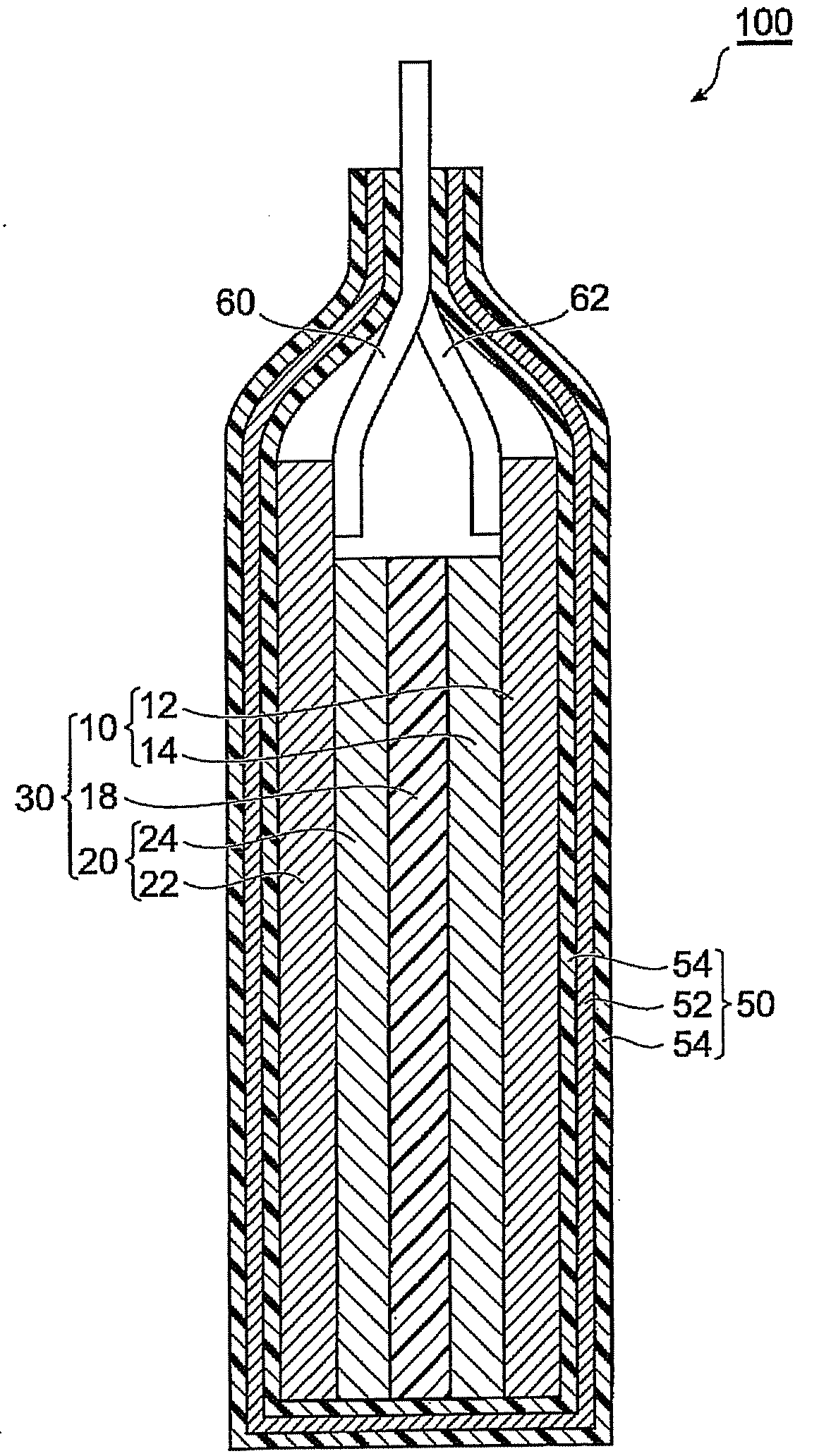

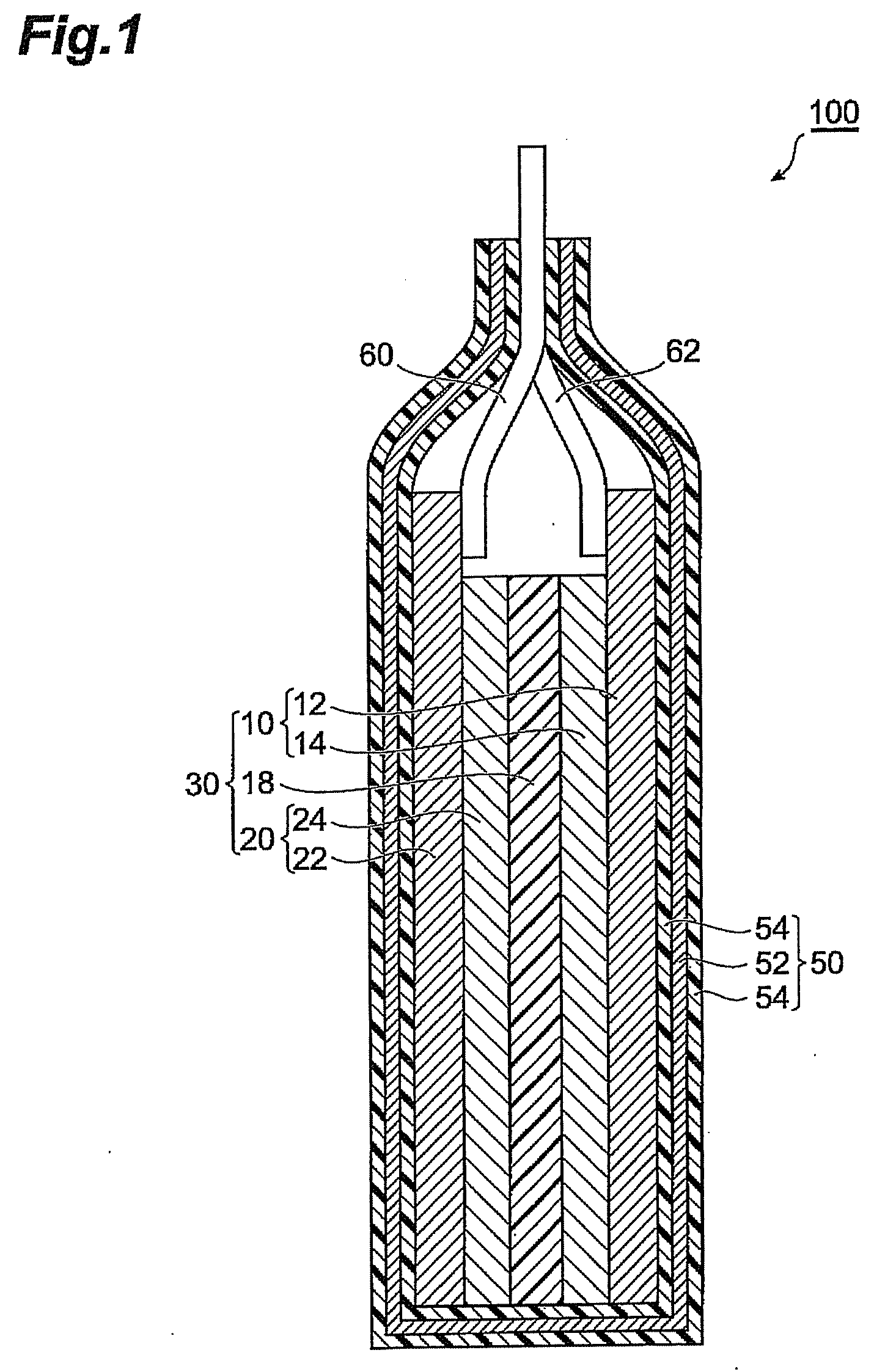

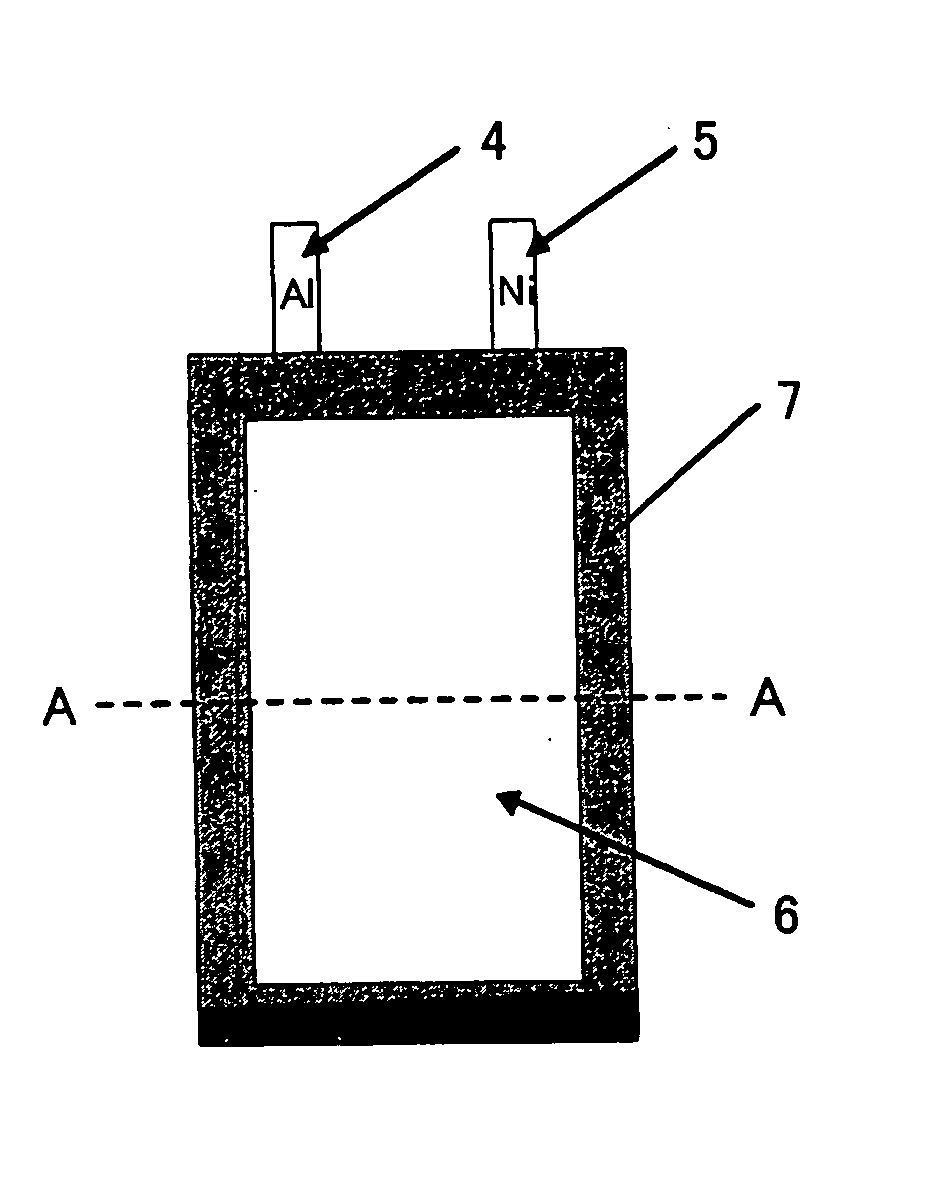

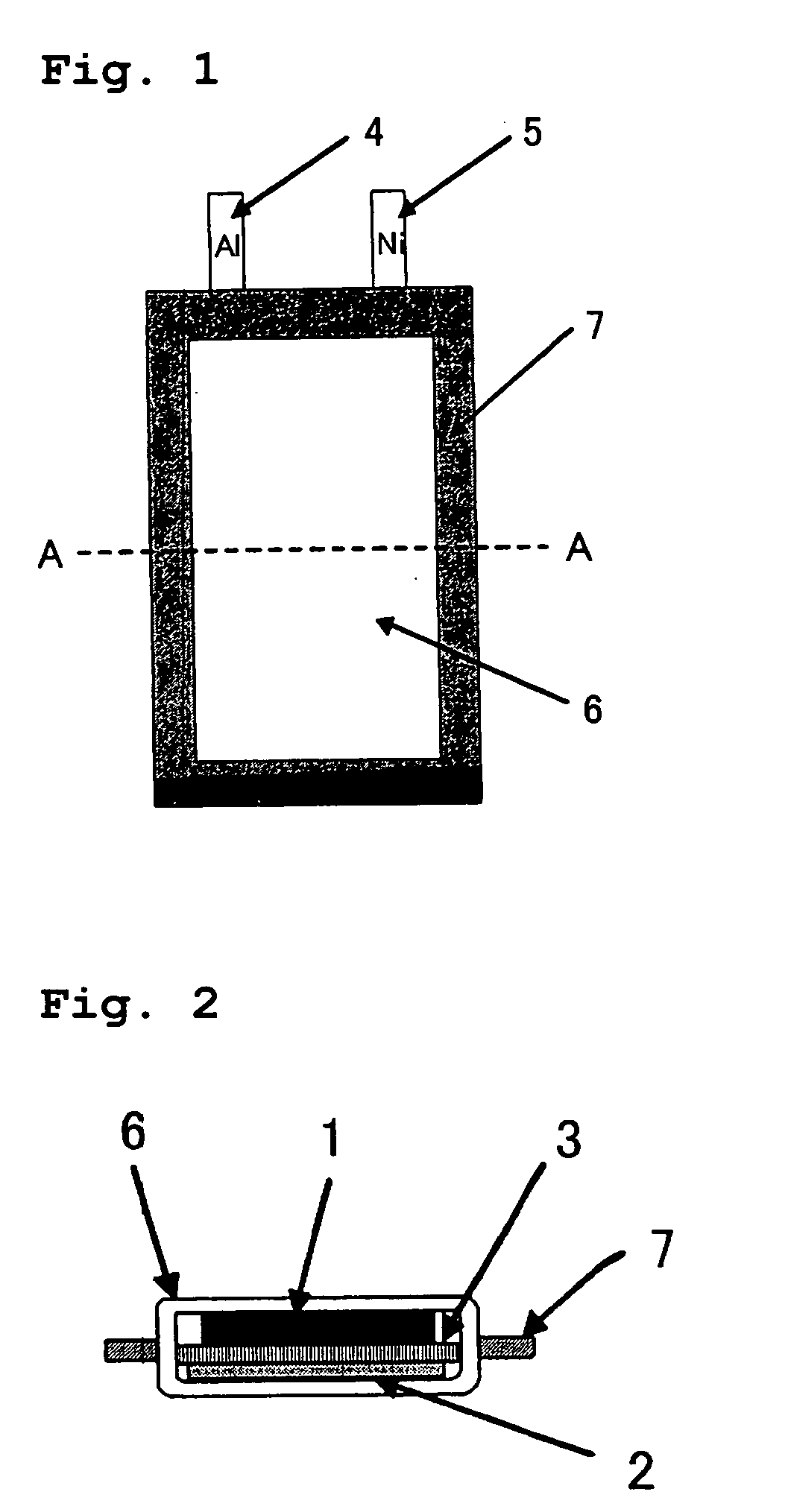

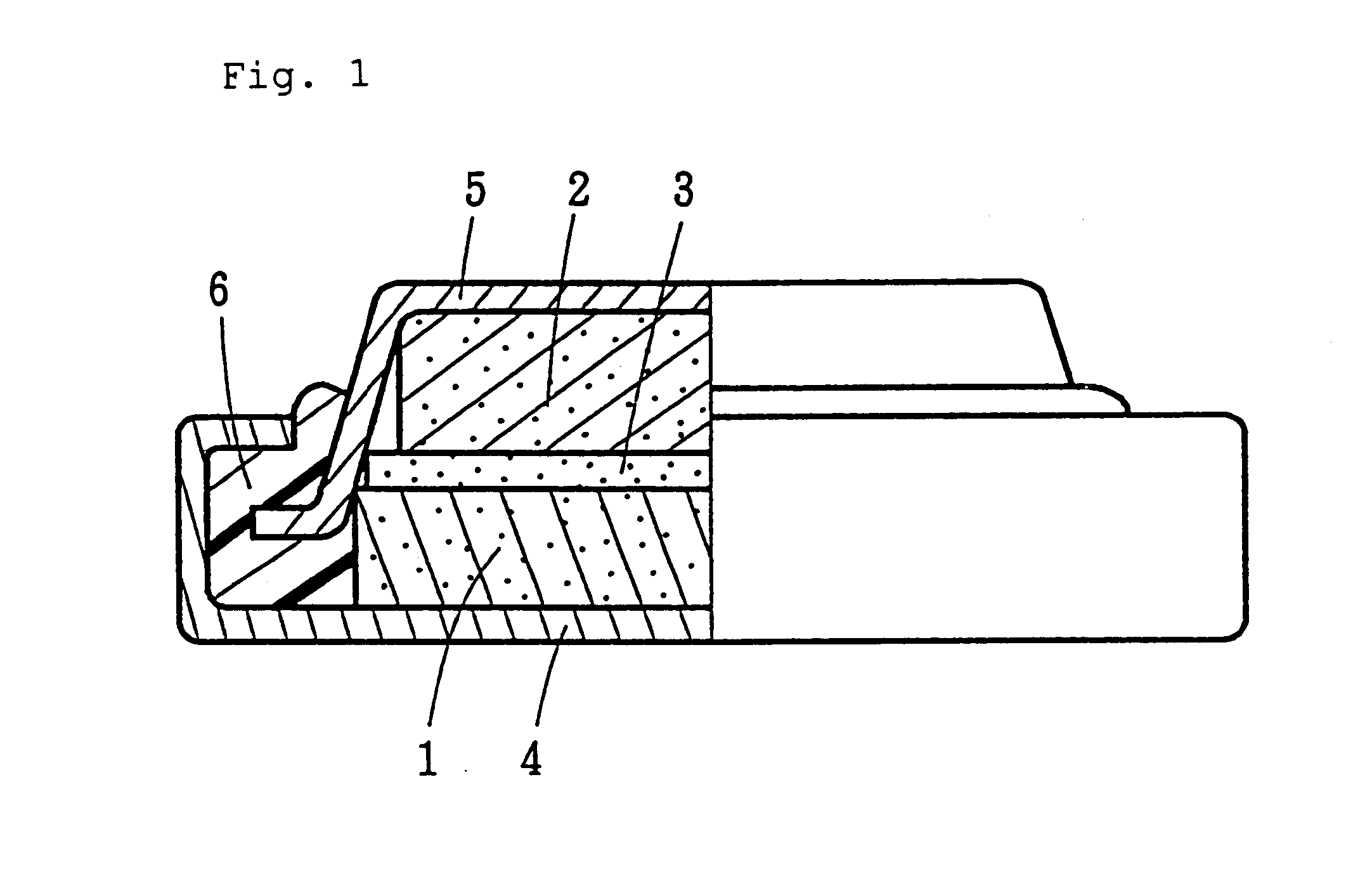

InactiveUS20060134517A1Improve charge and discharge performanceGood charge and discharge cycle performancePositive electrodesLi-accumulatorsLithium carbonateComposite oxide

Charge-discharge cycle performance is improved in a lithium secondary battery utilizing a material containing silicon as a positive electrode active material. A lithium secondary battery includes a negative electrode (2) containing silicon as a negative electrode active material, a positive electrode (1) containing a lithium-transition metal composite oxide, and a non-aqueous electrolyte. Lithium carbonate is added in the positive electrode (1), and carbon dioxide is dissolved in the non-aqueous electrolyte.

