One-step in-situ preparation method of rGO/VS4/S compound as lithium sulfur battery cathode material

An in-situ preparation technology for lithium-sulfur batteries, applied in battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve problems such as the inability to meet the electrochemical performance requirements of sulfur cathodes, achieve the suppression of shuttle effects, and be easy to popularize and prepare The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

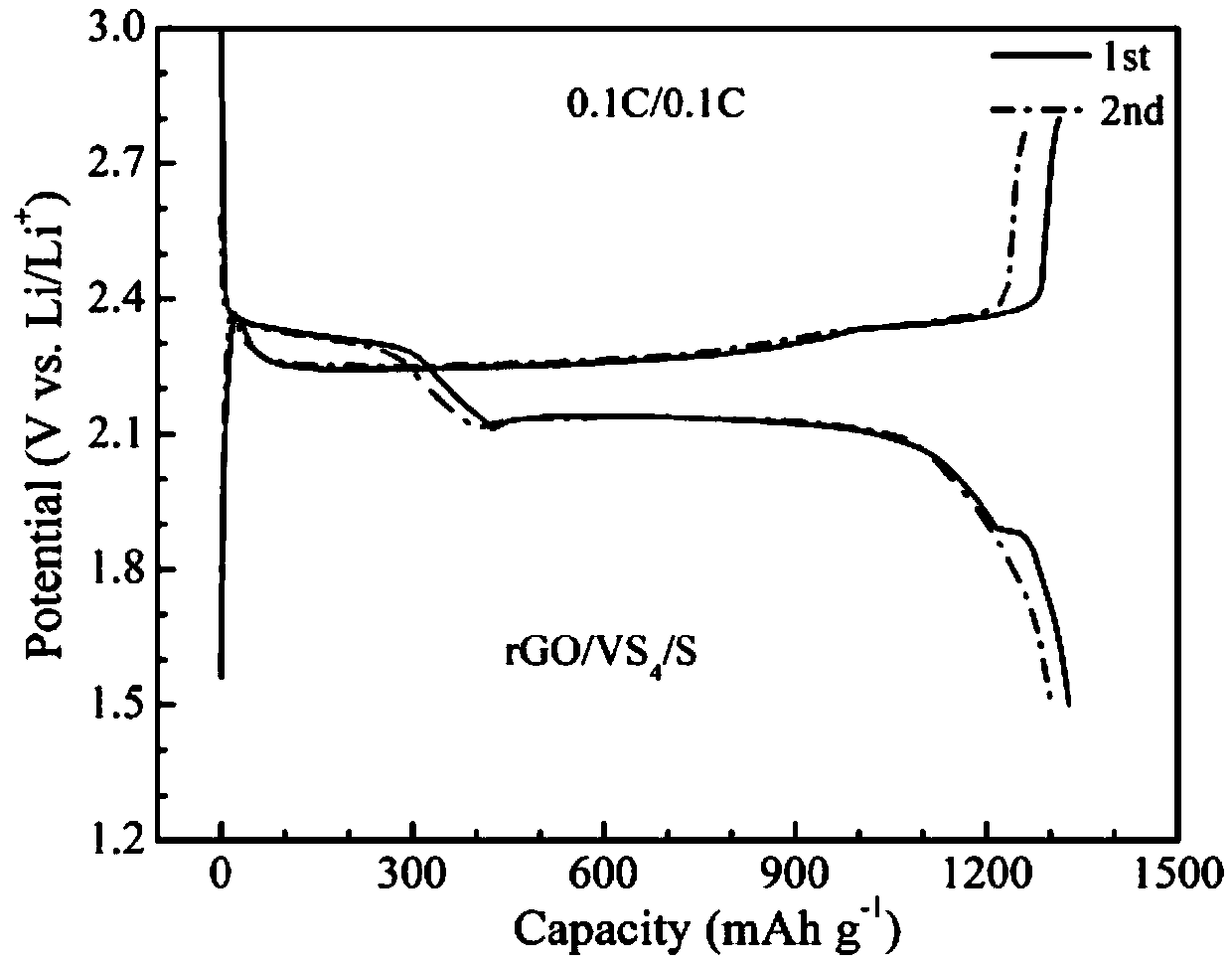

[0031] In order to improve the conductivity and utilization rate of the sulfur cathode, suppress the "shuttle effect" of polysulfide ions in the charging and discharging process, and meet the market's needs for the electrochemical performance of the above-mentioned sulfur cathode, the present invention proposes a one-step method to prepare rGO / VS 4 / S composites as cathode materials for high-performance lithium-sulfur batteries. The preparation method comprises the following steps:

[0032] First, the stoichiometric ratio of vanadium source and sulfur source is added to the graphene oxide (GO) solution, so that the molar ratio of sulfur to vanadium element S / V>10, and an appropriate amount of oxidant is added, stirred evenly, and the above solution is added to the hydrothermal reaction Kettle, carry out hydrothermal reaction at a certain temperature, at this time S 2– oxidized to S by oxidant 2 2– , first generate VS on the rGO surface 4 , get rGO / VS 4 complex, while the ...

