Lithium-rich antiperovskite oxide composite electrolyte and preparation method and application thereof

A composite electrolyte, anti-perovskite technology, used in solid electrolytes, non-aqueous electrolytes, non-aqueous electrolyte batteries, etc., can solve problems such as high stability, high ionic conductivity, and low interface impedance, and achieve good wettability, The effect of increasing the contact area and controllable conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] Correspondingly, an embodiment of the present invention provides a method for preparing an all-solid-state battery, including the following steps:

[0048] G01: Prepare lithium-rich anti-perovskite oxide composite electrolyte according to any of the above-mentioned preparation methods;

[0049] G02: heating and melting the lithium-rich anti-perovskite oxide composite electrolyte to obtain a lithium-rich anti-perovskite oxide composite electrolyte solution;

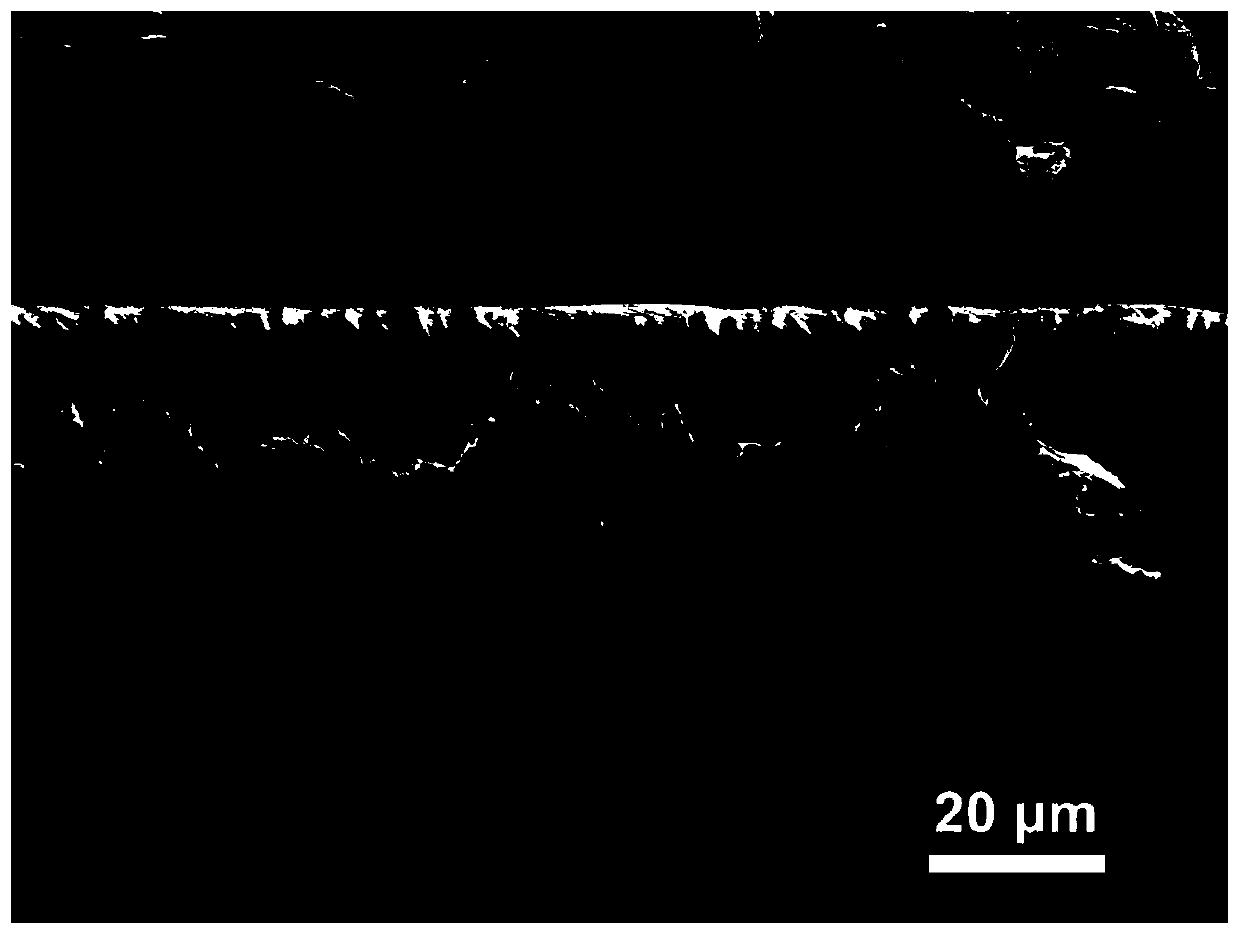

[0050] G03: Cast the lithium-rich anti-perovskite oxide composite electrolyte solution on the positive electrode sheet or the negative electrode sheet to form a composite electrolyte membrane;

[0051] G04: Paste oppositely arranged negative or positive electrode sheets on the composite electrolyte membrane, and cool to normal temperature to obtain a lithium-rich anti-perovskite battery.

[0052] Specifically, the entire process of the above-mentioned solution casting method is operated in an inert gas glove box. The operatio...

Embodiment 1

[0061] A method for preparing a lithium-rich anti-perovskite oxide composite electrolyte, the lithium-rich anti-perovskite oxide composite electrolyte is prepared by a solution casting method, and specifically includes the following steps:

[0062] The polymer (PCL), lithium salt (LiTFSI) and lithium-rich anti-perovskite oxide (Li 3 OCl 0.6 Br 0.4 ) Dissolve in the organic solvent acetonitrile according to the mass ratio of 6:2:2, stir the mixed solution to form a uniform solution, cast it on a polytetrafluoroethylene board and place it in a vacuum drying oven at 60°C for 12 hours. Form a composite electrolyte.

Embodiment 2

[0064] A method for preparing lithium-rich anti-perovskite oxide composite electrolyte, the lithium-rich anti-perovskite oxide composite electrolyte is prepared by a solution casting method, specifically including the following steps: polymer (PCL), lithium salt (LiFSI) ) And lithium-rich anti-perovskite oxide (Li 3 OBr) is dissolved in organic solvent succinonitrile according to the mass ratio of 5:1:1, the mixed solution is stirred to form a uniform solution, and it is cast on a polytetrafluoroethylene board and placed in a vacuum drying oven at 60°C for 20h Then, a composite electrolyte can be formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com