A preparation method of hybrid surface of layered cathode material for lithium ion battery

A technology for lithium ion batteries and positive electrode materials is applied in the field of preparation of hybrid surfaces of layered positive electrode materials for lithium ion batteries, and achieves the effects of stabilizing the surface structure, improving electrochemical performance, and being easy to popularize.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method comprises the following steps:

[0040] The first step: preparing a Ni-Co-Mn precursor according to the molar ratio of the transition metal element shown in the general formula of the layered positive electrode material;

[0041] There are multiple methods for preparing Ni-Co-Mn precursors in the prior art. From the perspective of synthesis effect, the present invention adopts the co-precipitation method to synthesize Ni-Co-Mn precursors. The types of the precursors include [Ni 1-x-y co x mn y ](OH) 2 or [Ni 1-x-y co x mn y ]CO 3 , can be prepared by conventional methods in the prior art, for example, by one or both of hydroxide or carbonate co-precipitation methods.

[0042] The second step: the Ni-Co-Mn precursor obtained in the above steps is placed in a polyanion (XO 4 ) n- solution, stirred at 20-80°C for 1-12h, wherein the molar ratio of the polyanion to the transition metal ion in the solution is (XO 4 ) n- / (Ni-Co-Mn)=0.02~0.1, at...

Embodiment 1

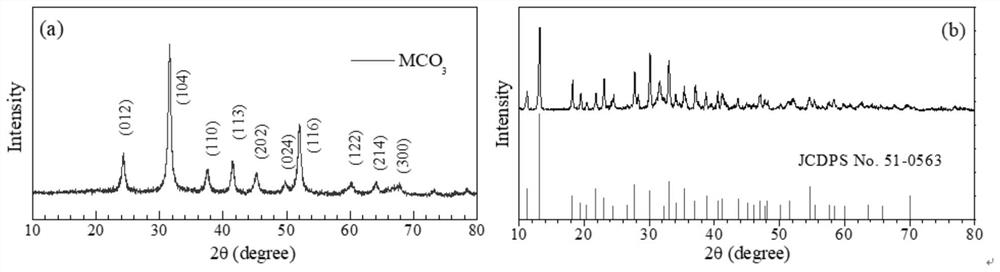

[0066] Embodiment 1 prepares precursor [Ni 1 / 6 co 1 / 6 mn 4 / 6 ]CO 3

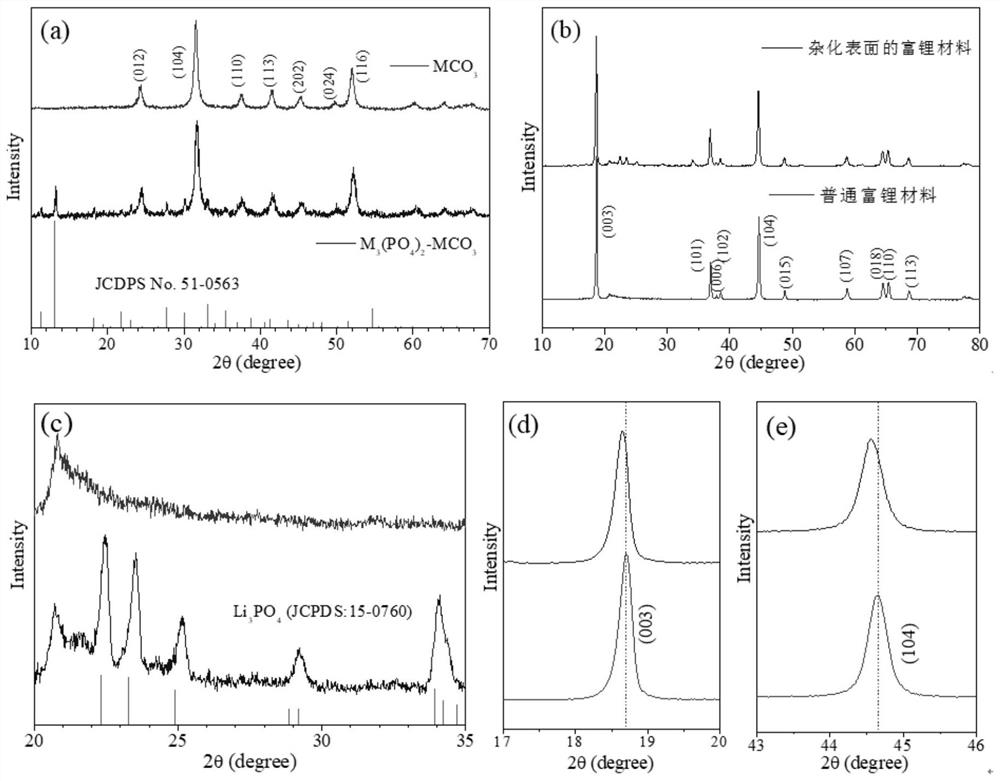

