Method for preparing lithium-sulfur battery positive electrode material of composite metal organic framework

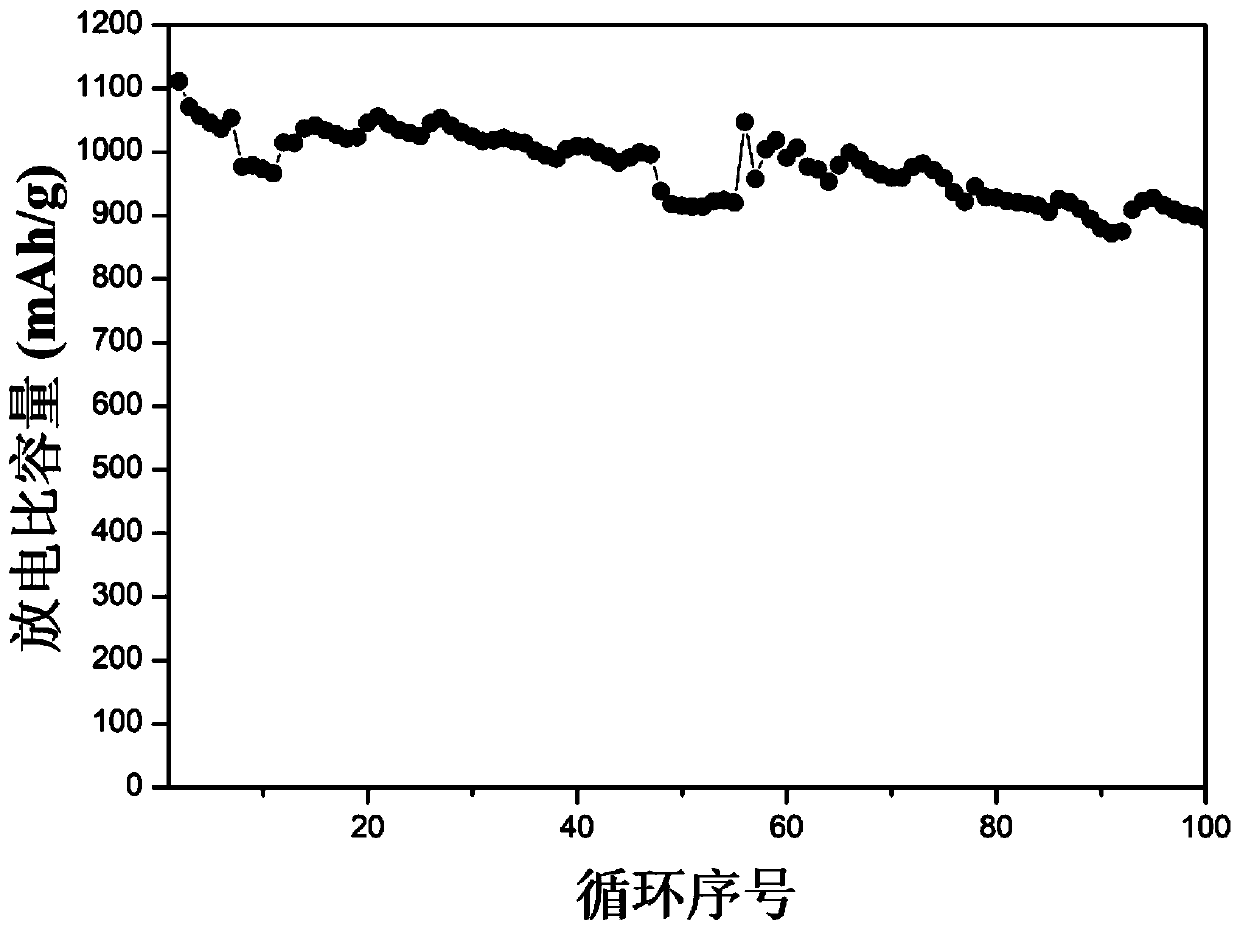

An organic framework and lithium-sulfur battery technology, applied in the field of material chemistry, can solve the problems of poor cycle performance of lithium-sulfur batteries, corrosion of metal lithium, loss of active materials, loss of active materials, etc., to improve redox reaction kinetics, excellent cycle Stability, the effect of inhibiting the shuttle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

