A positive electrode material for lithium secondary cell, and preparation and usage thereof

A lithium secondary battery and positive electrode material technology, which is applied in electrode manufacturing, battery electrodes, circuits, etc., can solve the problem that the specific capacity and charge-discharge cycle of positive electrode materials are not very ideal, and cannot meet the needs of large capacity or high power density lithium secondary batteries. Battery and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

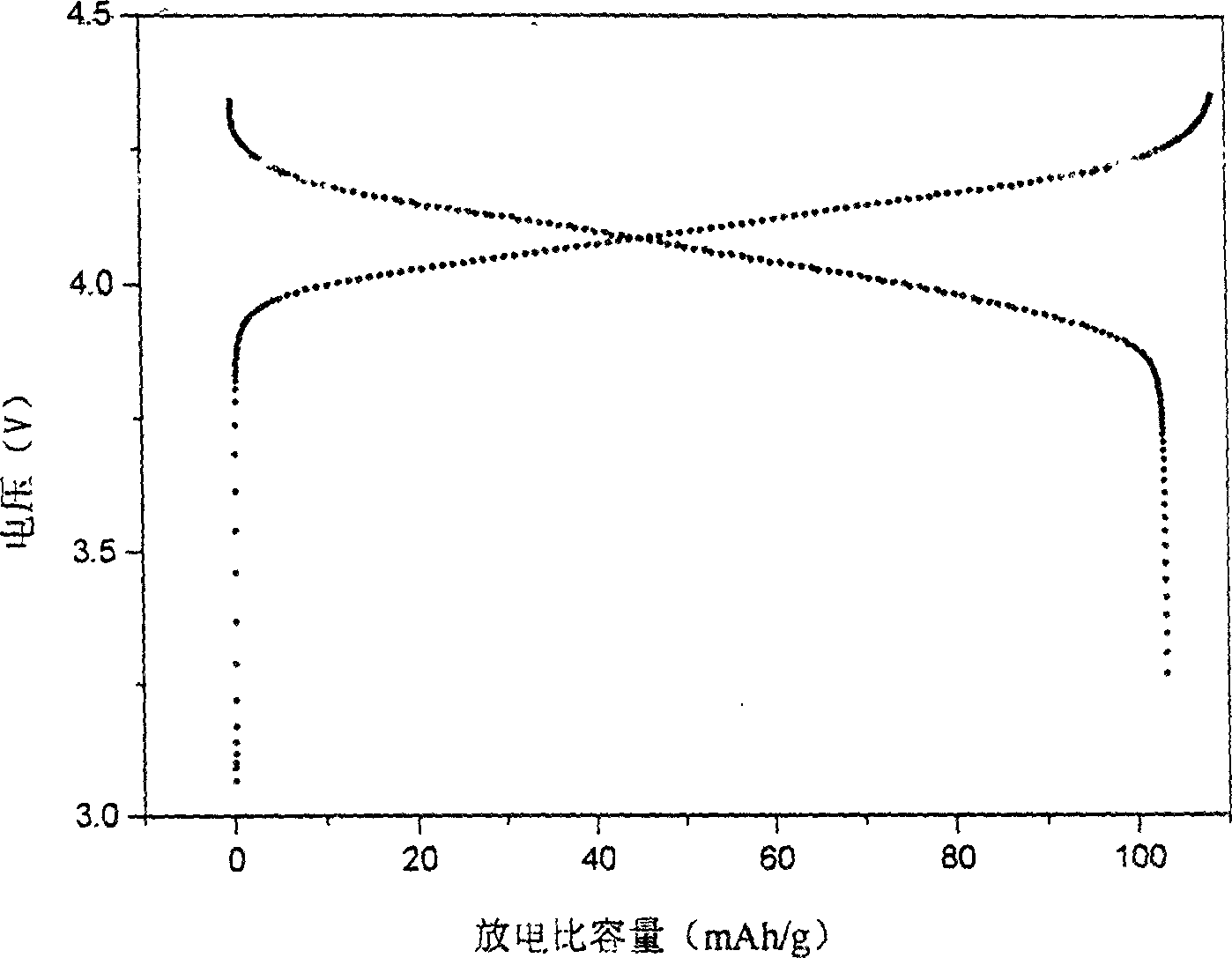

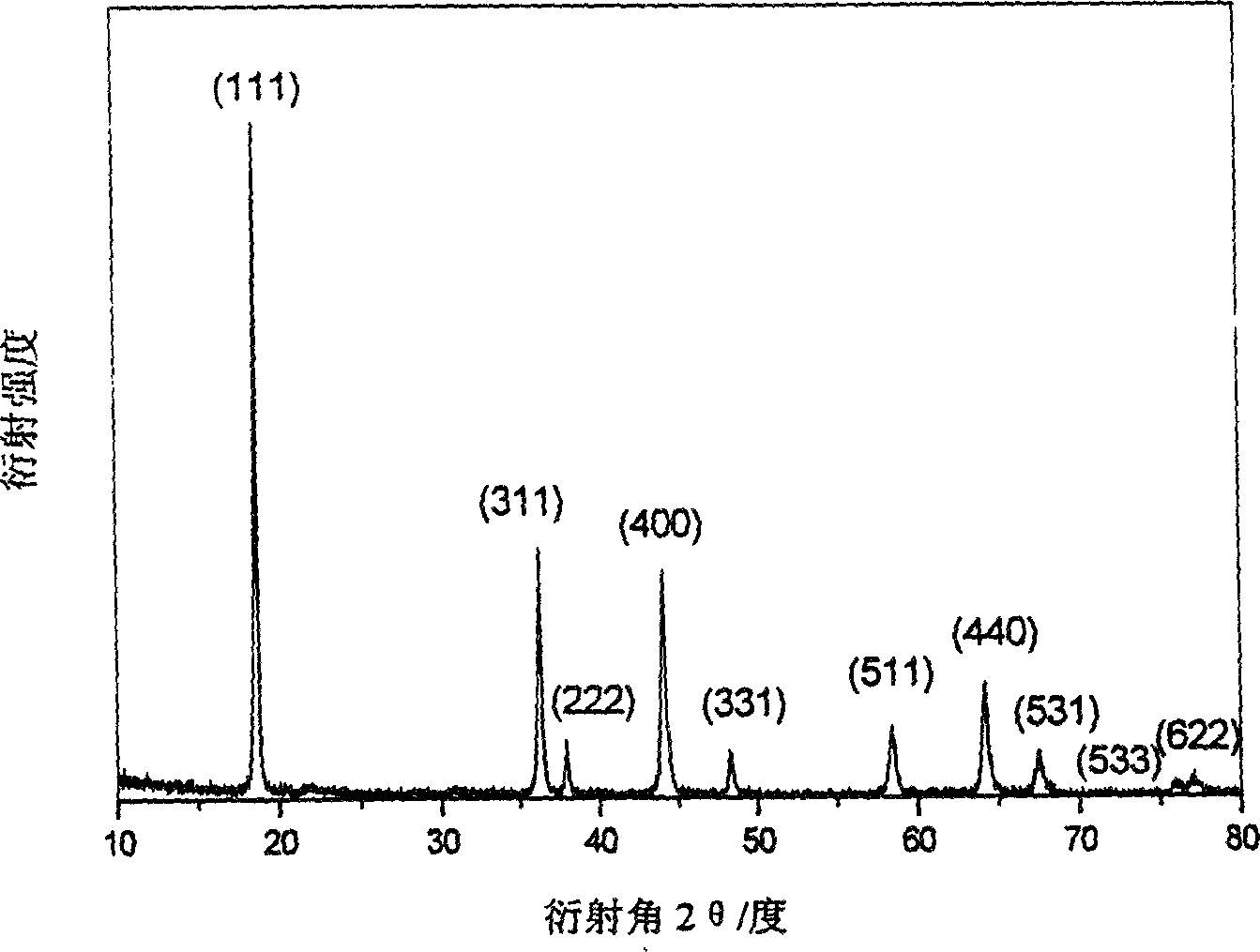

[0078] Embodiment 1, according to the preparation method of the present invention-preparation process LiAlO 2 Modified spinel LiMn 2 o 4 Lithium-ion battery active cathode material

[0079] Mix 2mol / l manganese sulfate aqueous solution and 4mol / l sodium hydroxide aqueous solution and 2.0mol / l H 2 o 2 Added to the reactor at the same time, the manganese sulfate and H 2 o 2 The molar ratio is 1:1, the PH=12 is controlled by controlling the amount of sodium hydroxide added, the reaction temperature is 50°C, stirred for 5 hours, then filtered, washed, and dried in an oven at 120°C to obtain the Mn-containing oxide compound and hydroxide mixture.

[0080] Add 50 grams of manganese oxide or hydroxide precursor prepared by the chemical precipitation technology into the aluminum nitrate solution with a concentration of 1 mol / l, wherein the molar ratio of aluminum nitrate to manganese-containing precursor is 0.1:1. while stirring

[0081] Gradually add 4 mol / l ammonia water unt...