[0067] Weigh 2.19Kg NiSO 4 ·6H 2 O, 2.34Kg CoSO 4 ·7H 2 O and 5.63Kg MnSO 4 ·H 2 O preparation concentration is 25L of 2M salt solution. Add the above salt solution to 1L h -1 The speed is added dropwise to the rotating speed of 600rpm in the continuous stirring reactor, and at the same time with 5M Na 2 CO 3 The mixed solution of the solution and 0.5M ammonia solution controls the pH value in the kettle to about 8 until the salt solution is completely consumed, and the precipitate is centrifuged, washed, and dried to obtain the precursor [Ni 1 / 6 co 1 / 6 mn 4 / 6 ]CO 3 , its XRD such as figure 1 shown. The precursor (Ni 1 / 6 co 1 / 6 mn 4 / 6 )CO 3 Put in 0.1M KH 2 PO 4 (50ml) The M formed after stirring the solution for 4h 3 (PO 4 ) 2 Coating (Ni 1 / 6 co 1 / 6 mn 4 / 6 )CO 3 ,Such as figure 2 (a). The M 3 (PO 4 ) 2 Coating (Ni 1 / 6 co 1 / 6 mn 4 / 6 )CO 3 with stoichiometric battery-g...

Embodiment 2

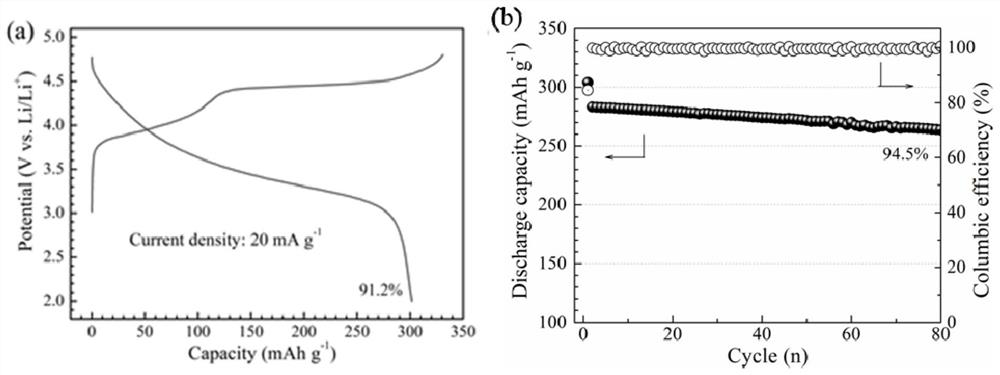

[0071] The hybrid surface lithium-rich layered positive electrode material of Example 1 was prepared as an electrode, and a 2032 button battery was assembled, and a charge-discharge test was performed at a voltage of 2.0-4.8V and a current density of 20mA / g. The hybrid surface lithium-rich layered Cathode material Li 1.2 [Ni 0.13 co 0.13 mn 0.54 ]O 2 The discharge specific capacity in the first week is 301.2mAh / g, such as image 3 Shown in (a); Its capacity retention rate is 94.5% after 80 weeks of charge-discharge cycles, as image 3 (b) shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com