Graphene-coated sulfur/porous carbon composite positive electrode material and preparation method thereof

A technology of graphene coating and composite materials, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of low electrochemical performance, achieve high content, improve the utilization rate of active materials, and inhibit the effect of dissolution loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

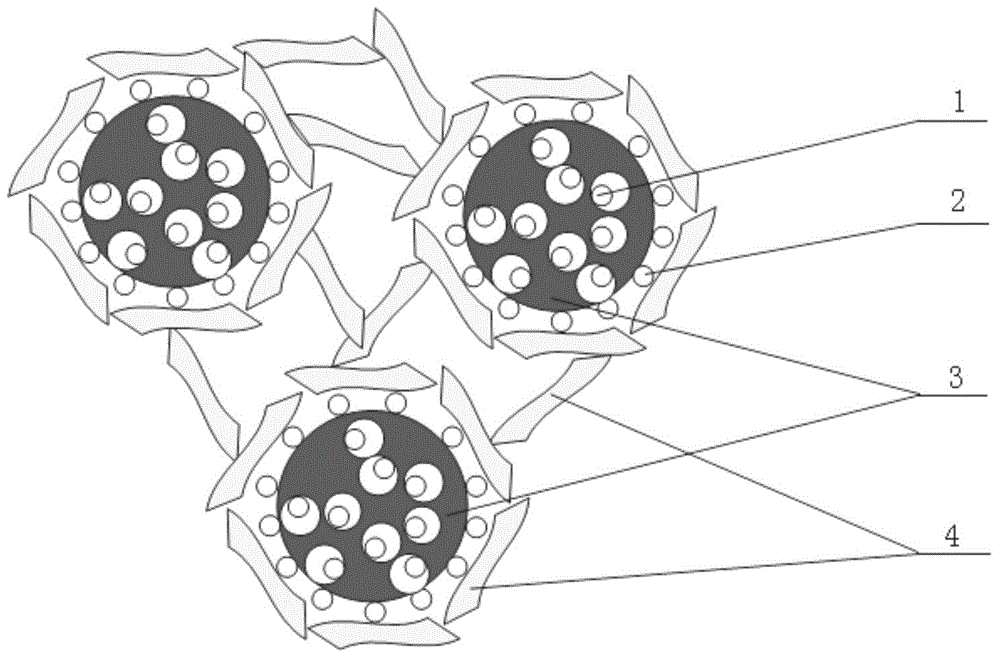

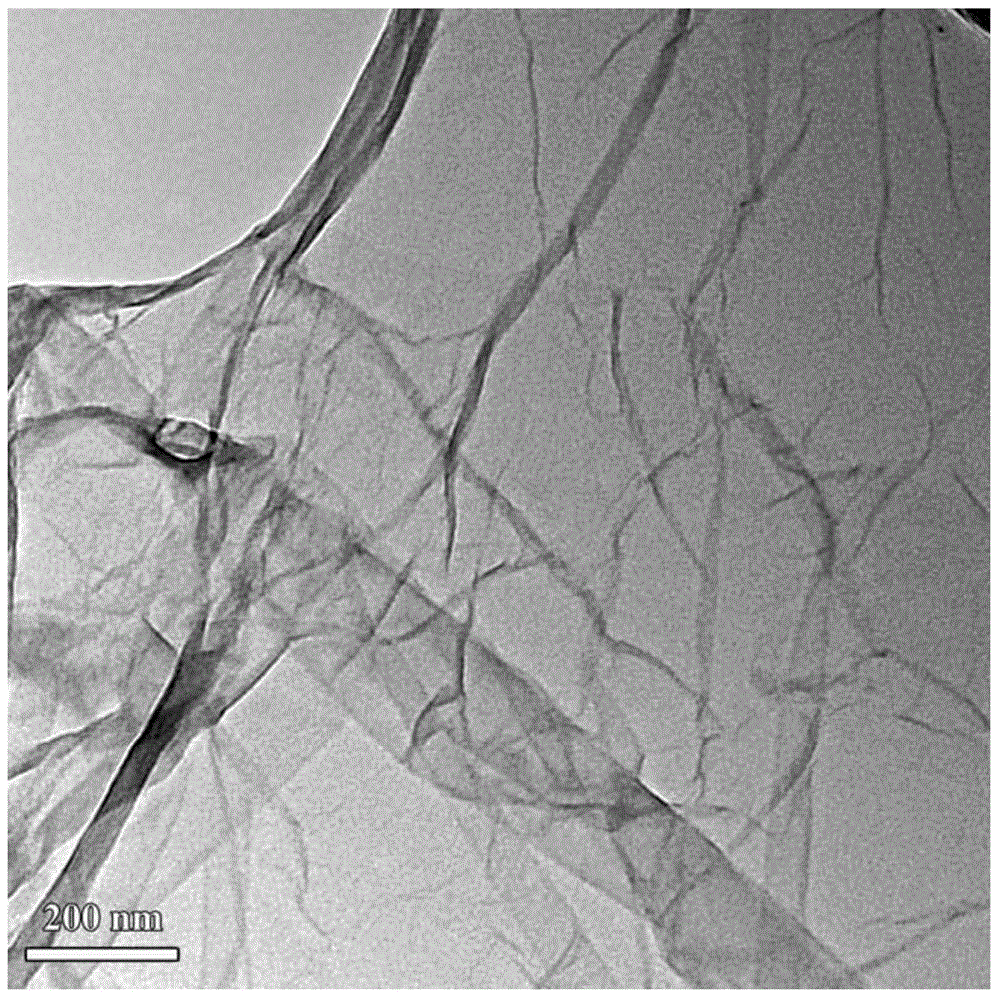

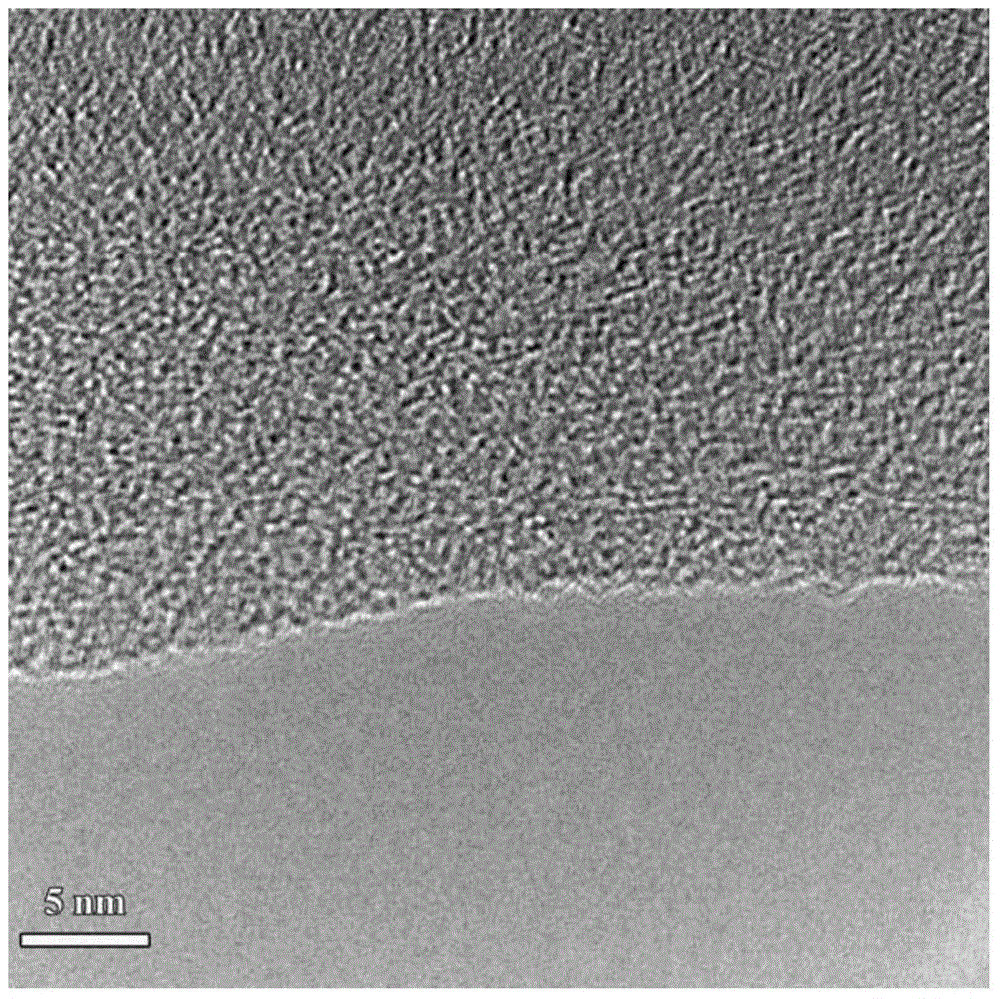

[0044] Embodiment 1: The graphene-coated sulfur / porous carbon composite material of this embodiment is that the outer surface of the sulfur / porous carbon composite particle is uniformly coated with graphene sheets, and the sulfur / porous carbon composite material coated with graphene A graphene conductive network is formed between the carbon composite particles, and the graphene-coated sulfur / porous carbon composite has a hierarchical core-shell structure, and the mass ratio of sulfur, porous carbon and graphene coating is 1:(0.02~ 20): (0.02~20); wherein, the sulfur / porous carbon composite material is that sulfur is dispersed on the surface of the porous carbon material and in the pores, and the porous carbon is composed of activated carbon, graphene, carbon black, carbon nanotubes, template porous One or more of carbon, carbon fiber, carbon aerogel, and carbide-derived carbon.

[0045] The graphene-coated sulfur / porous carbon composite material of the present embodiment unifo...

specific Embodiment approach 2

[0046] Embodiment 2: This embodiment differs from Embodiment 1 in that the mass ratio of sulfur, porous carbon and graphene coating is 1:(0.1-2):(0.1-2). Others are the same as in the first embodiment.

specific Embodiment approach 3

[0047] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the mass ratio of sulfur, porous carbon and graphene coating is 1:0.33:0.17. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com