Patents

Literature

84results about How to "Stable surface structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanosurface

ActiveUS20100173264A1Reduced strengthReduce the amount requiredMaterial nanotechnologyDental implantsNanostructureOxalic acid

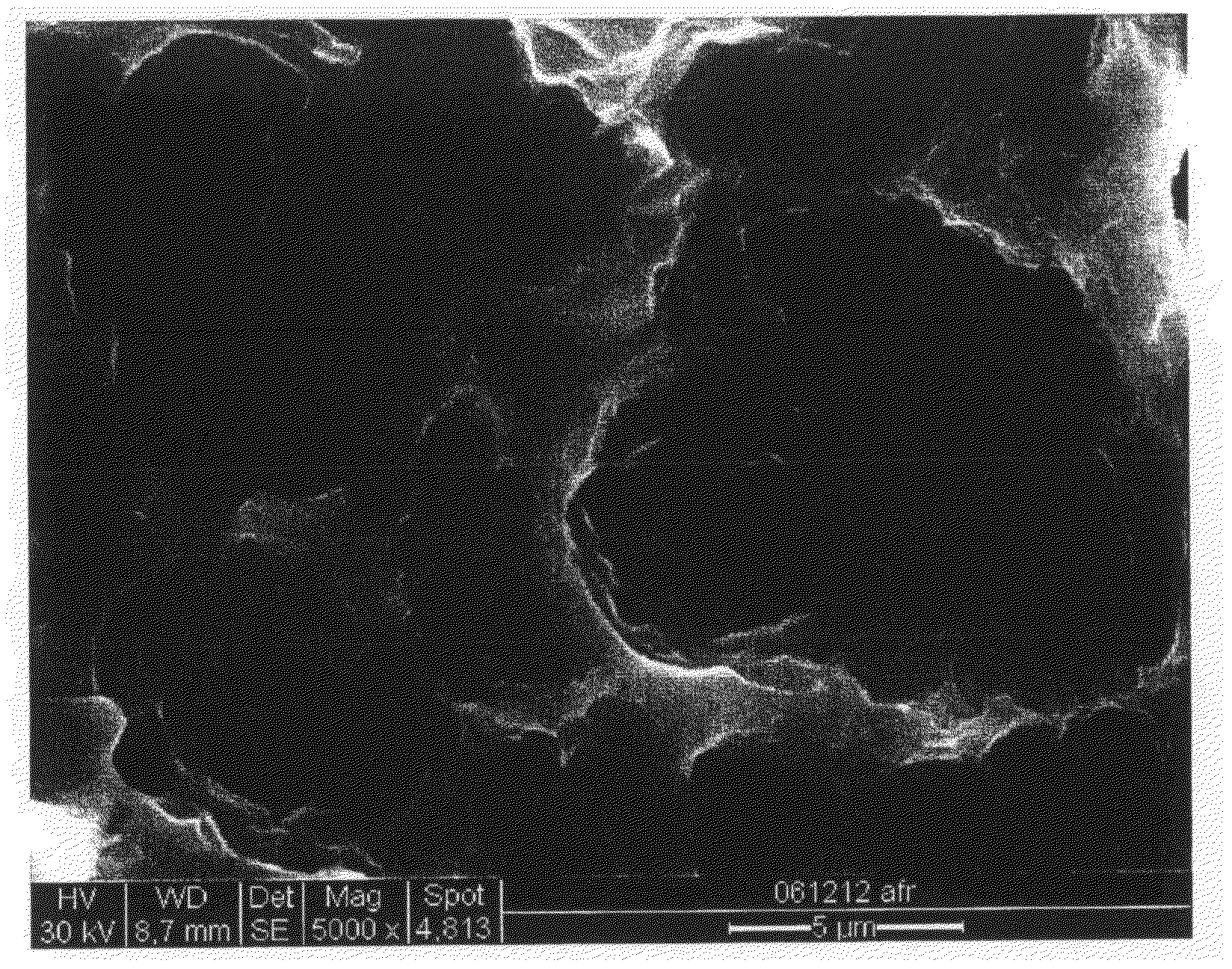

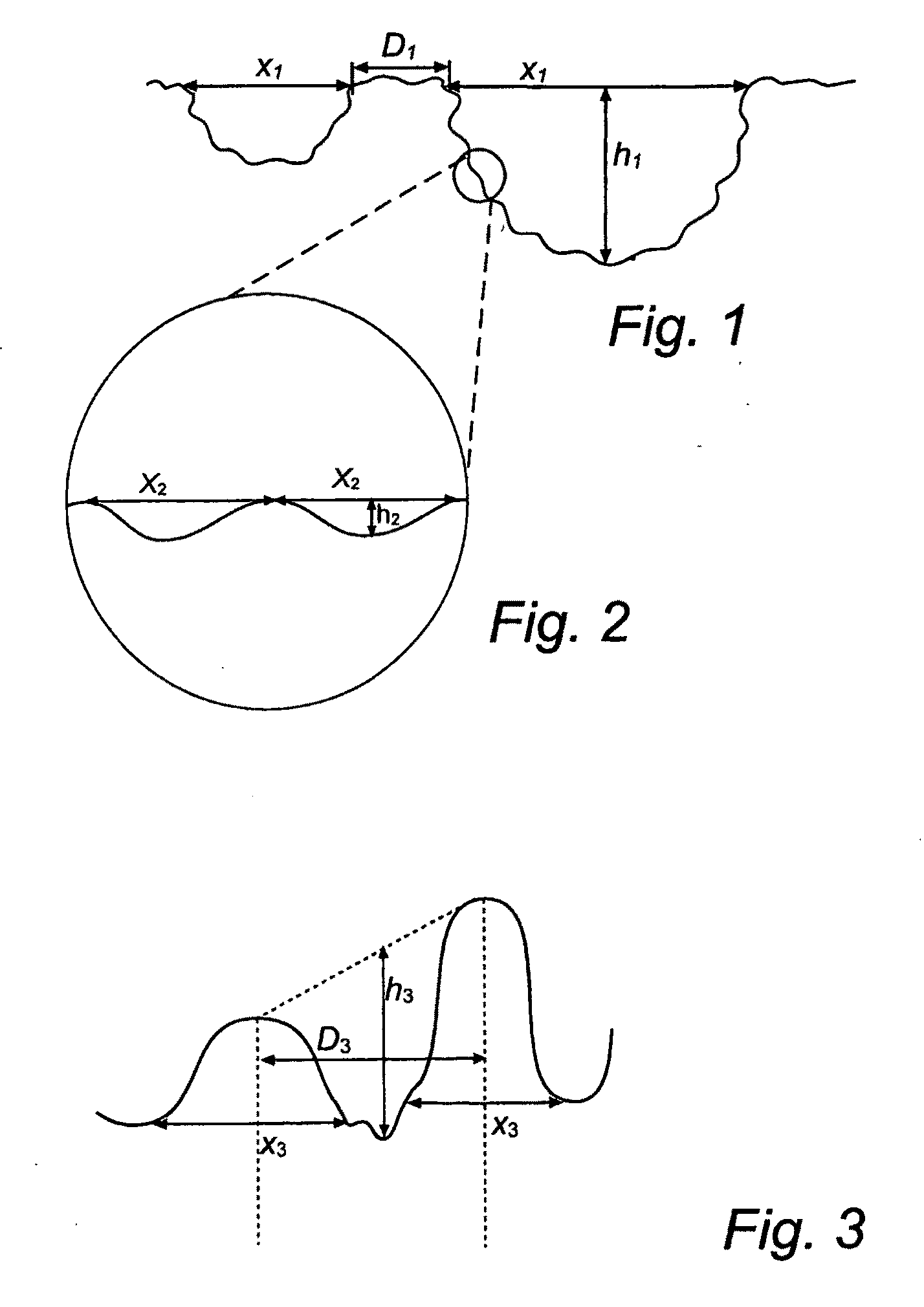

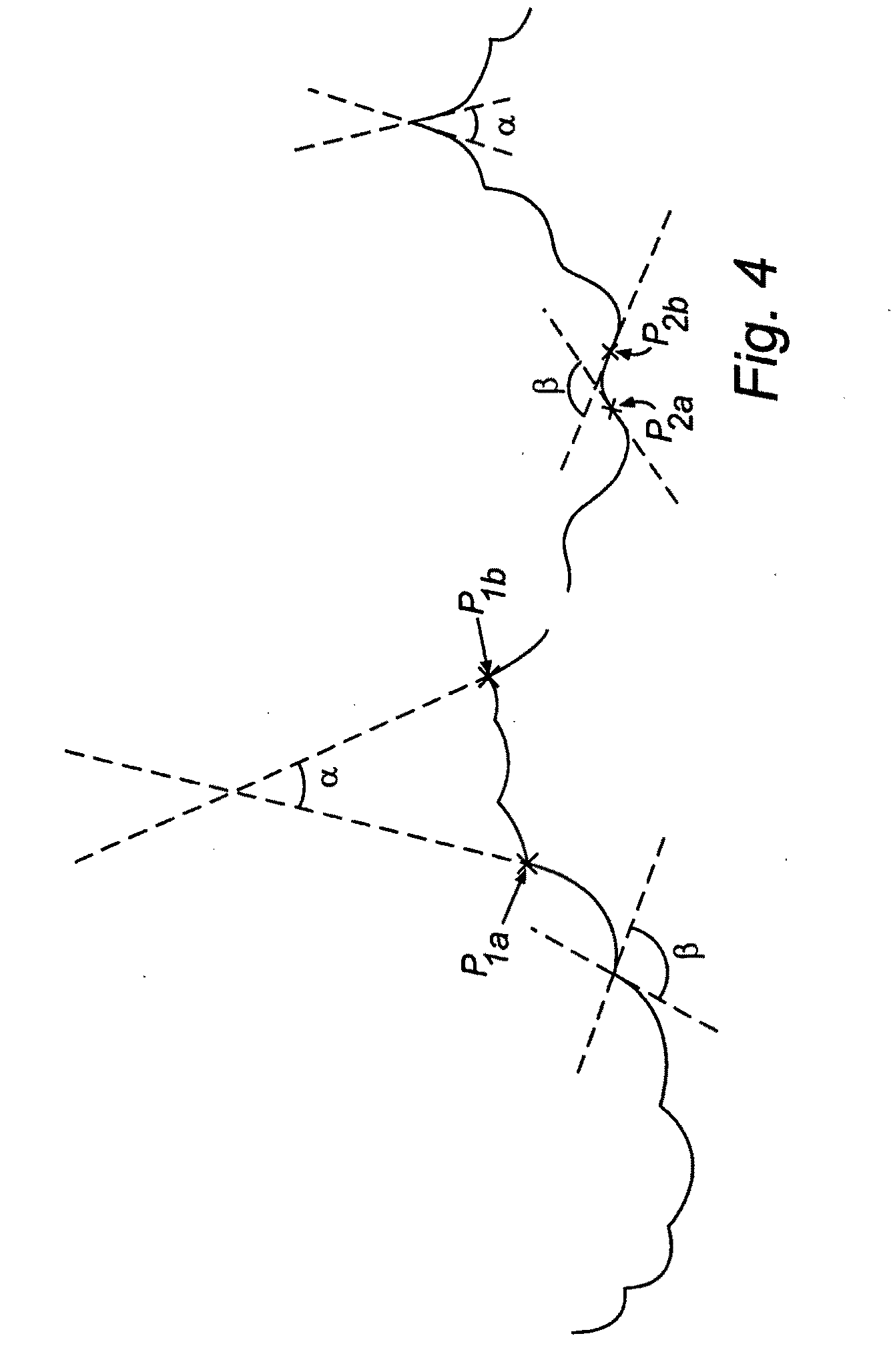

The invention relates to a method for modification of a biocompatible component comprising the steps of a) providing a biocompatible component at least partly covered by metallic oxide; and b) treating at least a part of said component, which part is covered by said metallic oxide, with an aqueous composition comprising oxalic acid; whereby a modified metallic oxide is obtained. The invention also relates to a biocompatible component comprising a substrate having a surface comprising a) a microstructure comprising pits separated by plateus and / or ridges; and b) a primary nanostructure being superimposed on said microstructure, said primary nanostructure comprising depressions arranged in a wave-like formation.

