Hydrothermal Preparation Method of Graphene-coated Sulfur/Porous Carbon Composite Cathode Material

A composite cathode material, graphene coating technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve problems such as low electrochemical performance, and achieve the effect of inhibiting dissolution loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

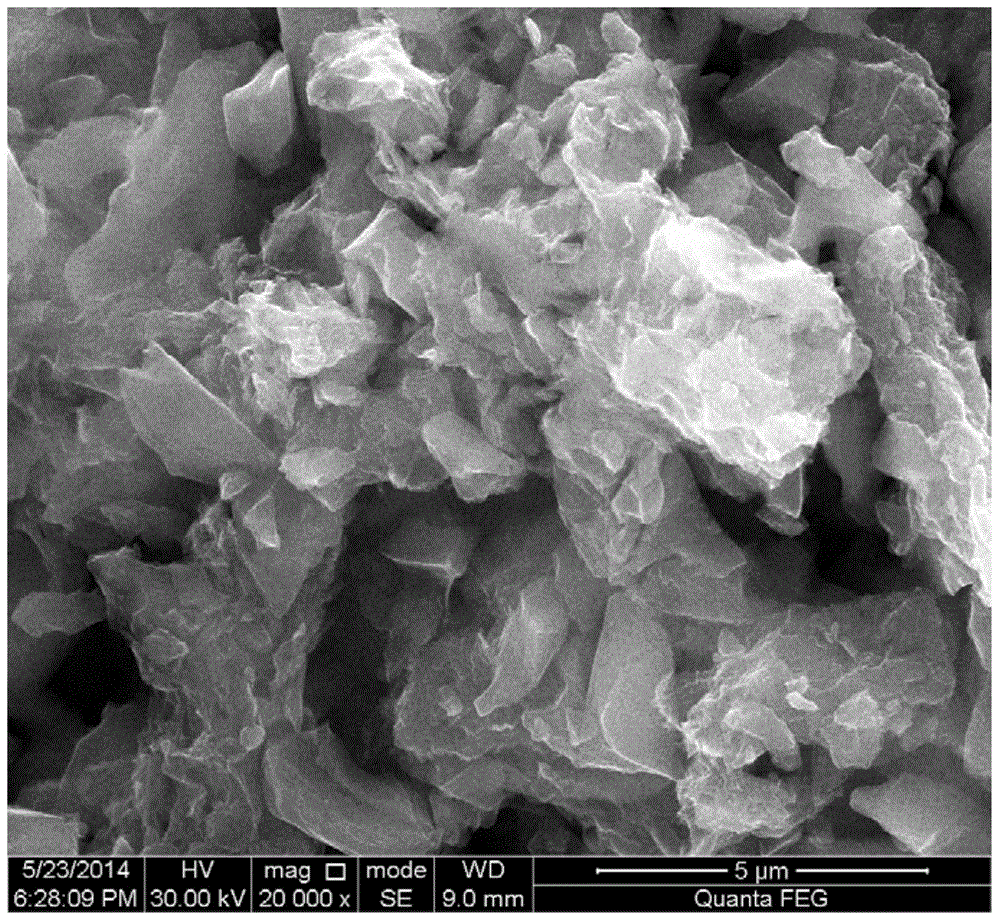

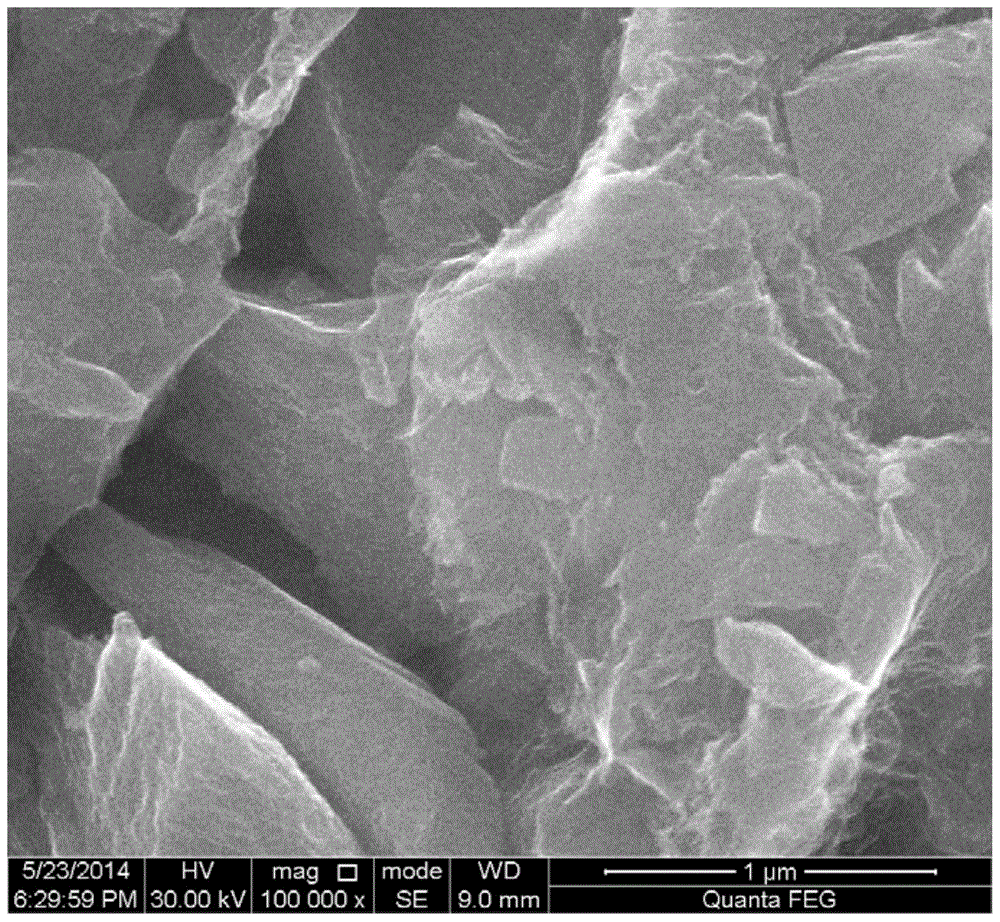

[0058] Embodiment 1: The hydrothermal preparation method of the graphene-coated sulfur / porous carbon composite positive electrode material of the present embodiment is carried out according to the following steps:

[0059] 1. Prepare graphene slurry: the graphene slurry is composed of graphene and water, and the graphene sheets are uniformly dispersed in the slurry; wherein, the water content of the graphene slurry is 90% to 99.99%;

[0060] 2. Preparation of sulfur / porous carbon composite materials, wherein the porous carbon material is one or several of activated carbon, graphene, carbon black, carbon nanotubes, template porous carbon, carbon fiber, carbon aerogel, and carbide-derived carbon Composition, the mass ratio of sulfur and porous carbon in the sulfur / porous carbon composite material is 1:(0.02~20);

[0061] Three, according to the mass ratio of the graphene in the graphene slurry and the sulfur in the sulfur / porous carbon composite material is (0.02~20):1, the sulf...

specific Embodiment approach 2

[0063] Specific embodiment two: what this embodiment is different from specific embodiment one is that the specific preparation method of the graphene slurry in step one is as follows:

[0064] (1) Take graphite and reducing agent; wherein the mass ratio of graphite and reducing agent is 1:(0.1~1000); reducing agent is one or a combination of several in ascorbic acid, KOH, NaOH, LiOH and ammonia;

[0065] (2) the graphite oxidation that step (1) is taken becomes graphite oxide;

[0066] (3) According to the concentration of graphite oxide is 0.01mg mL -1 ~50mg mL -1 , adding the graphite oxide obtained in step (2) into water, stripping and dispersing for 0.5 to 10 hours under ultrasonic conditions with a frequency of 20 to 100 KHz, to obtain a graphene oxide aqueous dispersion;

[0067] (4) under the condition that the temperature is 4° C. to 100° C., add a reducing agent to the graphene oxide aqueous dispersion obtained in step (3), and reduce it for 0.2 h to 24 h under ult...

specific Embodiment approach 3

[0071] Specific embodiment three: what this embodiment is different from specific embodiment one or two is that graphite oxidation becomes the method for graphite oxide in step (2) as follows: in dry beaker, add 120mL mass percent concentration and be 98% H 2 SO 4 , then place the beaker in an ice-water bath, add 5g graphite and 2.5g NaNO 3 , stirring at a speed of 50-500 rpm, while gradually adding 15g of powdered KMnO 4 , continue to react for 2 hours in an ice-water bath and stirring; move the beaker into a constant temperature oil bath at 35±1°C and continue to react for 2 hours; slowly add 360mL of distilled water under stirring at a speed of 50 to 500 rpm, and control the temperature to be constant At 75°C, continue the constant temperature reaction for 1h; add 1000mL of distilled water at a temperature of 40°C, add 50mL of hydrogen peroxide with a concentration of 30% by mass, and then vacuum filter; wash the filter cake with hydrochloric acid with a concentration of 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com