Owner:SANYO ELECTRIC CO LTD

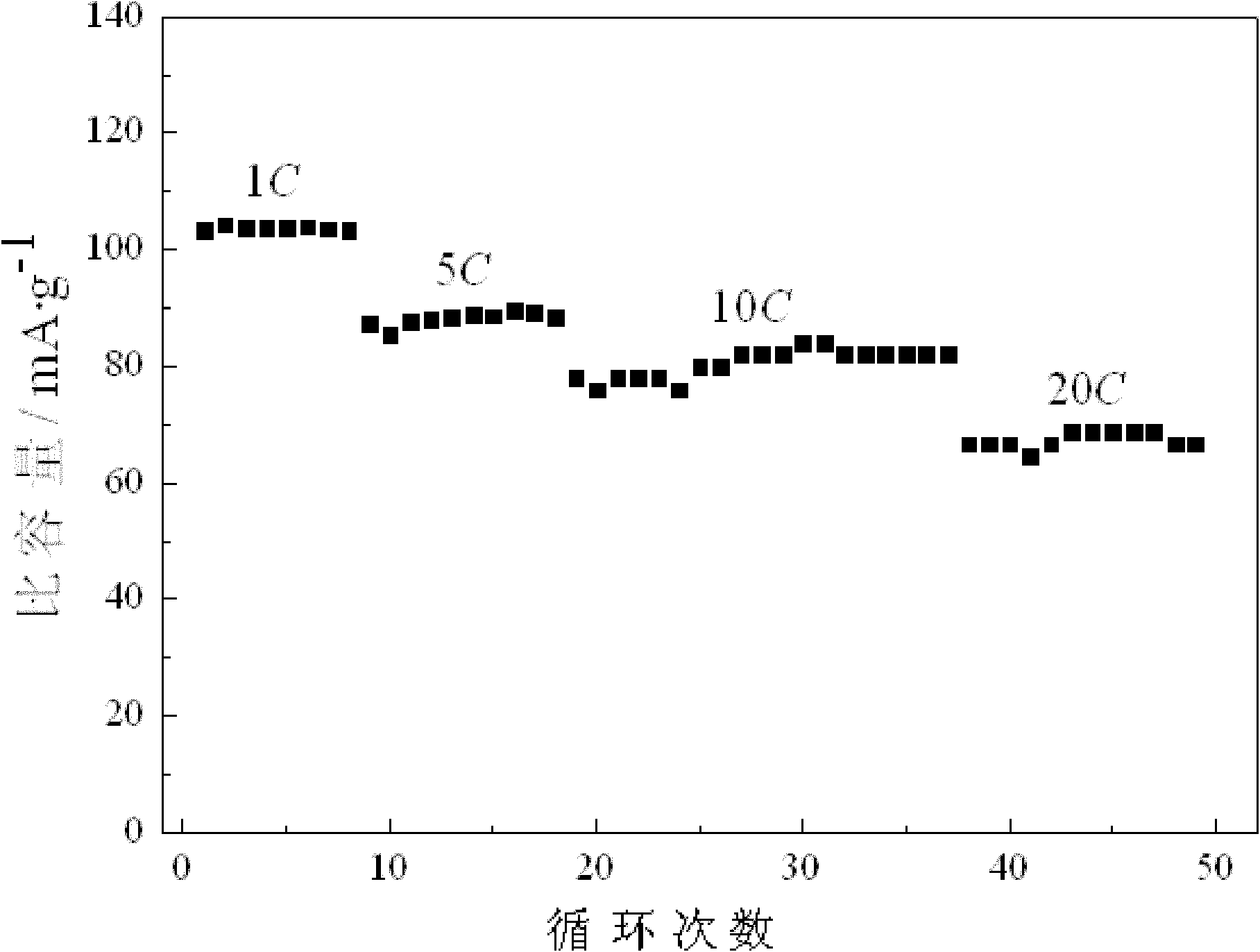

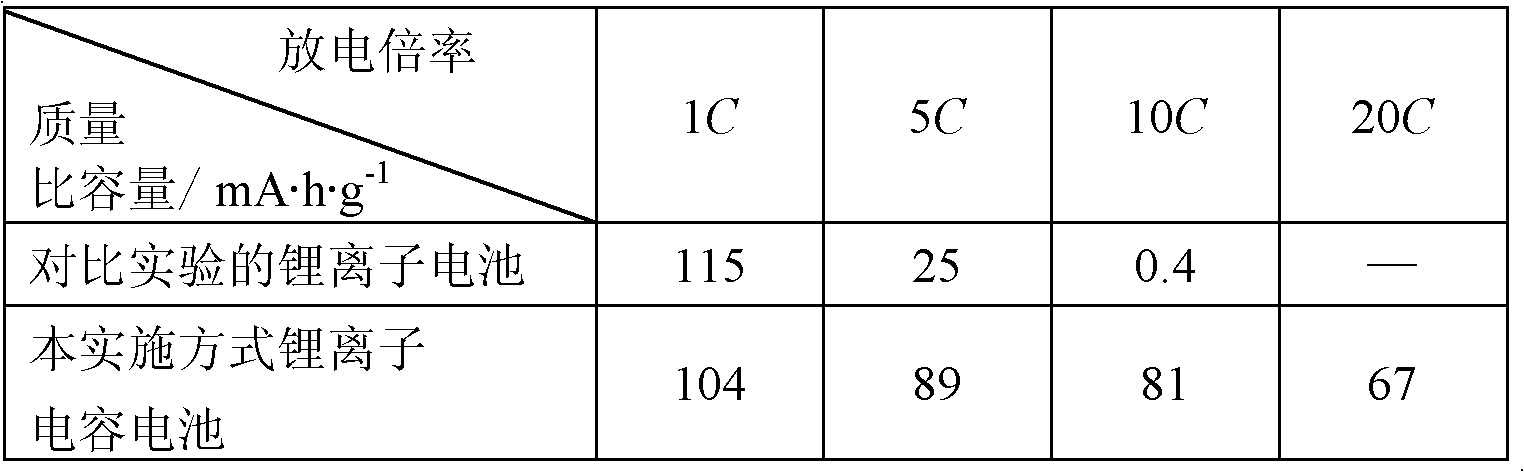

Capacitor carbon/lithium iron phosphate composite material, preparation method thereof and lithium-ion capacitor battery using same as cathode material

InactiveCN101944588AImprove high rate charge and discharge performanceIncrease surface areaElectrolytic capacitorsNon-aqueous electrolyte accumulator electrodesCapacitanceElectrical battery

The invention discloses a capacitor carbon / lithium iron phosphate composite material, a preparation method thereof and a lithium-ion capacitor battery using the same as a cathode material and relates to a lithium iron phosphate material, a preparation method and a lithium-ion capacitor battery using the lithium iron phosphate material as a cathode material, solving the problems of higher preparation cost of the traditional lithium iron phosphate and poor high-magnification charge / discharge properties of the lithium-ion batteries prepared from the traditional lithium iron phosphate. The composite material is formed by loading the lithium iron phosphate on activated carbon. The preparation method comprises the following steps of: preparing a lithium iron phosphate precursor by using a trivalent ferric salt, a phosphorus compound, a lithium source compound and an organic micromolecule carbon source as raw materials; and then mixing the precursor with the activated carbon and sintering. In the invention, the cathode sizing agent of the lithium-ion capacitor battery comprises the capacitor carbon / lithium iron phosphate composite material, a conductive agent and a bonding agent; the particle size distribution of the composite material is uniform; the trivalent ferric salt is used as a raw material, and the cost on the preparation is low; and the capacitor battery has good charge / discharge cycle performances and the mass specific capacity larger than 60mA.h.g<-1> under 20C magnification.

Owner:HARBIN INST OF TECH

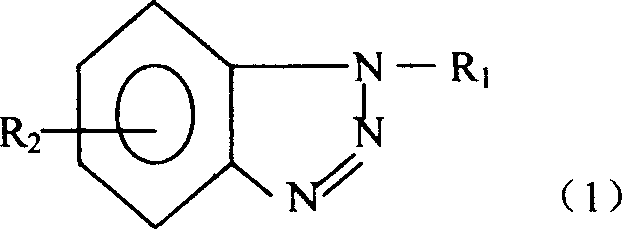

Cell liquor and lithium ion battery therefor

InactiveCN1819324AReduce corrosionReduce gas productionOrganic electrolyte cellsSecondary cellsCopper foilLithium-ion battery

The invention consists of benzotriazole compounds and an electrode comprising at least one of vinyl ethylene carbonate, vinylene carbonate, cyclic sulfonic acid, and cyclic sulfite. It is for use in forming a thin and dens passive film to reduce the gas production rate at process of cell forming, and to decrease corrosion of copper foil and aluminum foil of current collector, and to reduce the impedance of battery.

