Non-aqueous electrolyte battery and battery pack

A non-aqueous electrolyte and battery technology, used in non-aqueous electrolyte batteries, battery electrodes, battery pack components, etc., can solve problems such as the decline of cycle characteristics, and achieve the effect of reducing twisting and excellent charge-discharge cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

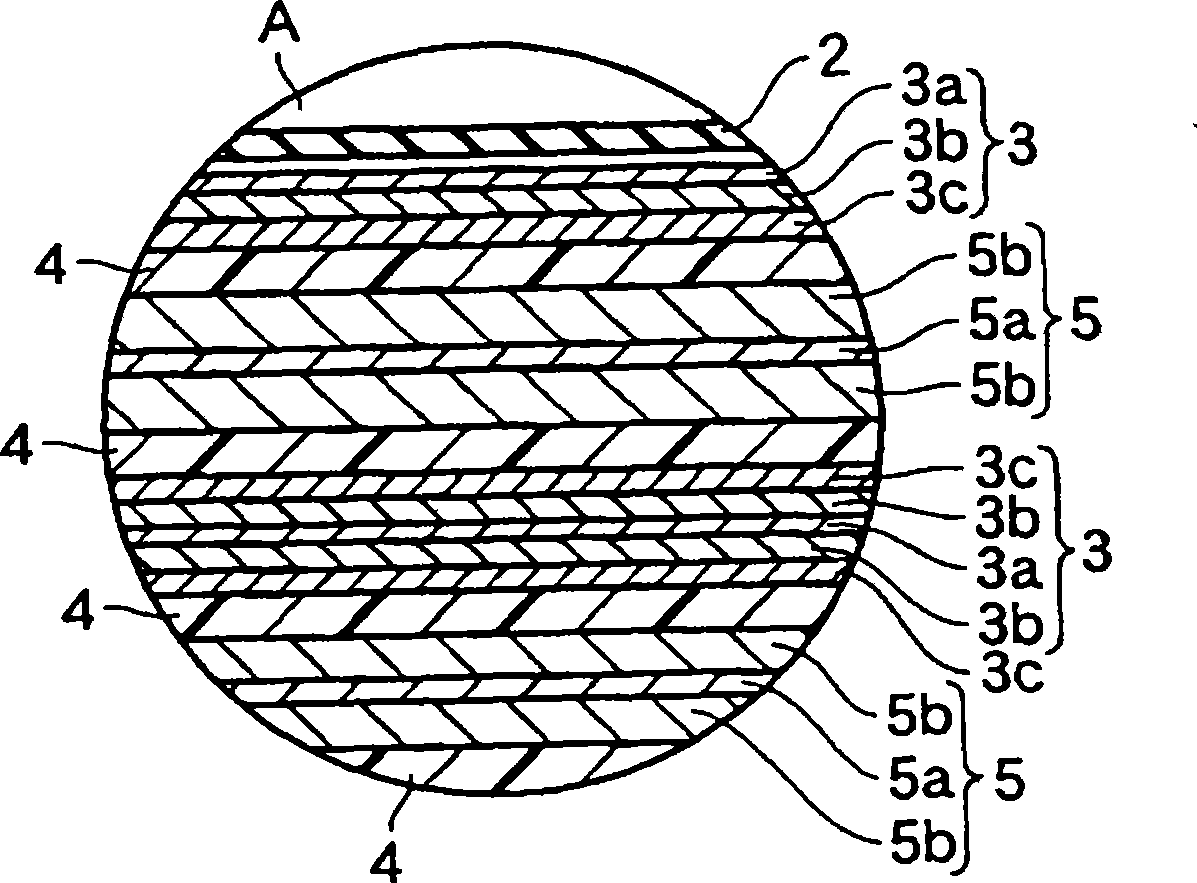

no. 1 approach

[0026] The nonaqueous electrolyte battery of the first embodiment includes a negative electrode, a positive electrode, and a separator interposed between the positive and negative electrodes. An electrode group composed of such a negative electrode, a positive electrode, and a separator is accommodated in an outer packaging material, and at least the electrode group contains a nonaqueous electrolyte. The positive electrode has a positive electrode layer. The negative electrode has a structure in which a negative electrode layer containing a negative electrode active material is formed on the surface of a negative electrode current collector. The negative electrode layer has a structure in which a plurality of layers containing different negative electrode active materials are laminated. Among these stacked layers, the layer in contact with the negative electrode current collector contains spinel-type lithium titanate as the negative electrode active material, and the layer op...

no. 2 approach

[0076] The battery pack of the second embodiment has a plurality of the above-mentioned non-aqueous electrolyte batteries (cells), and the cells are electrically arranged in series or in parallel.

