Cyanate ester modified PVDF binder, positive pole piece applying same and lithium-sulfur battery

A technology of lithium-sulfur battery and positive pole piece, which is applied in lithium batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of low F atom polarizability, low polymer flexibility, and poor adhesion, etc. Achieve the effect of alleviating the shuttle effect, improving the adhesion, and improving the electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

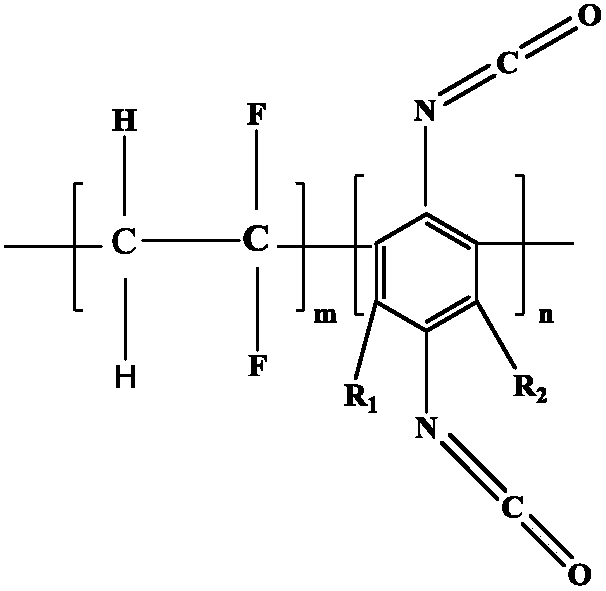

[0026] In this embodiment, the cyanate-modified PVDF binder contains the cyanate-modified PVDF binder which is polymerized from monomer vinylidene fluoride and isocyanate-based monomers, and its structural formula is as follows:

[0027]

[0028] Among them, R 1 is hydrogen or R 1 from C 1-8 straight-chain or branched-chain alkyl; R 2 is hydrogen or R 2 from C 1-8 straight-chain or branched-chain alkyl; m and n are both integers greater than 0.

[0029] The preparation method of the above-mentioned cyanate ester modified PVDF binder is as follows: put PVDF into 2mol / L NaOH aqueous solution and stir, then wash and dry to obtain a PVDF sample containing double bonds, and mix the sample and dimethyl isocyanate powder by pressing Add to the acetone solvent with a mass ratio of 3:1, then add N,N-dimethylformamide (DMF), control the temperature and pre-mix at 80°C for 0.5h, remove the organic solvent; finally add dicumyl peroxide (DCP), under the protection of an inert gas,...

Embodiment 2

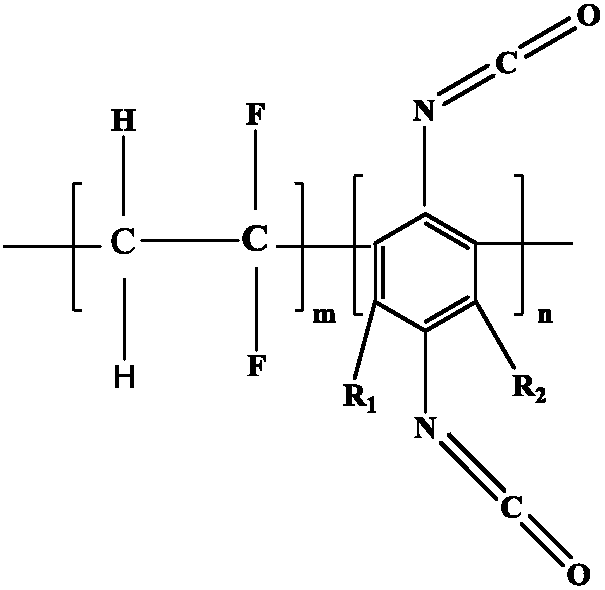

[0035] In this embodiment, the cyanate-modified PVDF binder contains the cyanate-modified PVDF binder which is polymerized from monomer vinylidene fluoride and isocyanate-based monomers, and its structural formula is as follows:

[0036]

[0037] Among them, R 1 is hydrogen or R 1 from C 1-8 straight-chain or branched-chain alkyl; R 2 is hydrogen or R 2 from C 1-8 straight-chain or branched-chain alkyl; m and n are both integers greater than 0.

[0038]The preparation method of the above-mentioned cyanate-modified PVDF binder is as follows: put PVDF into NaOH aqueous solution and stir, then wash and dry to obtain a PVDF sample containing double bonds, and add the mixed powder of the sample and dimethyl isocyanate to acetone Add N,N-dimethylformamide (DMF) to the solvent, pre-mix at 80°C for 0.5 h under temperature control, then remove the organic solvent; finally add dicumyl peroxide (DCP), under inert gas protection Control the temperature at 100°C, stir for 1-2 hour...

Embodiment 3

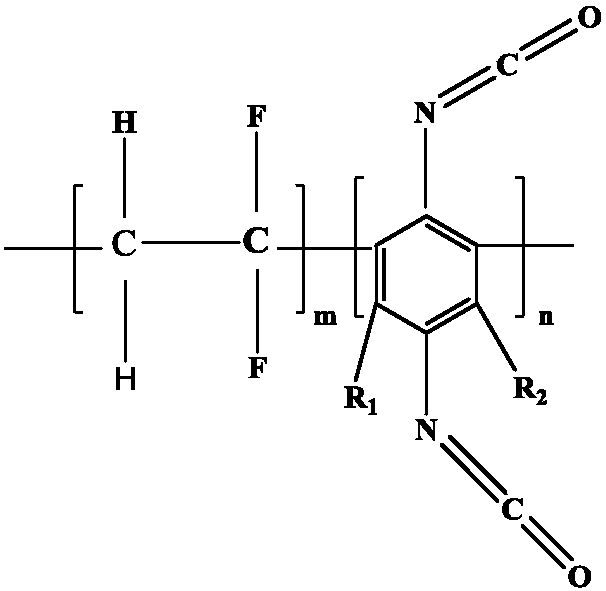

[0044] In this embodiment, the cyanate-modified PVDF binder contains the cyanate-modified PVDF binder which is polymerized from monomer vinylidene fluoride and isocyanate-based monomers, and its structural formula is as follows:

[0045]

[0046] Among them, R 1 is hydrogen or R 1 from C 1-8 straight-chain or branched-chain alkyl; R 2 is hydrogen or R 2 from C 1-8 straight-chain or branched-chain alkyl; m and n are both integers greater than 0.

[0047] The preparation method of the above-mentioned cyanate-modified PVDF binder is as follows: put PVDF into NaOH aqueous solution and stir, then wash and dry to obtain a PVDF sample containing double bonds, and add the mixed powder of the sample and dimethyl isocyanate to acetone Add N,N-dimethylformamide (DMF) to the solvent, pre-mix at 80°C for 0.5 h under temperature control, then remove the organic solvent; finally add dicumyl peroxide (DCP), under inert gas protection Control the temperature at 100°C, stir for 1-2 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com