Owner:ASTRA TECH SE

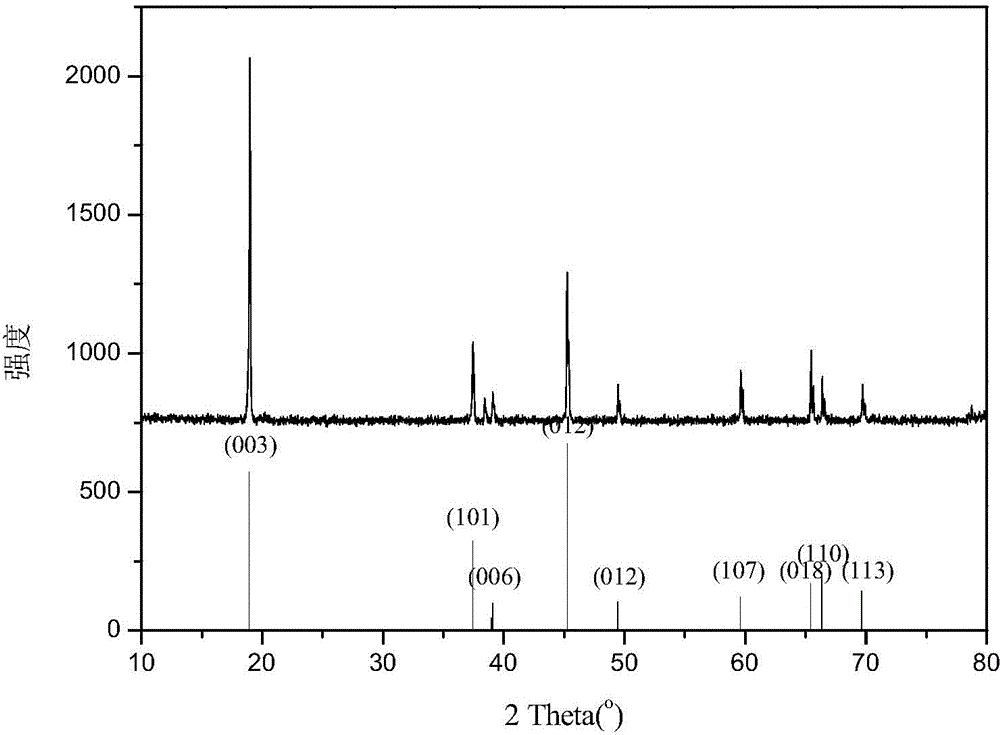

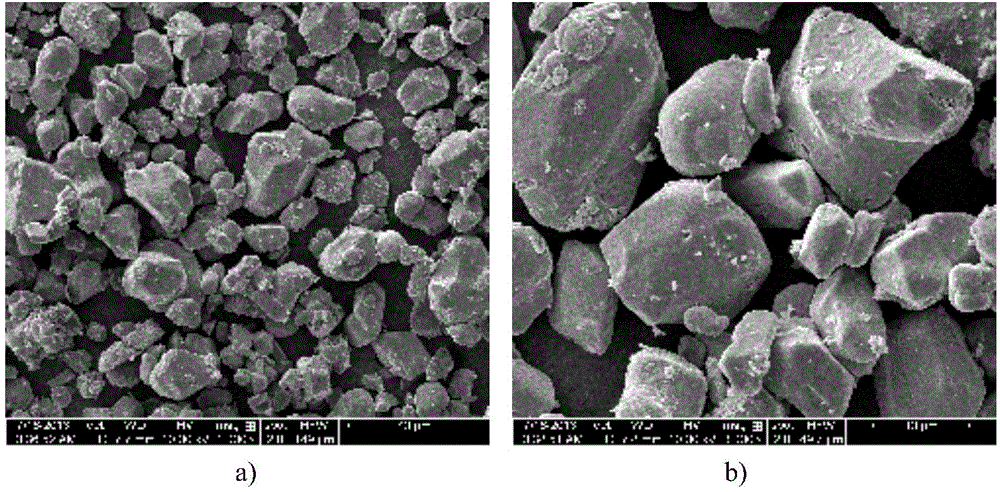

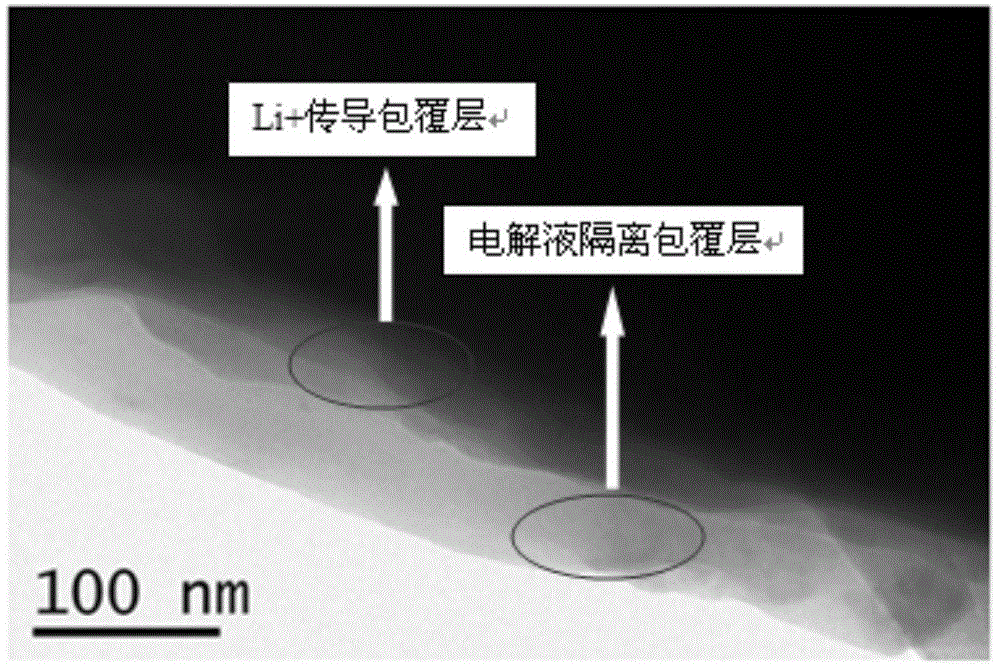

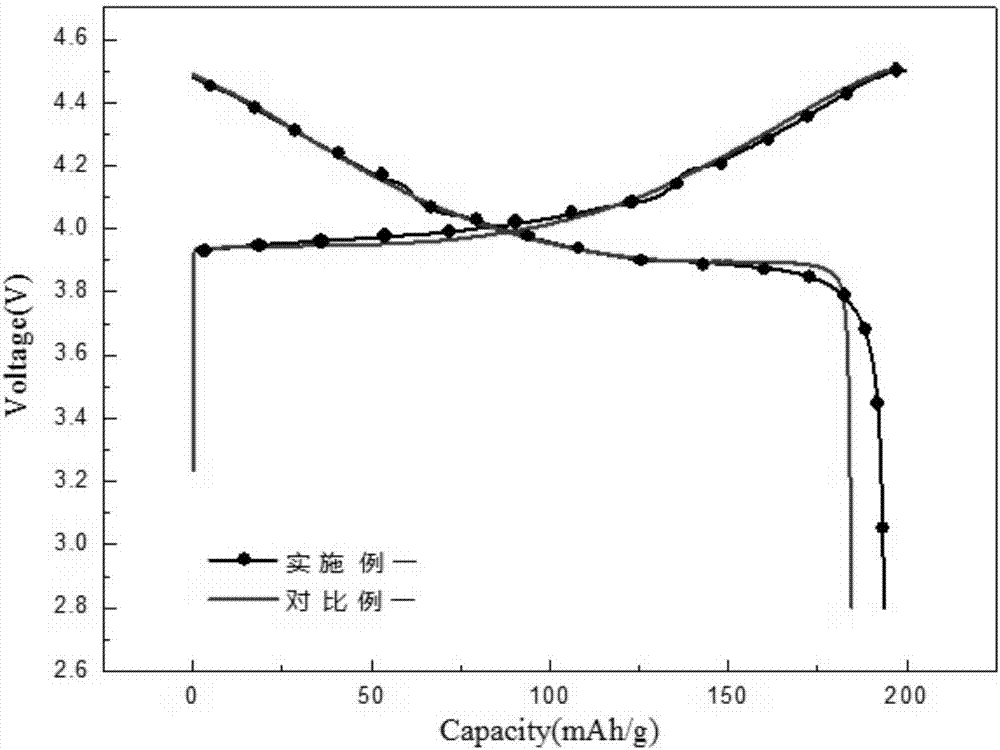

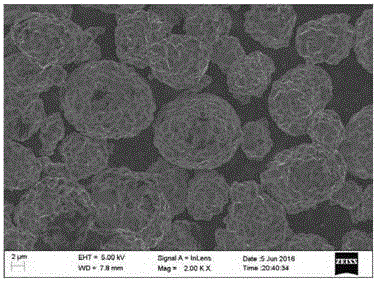

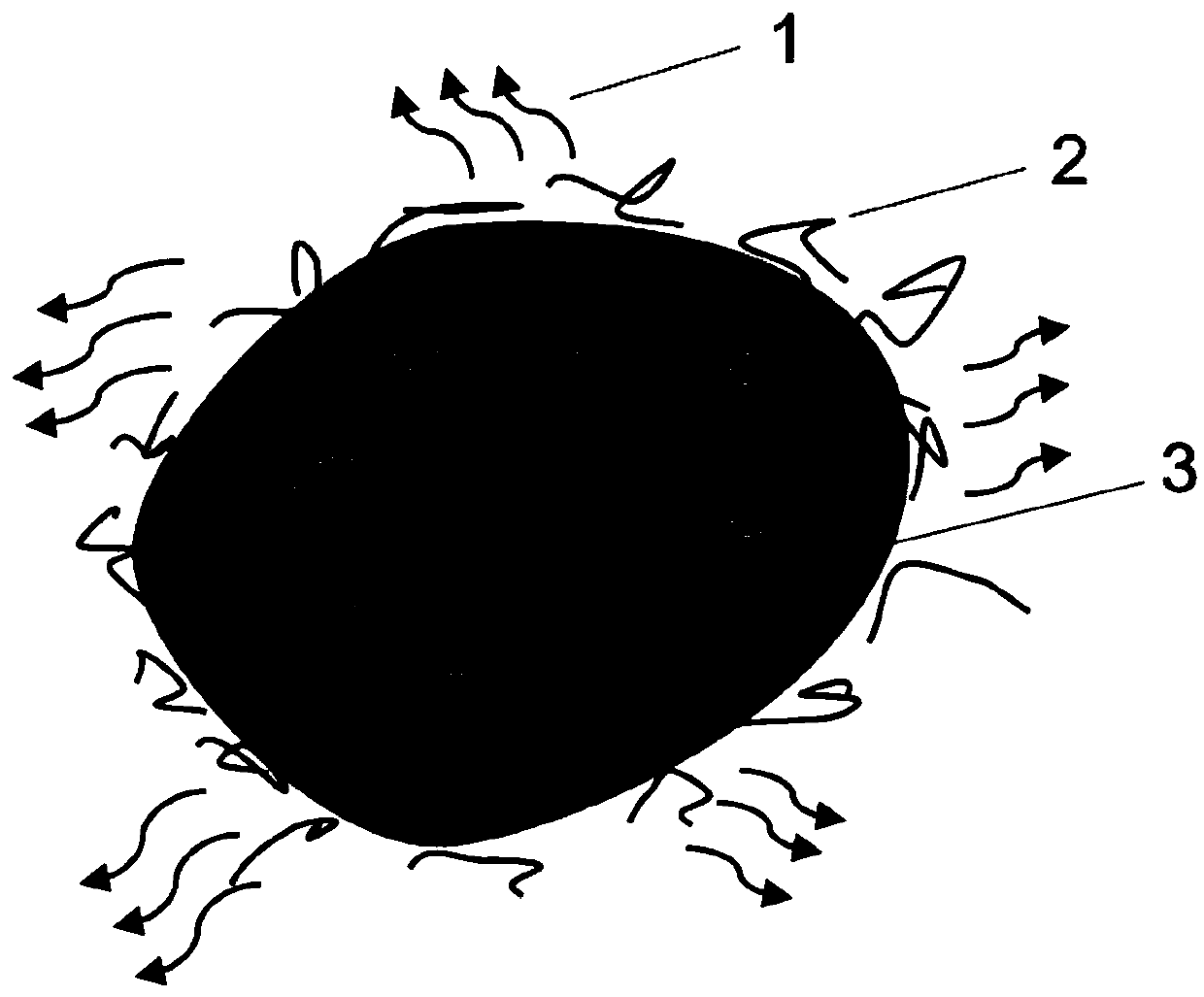

Surface-modified lithium cobaltate material and preparation method thereof

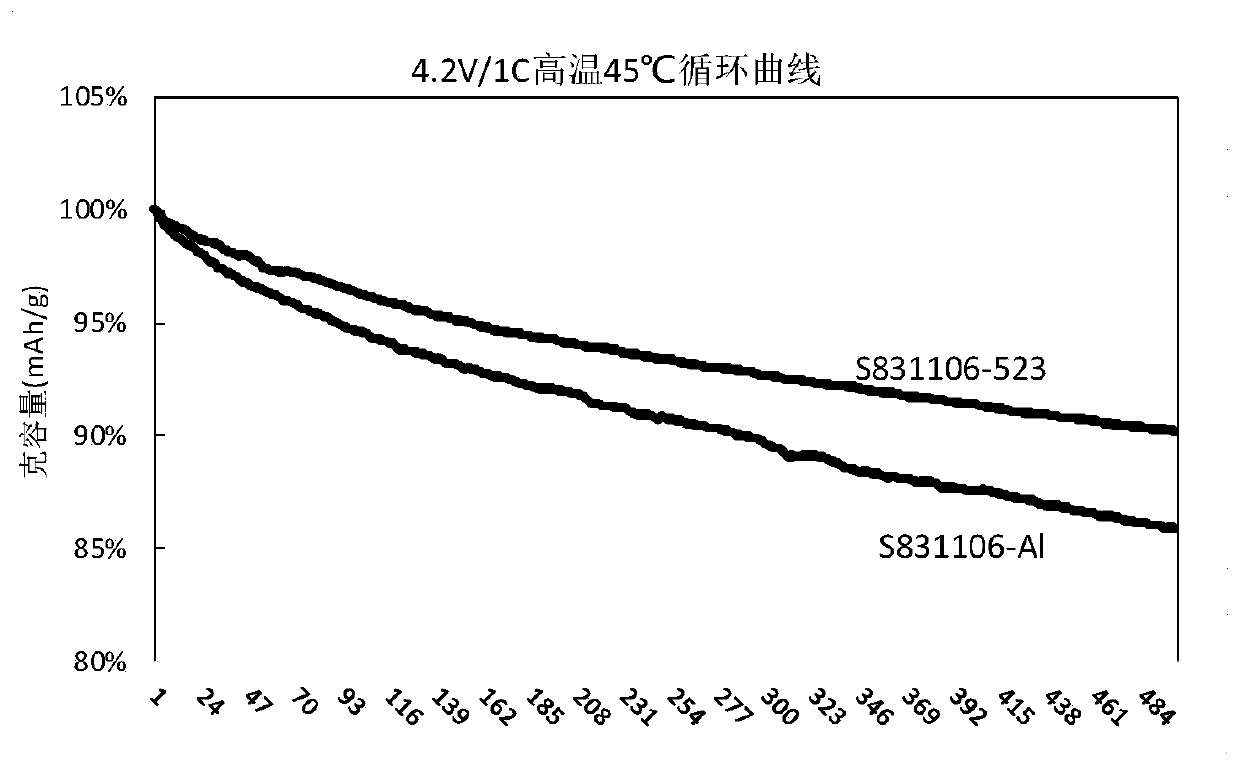

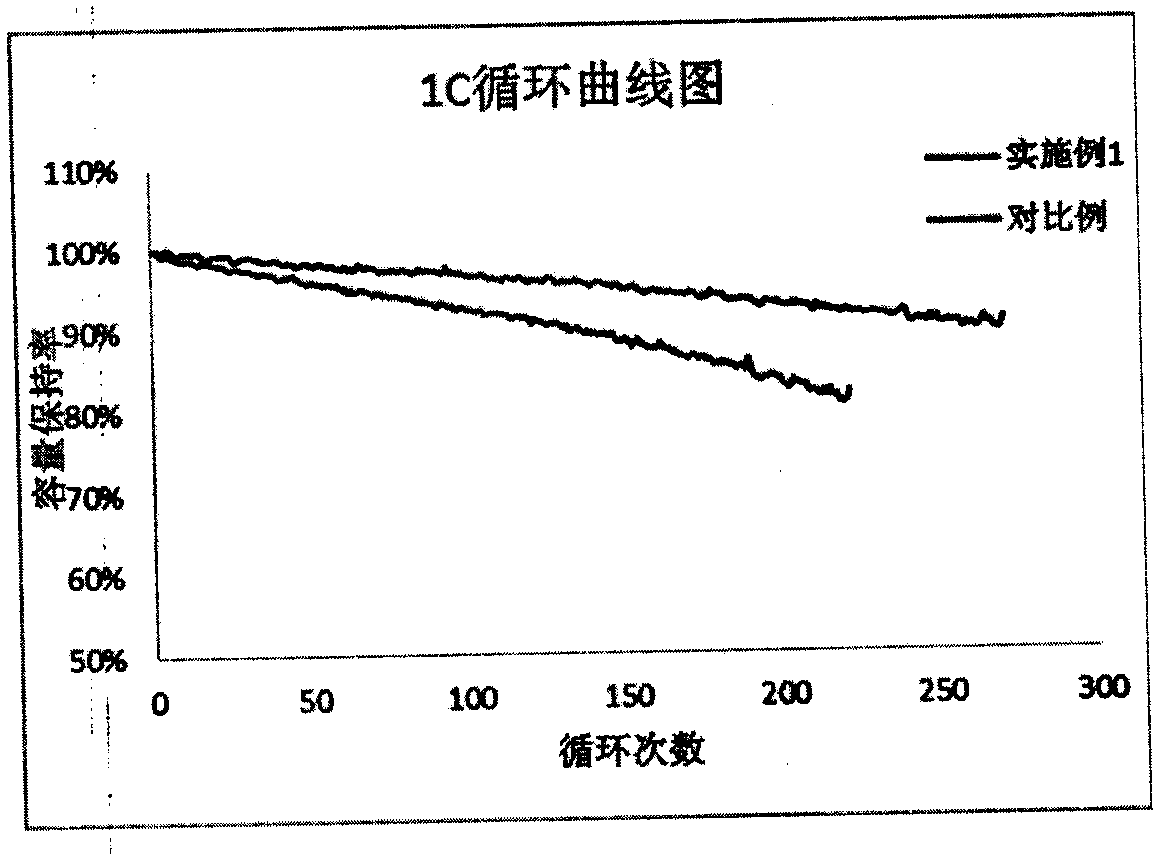

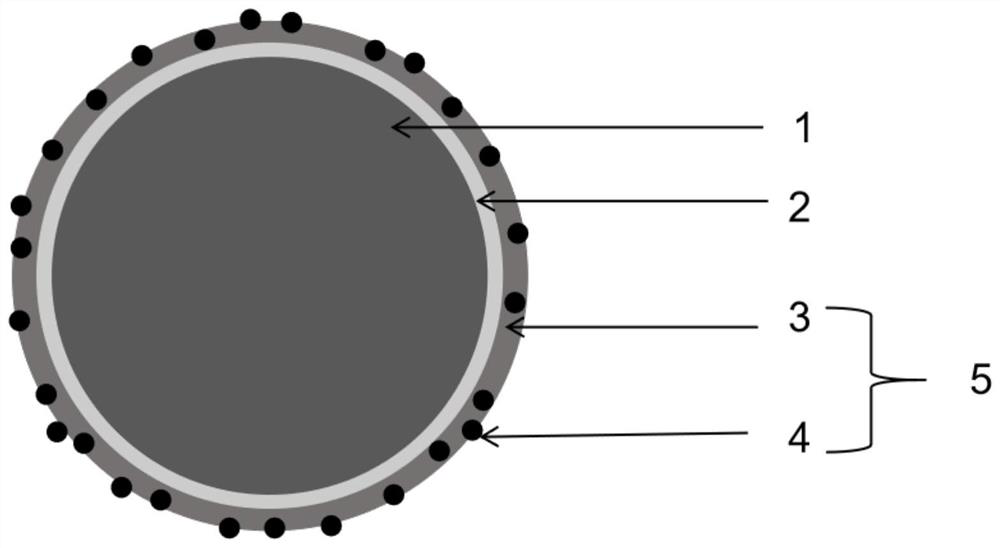

ActiveCN103606674AHigh discharge specific capacityLess side effectsCell electrodesLithiumDouble coating

The invention discloses a surface-modified lithium cobaltate material and a preparation method thereof. The lithium cobaltate material comprises a core particle and a surface-modified layer coating the core particle, wherein the core particle is a lithium cobaltate-based positive material with a structural formula as follows: LixCo(1-y)MyO2, wherein x is greater than 1 and not greater than 1.2, y is not less than 0 and not greater than 0.1, M is a doping element; the surface-modified layer comprises a Li<+1> conducting layer and an electrolyte isolating layer; the core particle is coated by the Li<+1> conducting layer and the electrolyte isolating layer in sequence. According to the invention, by sufficiently utilizing dynamic characteristic that different substances react with residual Li salt on the surface of the lithium cobaltate, and characteristic of final reaction product performance, the lithium cobaltate material with double coating layers is prepared. The material is high in comprehensive performances, has high discharge capacity, high cycling stability and the like. The preparation method disclosed by the invention is simple in process and easily realizes industrial production.

