Lithium ion battery, and anode material and preparation method thereof

A technology for lithium-ion batteries and positive electrode materials, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of high price, unfavorable cost reduction of lithium-ion batteries, and limited application range of lithium-ion, and achieves easy operation and preparation method Simple and feasible, excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

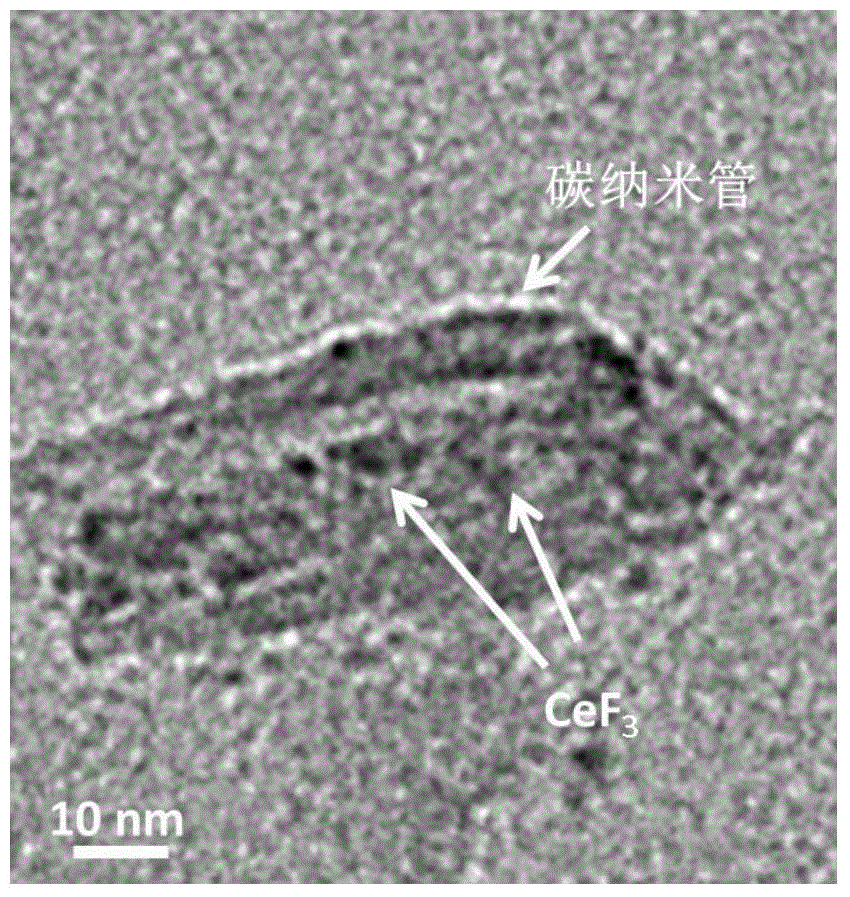

[0023] The preparation method of the positive electrode material of the lithium ion battery according to the second aspect of the present invention is used to prepare the positive electrode material of the lithium ion battery according to the first aspect of the present invention, comprising the steps of: (1) adding the cerium source to the organic solvent, Elevating the temperature to promote the dissolution of the cerium source to obtain a certain concentration of the cerium source solution; (2) adding a certain amount of porous carbon source to the cerium source solution, and then ultrasonically dispersing the porous carbon source to evenly disperse the porous carbon source in the cerium source solution to obtain the first mixture; (3) vacuumize the first mixture after heating up; (4) under the condition of continuous stirring, add fluorine source to the first mixture to obtain the second mixture; (5) leave the second mixture standing, and then separate, CeF was obtained by ...

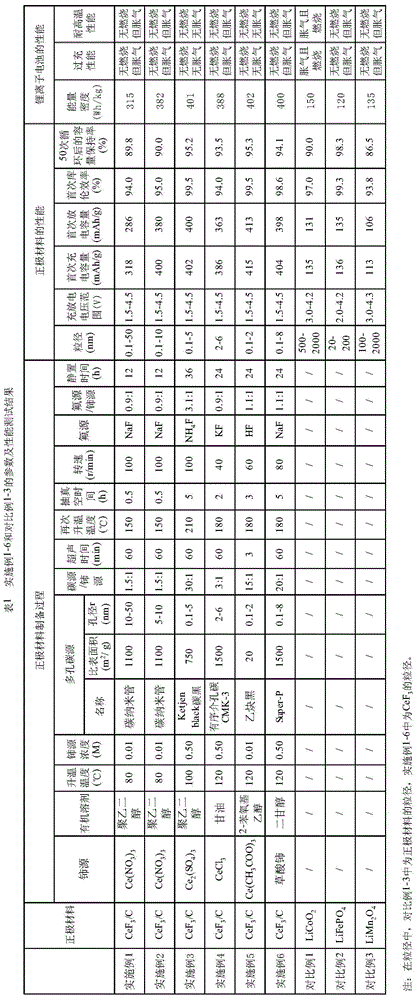

Embodiment 1

[0044] 1. Preparation of cathode materials for lithium-ion batteries

[0045] (1) The cerium source Ce(NO 3 ) 3 Adding polyethylene glycol, a solvent with a weight average molecular weight of 600, and raising the temperature to 80°C to promote the dissolution of the cerium source, to obtain a cerium source solution with a molar concentration of 0.01M;

[0046] (2) Add cerium source Ce(NO 3 ) 3 The porous carbon source carbon nanotubes with a molar ratio of 1.5:1, and then ultrasonically dispersed for 60 minutes to uniformly disperse the porous carbon source in the cerium source solution to obtain the first mixture, wherein the specific surface area of the carbon nanotubes is 1100m 2 / g, pore size 10nm≤r≤50nm;

[0047] (3) Elevate the temperature of the first mixture to 150°C and then vacuumize for 0.5h;

[0048] (4) Under the condition of continuous stirring at 100r / min, add the cerium source Ce(NO 3 ) 3 The mol ratio is the fluorine source NaF of 0.9:1, obtains the s...

Embodiment 2

[0059] Lithium-ion batteries were prepared according to the method of Example 1, except that in the step of preparing the positive electrode material of lithium-ion batteries (i.e. step 1),

[0060] (1) The cerium source Ce(NO 3 ) 3 Adding polyethylene glycol, a solvent with a weight average molecular weight of 600, and raising the temperature to 80°C to promote the dissolution of the cerium source, to obtain a cerium source solution with a molar concentration of 0.01M;

[0061] (2) Add cerium source Ce(NO 3 ) 3 The porous carbon source carbon nanotubes with a molar ratio of 1.5:1, and then ultrasonically dispersed for 60 minutes to uniformly disperse the porous carbon source in the cerium source solution to obtain the first mixture, wherein the specific surface area of the carbon nanotubes is 1100m 2 / g, pore size 5nm≤r≤10nm;

[0062] (3) Elevate the temperature of the first mixture to 150°C and then vacuumize for 0.5h;

[0063] (4) Under the condition of continuous st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com