Electrode structure of lithium sulfur battery and processing technology therefor

An electrode structure, lithium-sulfur battery technology, applied in the direction of battery electrodes, non-aqueous electrolyte battery electrodes, electrode manufacturing, etc., can solve the problems of low utilization rate of positive electrode sulfur, short cycle life, etc., to suppress the shuttle effect, improve cycle life, Facilitate the effect of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

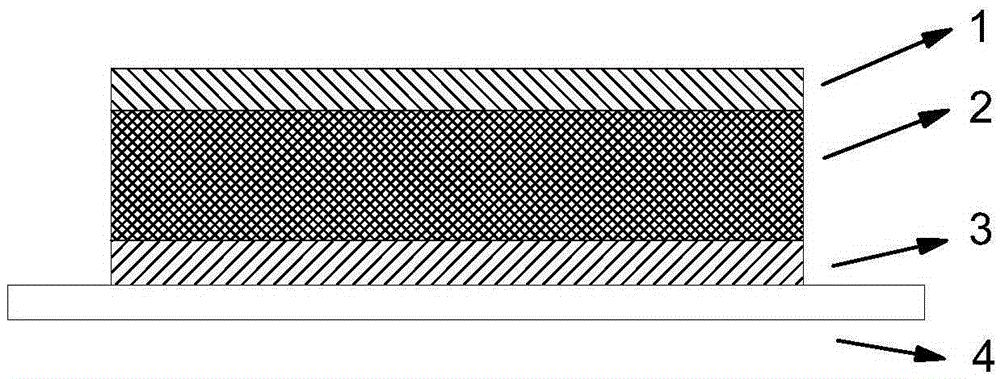

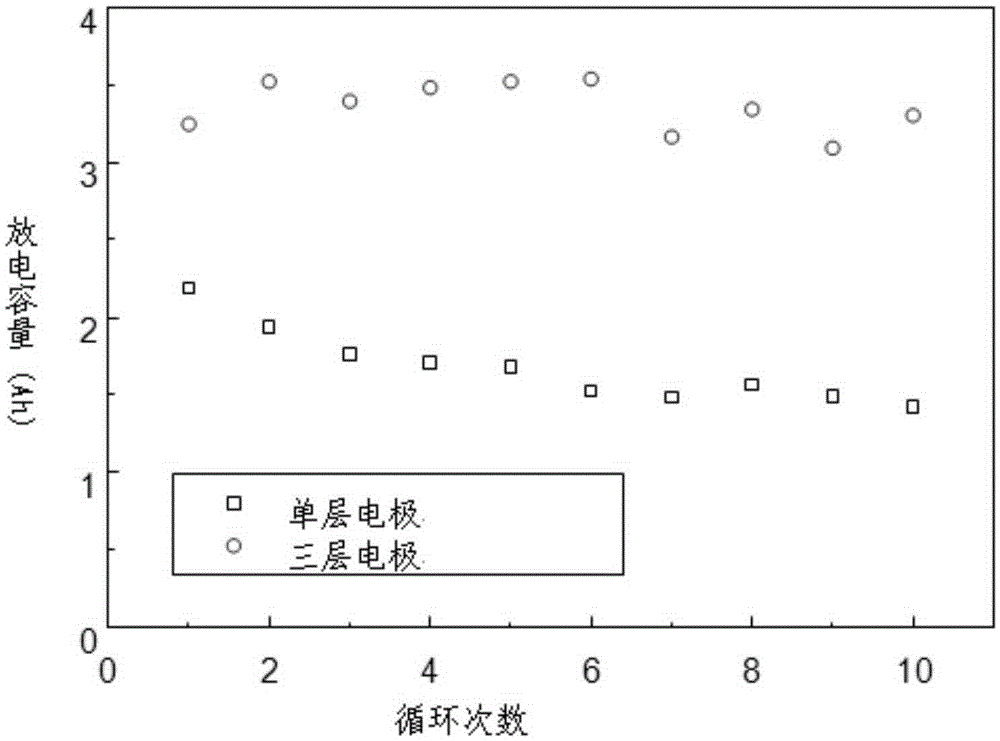

[0028] see figure 1 and figure 2 , an electrode structure of a lithium-sulfur battery, comprising a sulfur-containing active material layer 2 and a current collector 4; the upper surface of the active material layer 2 is coated with a first carbon coating 1, and the active material layer 2 The lower surface of the is coated with a second carbon coating 3 located between the active material layer 2 and the current collector 4 .

[0029] Further: the specific surface area of the first carbon coating 1 is greater than 20m 2 / g.

[0030] Further: the bulk density of the first carbon coating 1 is less than 1g / m 3 .

[0031] Further: the specific surface area of the second carbon coating 3 is greater than 20m 2 / g.

[0032] Further: the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com