Owner:QINGHAI TAIFENG XIANXING LITHIUM ENERGY TECH CO LTD

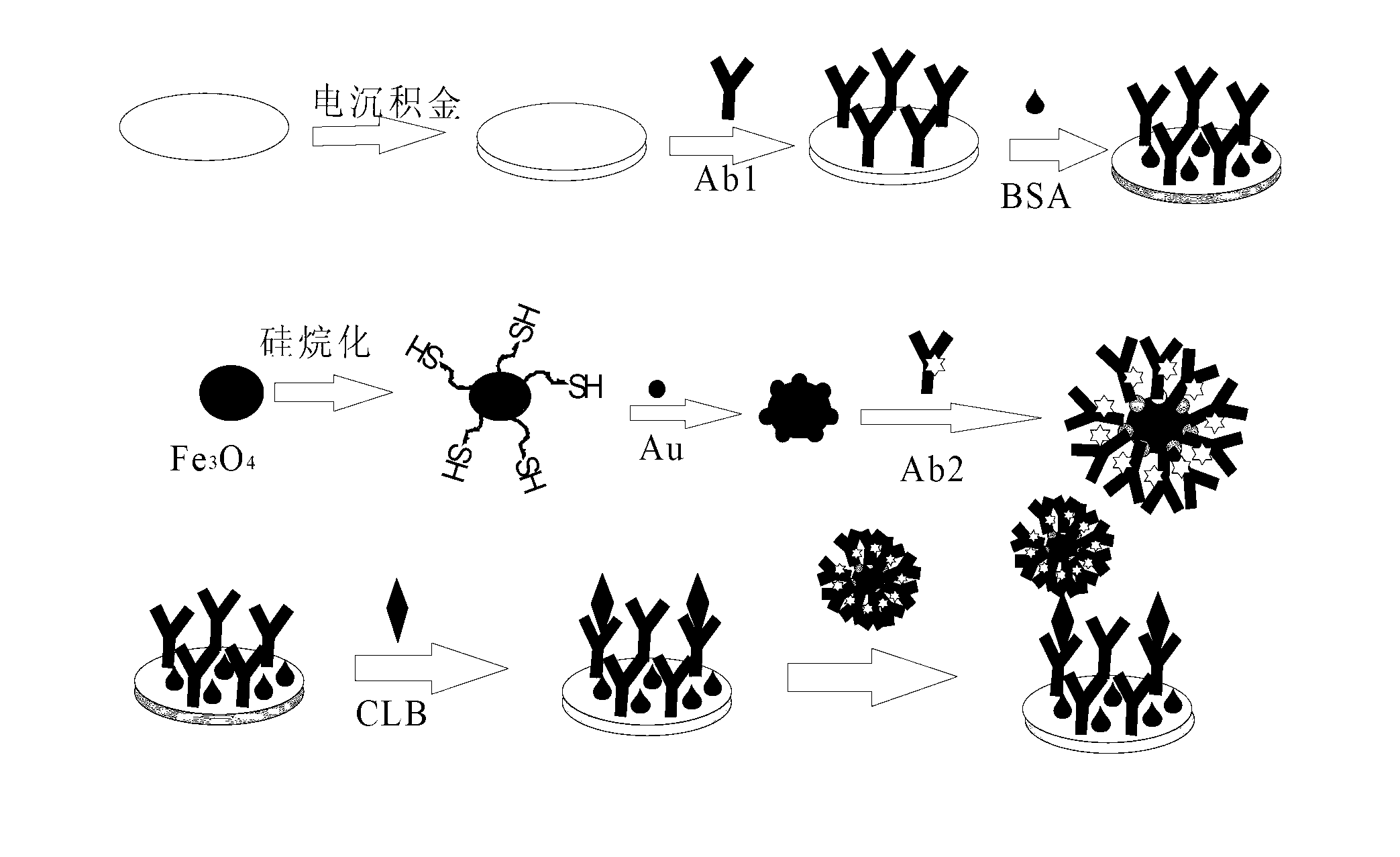

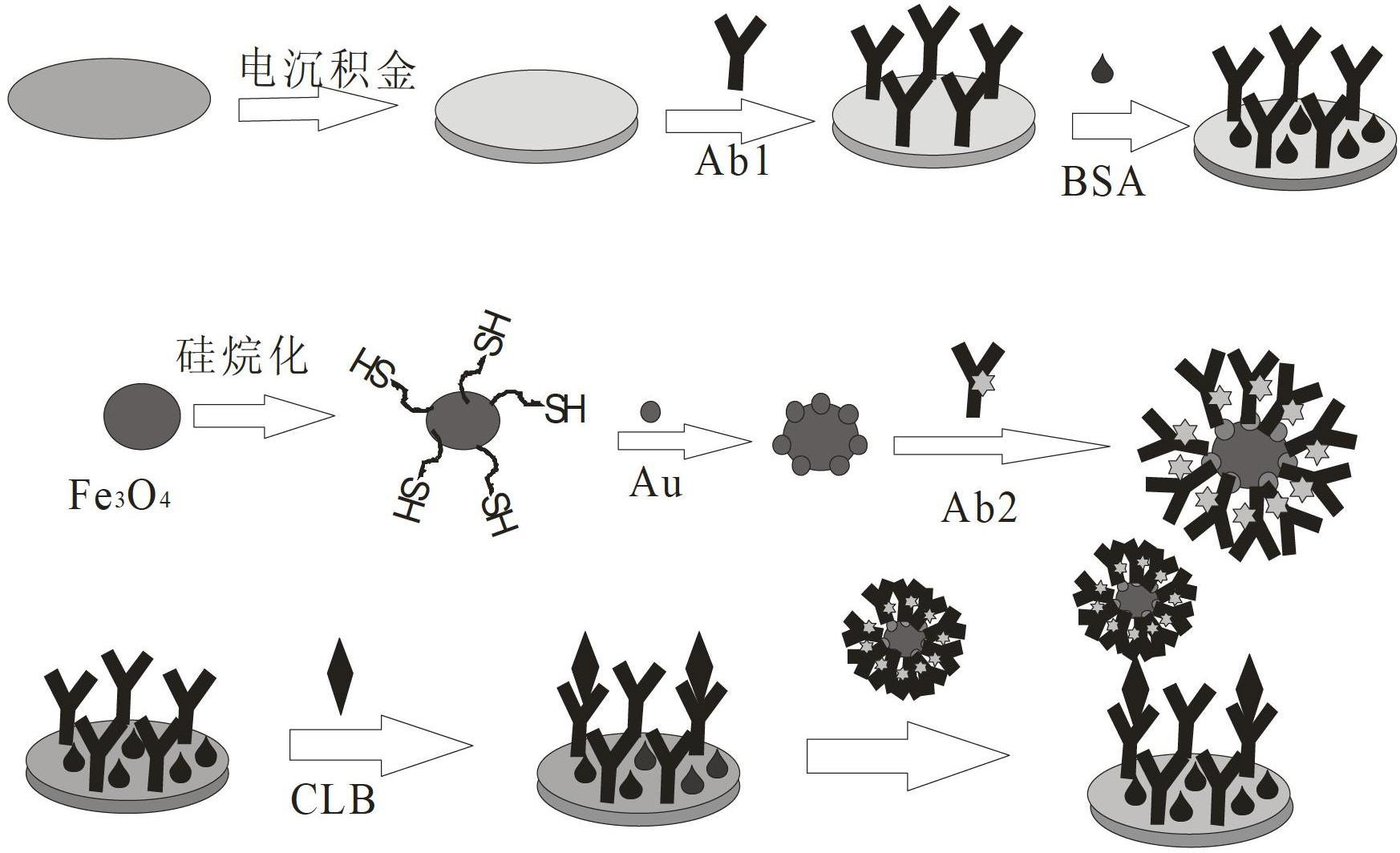

Preparation method and application of magnetic sandwich nano immunosensor

The invention discloses a preparation method of a magnetic sandwich nano immunosensor and application of the preparation method. The preparation method is characterized by comprising the following steps: mixing and stirring a collaurum solution and silane ferriferrous oxide into a colorless and transparent solution, and carrying out magnetic separation by externally applying a magnet to obtain FE3O4 / Au colloid nano magnetic beads; loading horse radish peroxidase (HRP) and secondary antibodies of an object to be measured to the FE3O4 / Au colloid nano magnetic beads to obtain a secondary antibody probe Fe3O4 / Au-HRP-Ab2; electrically depositing Au to a glassy carbon electrode, loading primary antibodies of the object to be measured, and then closing non-specific active sites by using protein to obtain an Abl / Au / GCE electrode; and finally, loading antigen to the Abl / Au / GCE electrode, and then obtaining the sandwich nano immunosensor by combining the magnet probe. The magnetic sandwich nano immunosensor can be used for measuring the concentration of melamine, tonyred, clenbuterol or estrogen in food and has the advantages of high detection speed, high accuracy and sensitivity and low cost.

Owner:NINGBO UNIV

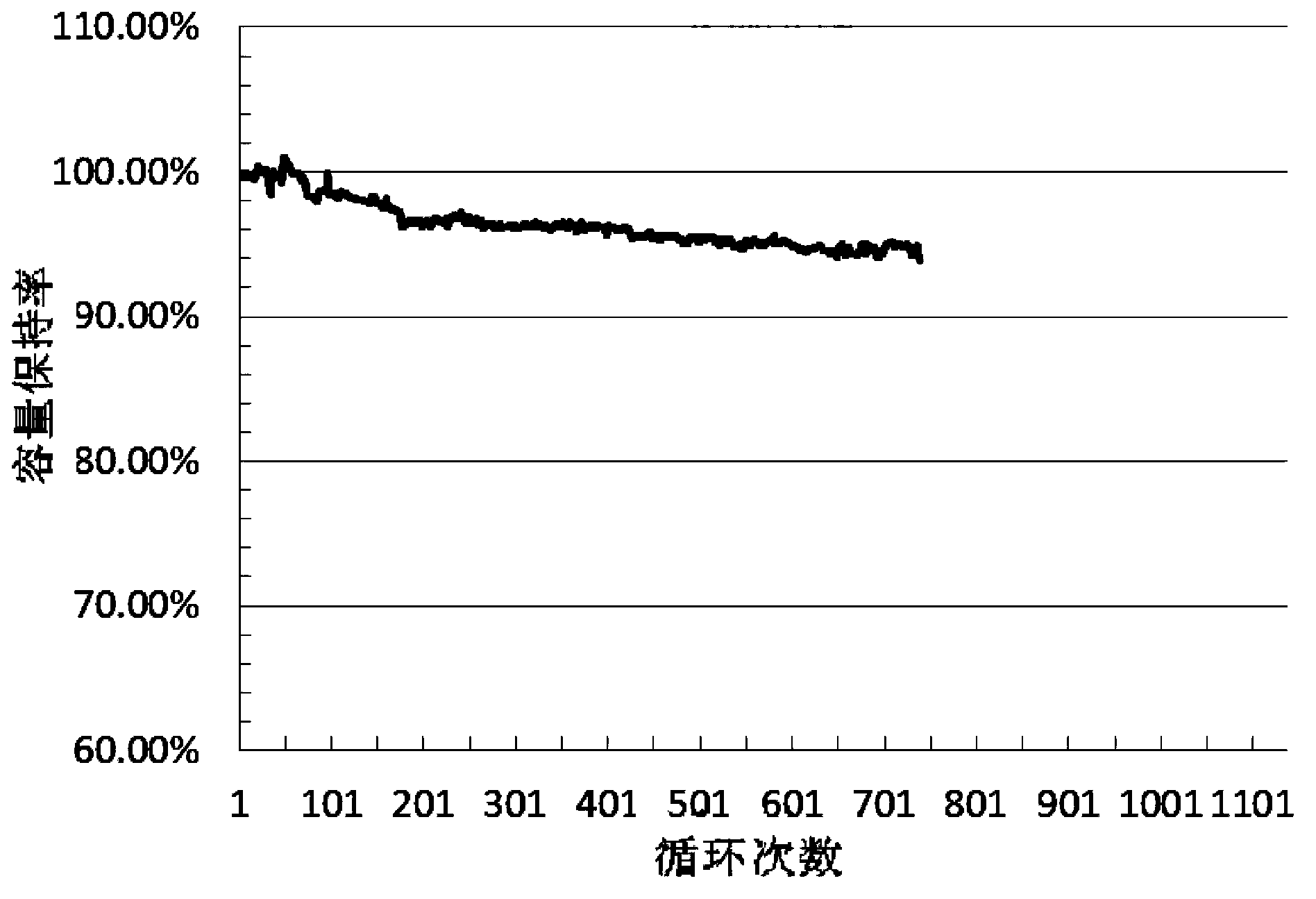

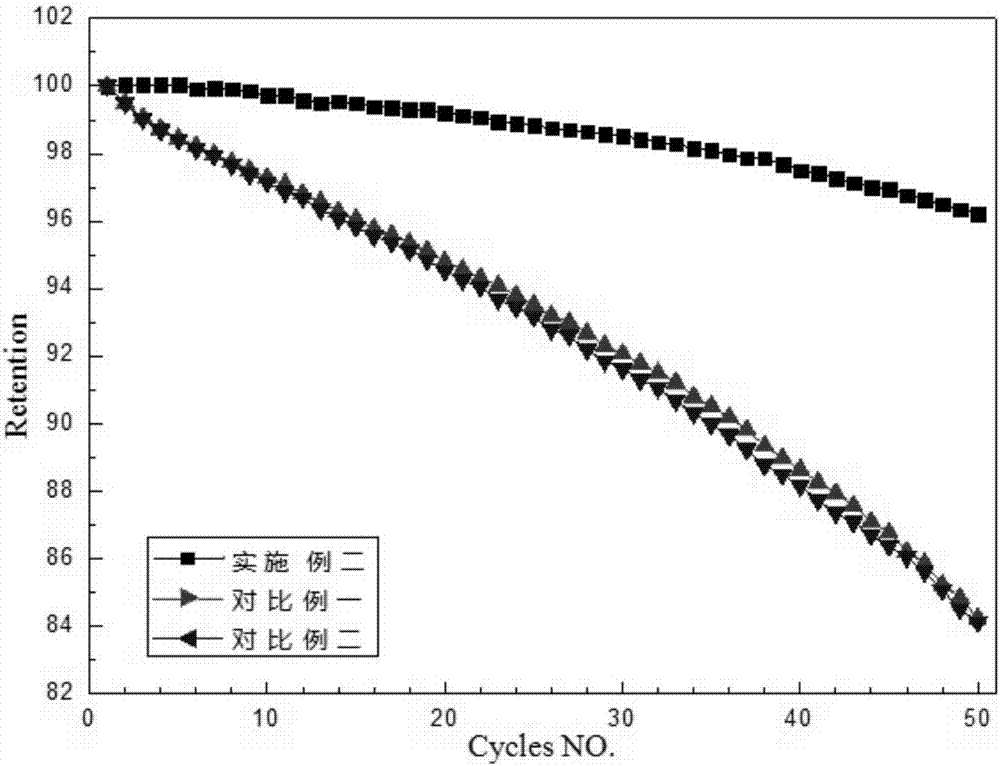

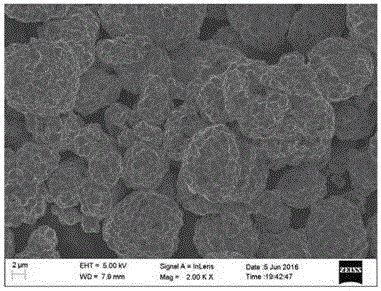

Doped lithium cobaltate having composite cladding layer and preparation method and application thereof

