Graphene-coated lithium vanadium phosphate cathode material and preparation method thereof

A graphene-coated, lithium vanadium phosphate technology, applied in battery electrodes, electrical components, circuits, etc., can solve problems such as being unsuitable for large-scale industrial production, unreasonable component distribution and structure, and cumbersome preparation process, and achieving suitable The effect of large-scale industrial production, simple, efficient and reasonable preparation process, and optimized preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

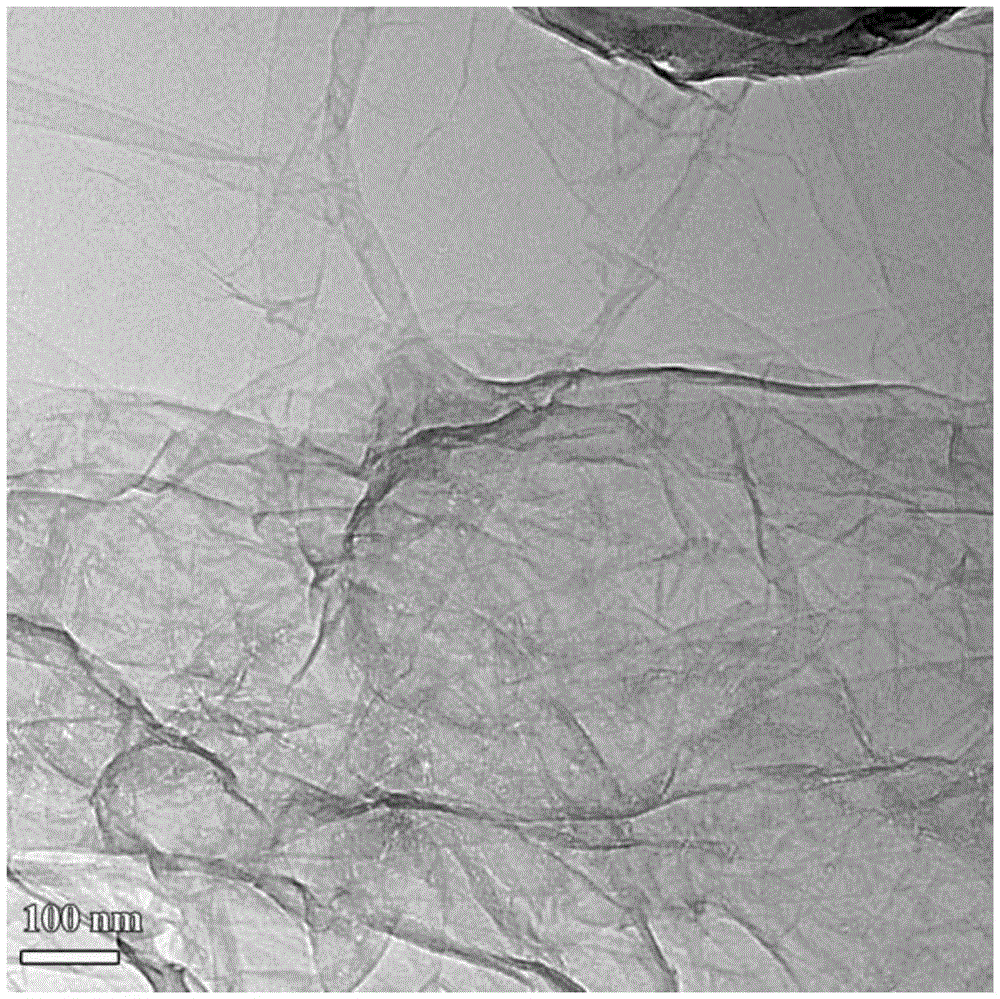

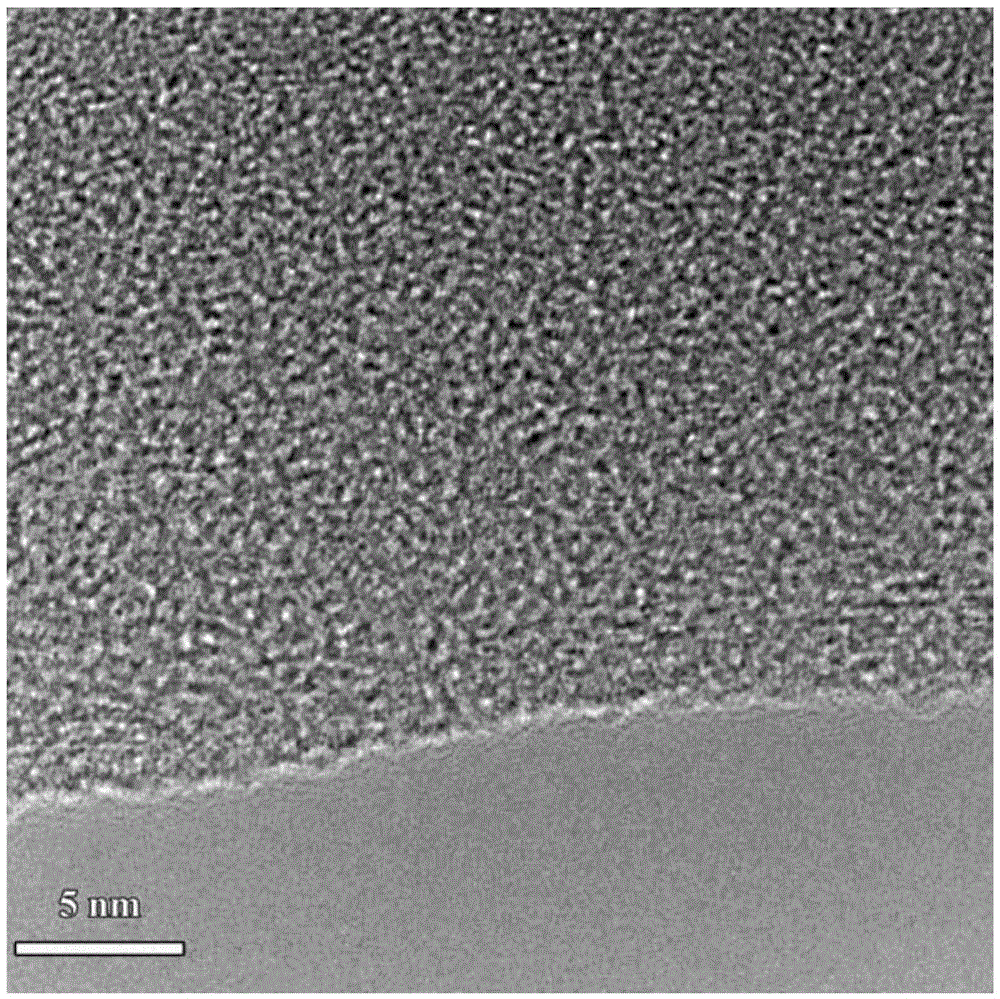

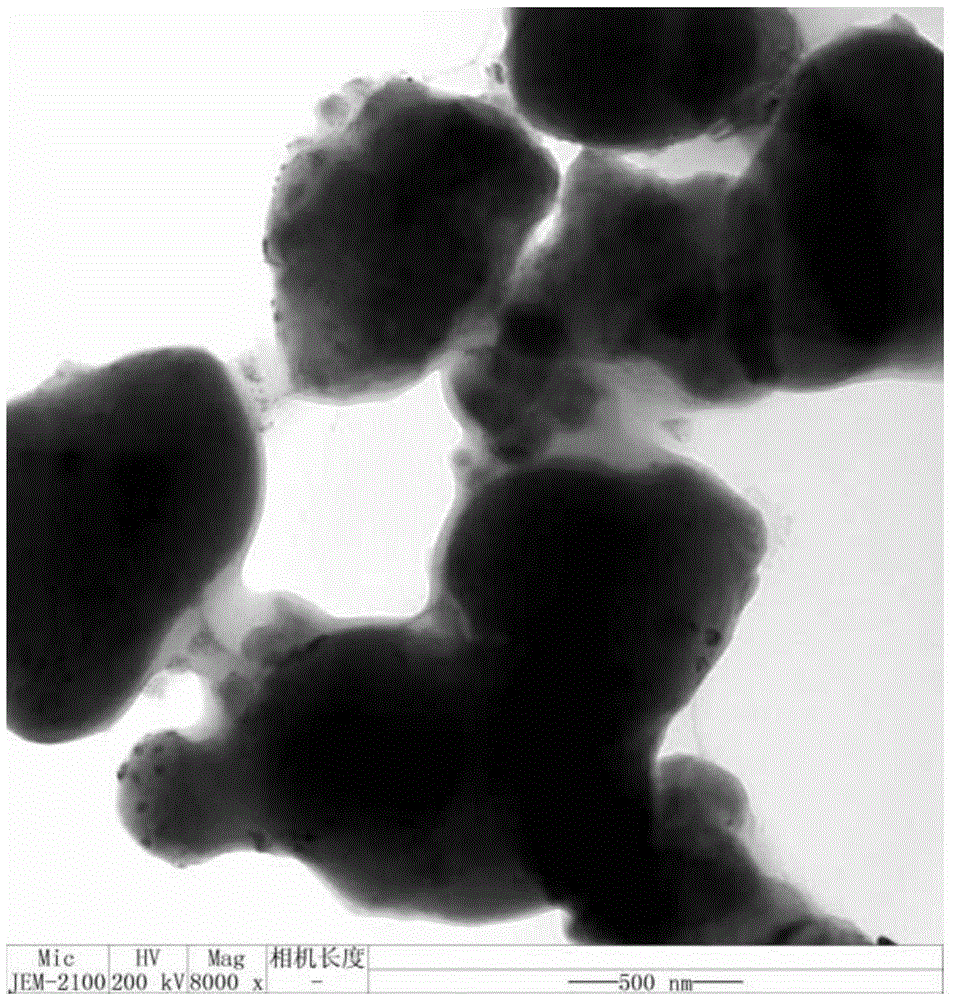

[0045] Specific Embodiment 1: The graphene-coated lithium vanadium phosphate positive electrode material of this embodiment is composed of graphene as the coating shell and lithium vanadium phosphate as the core, and at the same time, the graphene-coated shells are connected to each other to form a three-dimensional conductive network classification A core-shell structure composite material, wherein the mass percentage of graphene in the composite material is 0.1% to 15%.

[0046] The graphene-coated lithium vanadium phosphate positive electrode material of the present embodiment has a unique hierarchical core-shell structure. Compared with the prior art, it has the following advantages: (1) the graphene used for coating is first passed through lithium hydroxide Pre-reduced, then further reduced by high-temperature calcination, the graphene coating layer in the obtained composite material has a high degree of reduction and good conductivity; (2) graphene in graphene-lithium hyd...

specific Embodiment approach 2

[0047] Embodiment 2: This embodiment is different from Embodiment 1 in that the mass percentage of graphene in the composite material is 1%-12%. Others are the same as the first embodiment.

specific Embodiment approach 3

[0048] Embodiment 3: This embodiment is different from Embodiment 1 in that the mass percentage of graphene in the composite material is 3% to 8%. Others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com