Red phosphorus modified composite separator, preparation method and application thereof

A composite diaphragm, red phosphorus technology, applied in electrical components, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of increased cost of lithium-sulfur batteries, complex synthesis processes, etc., to facilitate large-scale preparation, improve utilization, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides a preparation method for the above-mentioned composite diaphragm, comprising the following preparation steps:

[0032] Mix nano-nano red phosphorus particles, conductive carbon, binder and solvent to obtain a suspension;

[0033] The suspension is coated on one side of the base diaphragm for the lithium-ion battery, and dried to obtain a red phosphorus-modified composite diaphragm.

[0034] The invention mixes nanometer red phosphorus particles, conductive carbon, binder and solvent to obtain suspension.

[0035] In the present invention, the red phosphorus raw material is preferably ground to prepare nano red phosphorus particles meeting the above particle size requirements.

[0036] In the present invention, the method of grinding preferably adopts the method of ball milling, the time of the ball milling is preferably 4-27h, more preferably 10-20h; the speed of the ball milling is preferably 200-3000r / min, more preferably 500 to 2...

Embodiment 1

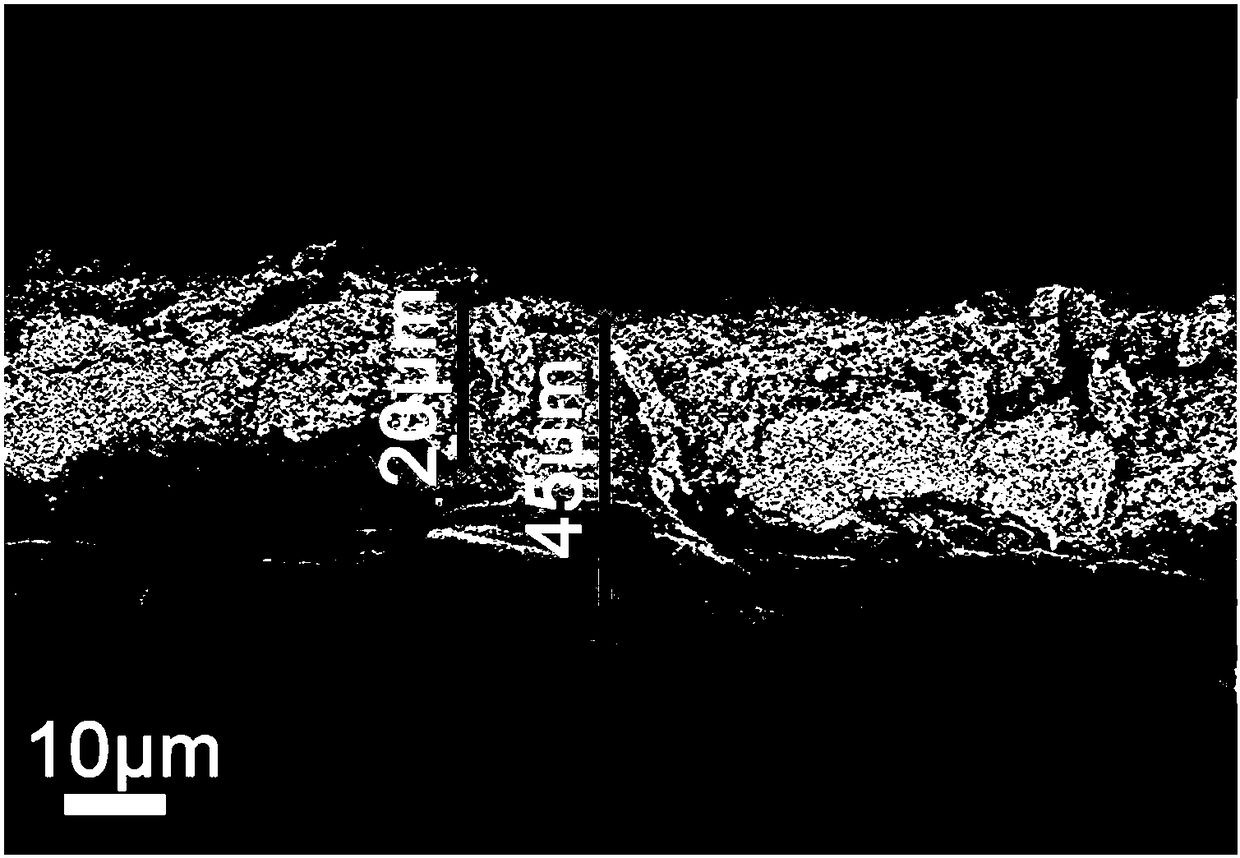

[0058] (1) Put red phosphorus into a ball mill at a speed of 400 rpm, and ball mill for 4 hours to prepare nanometer red phosphorus particles. The SEM images of the prepared nano-red phosphorus particles are as follows: figure 1 shown. From figure 1 It can be seen from the figure that the nano-red phosphorus particles prepared in this embodiment are spherical particles with a size of 50-200 nm, which is conducive to uniform distribution in the composite coating.

[0059] (2) Weigh 10 g of the prepared nano-red phosphorus particles and stir with a 70-g acetylene black mixer at a speed of 300 rpm for 2 hours to uniformly mix the nano-red phosphorus particles with the conductive carbon.

[0060] (3) The PVDF of 20g and the NMP of 200g are mixed with the mixture of nano-red phosphorus particles and conductive carbon in step (2), stirred with a stirrer, and the rotating speed is 800 rpm, and stirred for 8 hours.

[0061] (4) Coating the suspension prepared in step (3) on the PP ...

Embodiment 2

[0064] (1) Put red phosphorus into a ball mill with a rotating speed of 1000 rpm, and ball mill for 72 hours to prepare nano-red phosphorus particles with a particle size of 100-300nm.

[0065] (2) Weigh 200 g of the prepared nano-red phosphorus particles, stir with a 650-g carbon nanotube mixer at a speed of 400 rpm, and stir for 1 hour to uniformly mix the nano-red phosphorus particles with the conductive carbon.

[0066] (3) Weigh 150g of CMC and 1000g of deionized water and the mixture of nano-red phosphorus particles and conductive carbon in step 2, stir with a stirrer at a speed of 2000 rpm, and stir for 6 hours.

[0067] (4) Coating the suspension prepared in step (3) on the PP diaphragm, controlling the thickness to 20 microns, and drying at 70° C. to obtain a red phosphorus-modified composite diaphragm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com