Owner:ZHEJIANG FIRE RETARDENT LITHIUM ELECTRIC MATERIALS

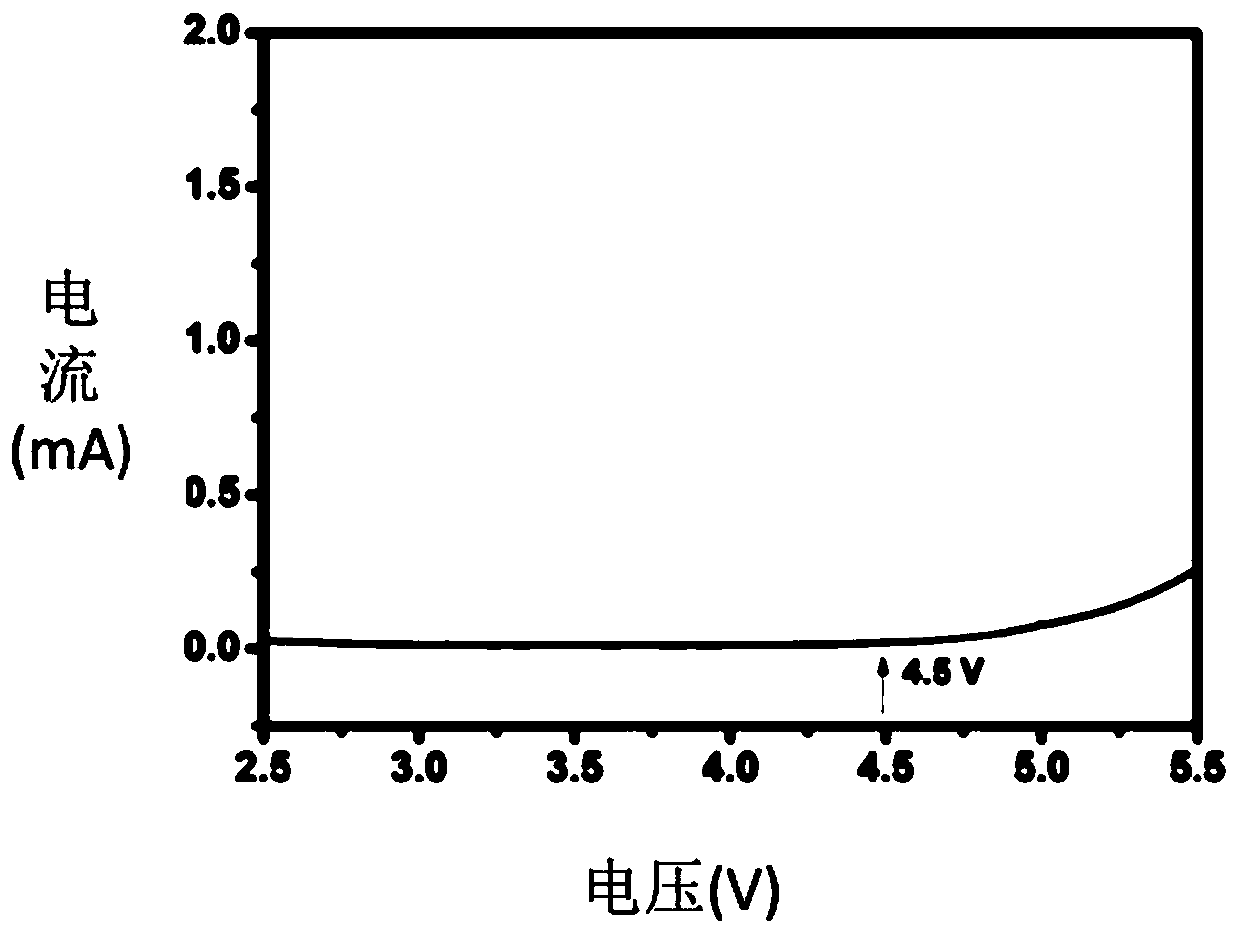

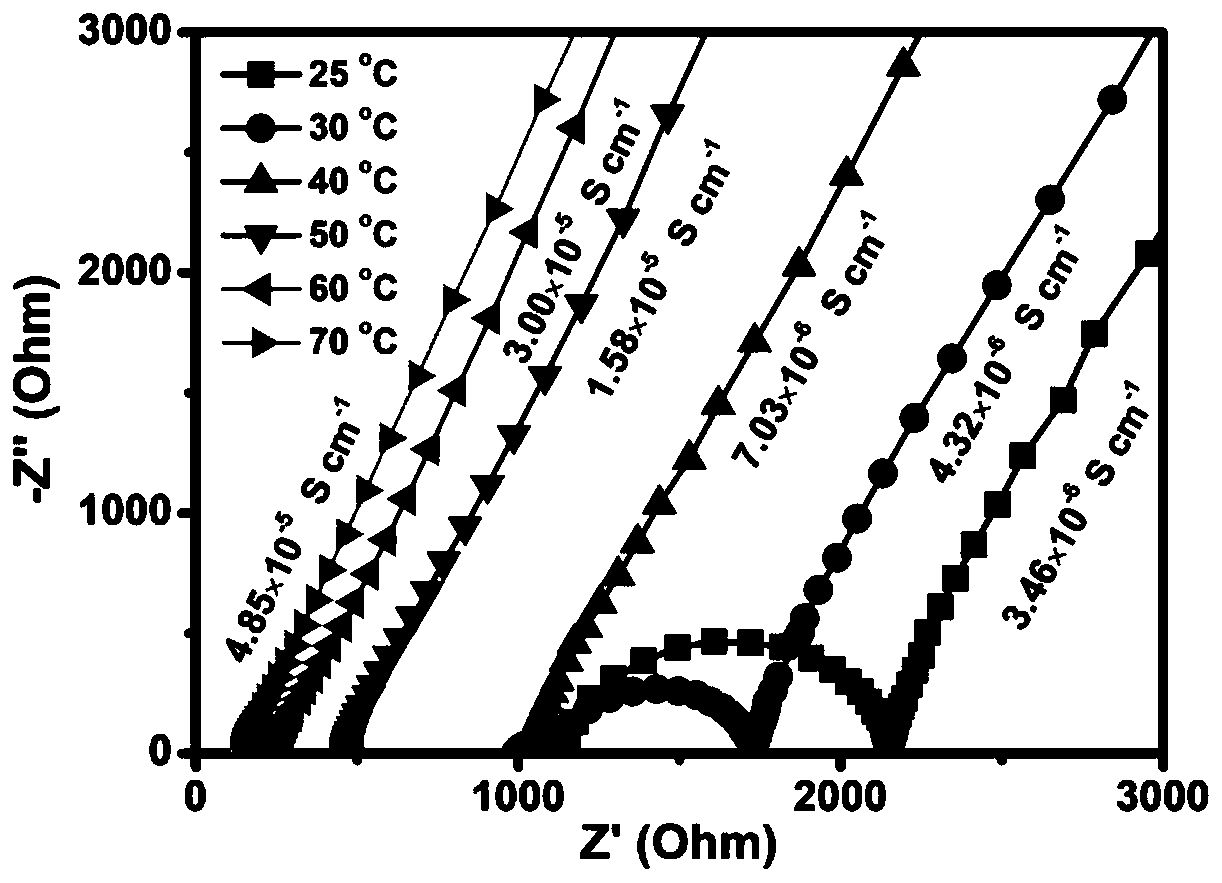

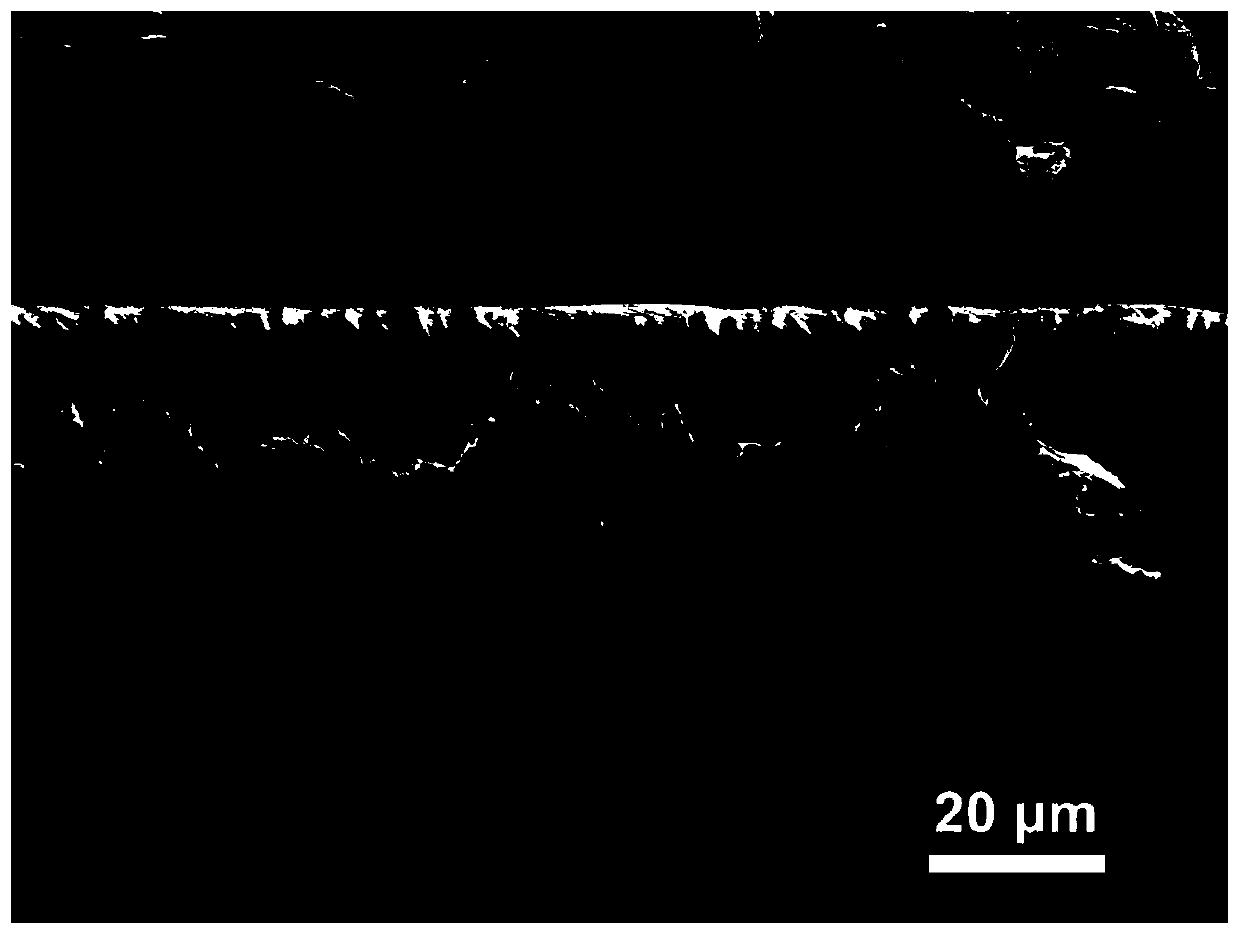

Lithium-rich antiperovskite oxide composite electrolyte and preparation method and application thereof