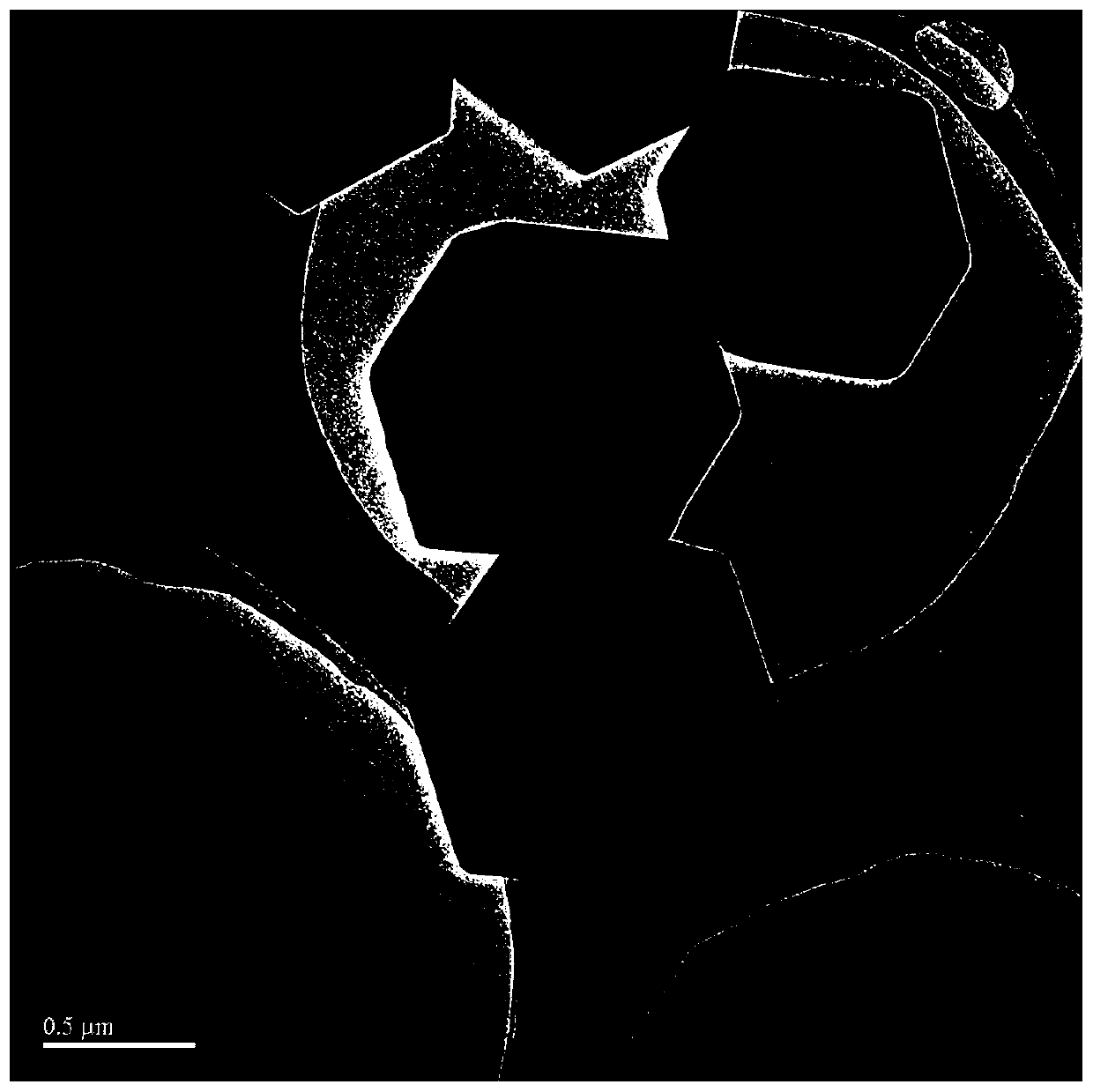

[0029] Step 1: Synthesize ZIF67 material:

[0030] 1.145g Co(NO 3 ) 2 ·6H 2 O was dissolved in 125ml of methanol, stirred until completely dissolved to obtain Co(NO 3 ) 2 ·6H 2 O solution. 1.640 g of 2-methylimidazole (Hmim) was dissolved in 125 mL of methanol, and stirred until completely dissolved to obtain a 2-methylimidazole solution. Pour the 2-methylimidazole solution slowly into Co(NO 3 ) 2 ·6H 2 In the O solution, stir for 30 min. After the purple clear liquid turns into a purple turbid liquid, leave it to stand and age for 24 hours, and centrifuge to collect the precipitate. Subsequently, it was washed 5 times with methanol, 2 times with ethanol, and dried in vacuum at 60° C. for 24 hours to obtain ZIF67 material.

[0031] Step 2: Synthesize ZIF67 / ZnO material:

[0032] 0.3864g Zn(CH 3 COO) 2 ·H 2 O was added to 50ml methanol, put on the heating plate at 65℃ and stirred until completely dissolved to obtain Zn(CH 3 COO) 2 ·H 2 O solution. Put 0.2384g of KOH into 40ml of me...

Embodiment example 2

[0038] Step 1: Synthesize ZIF67 material:

[0039] 1.145g Co(NO 3 ) 2 ·6H 2 O was dissolved in 125ml of methanol, stirred until completely dissolved to obtain Co(NO 3 ) 2 ·6H 2 O solution. 1.640 g of 2-methylimidazole (Hmim) was dissolved in 125 mL of methanol, and stirred until completely dissolved to obtain a 2-methylimidazole solution. Pour the 2-methylimidazole solution slowly into Co(NO 3 ) 2 ·6H 2 In the O solution, stir for 30 min. After the purple clear liquid turns into a purple turbid liquid, leave it to stand and age for 24 hours, and centrifuge to collect the precipitate. Then it was washed with methanol for 5 times by centrifugation, and washed with ethanol for 2 times, and dried in vacuum at 60° C. for 24 hours to obtain the ZIF67 material.

[0040] Step 2: Synthesis of ZIF67 / ZnO:

[0041] 0.3864g Zn(CH 3 COO) 2 ·H 2 O was added to 50ml methanol, put on the heating plate at 65℃ and stirred until completely dissolved to obtain Zn(CH 3 COO) 2 ·H 2 O solution. Put 0.238...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com