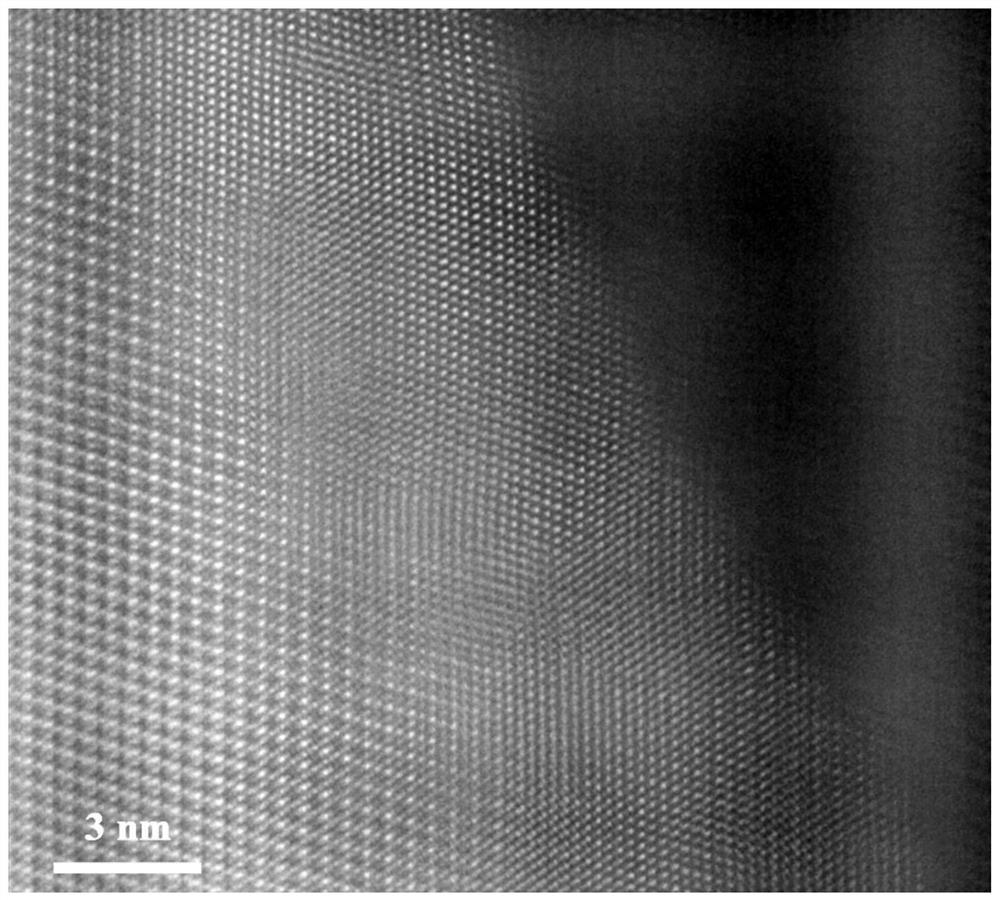

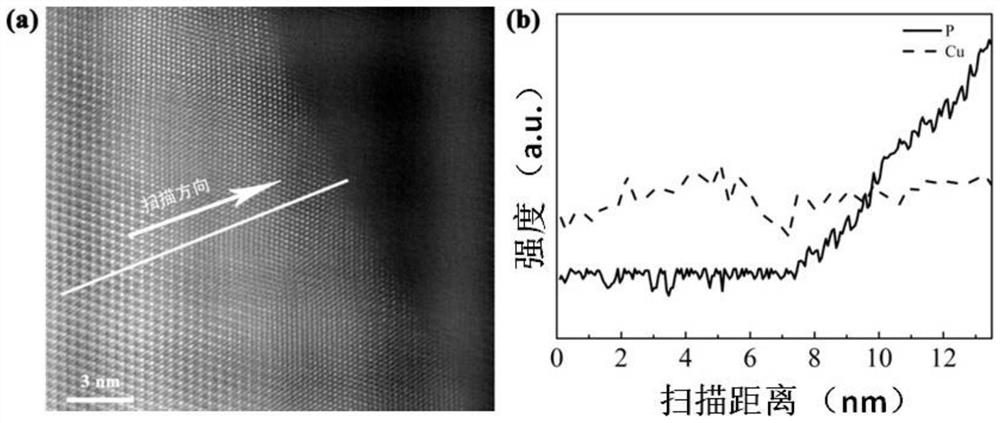

ActiveCN109256531ASlow down the increase in impedanceLess side effectsCell electrodesSecondary cellsLithium-ion batterySide reaction

The present application discloses a doped lithium cobaltate having a composite cladding layer, which has a particularly stable surface structure as a cathode material for lithium ion batteries, At that same time, the surface coat layer has electrochemical activity and lithium ion transport ability, In the prepared lithium ion battery, the electrode material can be blocked from directly contactingwith the electrolyte, the side reaction inside the battery can be reduced, and the safety performance can be improved. At the same time, the cladding layer has lithium ion transport ability, and the impedance increase in the battery cycle process can be limited slowed down.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

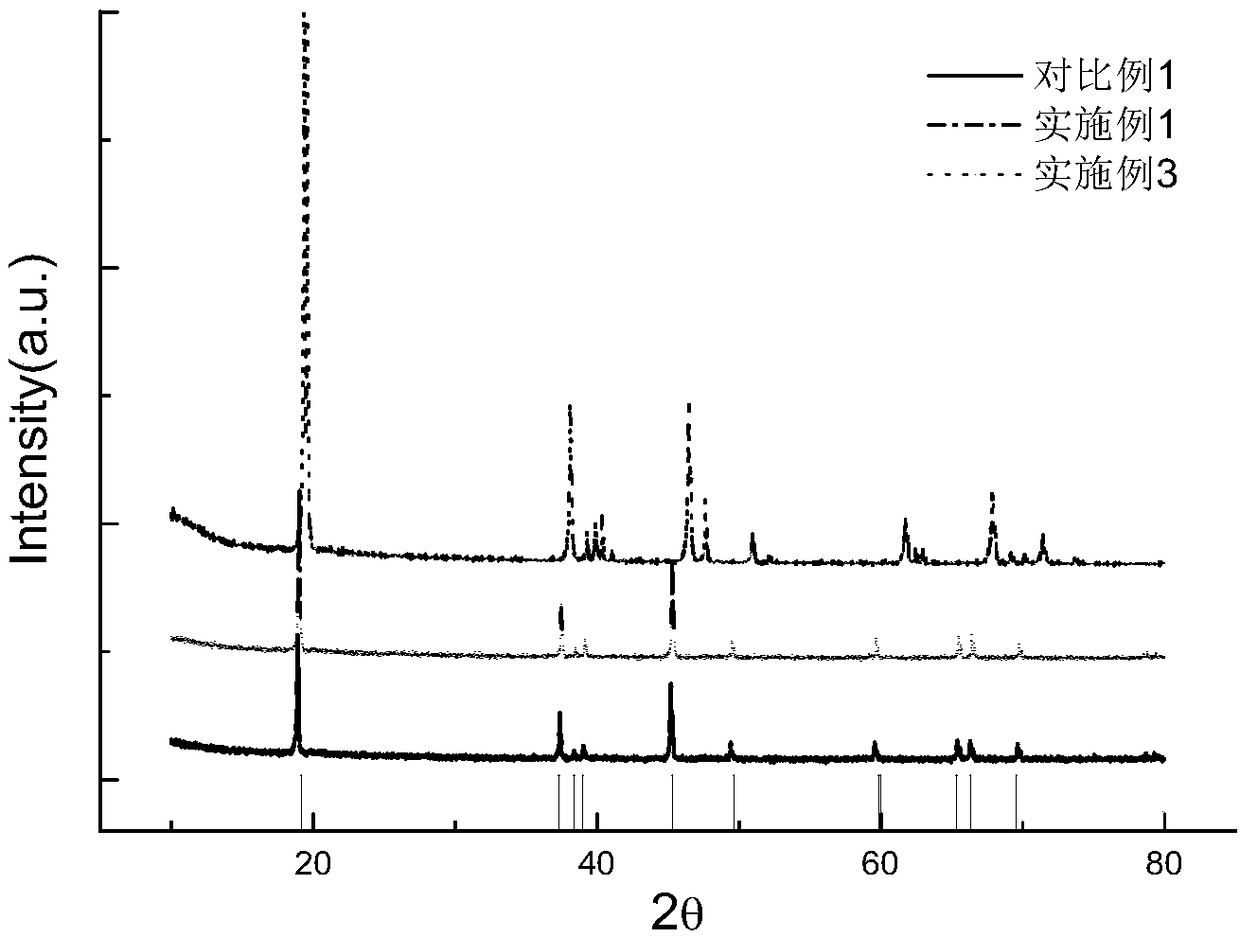

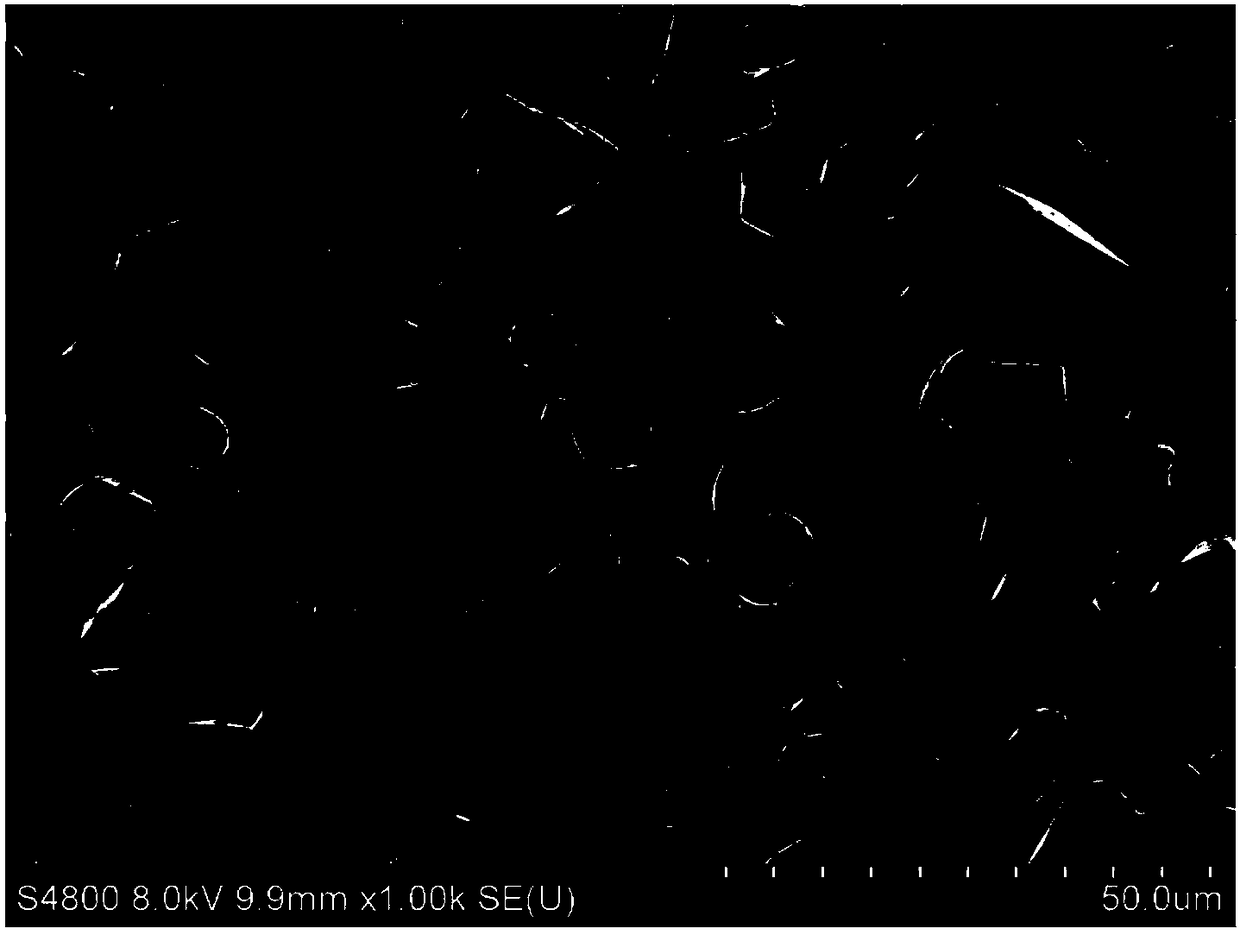

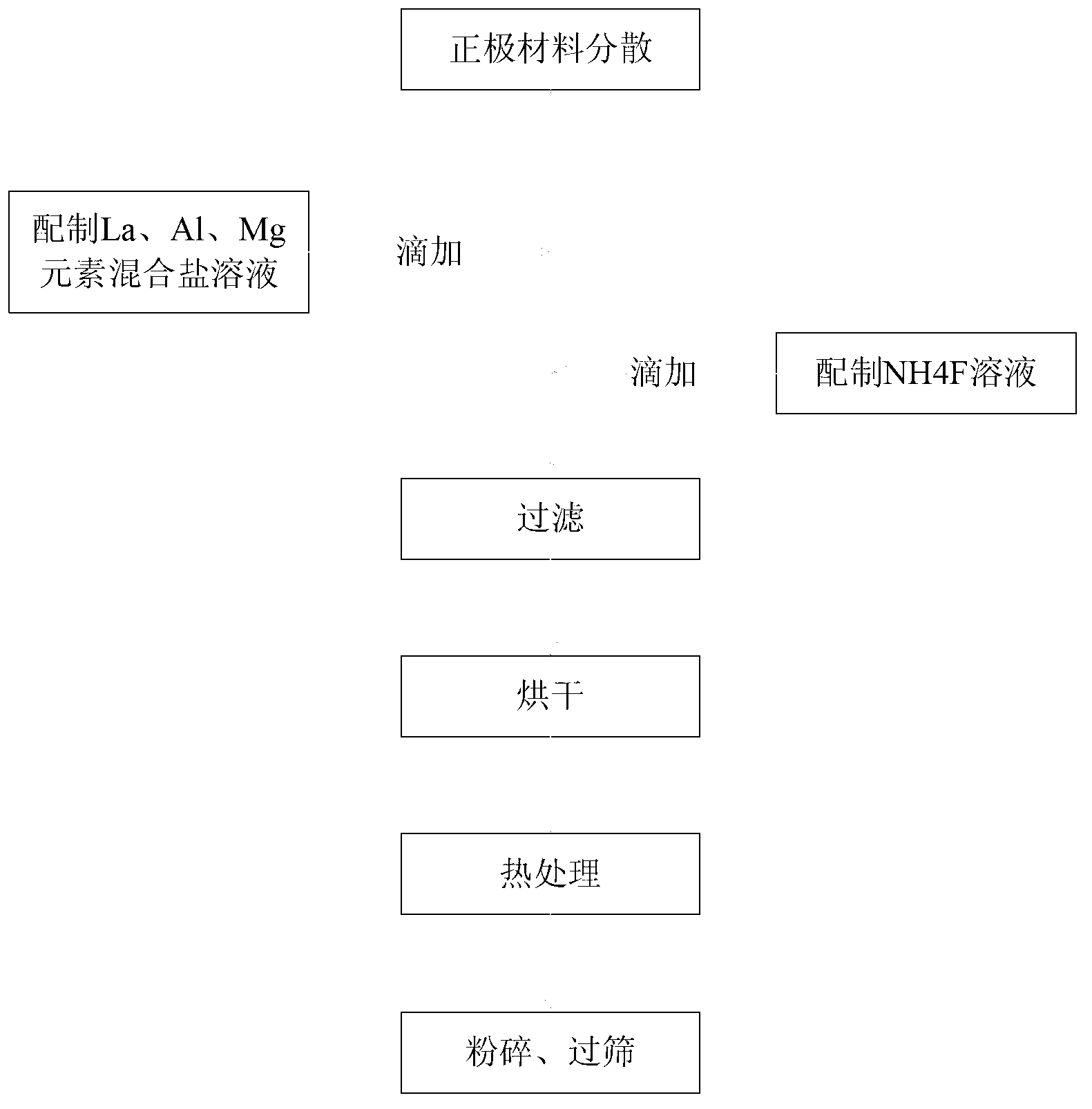

Compounding and coating method of anode material for lithium ion cell

InactiveCN103022502AImprove cycle performanceImprove rate discharge performanceCell electrodesLithiumManganese oxide

The invention discloses a compounding and coating method of an anode material for a lithium ion cell. The compounding and coating method comprises the steps that fluorides of La, Al and Mg are coprecipitated on the surface of a lithium ion anode material in a liquid phase; and then, the anode material for the lithium ion cell cooperatively coated by La3+, Al3+, Mg2+ and F- is obtained by heat treatment. With the adoption of the coating treatment, the circulating property and the rate discharge property of the anode material under the charge cut-off voltage are improved; and the high-temperature circulating property of a spinel manganese oxide lithium material and the ordinary pressure circulating property of a nickelic anode material are improved.