InactiveCN109786822ASimple preparation processEasy to operateSolid electrolytesNon-aqueous electrolyte accumulatorsPolymer electrolytesComposite electrolyte

The invention provides a lithium-rich antiperovskite oxide composite electrolyte. The materials of the lithium-rich antiperovskite oxide composite electrolyte comprise a polymer, a lithium salt and afiller, and the filler is lithium-rich antiperovskite oxide; the structural formula of the lithium-rich antiperovskite oxide is Li3-xHxOA1-yBy, wherein A and B are halogen elements, x is not more than1 and not less than 0, and y is not more than 1 and not less than 0. By using the lithium-rich antiperovskite oxide electrolyte as the filler, the ionic conductivity and electrochemical window of thecomposite polymer electrolyte can be improved, the mechanical property of the composite electrolyte can be increased, the interface impedance between the electrolyte and the lithium-based negative pole can be reduced, and thus the acquired composite electrolyte has the relatively high lithium ion conductivity, good bending mechanical property, and relatively high interface stability.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

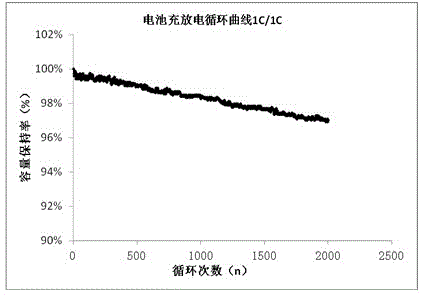

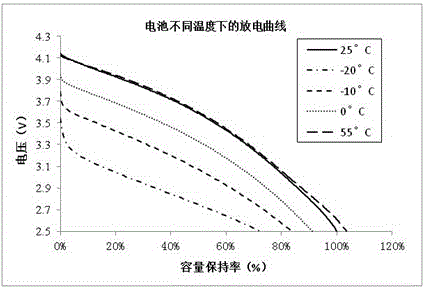

Long-service-life lithium ion battery and manufacture method thereof

InactiveCN103560266AGood charge and discharge cycle performanceGood low and high temperature discharge characteristicsCell electrodesFinal product manufactureChemistryCharge and discharge

The invention discloses a long-service-life lithium ion battery and a manufacture method thereof. The long-service-life lithium ion battery comprises an anode material, a cathode material, a diaphragm and electrolyte. The long-service-life lithium ion battery provided by the invention has the advantages of excellent charge and discharge circulating performances, good low-temperature and high-temperature discharge characteristics, wide use temperature range and good safety, and can be used for storing and converting clean energy as an energy storage system.

Owner:TIANJIN ENERGIES

Gel polymer electrolyte, polymer battery and preparing method

ActiveCN101747642AImprove conductivityPrevent crystallizationSecondary cellsPolymer electrolytesLithium sulphate

The present invention provides a gel polymer electrolyte. The gel polymer electrolyte comprises a polymer, an electrolyte, an organic solvent and inorganic fillers. The electrolyte, the organic solvent and the inorganic fillers are dispersed in the polymer. The inorganic fillers are lithium sulfate and / or lithium bisulfate. The present invention also provides a polymer battery containing the gel polymer electrolyte and a preparing method thereof. The preparing method of the polymer battery comprises the steps: mixed solution containing the electrolyte, the inorganic fillers, a polymerizable monomer and the organic solvent is added between the positive pole and the negative pole of the battery, the polymerizable monomer in the mixed solution is then polymerized under polymerization conditions, and a substance in a gel state is obtained. As lithium sulfate and / or lithium bisulfate are used as the inorganic fillers in the gel polymer electrolyte, the conductivity of the gel polymer electrolyte and the rate discharge performance of the battery containing the gel polymer electrolyte are obviously improved.

Owner:BYD CO LTD

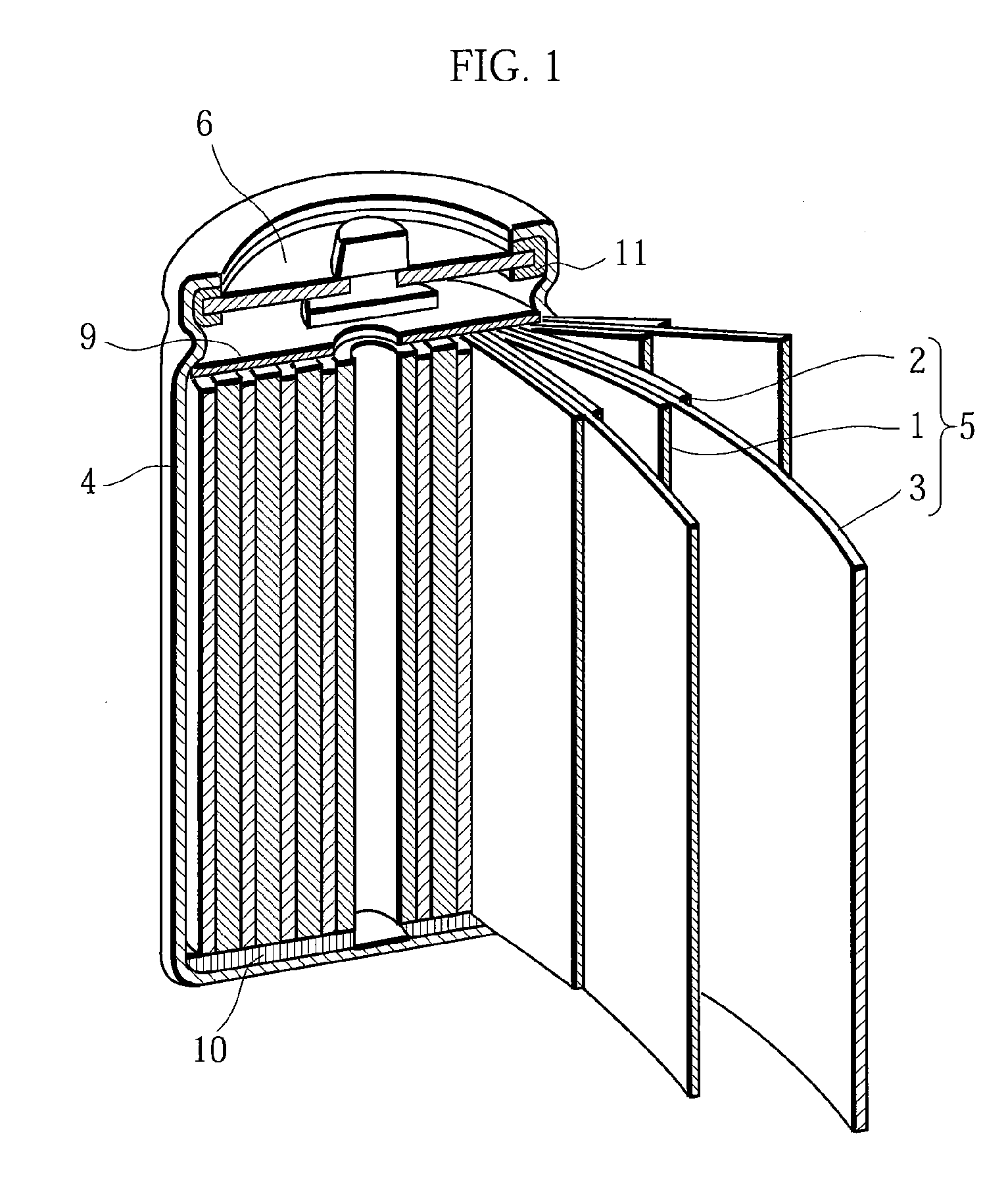

Lithium secondary battery

ActiveUS20060068290A1Stable crystal structureGood charge-discharge cycle performanceActive material electrodesElectrode collector coatingComposite oxideNickel