Embodiment 1

[0042] Embodiment 1rGO / VS 4 / S (S content 70%) complex

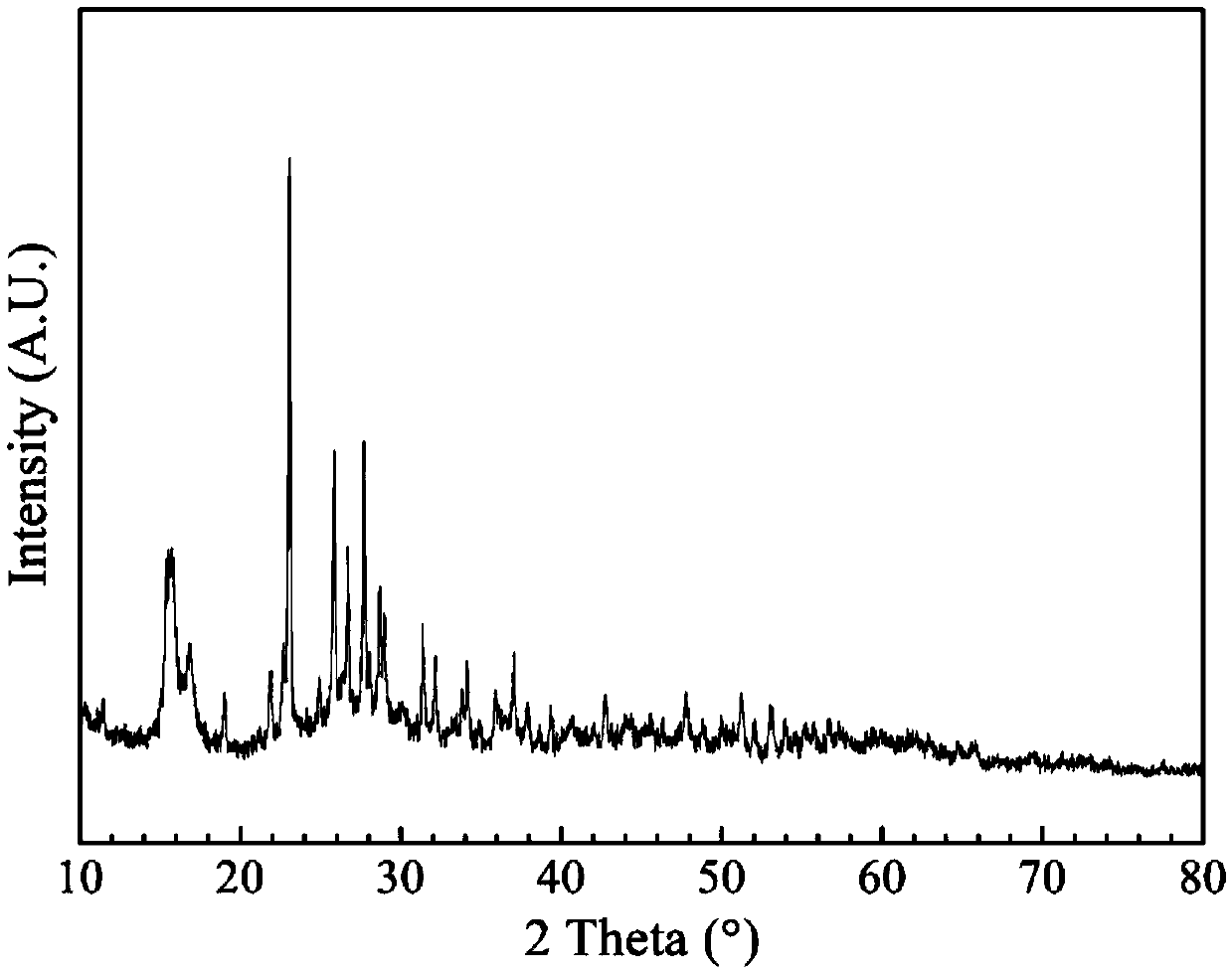

[0043] Weigh 0.3575g Na 3 VO 4 12H 2 O as vanadium source and 1.82g thioacetamide as sulfur source were added to 80mL graphene oxide (GO, 2mg / mL) solution so that the molar ratio of sulfur to vanadium was S / V=27, and 1mL HNO was added 3 As an oxidant, stir evenly, add the above solution into a hydrothermal reactor, and conduct a hydrothermal reaction at 160°C for 24 hours to prepare rGO / VS 4 / S complex, where rGO / VS 4 / S mass content ratio is about 15%: 15%: 70% wt., its XRD is as follows figure 1 .

Embodiment 2

[0046] Example 2: rGO / VS 4 / S (S content 85%) complex

[0047] Weigh 0.447g Na 3 VO 4 12H 2 O as vanadium source and 4.068g thioacetamide as sulfur source were added to 50mL graphene oxide (GO, 2mg / mL) solution so that the molar ratio of sulfur to vanadium was S / V=48, and 1mL H 2 o 2 As an oxidant, stir evenly, add the above solution into a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 160°C for 20 hours to prepare rGO / VS 4 / S complex, where rGO / VS 4 / S mass content ratio is about 5%: 10%: 85% wt., its SEM is as figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com