Owner:TIANJIN B&M SCI & TECH

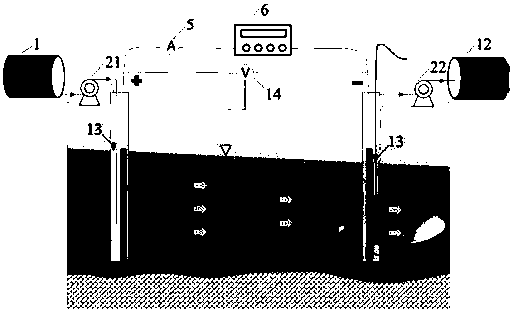

Apparatus and method for repairing polluted soil and underwater by cooperation of in-situ electricity and electrochemistry

InactiveCN108213070ASimple preparation processReduce manufacturing costContaminated soil reclamationElectrochemical degradationEngineering

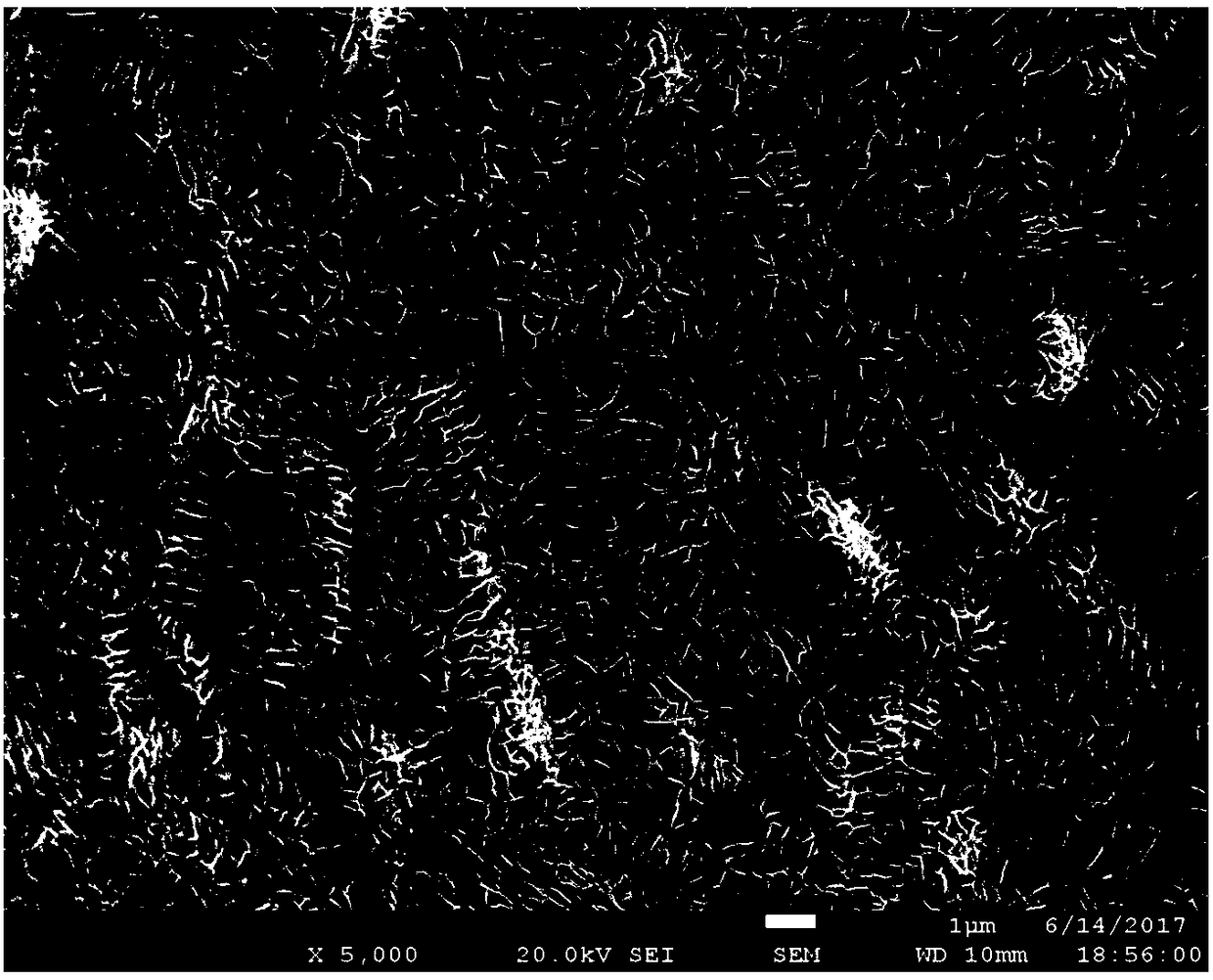

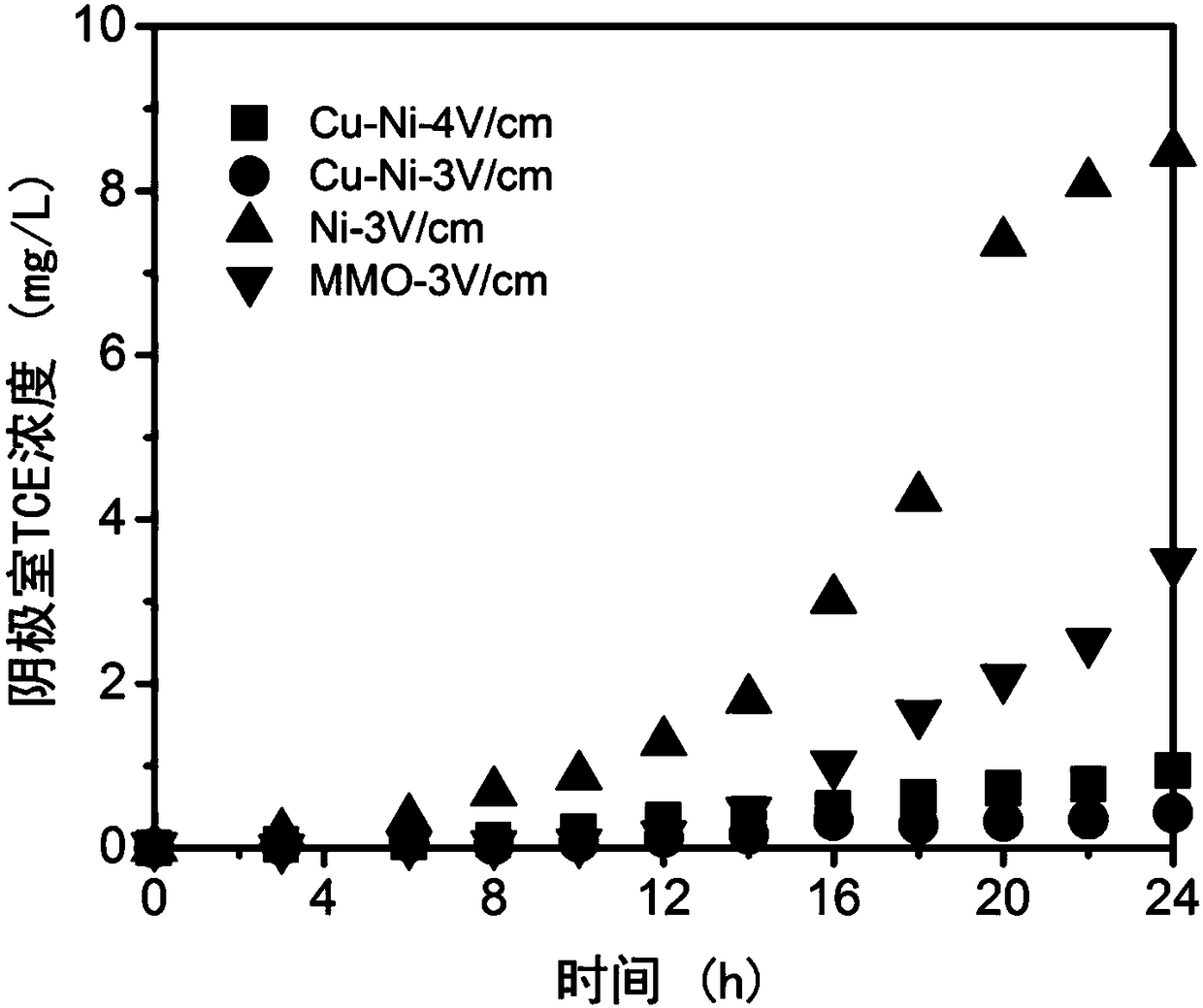

The invention relates to an apparatus and a method for repairing polluted soil and underwater by cooperation of in-situ electricity and electrochemistry. In the method, a mono-metal or double-metal electrode having a nano-scale surface or an air cathode having advanced pollutant oxidation function is formed for reducing and degrading organic pollutants, then the formed electrode is used as a cathode in the electric repairing apparatus; a direct-current electric field is applied to a medium to migrate the organic pollutants in the medium to the cathode, thus achieving cooperation of electric field driven pollutant migration and in-situ electrode electrochemical degradation. The method avoids complex engineering problems, such as secondary treatment after extraction of a cathode solution, extra addition of a redox agent, arrangement of PRB and the like, during a conventional electric repairing process, and can significantly reduce engineering work load and repairing cost in the electricrepairing. The invention provides the in-situ repairing method for the polluted soil and underwater, which is simple in preparation, is low in cost and has high-effective cooperation.

Owner:TSINGHUA UNIV

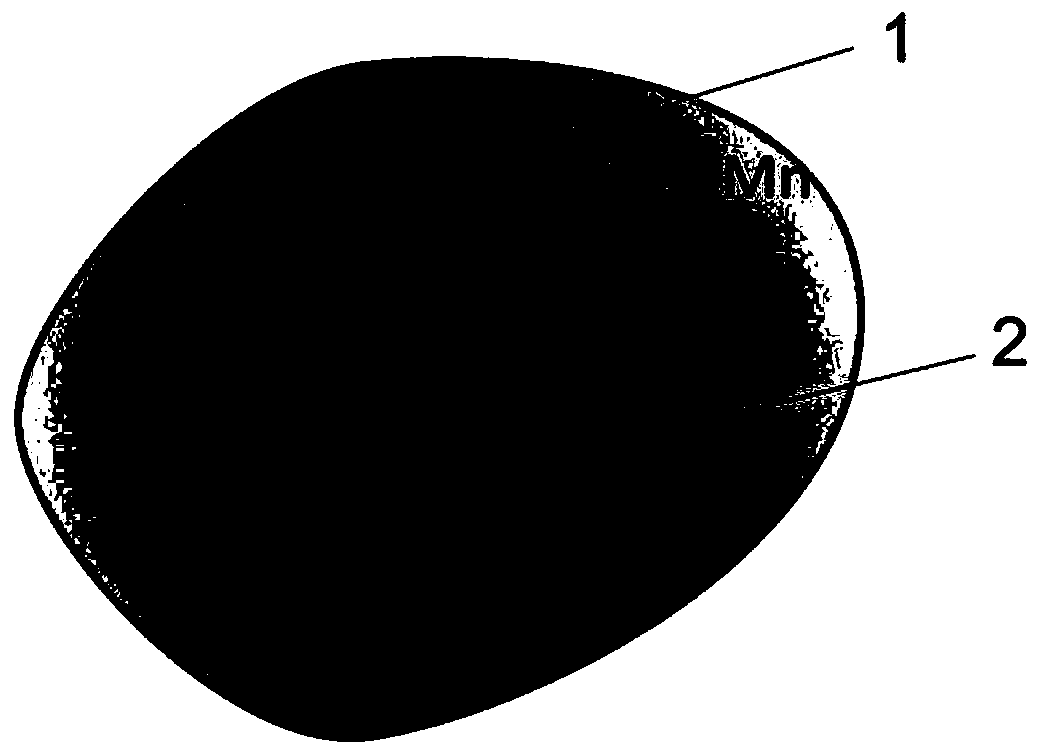

Core-shell high-nickel monocrystal nickel cobalt lithium manganate positive electrode material and preparation method and application thereof

ActiveCN110165193AAvoid breakingIncrease compaction densityMaterial nanotechnologyCell electrodesManganateSingle crystal

The invention discloses a core-shell high-nickel monocrystal nickel cobalt lithium manganate positive electrode material and a preparation method and application thereof, and the positive electrode material comprises a core layer and a shell layer arranged on the outer surface of the core layer, wherein the core layer and the shell layer form a core-shell structure. The material of the core layeris Lia(NixCoyMn<1-x-y>)O2, wherein 1.0 <= a <= 1.15, 0.6 < x <= 0.95, 0.01 <= y <= 0.2, 1-x-y > 0, and the material of the core layer is of a monocrystal type; the material of the shell layer is Lib(NiiCojMnkM<1-i-j-k>)O2, wherein 0.9 <= b <= 1.05, 0.2 <= i <= 05, 0.15 <= j <= 0.5, 0.15 <= k <= 0.5, 1-i-j-k > 0, and M is one or more of Mg, Al, Zr, Ti and W. The preparation method comprises the following steps: firstly preparing high-nickel monocrystal lithium nickel cobalt manganate, then preparing nano lithium nickel cobalt manganate slurry, adding the high-nickel monocrystal lithium nickel cobalt manganate and an M-containing additive into the slurry, performing mixing, carrying out spray drying, and performing sintering in an oxygen atmosphere to prepare the lithium nickel cobalt manganate positive electrode material. The invention also discloses an application of the positive electrode material in lithium ion batteries. The positive electrode material has excellent first charge-discharge efficiency and high capacity retention rate, and also has excellent cycle performance and safety performance at a high temperature.

Owner:JIANGSU XIANGYING NEW ENERGY TECH CO LTD

Mixed cathode material for lithium ion batteries and preparation method thereof

The invention relates to the field of batteries, and in particular relates to a long-life, high-energy density and low-cost mixed cathode material for lithium ion secondary batteries and a preparation method thereof. The mixed cathode material for the lithium ion batteries, provided by the invention, comprises the following raw components in percentage by weight: 20-60% of doped lithium-manganese spinel composite oxide and 40-80% of doped lithium-nickel-cobalt-manganese composite oxide. According to the mixed cathode material for the lithium ion batteries, provided by the invention, proper doping is carried out on lithium-manganese spinel to ensure that the lattice imperfection can be effectively reduced, the crystal structure is stabilized, the lattice distortion is restrained, the manganese dissolution is reduced, the cycle life is prolonged, the large current charge-discharge property and safety performance can be improved so as to satisfy the important requirements on the lithium ion batteries for EV (Electric Vehicles) and HEV (Hybrid Electric Vehicles); for the lithium-nickel-cobalt-manganese composite oxide of a layered structure, the doping has the same effect and the cycle performance, the rate performance and the safety performance can be better improved.

