Three-dimensional porous silicon-based composite negative electrode material of lithium ion cell and preparation method thereof

A lithium-ion battery, three-dimensional porous technology, applied in the direction of battery electrodes, secondary batteries, electrode carriers/collectors, etc., can solve the problems of unsatisfactory cycle performance and commercial application, and improve high-rate charge and discharge performance, Improved charge-discharge cycle performance and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

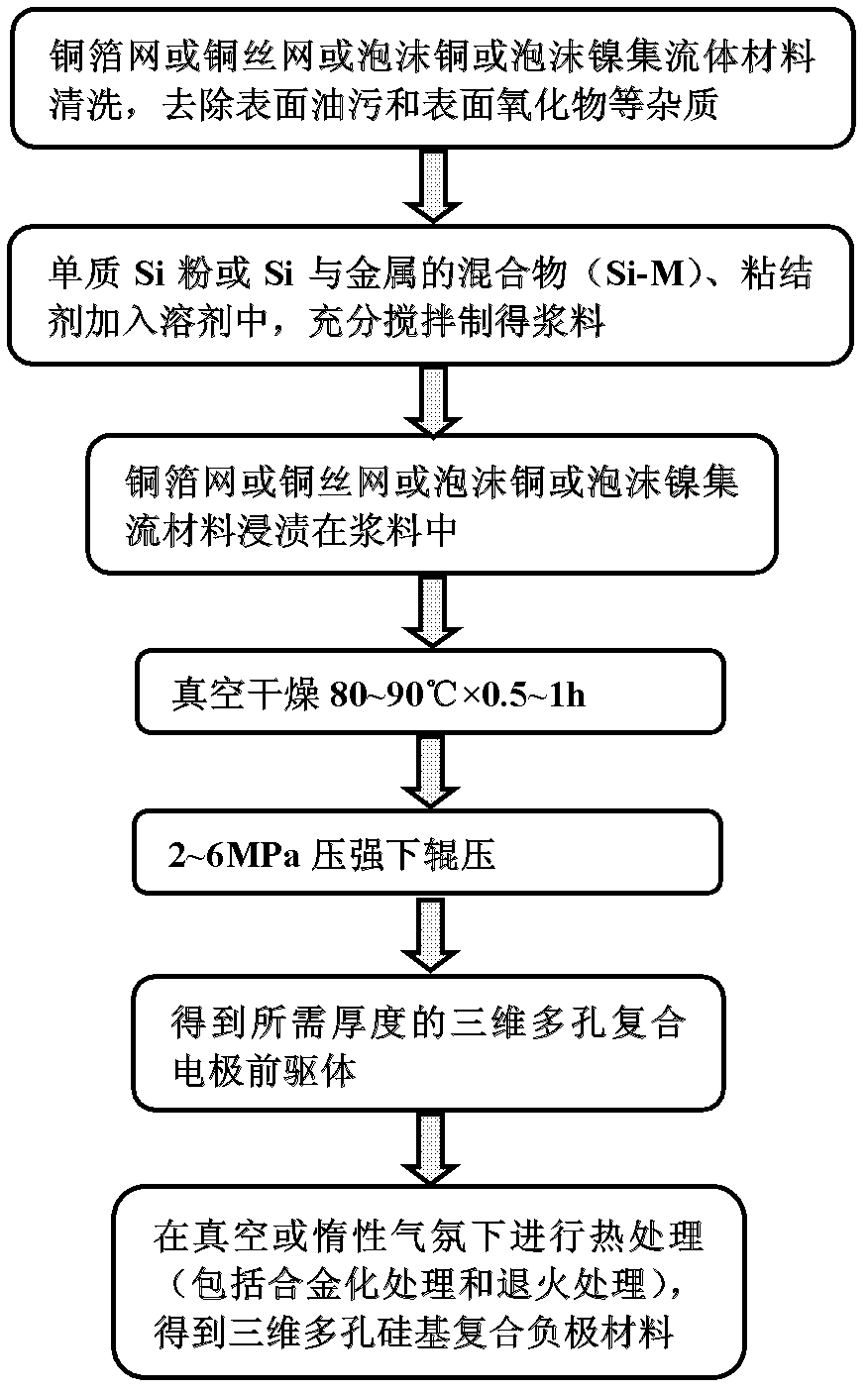

Method used

Image

Examples

Embodiment 1

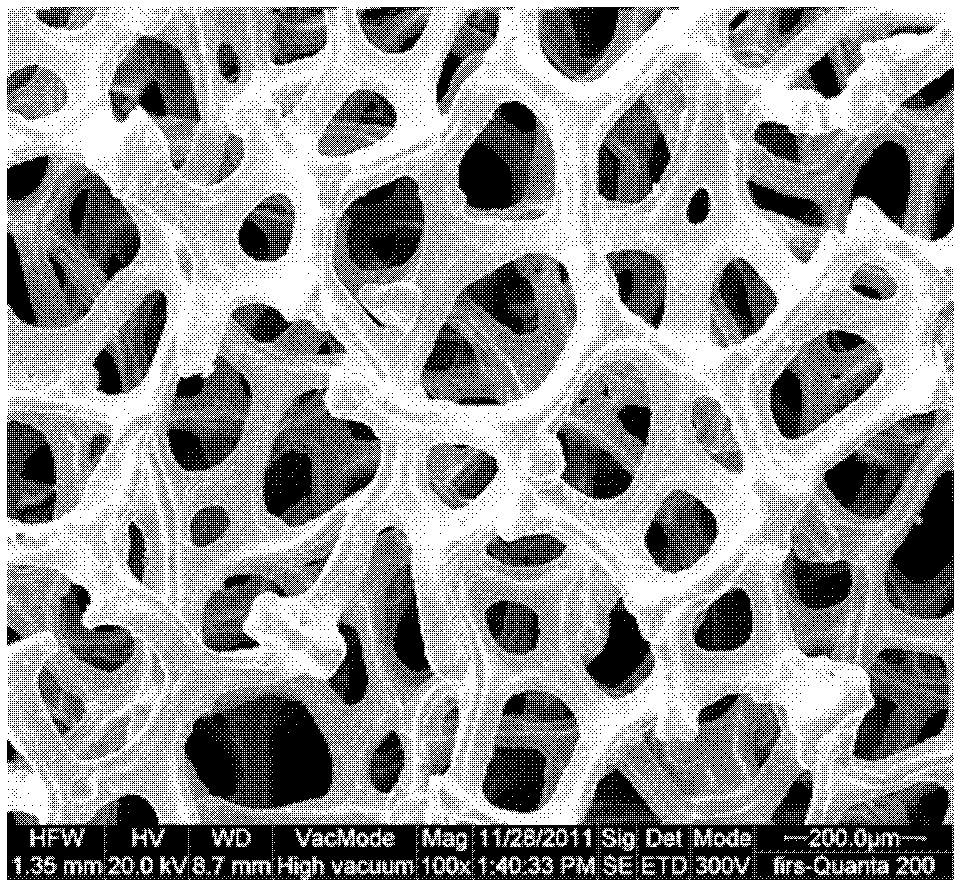

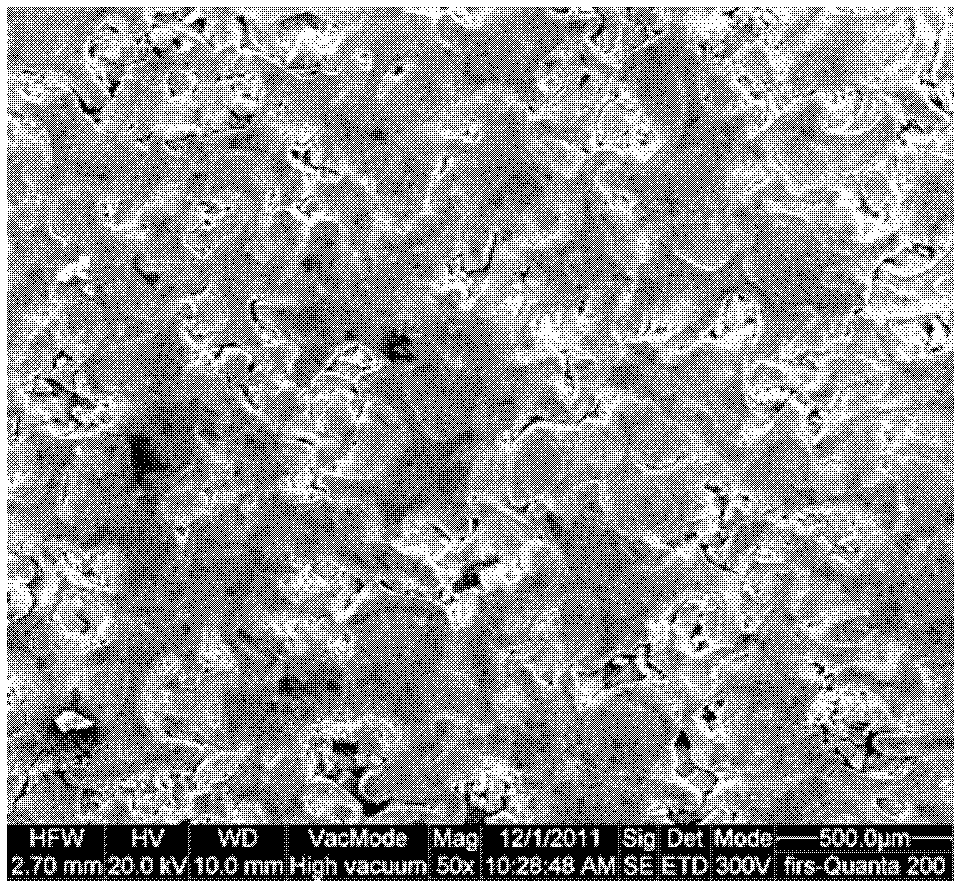

[0045] Clean the copper foil mesh or copper wire mesh or foamed copper or foamed nickel with an average pore size of 150 μm and a thickness of 700 μm with acetone, 10% dilute hydrochloric acid, distilled water and absolute ethanol in order to remove impurities such as surface oil and surface oxides . Elemental Si powder (purity is 99.5%, D 50 = 1.5 μm) and carboxymethylcellulose (CMC) were added into water at a mass ratio of 36:1, and stirred thoroughly to obtain a slurry (solid content: 35%). Immerse the copper foil mesh or copper wire mesh