Preparation method of MXene-carbon aerogel/TPU composite material

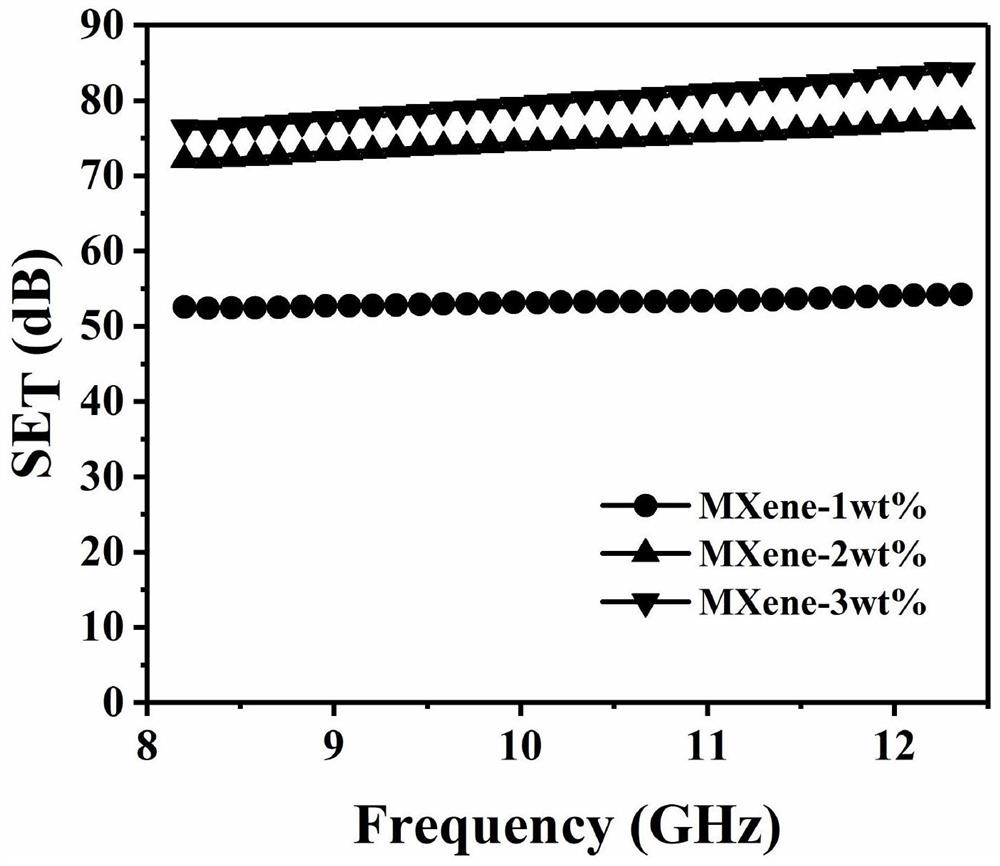

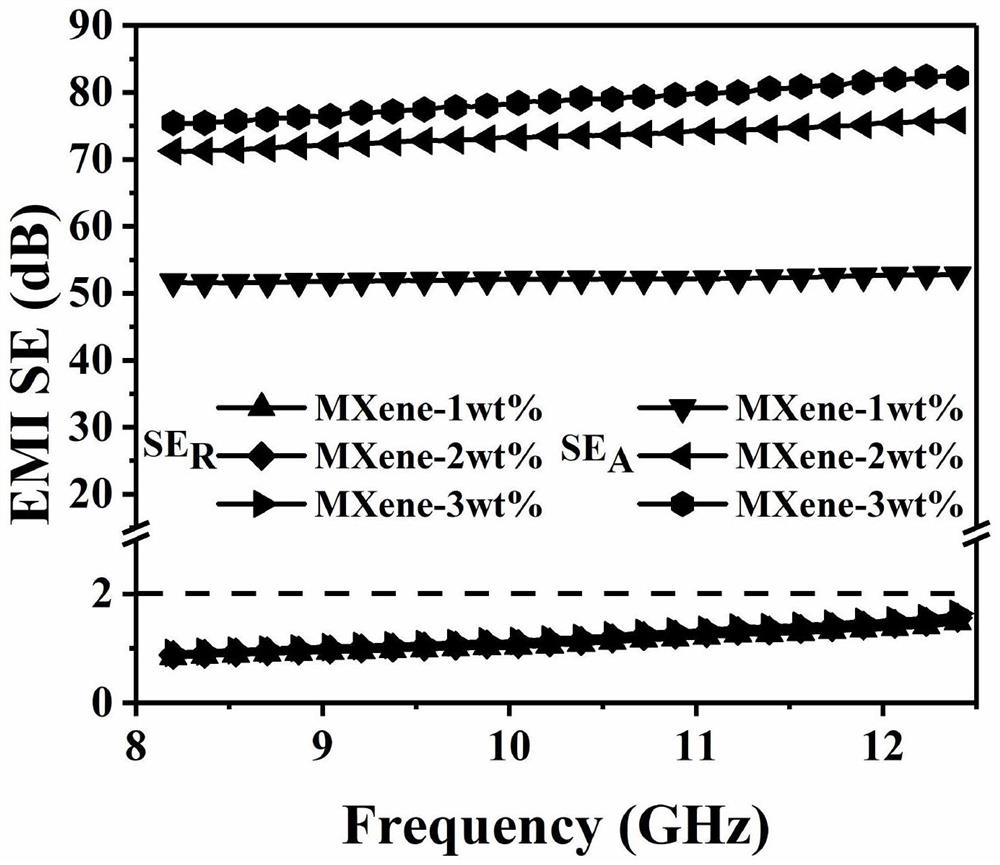

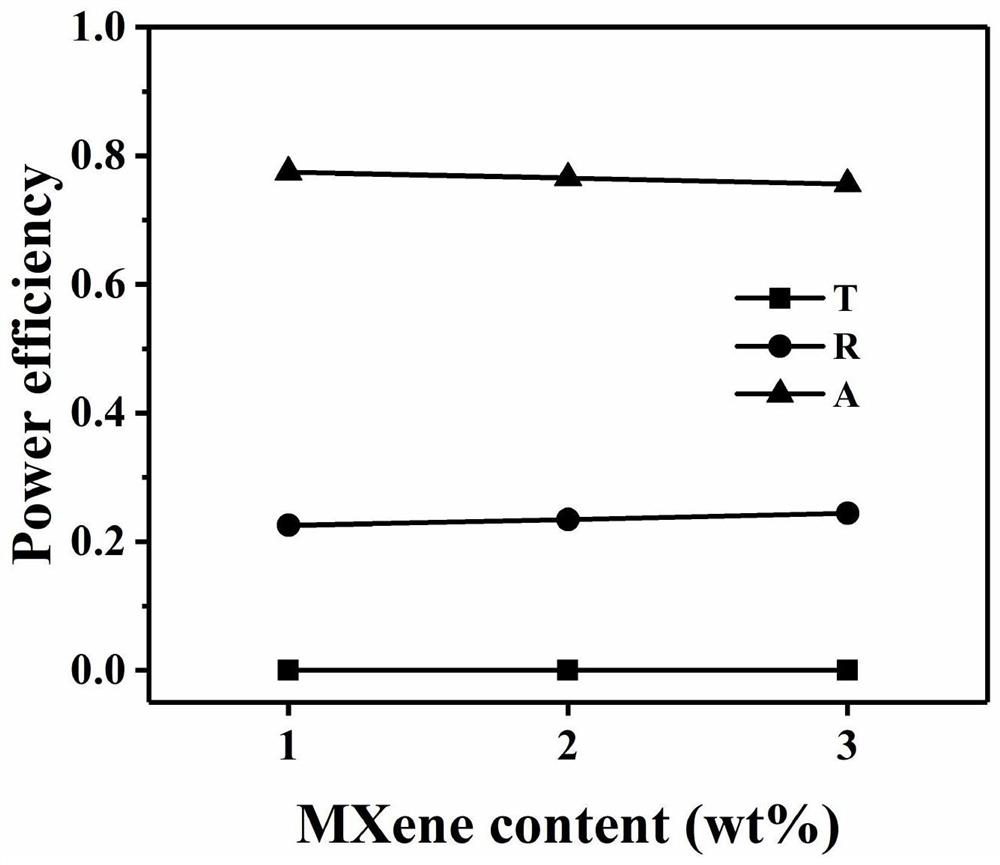

A technology of carbon airgel and composite materials, applied in the direction of electrical components, magnetic field/electric field shielding, etc., can solve the problems of low electromagnetic shielding performance and high reflection, and achieve the effect of simple and feasible preparation method, low filler and strong absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A kind of preparation method of MXene-carbon airgel / TPU composite material of the present invention, specifically implement according to the following steps:

[0050] Step 1, Etching Ti by LiF / HCl 3 AlC 2 (MAX phase) precursor to prepare few-layer MXene solution, the specific steps are as follows:

[0051] Step 1.1, fully mix 2gLiF with 40ml 9mol / L HCl, then slowly add 2gMAX phase precursor powder under ice bath conditions;

[0052] Step 1.2, the above mixture was stirred at 35°C for 24 hours to obtain Ti 3 C 2 T x The suspension was repeatedly washed with deionized water until the pH was 7, and centrifuged at a speed of 3500r / min;

