Rechargeable battery with nonaqueous electrolyte and process for producing negative electrode

A non-aqueous electrolyte and secondary battery technology, applied in the direction of non-aqueous electrolyte batteries, secondary batteries, battery electrodes, etc., can solve the problems of capacity reduction, Si cracking and micronization, and achieve high energy density and excellent cycle life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

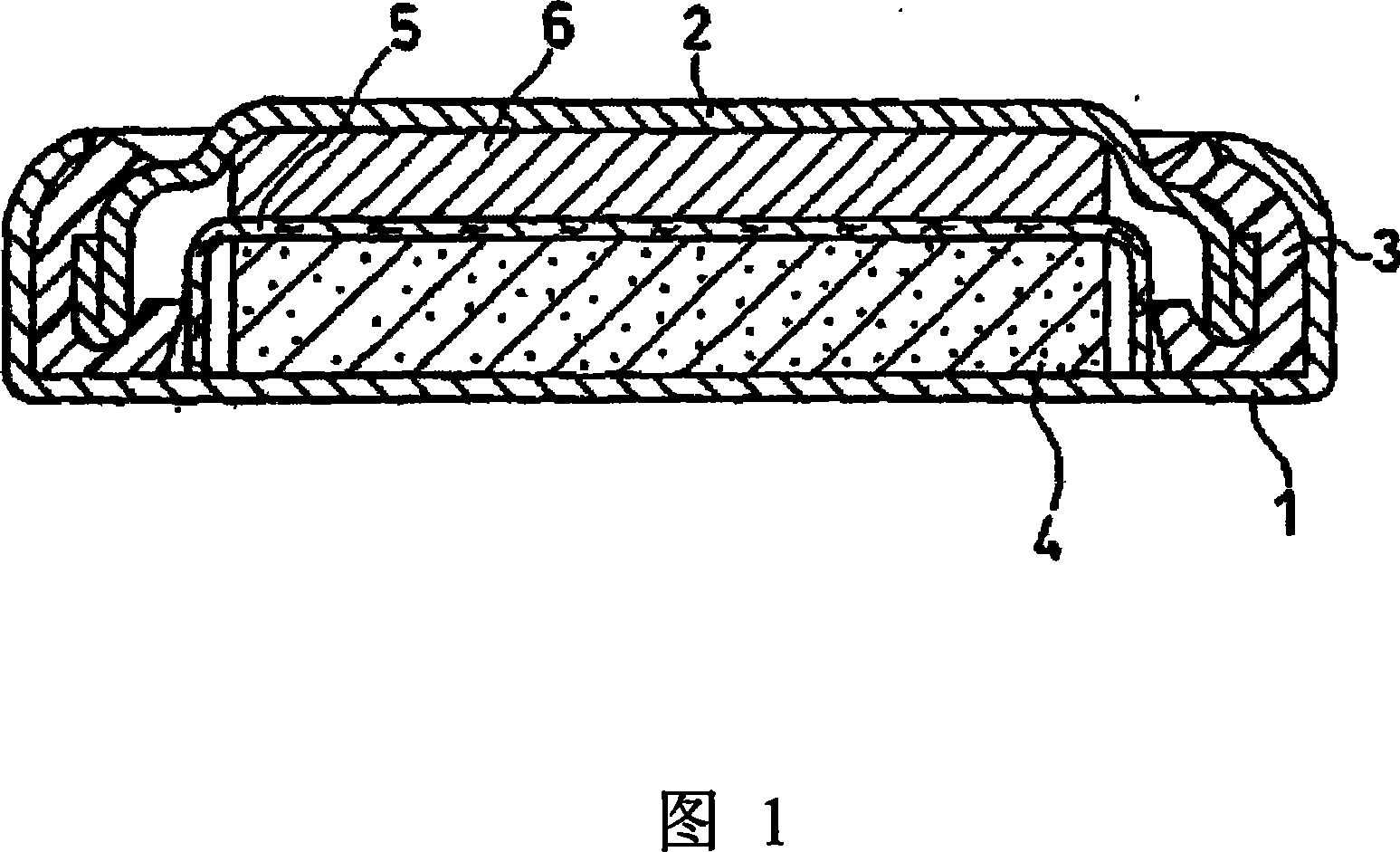

Image

Examples

Embodiment 1

[0110] In this example, the negative electrode active material obtained from the above powder mixture (1) was used, and the average particle diameter was examined. The weight ratio of the Si phase which is the A phase in the negative electrode active material was 30% by weight. The negative electrode active material was prepared by mechanical alloying method, and the measurement of its particle size distribution showed a wide particle size range of 0.5-200 μm and an average particle size (D50) of 50 μm. The negative electrode active material was adjusted to have the particle size distribution shown in Table 1 by classifying the negative electrode active material with a sieve. Then, a negative electrode sheet was molded using the negative electrode active material having each particle size distribution, and battery evaluation was performed using the negative electrode sheet. The negative electrode active materials of Batteries 1-8 were not classified with a sieve. Table 1 sho...

Embodiment 2

[0116] In this example, the negative electrode active material obtained from the above powder mixtures (2)-(5) was used. The weight ratio of the Si phase as the A phase in the negative electrode active material was 30% by weight. In Example 2, as shown in Table 3, as the kind of transition metal contained in the second phase (B phase) in the negative electrode active material, the cases of Ti, Zr, Ni, Cu and Fe were examined. Transition metals Co and Mn were also examined as comparative examples.

[0117] The preparation method of the negative electrode active material is as described above. The weight ratio of the Si phase as the A phase in the negative electrode active material was 30% by weight. The average particle diameters (D50) obtained after sieving were 1.0 μm, respectively, as shown in Table 2.

[0118] Each anode active material is the same as the above-mentioned materials except for using a different transition metal. However, all negative electrode sheets were...

Embodiment 3

[0125] This example examines a method of wet-milling an anode active material prepared by a mechanical alloying method using balls as a medium when the transition metal contained in phase B is Ti.

[0126] Zirconia balls with a diameter of 5 mm were used as the balls (medium). A 500ml polyethylene container was used as the container. 120 ml of n-butyl acetate was used as a dispersion medium. The rotation frequency of the ball mill was 120 rpm. Then, the negative active material was collected by removing the dispersion medium. The adjustment of the predetermined particle diameter is performed by adjusting the milling time.

[0127] The synthesis method of the negative electrode active material, and the preparation and evaluation methods of the battery are the same as in the above examples.

[0128] Table 3 shows the material yield when the particle size was adjusted by the wet milling of this example. In addition, for comparison, the material yield at the time of sieving i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com