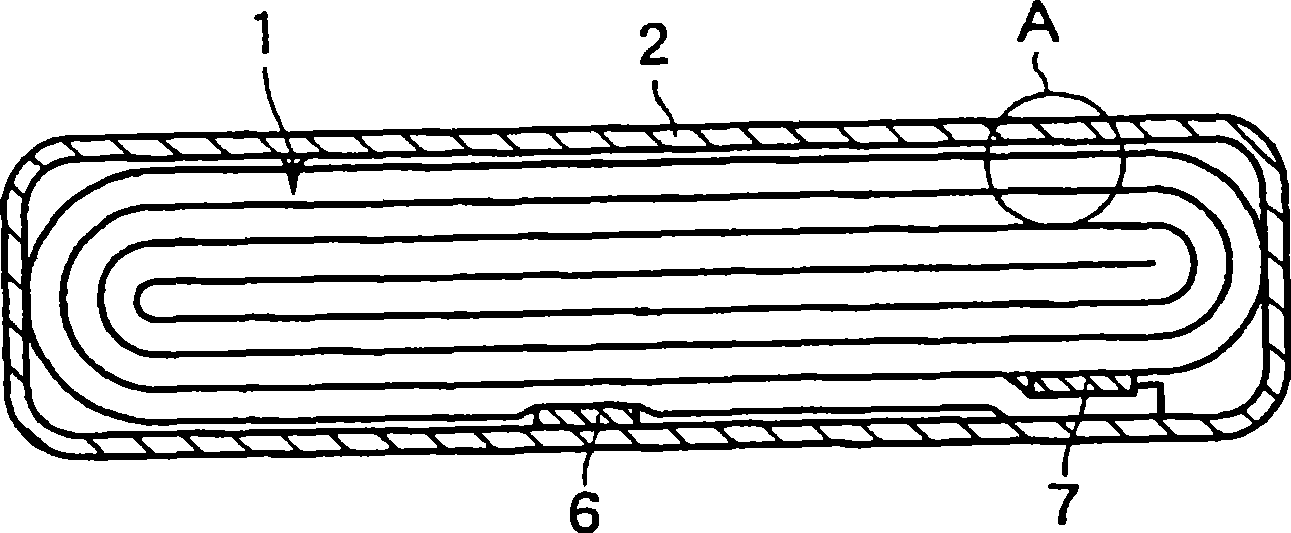

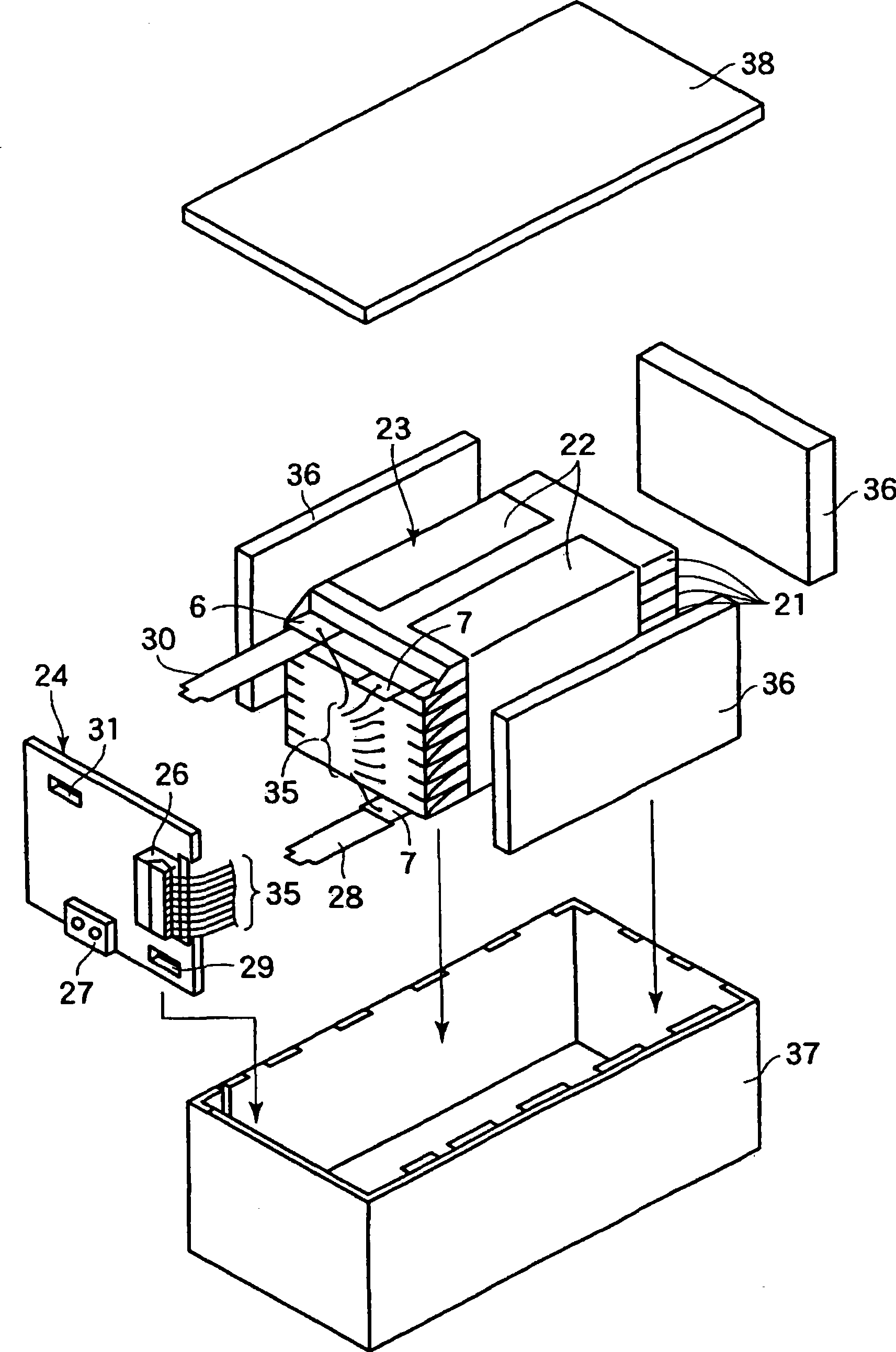

[0077] refer to image 3 and Figure 4 Such a battery pack will be described in detail. For a single cell, you can use figure 1 The flat type battery shown.

[0078] by the above figure 1 A plurality of unit cells 21 composed of the illustrated flat non-aqueous electrolyte battery are stacked so that the negative terminal 6 and the positive terminal 7 protruding outward are aligned in the same direction, and are fastened with an adhesive tape 22 to form a group. battery 23. These cells 21 as Figure 4 shown are electrically connected in series with each other.

[0079] The printed circuit board 24 is disposed so as to face the side surface of the cell 21 from which the negative terminal 6 and the positive terminal 7 protrude. On the printed circuit substrate 24, such as F...

Embodiment 1

[0090] 100 parts by weight of spinel lithium titanate, 7 parts by weight of carbon as a conductive agent, and 2 parts by weight of PVdF as a binder were added to N-methylpyrrolidone (NMP) and mixed to prepare a first slurry. In addition, 100 parts by weight of orthorhombite-type lithium titanate, 7 parts by weight of carbon as a conductive agent, and 2 parts by weight of PVdF as a binder were added to N-methylpyrrolidone (NMP) and mixed to prepare the second material. pulp.

[0091] Next, the above-mentioned first slurry is coated on a current collector made of aluminum foil with a thickness of 15 μm (purity: 99.99%, average crystal particle size: 10 μm), and when the first slurry is in a wet state, apply The above-mentioned second slurry was spread, dried and pressed to prepare a negative electrode having a negative electrode layer with a thickness of 30 μm.

[0092] For the thickness of the layer (containing spinel-type lithium titanate) in contact with the current collecto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com