A lithium secondary battery having high capacity and good charge-discharge cycle performance is provided. The lithium secondary battery includes a negative electrode (2) containing silicon as a negative electrode active material, a positive electrode (1) containing a positive electrode active material, and a non-aqueous electrolyte. The positive electrode active material is a lithium-transition metal composite oxide including a layered structure represented by the chemical formula LiaNixMnyCOzO2, where a, x, y, and z satisfy the expressions: 0≦a≦1.3, x+y+z=1, 0<x, 0≦y≦0.5, and 0≦z.), and the theoretical electrical capacity ratio of the positive electrode to the negative electrode (positive electrode / negative electrode) is 1.2 or less.

Owner:SANYO ELECTRIC CO LTD

Microwave synthesis method for multi-element lithium manganate-doped positive electrode material of lithium ion battery

InactiveCN101800309AImprove the first discharge capacityGood charge and discharge cycle performanceCell electrodesElectrolysisSynthesis methods

The invention relates to a microwave synthesis method for a multi-element lithium manganate-doped positive electrode material of a lithium ion battery. The method comprises the following steps: adding deionized water into raw materials comprising lithium carbonate micropowder, industrial pure electrolytic manganese dioxide micropowder, analytical pure magnesium oxide micropowder, nickelic trioxide micropowder and chromic oxide micropowder to perform wet combination; mixing the raw materials with a ball mill; drying; mixing and sieving the dried products to serve as crude materials; shaping the crude materials into green bodies, and putting the green bodies into a microwave oven for sintering; and after the sintering is finished, taking the materials out, crushing and sieving the materials to obtain the lithium manganate-doped positive electrode material of the lithium ion battery. The material serving as a positive electrode active material can be used for preparing a positive plate of the lithium ion battery. The method has the characteristics of simpleness, energy saving and consumption reduction, low cost and contribution to industrial production; and the assembled lithium ion battery has the advantages of high initial discharge capacity and high charge and discharge cycling performance. The lithium manganate-doped positive electrode material of the lithium ion battery obtained by the method can be applied to electric automobiles, mobile phones, laptops and other equipment.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Non-aqueous electrolyte battery and battery pack

InactiveCN101399371AReduce twistReduce peelingFinal product manufactureNegative electrodesManganeseSpinel

The invention provides a non-aqueous electrolyte battery which reduces the twisting of negative electrode or the peeling of the negative electrode layer from the current collector caused by volume changes on the occasion of charge / discharge reactions and enhancs the charge / discharge cycle characteristics. The non-aqueous electrolyte battery comprises a negative electrode comprising a current collector, and a negative electrode layer formed on one or both surfaces of the current collector, a positive electrode, and a separator interposed between the negative electrode and the positive electrode. The negative electrode layer comprises a plurality of layers laminated each other and containing a different active material each other, the layers comprising a first layer which is contacted with the current collector and contains spinel-type lithium titanate as an active material, and a second layer which is disposed to face the separator and contains Ramsdellite-type lithium titanate or anatase-type titanium oxide as an active material.

Owner:KK TOSHIBA

Carbon-coated lithium-rich positive electrode material as well as preparation method thereof

ActiveCN103545519AGood charge and discharge cycle performanceImproved magnification performanceCell electrodesCarbon layerLithium-ion battery

The invention belongs to the technical field of lithium ion battery positive electrode materials and discloses a carbon-coated lithium-rich positive electrode material as well as a preparation method thereof. The surface-coated lithium-rich material comprises a principal phase Li[LiaNi(1 / 2-3a / 2)M(n1 / 2+a / 2)]O2 (a being greater than 0 and less than 1 / 3) as well as a coated carbon layer. The preparation method of the material comprises the following steps: a step of preparing an intermediate phase of the lithium-rich material, namely Li[LiaNi(1 / 2-3a / 2)M(n1 / 2+a / 2)]O2 (a being greater than 0 and less than 1 / 3), a step of uniformly mixing the lithium-rich intermediate phase and a carbon source, and a step of quickly and thermally treating at a high speed. The lithium ion battery positive electrode material prepared by the preparation method disclosed by the invention greatly improves charging and discharging performances of the material under high multiplying power and can satisfy high-power development requirements. Moreover, the carbon-coated lithium-rich positive electrode material is low in material cost, simple in process, high in cost performance and suitable for industrial production.

