Metal intercalation molybdenum oxide material as well as preparation method and application thereof

A technology of molybdenum oxide and molybdenum oxide powder, which is applied in the direction of electrical components, battery electrodes, non-aqueous electrolyte storage batteries, etc., can solve the problems that cannot meet the urgent needs of high energy density energy storage devices, achieve the suppression of shuttle effect, improve discharge capacity, The effect of high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

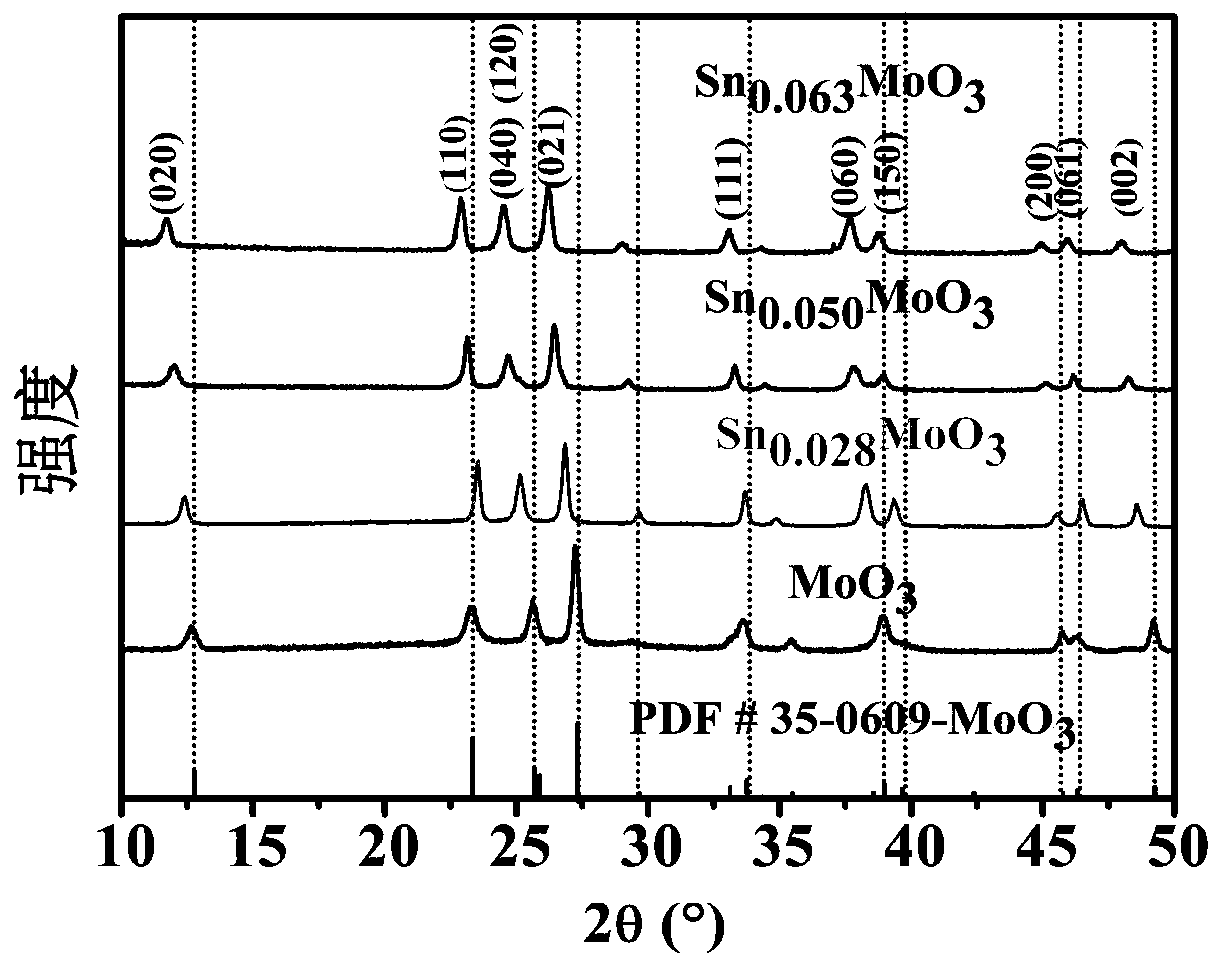

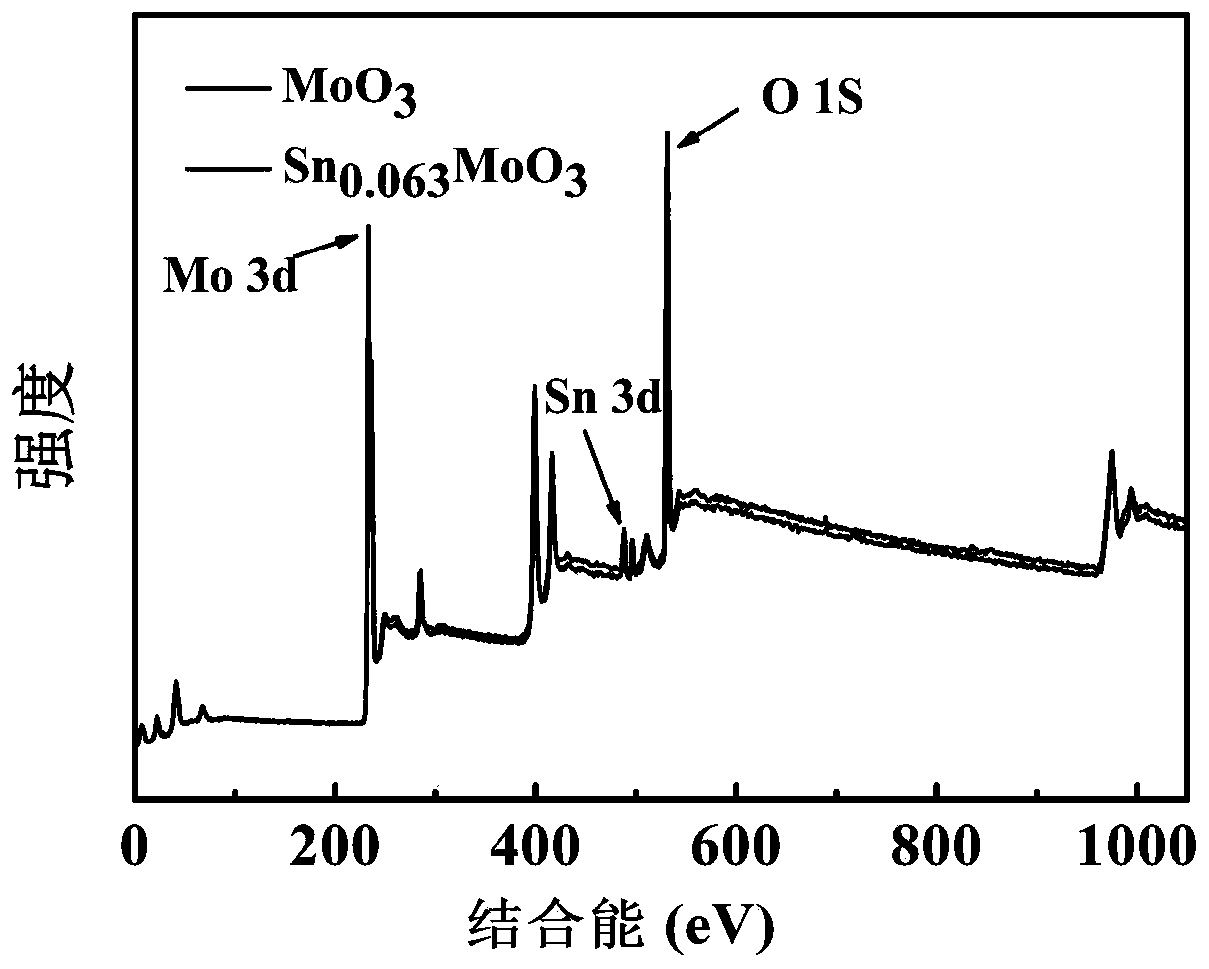

[0045] This embodiment provides a tin-intercalated molybdenum oxide material and a preparation method thereof, and the specific steps are as follows:

[0046] 1. Preparation of molybdenum oxide precursor

[0047] Add 0.2g of molybdenum powder into a 100mL hydrothermal reaction kettle, then add 20mL of deionized water and stir for 10min, then add 10mL of hydrogen peroxide, stir for 30min, transfer to an oven at 160°C for 10h, and then place the mixture at a low temperature of 0°C Cool down for 24 hours, wash the obtained solution three times with deionized water and ethanol respectively, and obtain a molybdenum oxide powder with a thickness of about 10 nm;

[0048] 2. Preparation of tin-intercalated molybdenum oxide

[0049] The obtained molybdenum oxide powder was uniformly dispersed in an acetone solution, 20 mg of stannous chloride was added while stirring, and 40 mg of tartaric acid was added, and reacted at 80° C. for 1 h. Naturally cooled to room temperature, washed wit...

Embodiment 2

[0051] This example provides a molybdenum oxide positive electrode material for a lithium-sulfur battery based on intercalation technology and its preparation. The specific steps are as shown in Example 1, and the difference is:

[0052] The molar ratio of tin to the molybdenum oxide is 0.028:1.

Embodiment 3

[0054] This example provides a molybdenum oxide positive electrode material for a lithium-sulfur battery based on intercalation technology and its preparation. The specific steps are as shown in Example 1, and the difference is:

[0055] The molar ratio of tin to the molybdenum oxide is 0.050:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com