Polyvinylpyrrolidone modified graphene coated sulfur/porous carbon composite anode material and preparation method thereof

A polyvinylpyrrolidone and graphene coating technology, applied in battery electrodes, electrical components, non-aqueous electrolyte batteries, etc., can solve problems such as low electrochemical performance, achieve high content, improve active material utilization, and inhibit dissolution loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

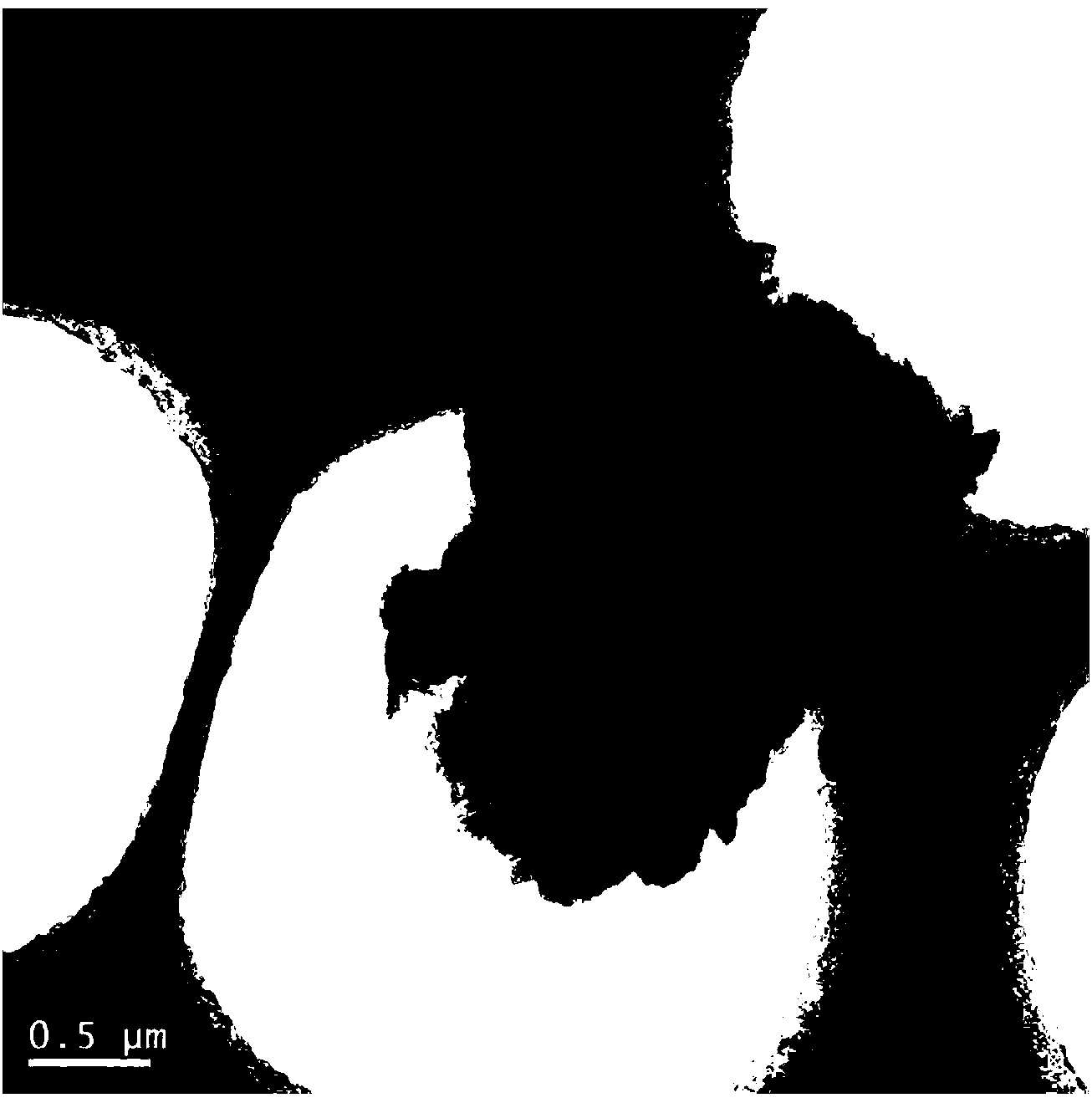

Image

Examples

specific Embodiment approach 1

[0042] Embodiment 1: The polyvinylpyrrolidone-modified graphene-coated sulfur / porous carbon composite material in this embodiment is to uniformly coat the polyvinylpyrrolidone-modified graphene sheet on the outer surface of the sulfur / porous carbon composite particle, and Polyvinylpyrrolidone-modified graphene-coated sulfur / porous carbon composite particles form a graphene conductive network; the polyvinylpyrrolidone-modified graphene-coated sulfur / porous carbon composite has a hierarchical core-shell structure, sulfur / porous The carbon composite is the core, and the polyvinylpyrrolidone-modified graphene is evenly coated on the outer surface of the sulfur / porous carbon composite particles to become a protective shell, and the polyvinylpyrrolidone is simultaneously adsorbed on the graphene and sulfur / porous carbon composites. On the surface of graphene, a considerable number of fixed connection points are established between graphene and sulfur / porous carbon composites, so that...

specific Embodiment approach 2

[0044] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the mass ratio of sulfur, porous carbon, polyvinylpyrrolidone and graphene coating is 1:(0.05~2):(0.002~0.2):(0.05 ~2). Others are the same as in the first embodiment.

specific Embodiment approach 3

[0045] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the mass ratio of sulfur, porous carbon, polyvinylpyrrolidone and graphene coating is 1:(0.1~1):(0.005~0.1):(0.1 ~1). Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com