Solvent-free method of preparing Co-MOF material based on cobalt-containing double metal oxide

A bimetallic oxide, solvent-free technology, applied in the field of MOF material preparation, can solve the problems of large amount of solvent, difficult product separation, complicated steps, etc., and achieve the effects of simple operation, high yield and short process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

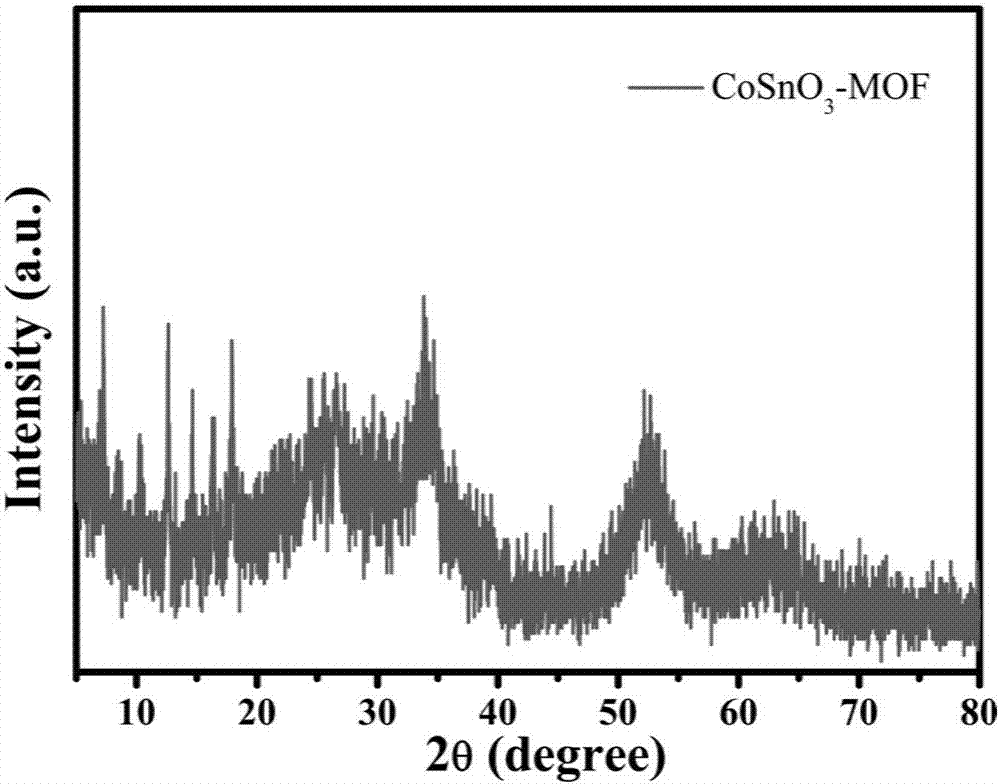

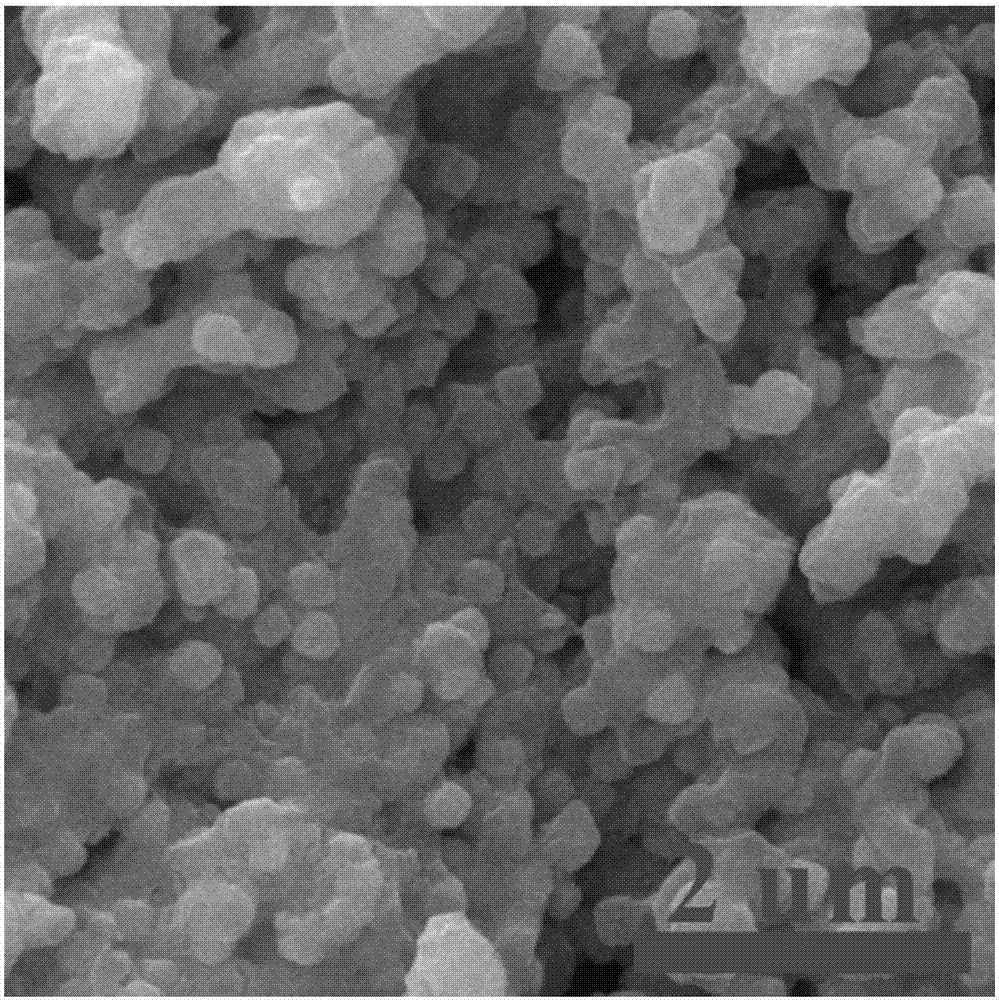

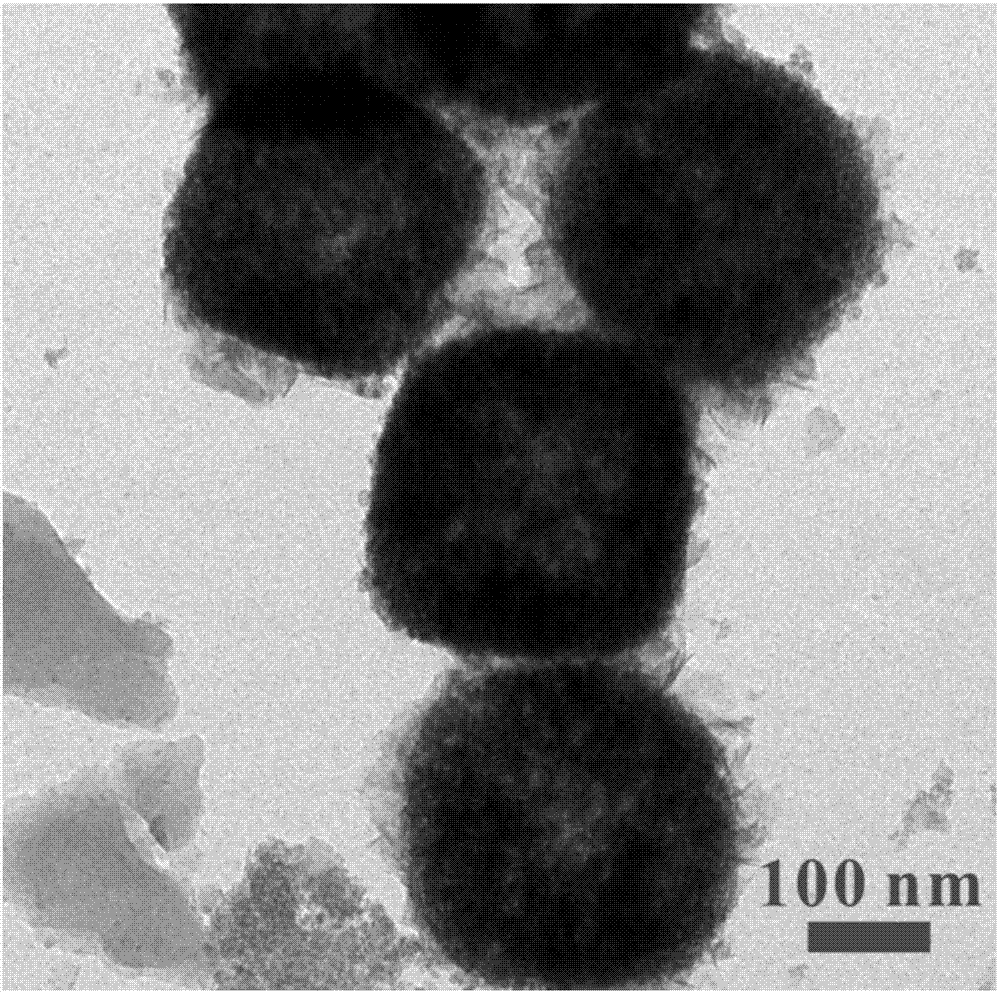

[0027] 200mg hollow nano-CoSnO 3 Mix with 200mg 2-methylimidazole, grind for 30min, put it in a 100mL reaction kettle, seal it, raise the temperature to 160℃ at a heating rate of 5℃ / min and let it stand for reaction for 10h. After the reaction, cool to obtain a grape red solid , ground to obtain about 350 mg Co-MOF. figure 1 It is its XRD picture, it can be seen that the Co-MOF prepared by this method has the same characteristic peaks as the standard Co-MOF (ZIF-67), indicating the reliability of this preparation method. figure 2 It is its scanning electron microscope photo. It can be seen that the obtained Co-MOF is composed of many nanocubes with a diameter of about 200-250nm, and a layer of film-like substance