Lithium-sulfur battery iron-based biomass carbon intermediate layer, preparation method thereof and lithium-sulfur battery

A biomass carbon, lithium-sulfur battery technology, applied in battery electrodes, lithium storage batteries, electrode manufacturing, etc., can solve the problems of high cost and complicated preparation process, and achieve the effect of guaranteeing effect, simple preparation process and improving performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A method for preparing an iron-based biomass carbon intermediate layer of a lithium-sulfur battery of the present invention comprises the following steps:

[0035] (1) Use 0.1-1mol / L hydrochloric acid to pickle waste biomass for 2-6 hours, then wash with water until neutral, and dry to obtain biomass. There are many impurities in the waste biomass. After pickling, some impurities are reduced and washed to neutral for subsequent treatment.

[0036] (2) Mix the biomass prepared in step (1) with ferric nitrate, ferric sulfate, and ferric chloride as an iron-containing reagent for 2-6 hours, and dry to obtain iron-based biomass. The mass fraction of the base biomass is 5-15%. If the mass fraction of the iron-containing reagent is too small, the electrochemical performance of the material will be affected, and if the mass fraction is too large, the stability of the material will be affected.

[0037] (3) Place the iron-containing biomass produced in step (2) in a tube furna...

Embodiment 1

[0040] Step 1: Soak waste biomass in 0.1 mol / L hydrochloric acid for 6 hours for pickling, then wash with water until neutral and dry. get biomass.

[0041] Step 2: mixing the biomass with the ferric nitrate solution and ultrasonically vibrating for 2 hours to obtain a solution with a mass fraction of the iron-containing reagent of 8%, and drying to obtain the iron-based biomass.

[0042] Step 3: Put the iron-based biomass produced in Step 2 in a tube furnace fed with argon, heat at 800° C. for 3 hours, and cool to room temperature to obtain iron-based biomass carbon.

[0043] Step 4: After the iron-based biomass produced in Step 3 is pressed into tablets, it is cut into a circular middle layer with a diameter of 16 mm by a cutting machine, and the preparation of the middle layer is completed.

