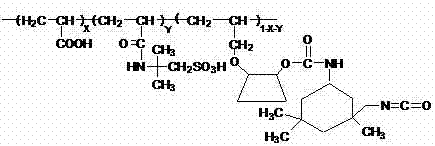

Acrylic acid(AA)/sodium 2-acrylamide-2-methylpro panesulfonic acid(AMPS-Na)/diisocyanate-modified allyl cyclodextrin (MACD) copolymer

A technology of copolymer and amps-na, applied in drilling composition, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problem of difficult control of drilling fluid properties, achieve good temperature resistance and salt resistance, preparation The method is simple and feasible, and the reaction conditions are mild.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Example 1 Preparation method of AA / AMPS-Na / MACD copolymer sewage treatment agent.

[0012] Add 150mL of the prepared MACD aqueous solution with a concentration of 0.01g / mL diisocyanate modified allyl cyclodextrin into a 250mL beaker, and then add 8.5mL with a concentration of 0.1g / mL acrylic acid AA aqueous solution and a concentration of 0.5g / mL Sodium 2-acrylamido-2-methylpropanesulfonate AMPS-Na aqueous solution 5Ml; then add 1mL potassium persulfate with a concentration of 0.3g / mL disodium ethylenediaminetetraacetic acid and a concentration of 0.5g / mL 1mL And the concentration is 1.0g / mL sodium bisulfite 0.5mL; stir well on a magnetic stirrer and mix well, then fill with nitrogen for 40min to deoxygenate, react at 60℃ for 6h to obtain the transparent colloidal product AA / AMPS-Na / MACD copolymer .

[0013] Measure the intrinsic viscosity of the AA / AMPS-Na / MACD copolymer according to the standard described in GB12005.1-89, and then measure the molecular weight of the copo...

Embodiment 2

[0014] Example 2 Decontamination effect of AA / AMPS-Na / MACD copolymer.

[0015] In order to evaluate the decontamination effect of the AA / AMPS-Na / MACD copolymer, an adsorption test was performed to prove it. Soak the obtained product in sewage containing organic molecules. The specific process is as follows: first prepare a mixed solution of deionized water and ethanol at a volume ratio of 90:10, and then add 10 ml of toluene and phenol mixed solution to the above mixed solution; The product AA / AMPS-Na / MACD prepared above is formulated into a copolymer aqueous solution of 10-100mg / L; finally the mixed solution prepared above is added to the polymer aqueous solution, after 24h, in a centrifuge at 5000r / min After separation for 10 minutes, the adsorption equilibrium concentration was measured by visible light spectrophotometer, which proved that the AA / AMPS-Na / MACD copolymer prepared by this invention has a good decontamination effect on wastewater containing organic solvents such ...

Embodiment 3

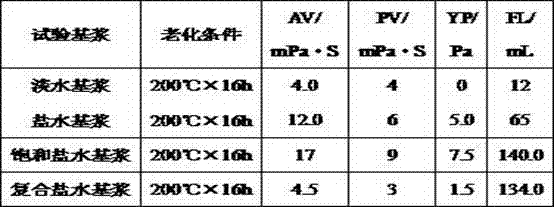

[0016] Example 3 The preparation method of AA / AMPS-Na / MACD copolymer fluid loss additive.

[0017] Add 100mL of the prepared MACD aqueous solution with a concentration of 0.01g / mL diisocyanate modified allyl cyclodextrin to a 250mL beaker, and then add 8.5mL with a concentration of 0.1g / mL acrylic acid AA aqueous solution and a concentration of 0.5g / mL 10mL of 2-acrylamido-2-methylpropanesulfonate sodium AMPS-Na aqueous solution; then add 1mL of disodium edetate with a concentration of 0.3g / mL and 1mL of potassium persulfate with a concentration of 0.5g / mL in sequence And the concentration is 1.0g / mL sodium bisulfite 0.5mL; stir well on a magnetic stirrer and mix evenly, then fill with nitrogen for 40min to remove oxygen, react at 35℃ for 5h to obtain the gel-like product AA / AMPS-Na / MACD copolymer .

[0018] Measure the intrinsic viscosity of the AA / AMPS-Na / MACD polymer according to the standard described in GB12005.1-89, and then measure the molecular weight of the polymer acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com