Microwave synthesis method for multi-element lithium manganate-doped positive electrode material of lithium ion battery

A lithium-ion battery, a technology doped with lithium manganese oxide, applied in battery electrodes, electrical components, circuits, etc., can solve problems such as short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

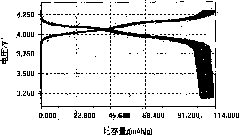

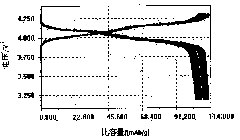

Image

Examples

Embodiment 1

[0018] Lithium carbonate micropowder with a purity of 99.5% and a particle size of 20 μm, industrially pure electrolytic manganese dioxide micropowder with a particle size of 30 μm, analytically pure magnesium oxide micropowder, analytically pure nickel sesquioxide micropowder, and analytically pure chromium trioxide micropowder are used as raw materials. Wherein each raw material is proportioned according to the atomic ratio, Li:Mn:Mg:Ni:Cr=1.00:1.5:0.02:0.01:0.02;

[0019] Add the weighed raw materials into deionized water for wet-bonding, the ratio of the raw materials to water is 1:1.2 by weight, mix them with a ball mill for 2 hours, put the wet-milled mixed raw materials into an oven at 100°C for 48 hours to dry, Dry-mix and sieve the dried raw materials as raw materials for microwave sintering;

[0020] Form the raw material on a hydraulic press, the forming pressure is 20Mpa, the blank size is φ50, and the height is 30mm;

[0021] Put the formed body into the microwav...

Embodiment 2

[0025] Lithium carbonate micropowder with a purity of 99.5% and a particle size of 25 μs, industrially pure electrolytic manganese dioxide micropowder with a particle size of 40 μs, analytically pure magnesium oxide micropowder, analytically pure nickel trioxide micropowder, and analytically pure chromium trioxide micropowder are used as raw materials. Wherein each raw material is proportioned according to the atomic ratio, Li:Mn:Mg:Ni:Cr=1.05:1.7:0.03:0.03:0.05;

[0026] Add the weighed raw materials into deionized water for wet-bonding, the ratio of the raw materials to water is 1:1.5 by weight, mix them with a ball mill for 3 hours, put the wet-milled mixed raw materials into an oven at 100°C for 54 hours to dry, Dry-mix and sieve the dried raw materials as raw materials for microwave sintering;

[0027] Form the raw material on the hydraulic press, the forming pressure is 25Mpa, the blank size is φ50 and the height is 40mm;

[0028] Put the formed body into the microwave ...

Embodiment 3

[0032] Lithium carbonate micropowder with a purity of 99.5% and a particle size of 30 μs, industrially pure electrolytic manganese dioxide micropowder with a particle size of 50 μs, analytically pure magnesium oxide micropowder, analytically pure nickel trioxide micropowder, and analytically pure chromium trioxide micropowder are used as raw materials. Wherein each raw material is proportioned according to the atomic ratio, Li:Mn:Mg:Ni:Cr=1.10:2.00:0.06:0.06:0.08;

[0033] Add the weighed raw materials into deionized water for wet-bonding, the ratio of the raw materials to water is 1:1.8 by weight, mix with a ball mill for 4 hours, put the wet-milled and mixed raw materials into an oven at 100°C for 60 hours for drying, Dry-mix and sieve the dried raw materials as raw materials for microwave sintering;

[0034] Form the raw material on a hydraulic press, the forming pressure is 30Mpa, the blank size is φ50 and the height is 50mm;

[0035] Put the formed body into the microwave ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com