Owner:SUZHOU QINGTAO NEW ENERGY TECH CO LTD

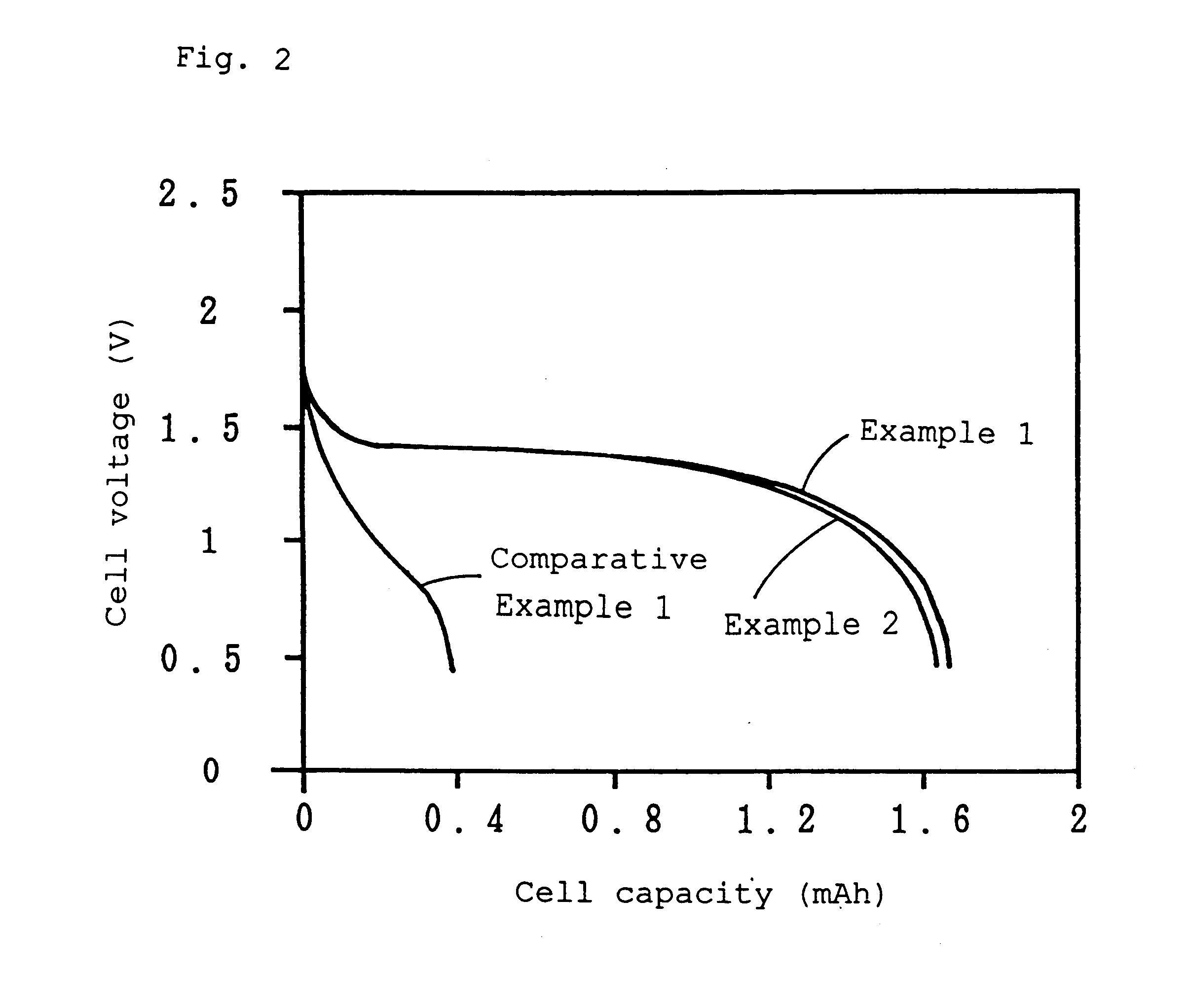

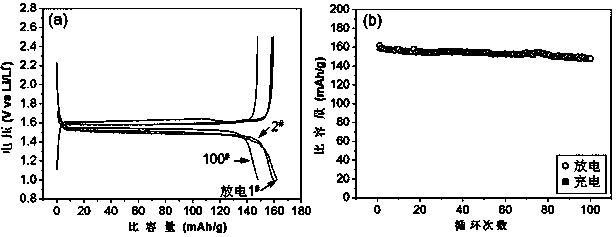

Nonaqueous secondary battery with lithium titanium cathode

InactiveUS6379843B1Easily dedopedLarge capacityAlkali titanatesFinal product manufactureLithiumOrganic solvent

A lithium secondary cell comprising a positive electrode containing a lithium titanate as an active material, a negative electrode containing a carbonaceous material as an active material, and an electrolytic solution comprising a solution of a lithium salt in an organic solvent. The lithium titanate preferably has a composition of the formula:(0.8<=x<=1.4 and 1.6<=y<=2.2). The lithium secondary cell has a high capacity suitable for use as a power source for a wristwatch and good charge-discharge properties, at a nominal voltage of 1.5 V.

Owner:HITACHI MAXELL ENERGY LTD

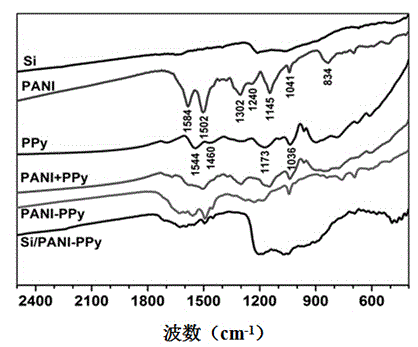

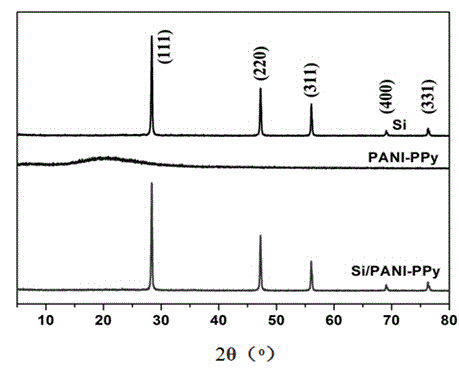

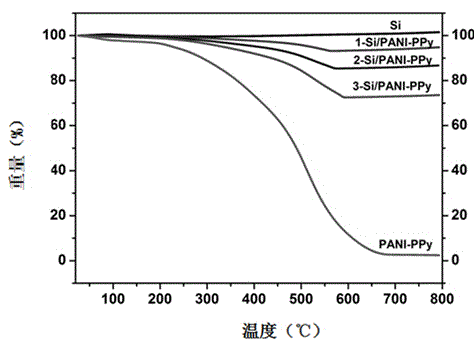

Method for preparing nanometer silicon conductive polymer composite material for lithium ion batteries

InactiveCN104157875ASimple preparation processRaw materials are easy to getMaterial nanotechnologyCell electrodesEnvironmental resistanceConductive polymer composite

The invention provides a nanometer silicon conductive polymer composite material, belonging to the technical field of lithium ion batteries. According to the nanometer silicon conductive polymer composite material, a silicon-based composite material is prepared by in-situ polymerization according to a chemical oxidation method in which silicon nanoparticles is used as an active substance, pyrrole and phenylamine are used as monomers, water is as a reaction solvent, p-methylbenzene sulfonic acid and absolute ethyl alcohol are used as dispersing agents, ammonium persulfate is used as oxidant and diluted hydrochloric acid is used as a protonic acid doping agent, the silicon-based composite material is of a core-shell structure in which silicon nanoparticles are uniformly coated with conductive polypyrrole-phenylamine, the core silicon nanoparticles have the lithium storage activity, and due to conductive polypyrrole-phenylamine of the shell, the conductivity of the silicon-based material is remarkably improved. Therefore, as a cathode material of the lithium ion battery, the composite material is relatively good in charge / discharge circulation property. In addition, the composite material provided by the invention is simple in preparation process, is prepared from easily available raw materials, is safe and environment-friendly and has a great commercial prospect in production of lithium ion batteries.

Owner:NORTHWEST NORMAL UNIVERSITY

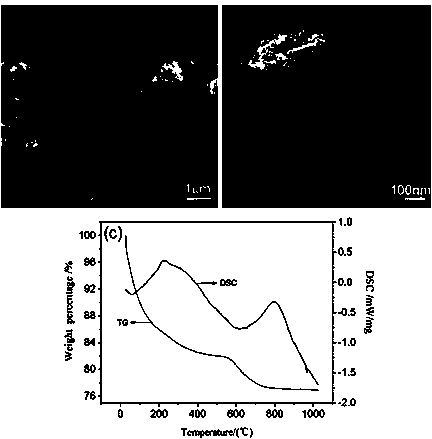

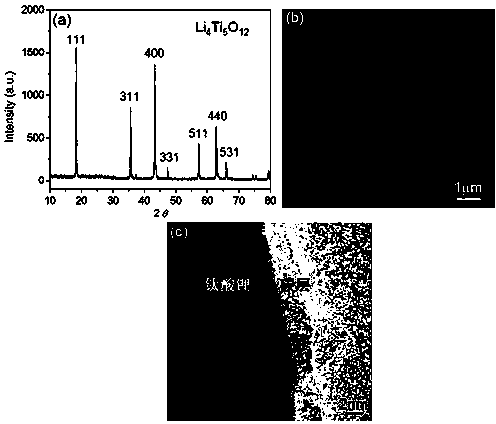

Method for preparing cathode material carbon-coated lithium titanate for lithium ion battery from metatitanic acid

The invention relates to a method for preparing a cathode material carbon-coated lithium titanate for a lithium ion battery from metatitanic acid. According to the method, metatitanic acid H2TiO3 is used as a titanium source, lithium carbonate or lithium hydroxide is used as a lithium source, and asphalt, phenolic resin or glucose is used as a carbon source. The carbon-coated lithium titanate Li4Ti5O12 / C can be obtained by washing metatitanic acid by oxalic acid and filtering, then uniformly mixing the three raw materials by a ball mill in a certain ratio, drying and then placing the mixture in a high-temperature heating furnace, and sintering in an inert gas shielding condition. According to the method disclosed by the invention, the selected titanium source, namely, metatitanic acid, is only about 1 / 5 of a titanium source, namely, titanium oxide TiO2 used in conventional lithium titanate preparation, so that the prepared Li4Ti5O12 / C is relatively low in cost, excellent in charge-discharge circulation performance, and capable of meeting requirements on cathode materials for lithium ion batteries. The method disclosed by the invention is simple in preparation process, easy for realization of industrial production, free from environmental pollution, and environmentally-friendly.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com