Flaky titanium carbide-loaded manganese dioxide composite material for super capacitor electrode material and preparation of flaky titanium carbide-loaded manganese dioxide composite material

A technology for supercapacitors and sheet-shaped titanium carbide, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, and can solve the problems of poor conductivity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

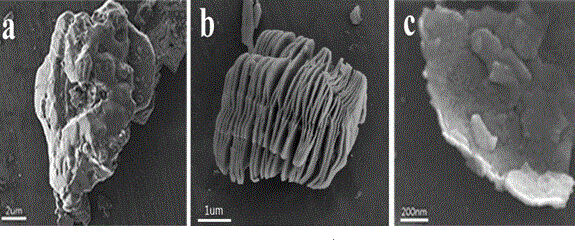

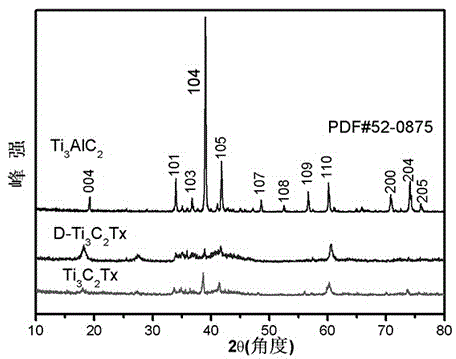

[0055] Ti 3 C 2 T x Preparation: 1gTi 3 AlC 2 Soak the powder in a plastic cup with 5mL 50% HF and stir it electrically for two hours, add 40mL deionized water and stir for 5 minutes, use a 50mL centrifuge tube to centrifuge and wash the solution 5 times until the pH reaches above 6, then vacuum dry at 50°C for 6 hours, grind , get Ti 3 C 2 T x powder;

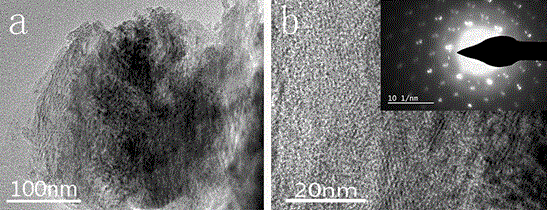

[0056] Monolayer Ti 3 C 2 T x Preparation: Ti 3 C 2 T x Soak the powder in 12mL dimethyl sulfoxide (DMSO) and stir it electrically for 18 hours, add 30mL deionized water, centrifuge at 9000 rpm, then disperse into 300mL degassed water and ultrasonicate for 5 hours; the solution after ultrasonication is obtained by centrifugation at 500rpm The supernatant, and centrifuging the supernatant at 9000rpm, discarding the supernatant, and vacuum drying at 50°C for 12 hours to obtain a titanium carbide powder with a sheet structure;

[0057] Monolayer Ti 3 C 2 T x / MnO 2 Preparation of composite materials: Weigh 1g of...

Embodiment 2

[0061] Ti 3 C 2 T x Preparation: the concentration of HF is 40%, and the dosage is 2.5mL with electric stirring for 1 hour, and the others are the same as in Example 1.

[0062] Monolayer Ti 3 C 2 T x Preparation: The amount of dimethyl sulfoxide (DMSO) was 10 mL, electric stirring for 10 hours, centrifugation at 5000 rpm, and then dispersed in 150 mL of degassed water for 4 hours of ultrasonication; the ultrasonicated solution was centrifuged at 300 rpm to obtain the supernatant, The supernatant was centrifuged at 6000 rpm, discarded, and vacuum-dried at 80° C. for 6 hours to obtain a titanium carbide powder with a sheet-like structure.

[0063] Monolayer Ti 3 C 2 T x / MnO 2 Preparation of the composite material: the mass ratio of the flaky carbonized titanium powder mixed with potassium permanganate was 1:8, the dosage of potassium permanganate was 8 grams, concentrated sulfuric acid was 0.25 mL, stirred for 1 hour, and the others were the same as in Example 1.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com