or foamed copper or foamed nickel current collector in the slurry, after fully impregnating and lightly scraping off the excess slurry on the surface, a copper foil mesh or copper wire mesh or copper wire mesh impregnated with slurry is formed. Foamed copper or foamed nickel current collector system, then make the copper foil mesh or copper wire mesh or foamed copper or foamed nickel current collector system impregnated with slurry vacuum...

Embodiment 2

[0048] Clean the copper foil mesh or copper wire mesh or foamed copper or foamed nickel with an average pore size of 100 μm and a thickness of 1000 μm with acetone, 10% dilute hydrochloric acid, distilled water and absolute ethanol in order to remove impurities such as surface oil and surface oxides . Elemental Si powder (purity is 99.9%, D 50 =100nm) and polyamide-imide (PAI) were added into N-methylpyrrolidone at a mass ratio of 45:1, and stirred thoroughly to obtain a slurry (solid content: 30%). Immerse the copper foil mesh or copper wire mesh or foamed copper or foamed nickel current collector in the slurry, after fully impregnating and lightly scraping off the excess slurry on the surface, a copper foil mesh or copper wire mesh or copper wire mesh impregnated with slurry is formed. Foamed copper or foamed nickel current collector system, followed by vacuum-drying the copper foil mesh or copper wire mesh or foamed copper or foamed nickel current collector system impregna...

Embodiment 3

[0051] Clean the copper foil mesh or copper wire mesh or foamed copper or foamed nickel with an average pore size of 100 μm and a thickness of 400 μm with acetone, 10% dilute hydrochloric acid, distilled water and absolute ethanol in order to remove impurities such as surface oil and surface oxides . Si-Sn mixed powder (Si purity 99.8%, D 50 =1.5μm; Sn purity is 99.6%, D 50 =100nm; and Si:Sn=1:1) and polyacrylic acid [poly(acrylic acid)] were added in the ethanol aqueous solution according to the mass ratio of 36:1, fully stirred to prepare slurry (solid content: 32%). Immerse the copper foil mesh or copper wire mesh or foamed copper or foamed nickel current collector in the slurry, after fully impregnating and lightly scraping off the excess slurry on the surface, a copper foil mesh or copper wire mesh or copper wire mesh impregnated with slurry is formed. The copper foam or nickel foam current collector system, followed by vacuum drying the copper foil mesh or copper wire ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com