[0053] Step 1.3, the Ti 3 C 2 T x Disperse the precipitate in 100ml deionized water, sonicate for 15min to promote the stratification of multi-layer MXene, then continue to centrifuge at a rate of 3500r / min for 15min, cycle several times, take the supernatant to obtain the MXene solution;

[0054] Step 2, preparing MXene-cellulose ...

Embodiment 2

[0065] A kind of preparation method of MXene-carbon airgel / TPU composite material of the present invention, specifically implement according to the following steps:

[0066] Step 1, Etching Ti by LiF / HCl 3 AlC 2 (MAX phase) precursor to prepare few-layer MXene solution, the specific steps are as follows:

[0067] Step 1.1, fully mix 2gLiF with 40ml 9mol / L HCl, then slowly add 2gMAX phase precursor powder under ice bath conditions;

[0068] Step 1.2, the above mixture was stirred at 35°C for 24 hours to obtain Ti 3 C 2 T x The suspension was repeatedly washed with deionized water and centrifuged at a rate of 3500r / min until the pH was 7;

[0069] Step 1.3, the Ti 3 C 2 T x Disperse the precipitate in 100ml deionized water, ultrasonicate for 15min to promote the stratification of multilayer MXene, then continue to centrifuge at a rate of 3500r / min for 15min, cycle several times, take the supernatant, and obtain the multilayer MXene solution;

[0070] Step 2, preparing M...

Embodiment 3

[0081] A kind of preparation method of MXene-carbon airgel / TPU composite material of the present invention, specifically implement according to the following steps:

[0082] Step 1, Etching Ti by LiF / HCl 3 AlC 2 (MAX phase) precursor to prepare few-layer MXene solution, the specific steps are as follows:

[0083] Step 1.1, fully mix 2gLiF with 40ml 9mol / L HCl, then slowly add 2gMAX phase precursor powder under ice bath conditions;

[0084] Step 1.2, the above mixture was stirred at 35°C for 24 hours to obtain Ti 3 C 2 T x The suspension was repeatedly washed with deionized water and centrifuged at a rate of 3500r / min until the pH was 7;

[0085] Step 1.3, the Ti 3 C 2 T x Disperse the precipitate in 100ml deionized water, ultrasonicate for 15min to promote the stratification of multilayer MXene, then continue to centrifuge at a rate of 3500r / min for 15min, cycle several times, take the supernatant, and obtain the multilayer MXene solution;

[0086] Step 2, preparing M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com