Embodiment 2~21

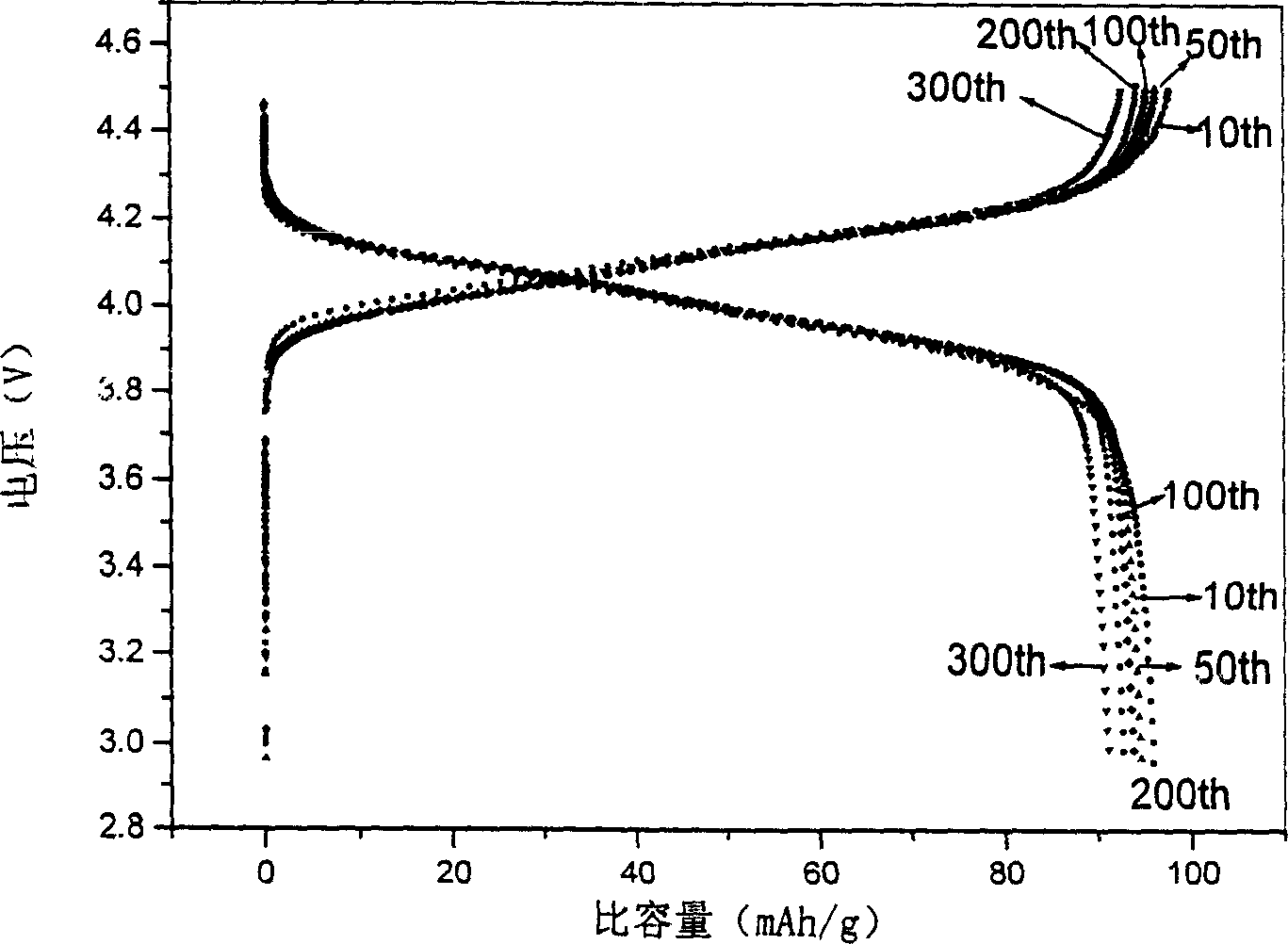

[0085] Embodiment 2~21, according to the preparation method of the present invention one is synthesized under different conditions a series of positive spinel structure lithium manganese oxide LiMn 2-z m z o 4 positive active material

[0086] According to the preparation method one provided by the present invention, under the different conditions listed in Table 1, a series of positive spinel structure lithium manganese oxides LiMn were synthesized. 2-z m z o 4 Positive active material.

[0087]

Embodiment 22

[0088] Example 22, LiAlO was prepared according to the second preparation method of the present invention 2 Modified spinel LiMn 2 o 4 Lithium-ion battery active cathode material

[0089] Mix 3mol / l manganese sulfate aqueous solution and 6mol / l sodium hydroxide aqueous solution and 1.5mol / l H 2 o 2 Added to the reactor at the same time, the manganese sulfate and H 2 o 2 The molar ratio is 1:1, the PH=11 is controlled by controlling the amount of sodium hydroxide added, the reaction temperature is 60°C, and stirring is carried out for 10 hours, then filtered, washed, and dried in an oven at 120°C to obtain Mn-containing oxidized compound and hydroxide mixture. The prepared manganese oxide or hydroxide precursor was directly mixed with LiOH.H 2 O is mixed according to a molar ratio of 2:1.05, 50% of water is added, mixed thoroughly, and then spray-dried, and the spray-dried powder is sintered at 800°C for 24 hours to synthesize LiMn with a spinel structure. 2 o 4 Materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com