Owner:SUZHOU GCL ENERGY TECH DEV CO LTD

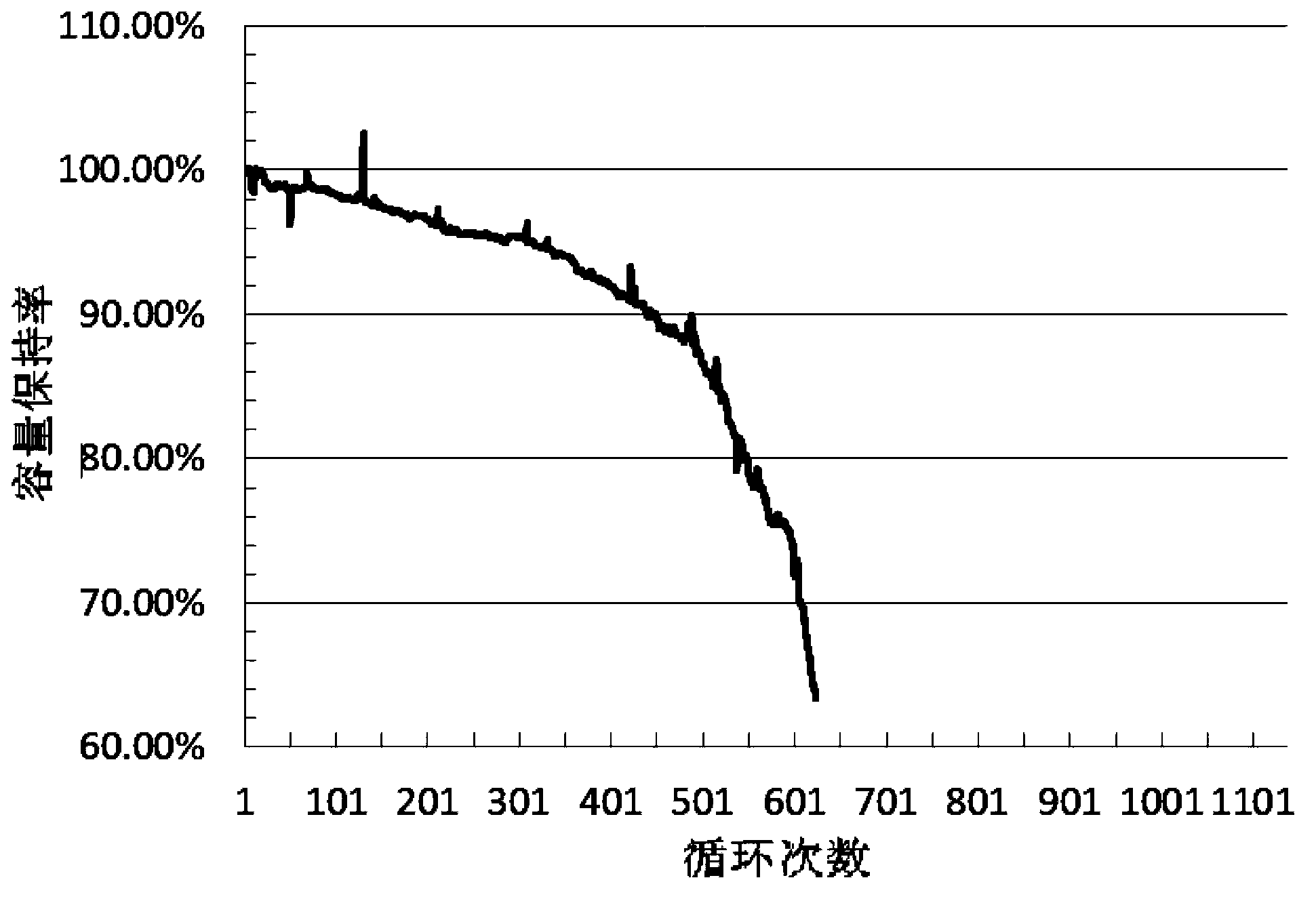

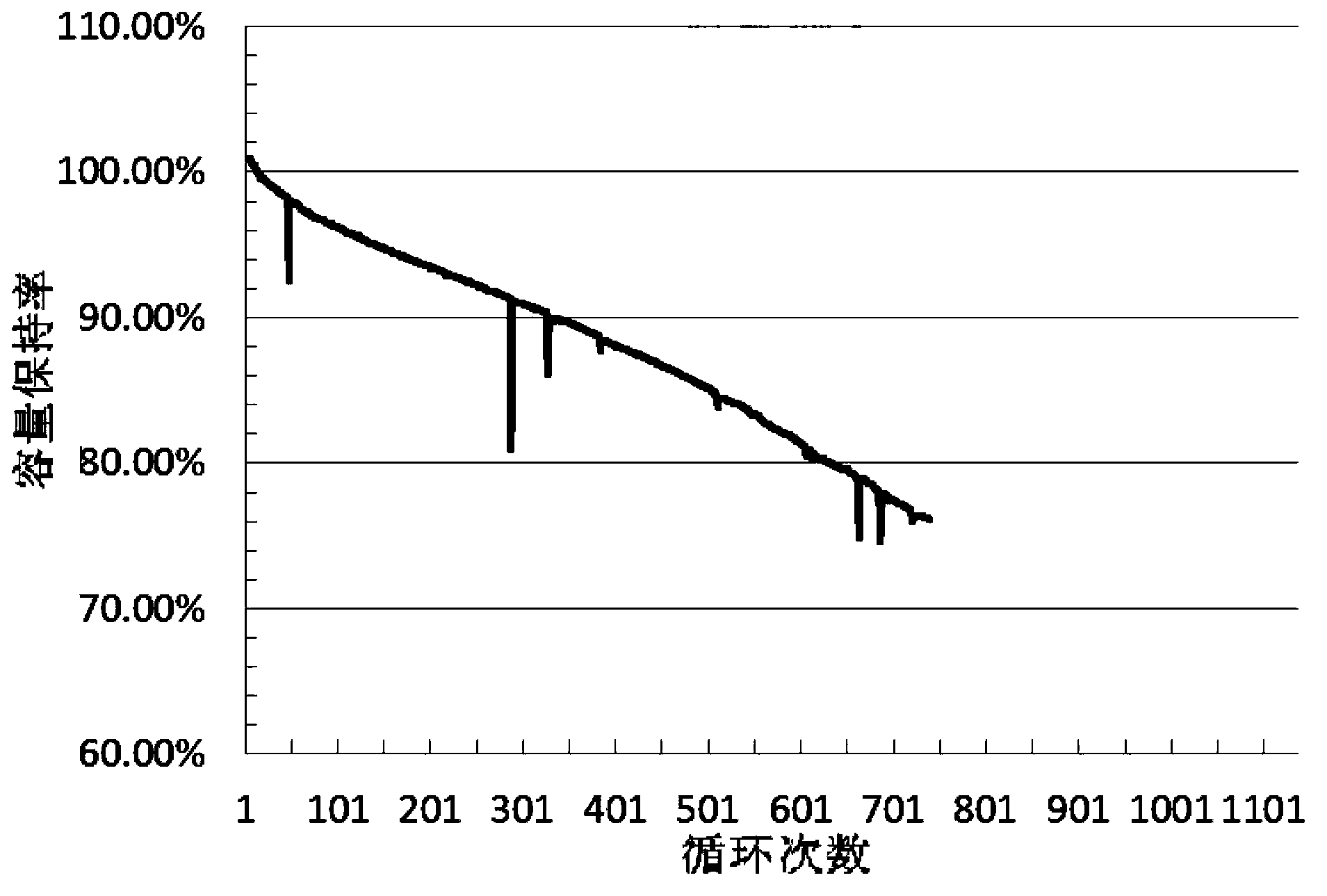

Gradient-doped high-energy-density type lithium cobalt oxide positive electrode material and preparation method thereof

ActiveCN108011103AElimination of structural mutationsIncrease the concentration of doping elementsCell electrodesSecondary cellsCobalt oxideHigh energy

The invention is applicable to the technical field of a lithium battery, and provides a gradient-doped high-energy-density type lithium cobalt oxide positive electrode material and a preparation method thereof. According to the lithium cobalt oxide material prepared by the method, Al and Mg concentrations in the material inner layer are relatively low while Al and Mg concentrations in the materialouter layer are relatively high, so that gradient doping distribution is formed, thereby eliminating structural sudden change caused by sudden change of the doped element concentrations; meanwhile, the doping element concentration on the surface of the material can be improved, and the material surface structure can be stabilized; in addition, after Al and Mg gradient-doped cobalt oxide X<2> is obtained, Mn, Ti, Zr and Ce doping and primary calcining are performed to obtain primary lithium cobalt oxide particles D1; and next, F and PO<4><3-> doping and secondary calcining are performed to finally obtain the gradient-doped high-energy-density type lithium cobalt oxide positive electrode material. By virtue of the preparation method, the electrochemical performance of the lithium cobalt oxide material in a high charging cut-off voltage can be improved effectively.

Owner:GEM JIANGSU COBALT IND CO LTD

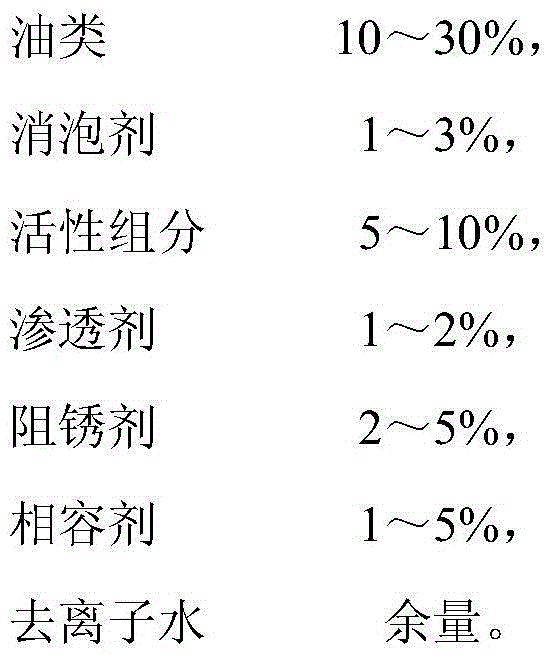

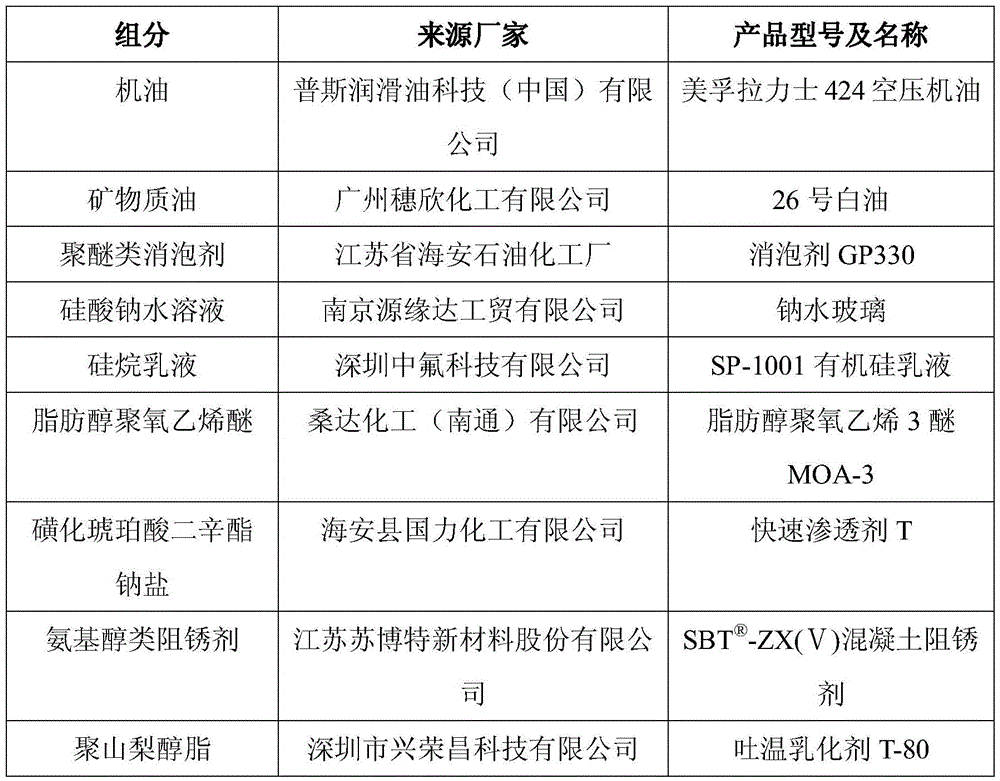

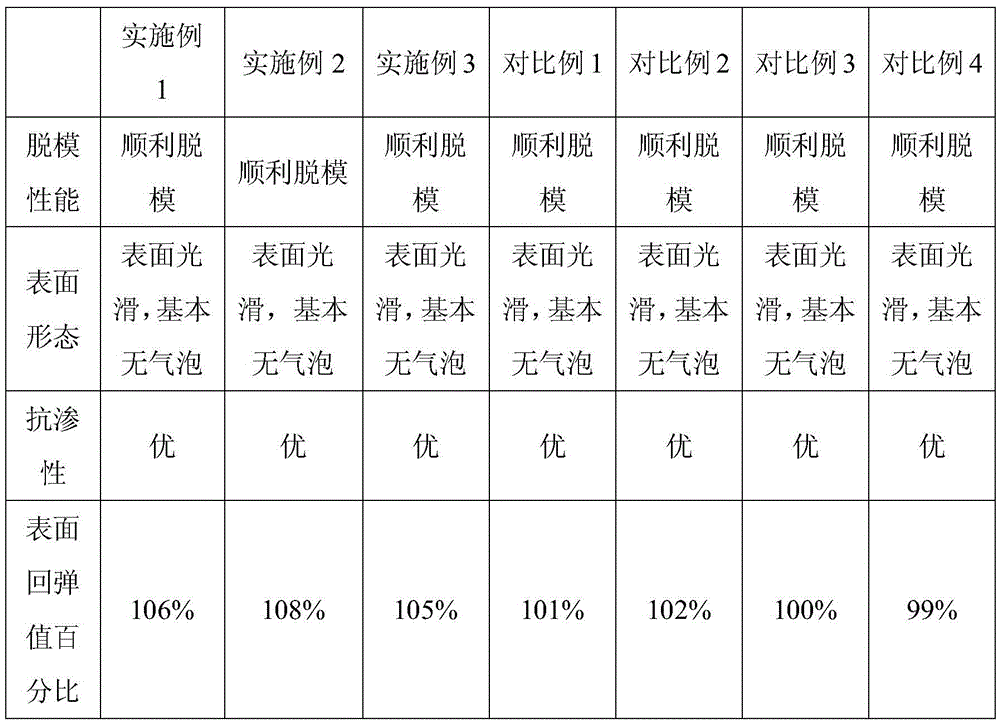

Surface reinforced concrete release agent

ActiveCN105713713AImprove surface strengthImprove surface wear resistanceCeramic shaping apparatusAdditivesReinforced concreteActive component

The invention provides a surface reinforced concrete release agent, comprising 10-30% of an oil, 1-3% of a defoaming agent, 5-10% of an active component, 1-2% of a penetrating agent, 2-5% of a corrosion inhibitor, 1-5% of a compatibilizer, and the balance of deionized water. The release agent is good in releasing effect and convenient to use and is good for surface performance and durability of concrete.