is covered on the surface, and its thickness is about 5-10nm. Connect all nanocube bridges together. image 3 shows the TEM image of the resulting Co-MOF, where CoSnO 3 The hollow nanostructure is still there, and its wall thickness is 20-30 nanometers, and a laye...

Embodiment 2

[0033] 180mg CoSb 2 o 4 Mix with 90mg 2-methylimidazole, grind for 30min, place it in a 50mL reactor, seal it, raise the temperature to 140℃ at a rate of 5℃ / min and let it stand for reaction for 8h. After the reaction, cool to obtain about 250mg Co -MOF, the specific surface area of the obtained MOF material is 168.5m 2 g -1 , much larger than the precursor CoSb 2 o 4 The specific surface area, the thickness of the MOF layer on the surface is 3-5nm, and the particle size range is 500-1000nm.

Embodiment 3

[0037] 100mg CoMnO 3Mix with 500mg 2-methylimidazole, grind for 30min, place it in a 50mL reactor, seal it, raise the temperature to 180℃ at a heating rate of 5℃ / min and let it stand for 6h. After the reaction, cool to obtain about 350mg Co -MOF, its particle size distribution is mainly around 200nm, TEM shows that the surface MOF thickness is in the range of 15-25nm, and the specific surface area is 668.5m 2 g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com