Method for preparing cathode material carbon-coated lithium titanate for lithium ion battery from metatitanic acid

A technology of carbon-coated lithium titanate and lithium-ion batteries, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of poor electrical conductivity, increased process, difficult to remove, etc., and achieves moderate conditions, easy industrial production, and technological process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

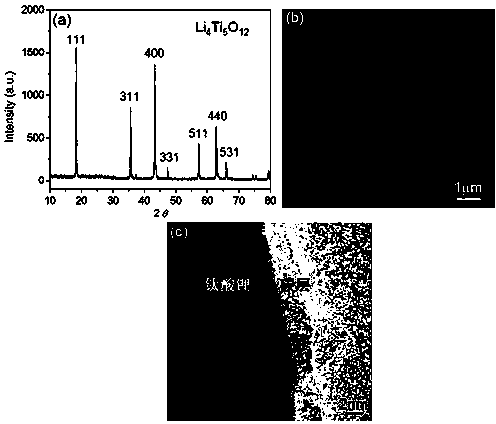

[0023] First, use deionized water and oxalic acid to prepare a certain concentration of oxalic acid solution, then stir and mix with metatitanic acid evenly, filter with a Buchner funnel, and rinse the filtrate with deionized water to obtain purified metatitanic acid. Lithium source Li 2 CO 3 , Purified metatitanic acid H 2 TiO 3 Mix the three raw materials with the carbon source pitch according to the following ratio, and the molar ratio of Li:Ti is 4.1:5. Add Li 2 CO 3 and H 2 TiO 3 , the amount of asphalt added is 5% of the sum of the weight of the lithium source and the titanium source; then it is fully mixed by ball milling, and the temperature is raised to 120 °C under an argon atmosphere 0 C for 3 hours at a constant temperature, then raised to 850 0 C for 12 hours, and finally cooled to room temperature.

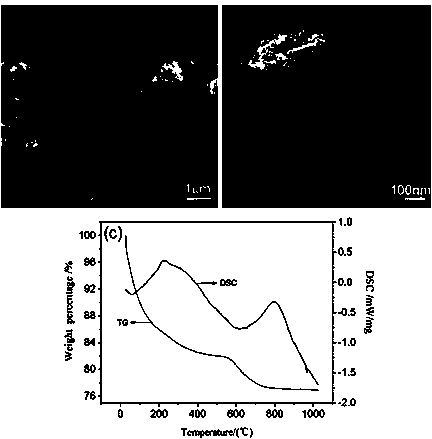

[0024] figure 1 (a) and (b) are metatitanic acid H 2 TiO 3 Low and high magnification scanning electron micrographs of H 2 TiO 3 The size of the second...

Embodiment 2

[0026] Metatitanic acid H purified from lithium source LiOH and titanium source 2 TiO 3 Mix the three raw materials with the carbon source phenolic resin according to the following ratio, the molar ratio of Li:Ti is 4:5, add LiOH and H 2 TiO 3 , the amount of phenolic resin added is 3% of the sum of the weight of the lithium source and the titanium source, and then it is thoroughly mixed by ball milling, and then in an argon atmosphere, the temperature is raised to 180 0 C for 2 hours at a constant temperature, then raised to 700 0 C at constant temperature for 20 hours; finally cooled to room temperature.

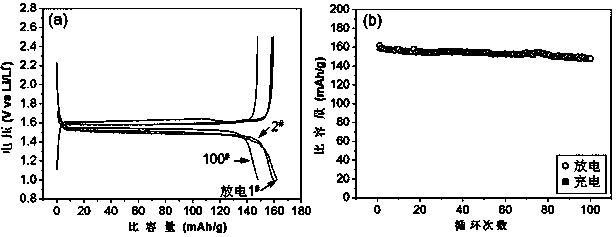

[0027] The carbon-coated lithium titanate composite powder material was prepared by the above method, and it was used as the negative electrode active material of the lithium-ion battery to prepare a lithium-ion button-type experimental battery, and its performance was tested. The results are as follows: Figure 4 shown. in Figure 4 The voltage-specific capacity cur...

Embodiment 3

[0029] Lithium source Li 2 CO 3 , Purified metatitanic acid H 2 TiO 3 and the three raw materials of glucose as carbon source were mixed uniformly by ball milling according to the following addition ratio, and the molar ratio of Li:Ti was 4.1:5. 2 CO 3 and H 2 TiO 3 , the amount of glucose added is 5% of the sum of the weight of the lithium source and the titanium source; then under a nitrogen atmosphere, the temperature is raised to 350 0 C for 1 hour, then the temperature continued to rise to 900 0 C for another 15 hours; finally cooled to room temperature.

[0030] Carbon-coated Li was prepared by the above method 4 Ti 5 o 12 / C composite powder material is used as the negative electrode active material of lithium ion battery to prepare lithium ion button-type experimental battery, and its electrochemical performance is tested. The results are as follows Figure 5 shown. in Figure 5 The voltage-specific capacity curve of (a) shows that the first discharge / char...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com