Owner:JIANGSU SOBUTE NEW MATERIALS +3

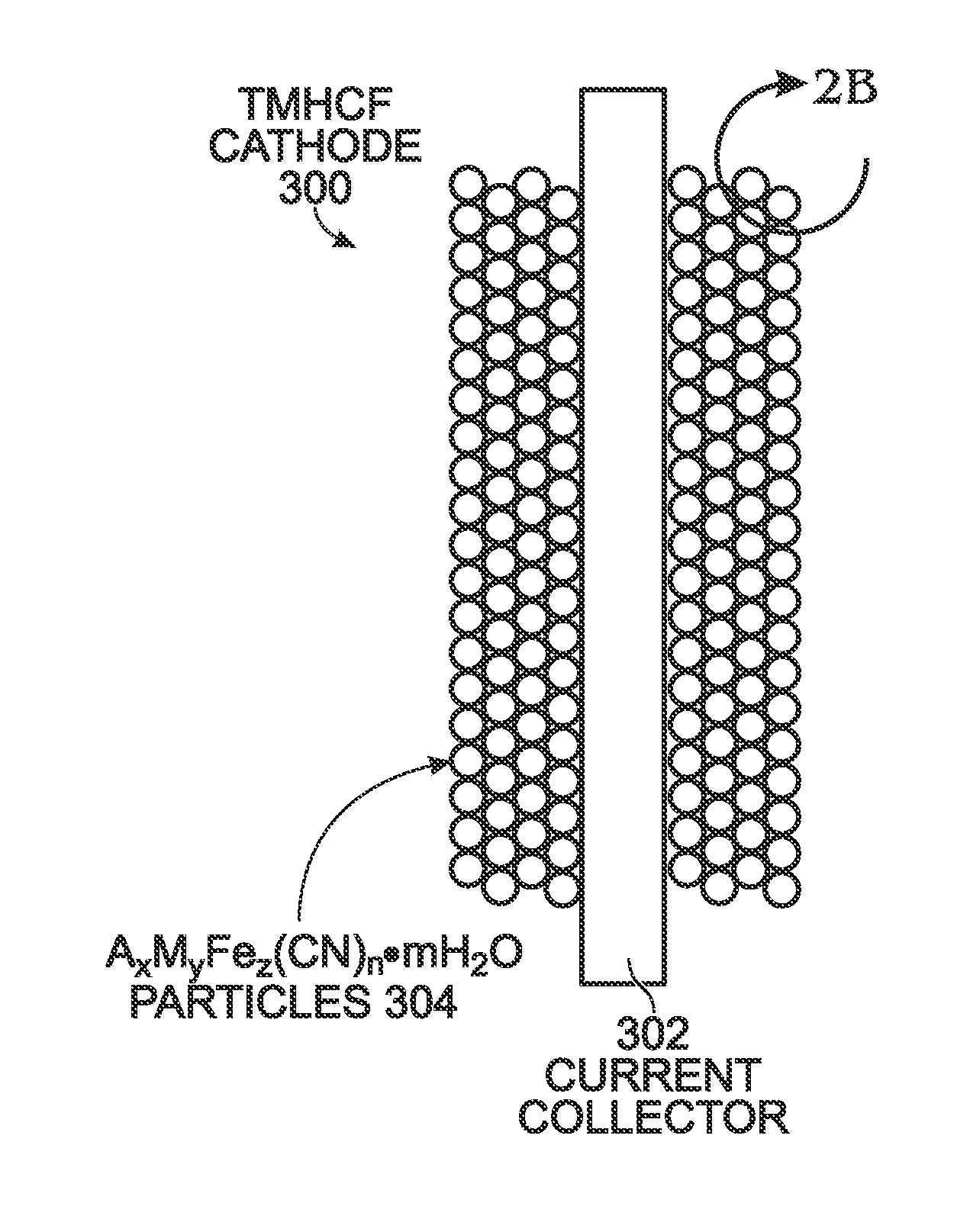

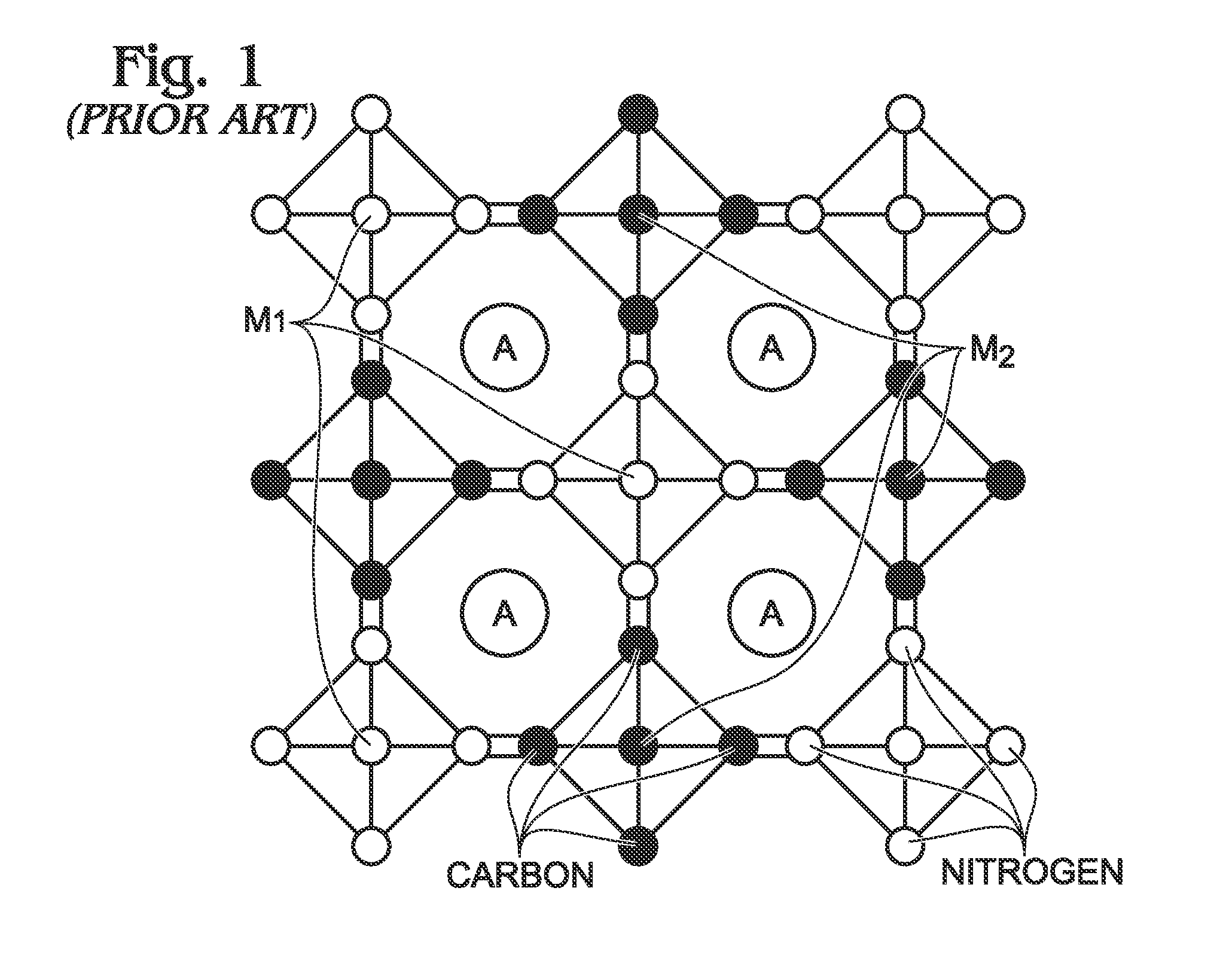

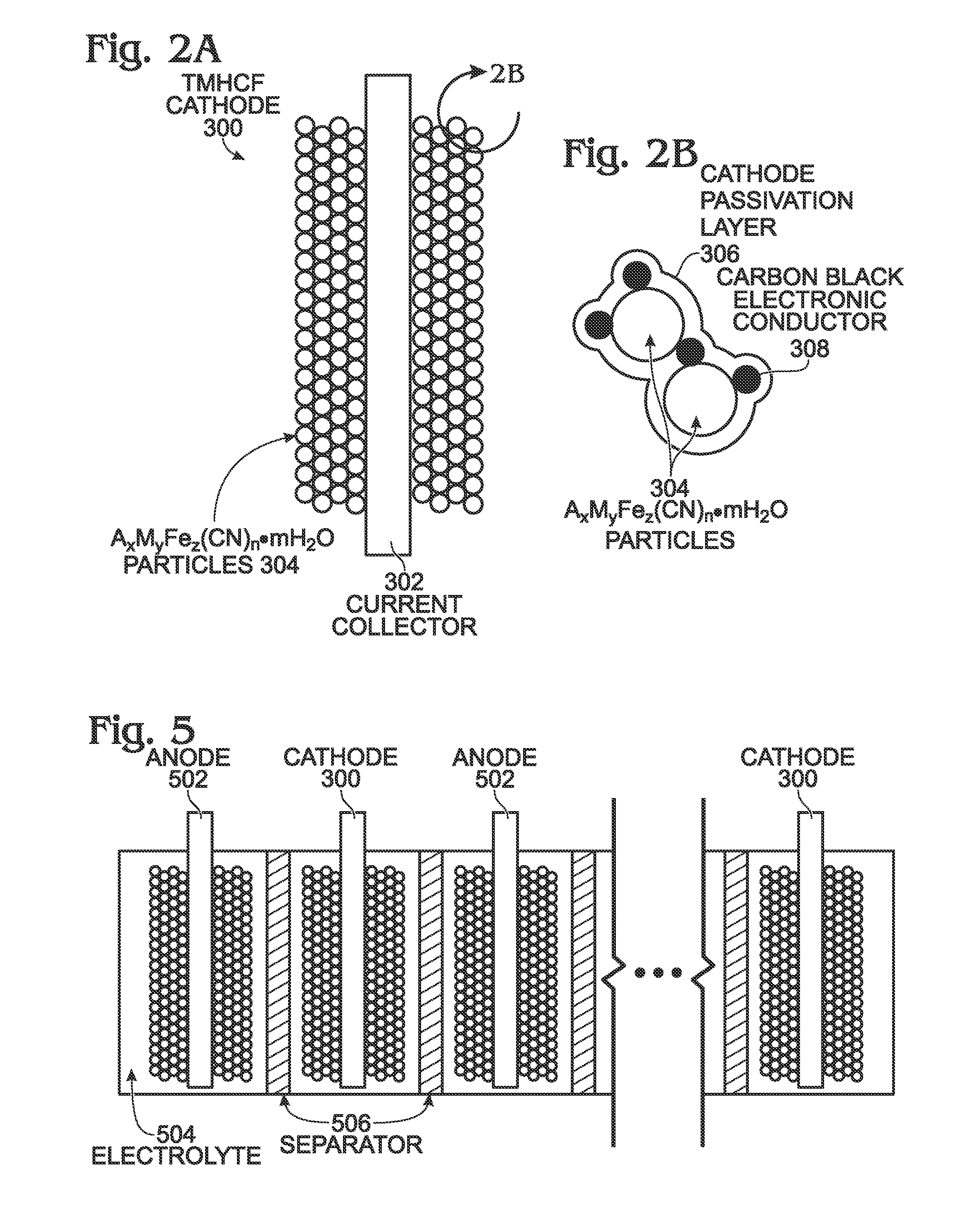

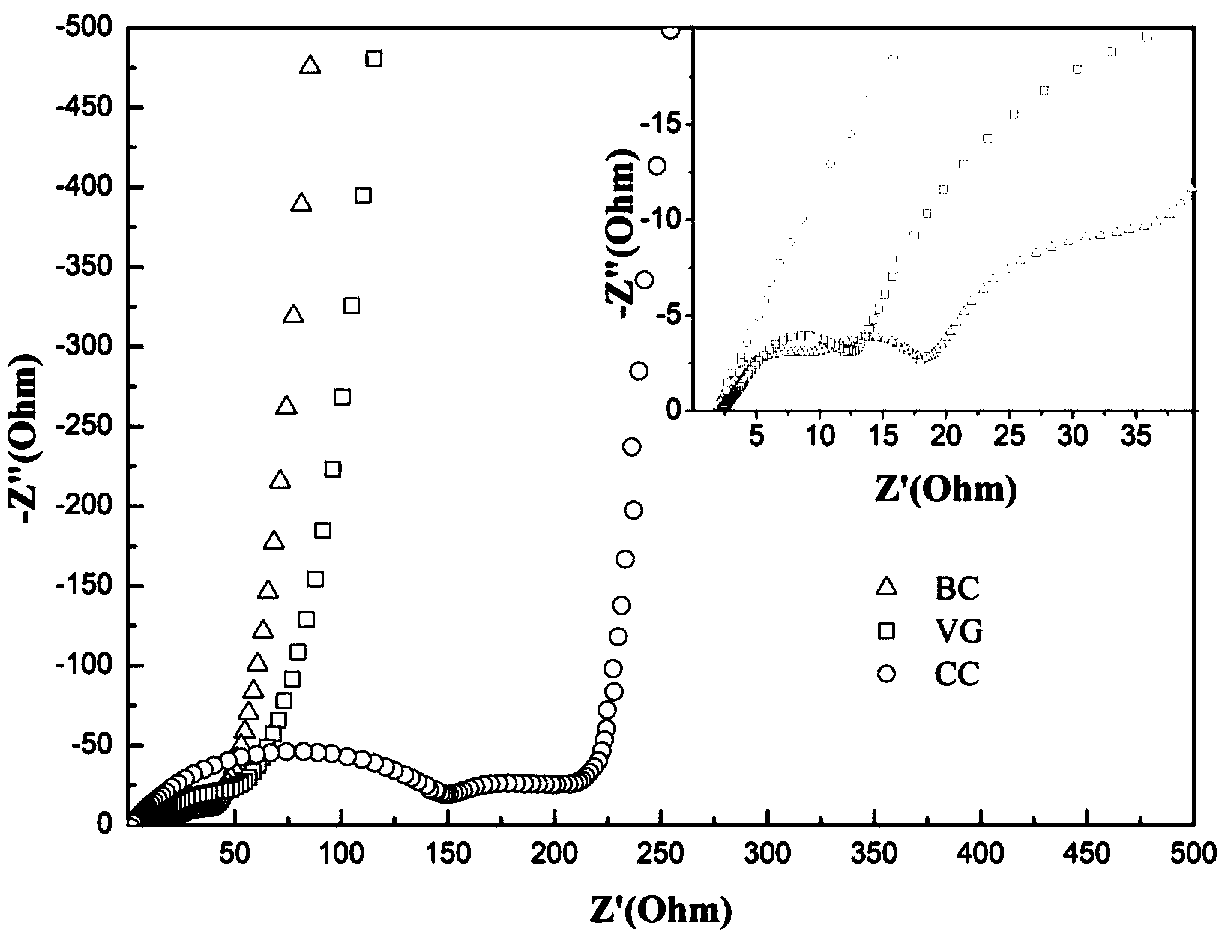

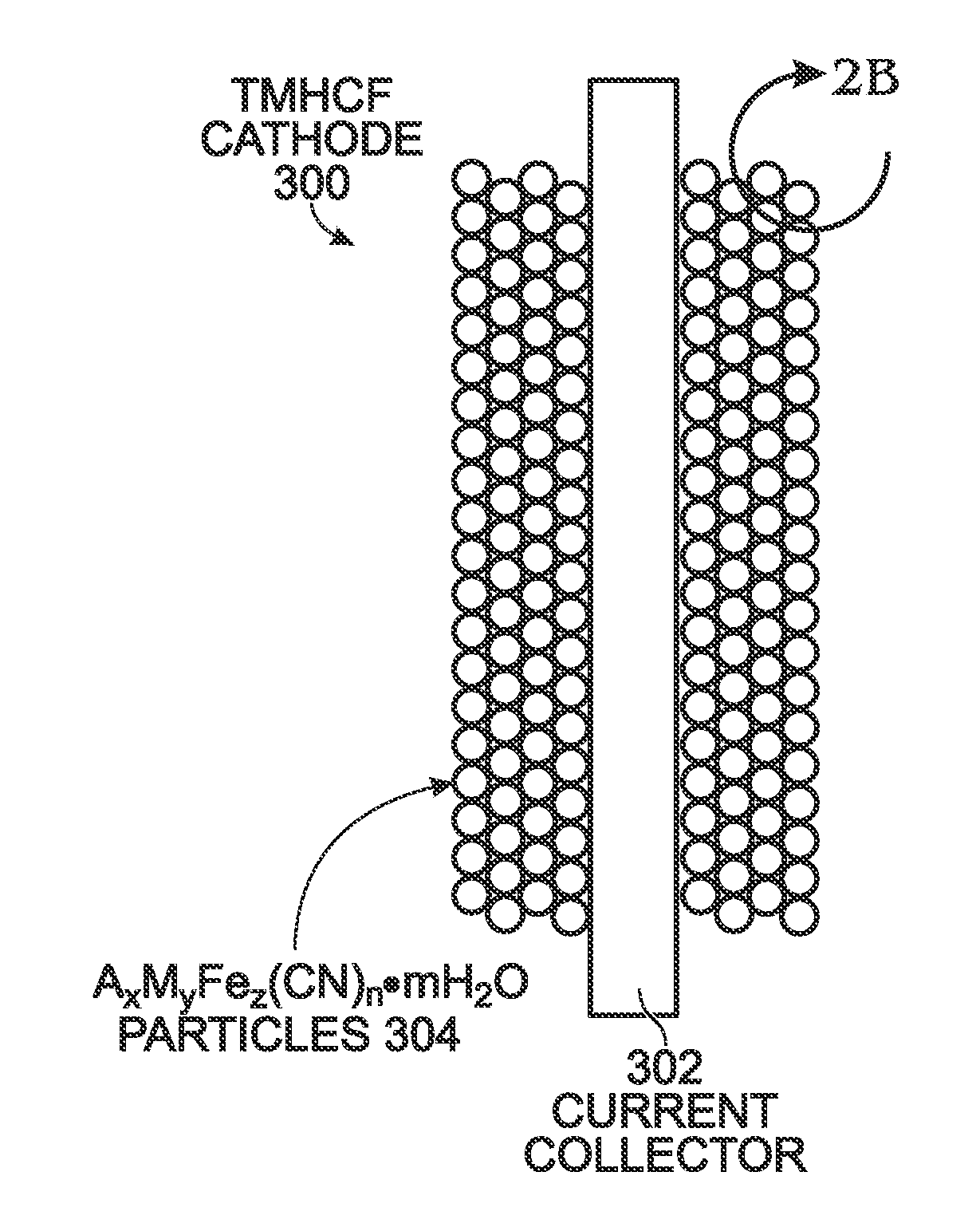