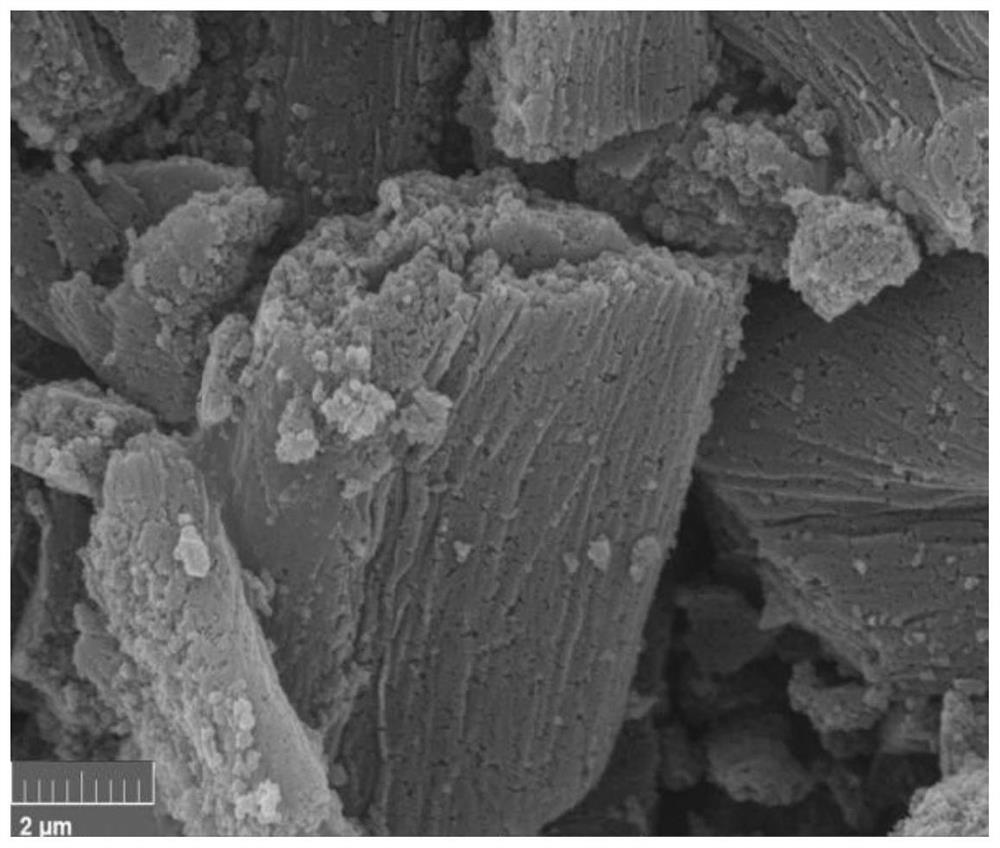

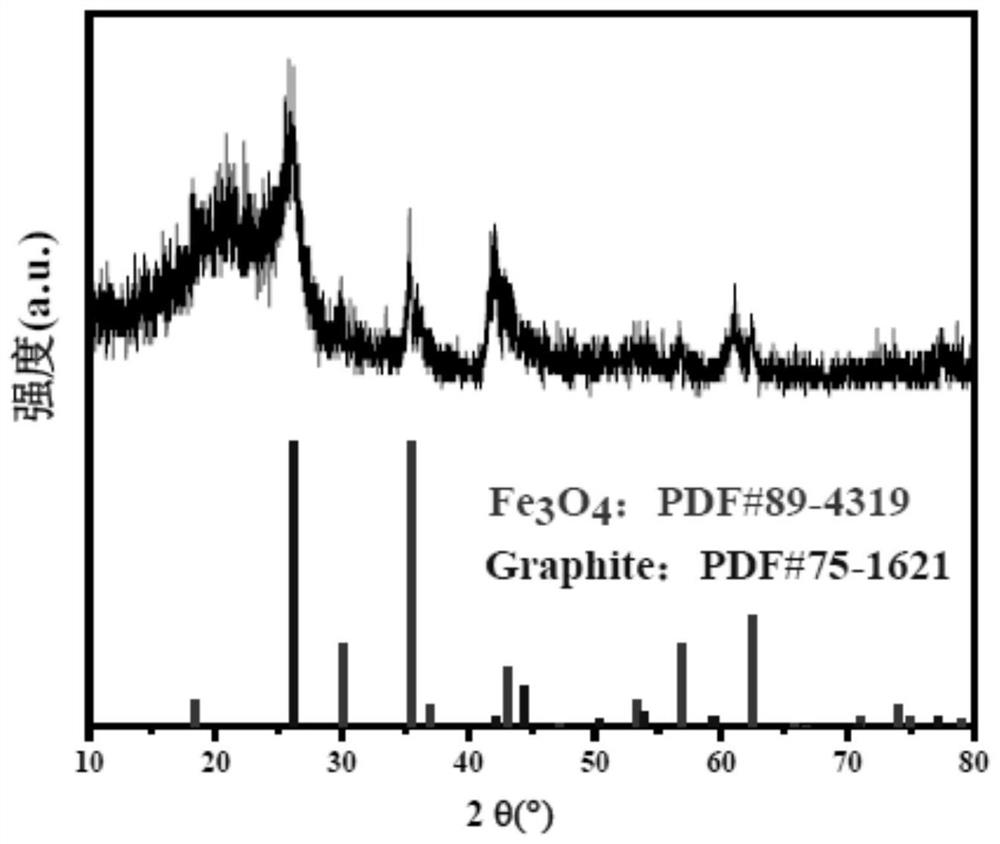

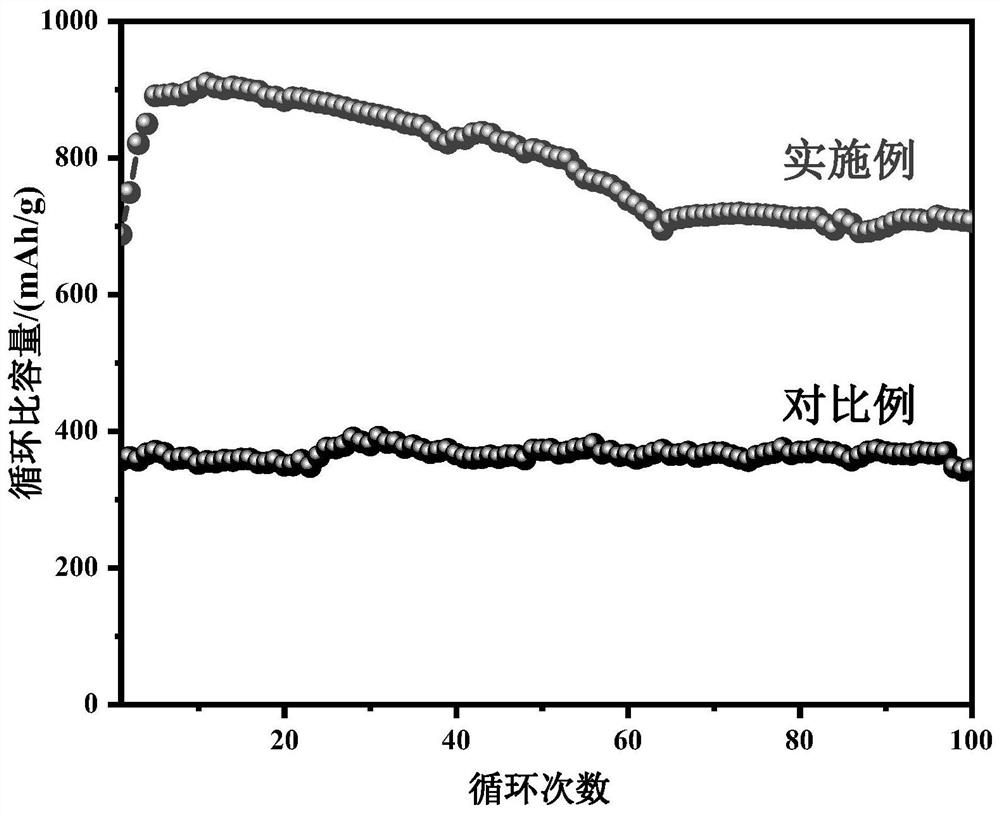

[0044] figure 1It is the SEM image of cotton soft towel as biomass after carbonization in Example 1. From the figure, it can be seen that cotton soft towel can provide a one-dimensio...

Embodiment 2

[0049] Step 1: Soak waste biomass in 0.2 mol / L hydrochloric acid for 5 hours for pickling, then wash with water until neutral and dry. get biomass.

[0050] Step 2: mixing the biomass with the ferric sulfate solution and ultrasonically vibrating for 3 hours to obtain a solution with a mass fraction of the iron-containing reagent of 15%, and drying to obtain the iron-based biomass.

[0051] Step 3: Put the iron-based biomass produced in Step 2 in a tube furnace fed with nitrogen, heat at 900° C. for 3 hours, and cool to room temperature to obtain iron-based biomass carbon.

[0052] Step 4: After the iron-based biomass carbon produced in Step 3 is pressed into sheets, it is cut into a circular middle layer with a diameter of 16 mm by a cutting machine, and the preparation of the middle layer is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com