Protected Transition Metal Hexacyanoferrate Battery Electrode

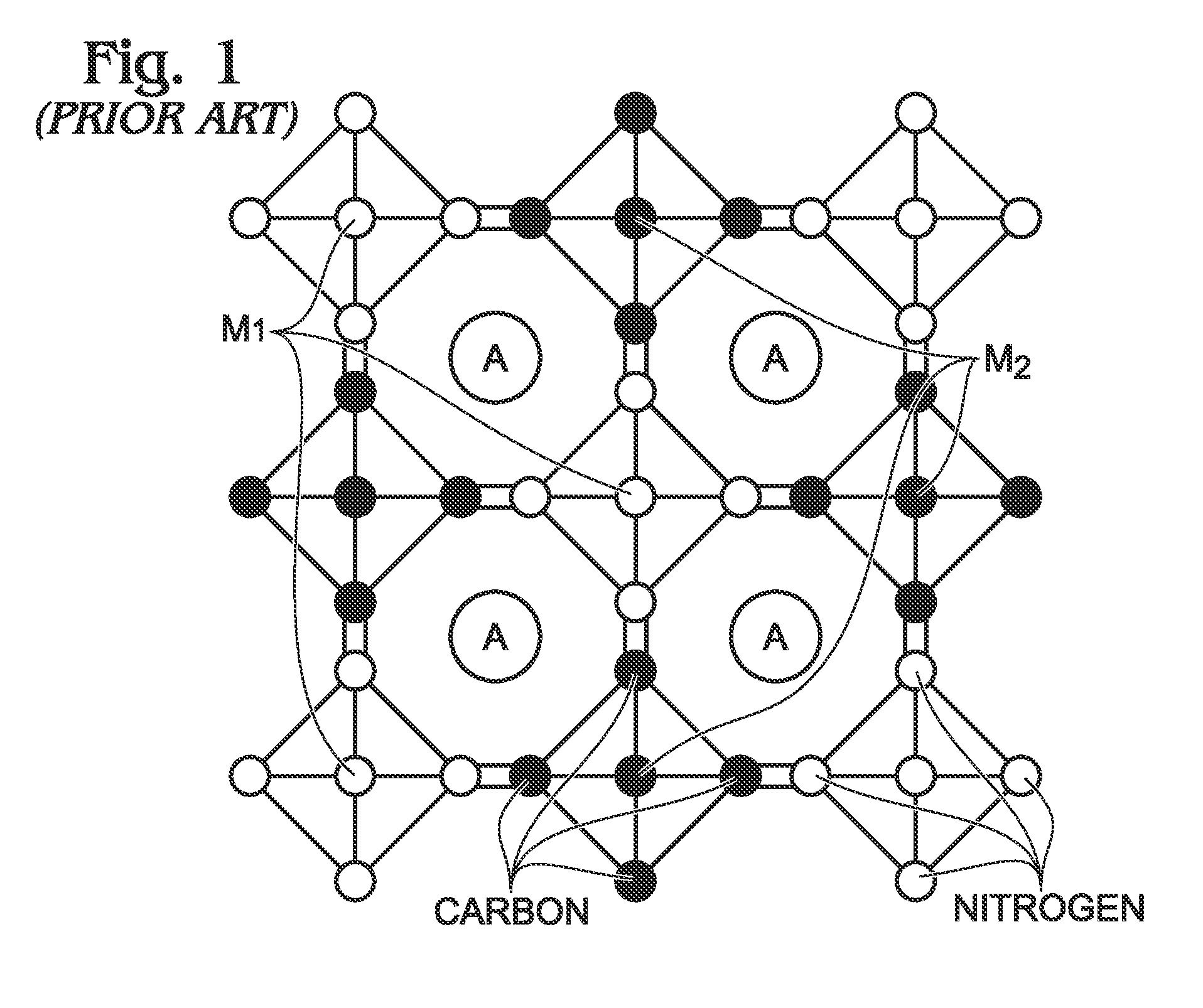

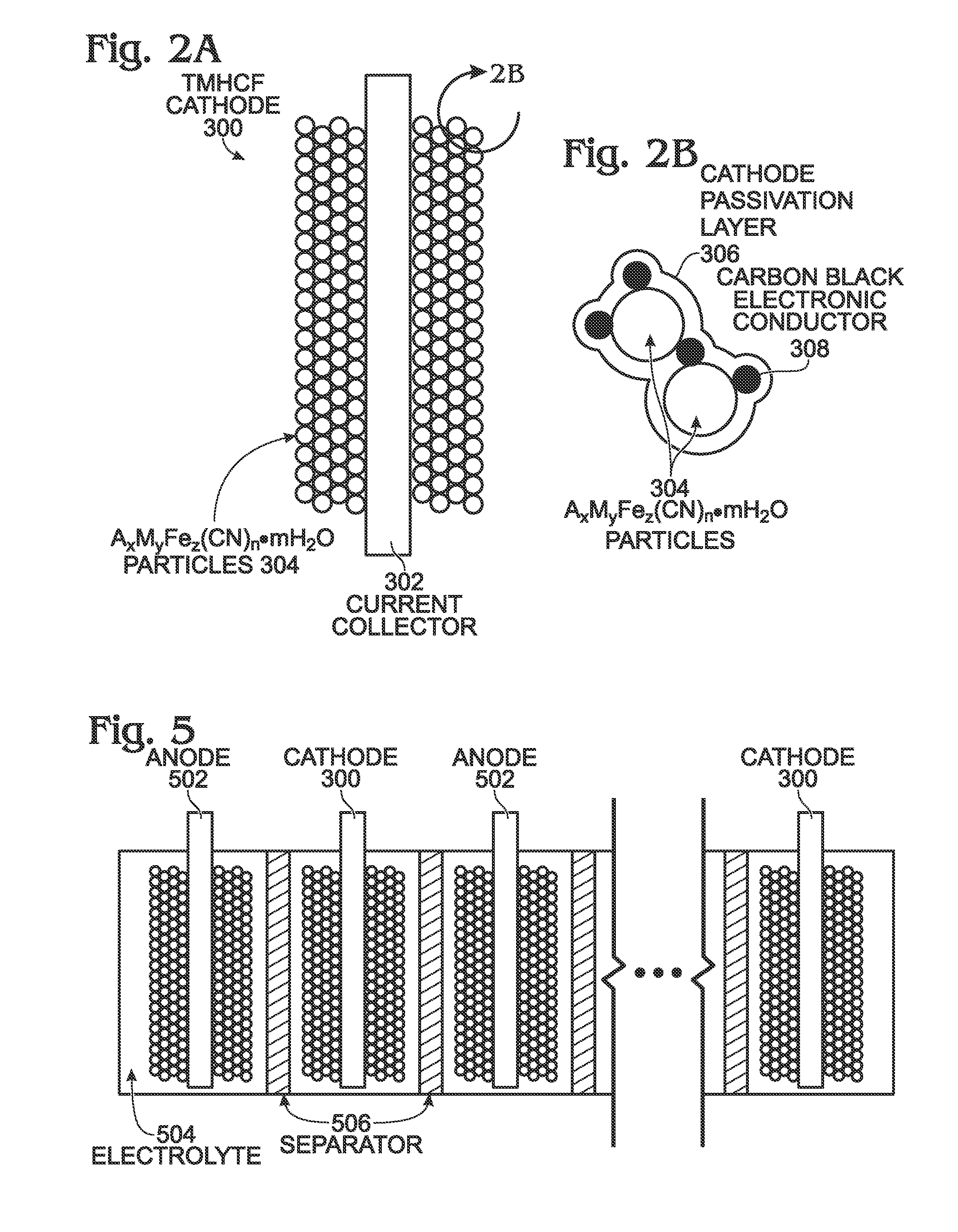

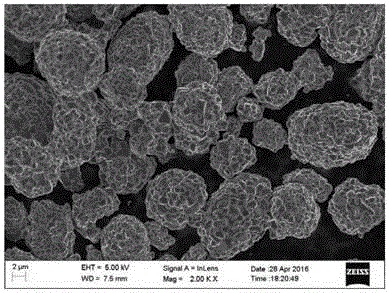

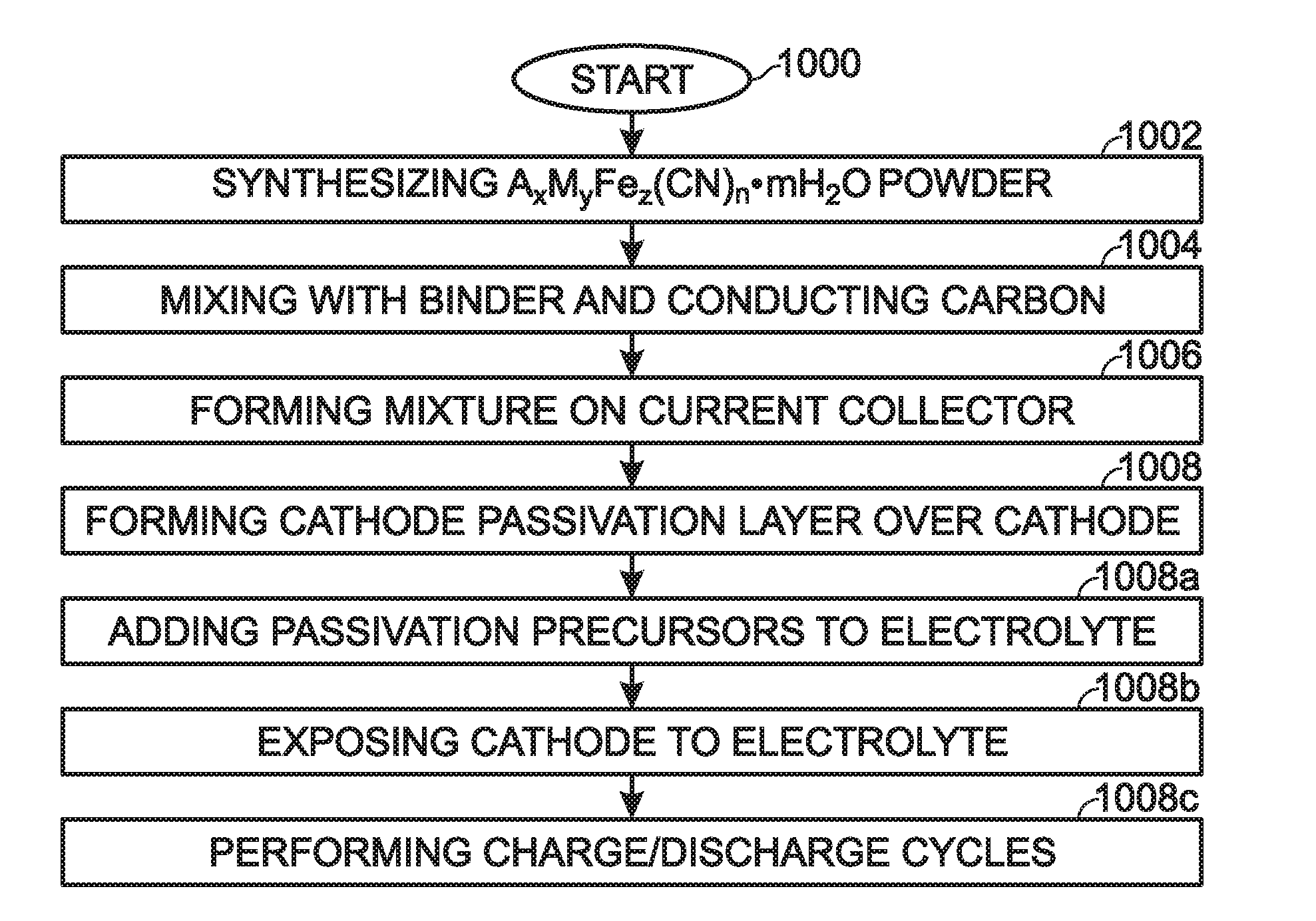

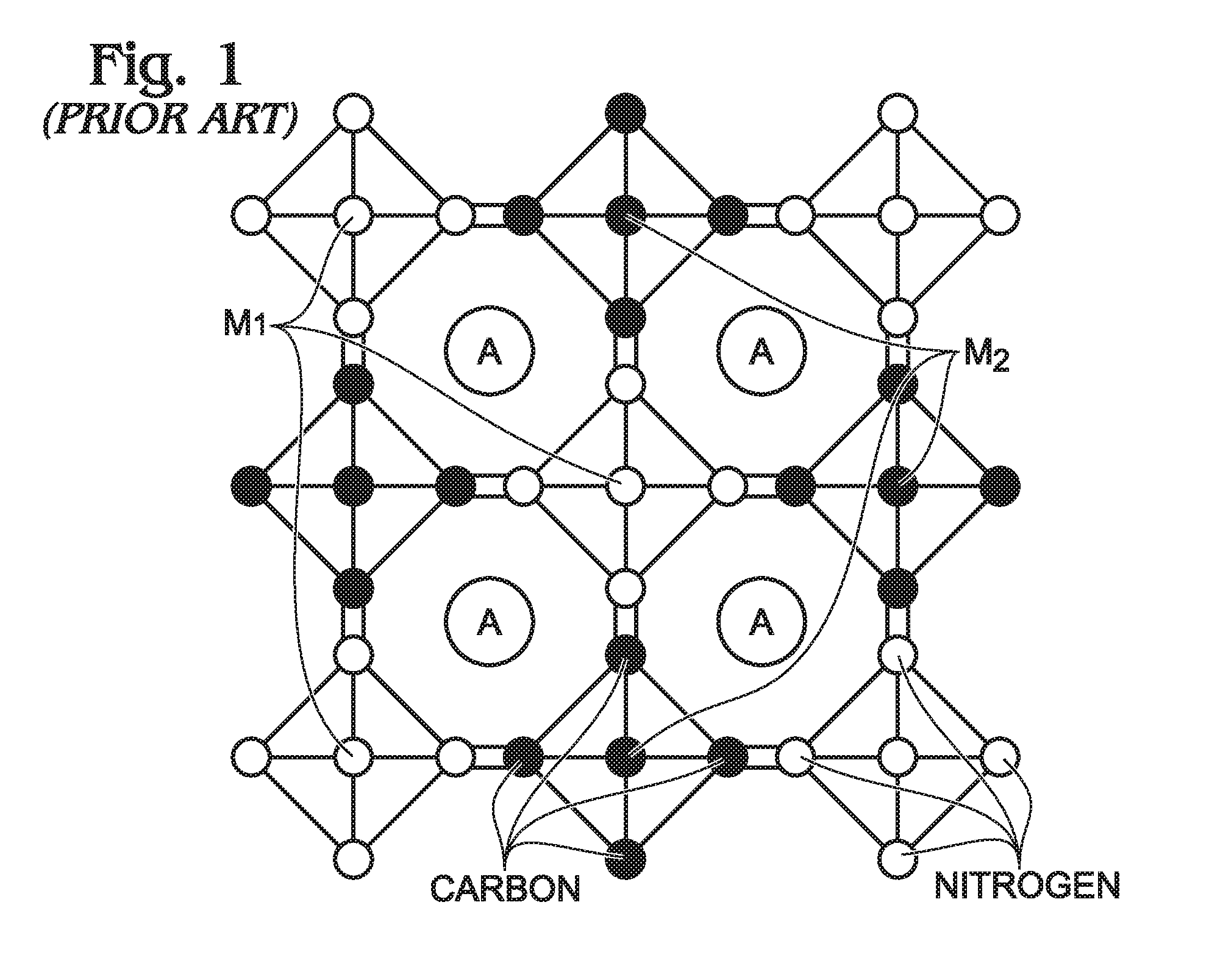

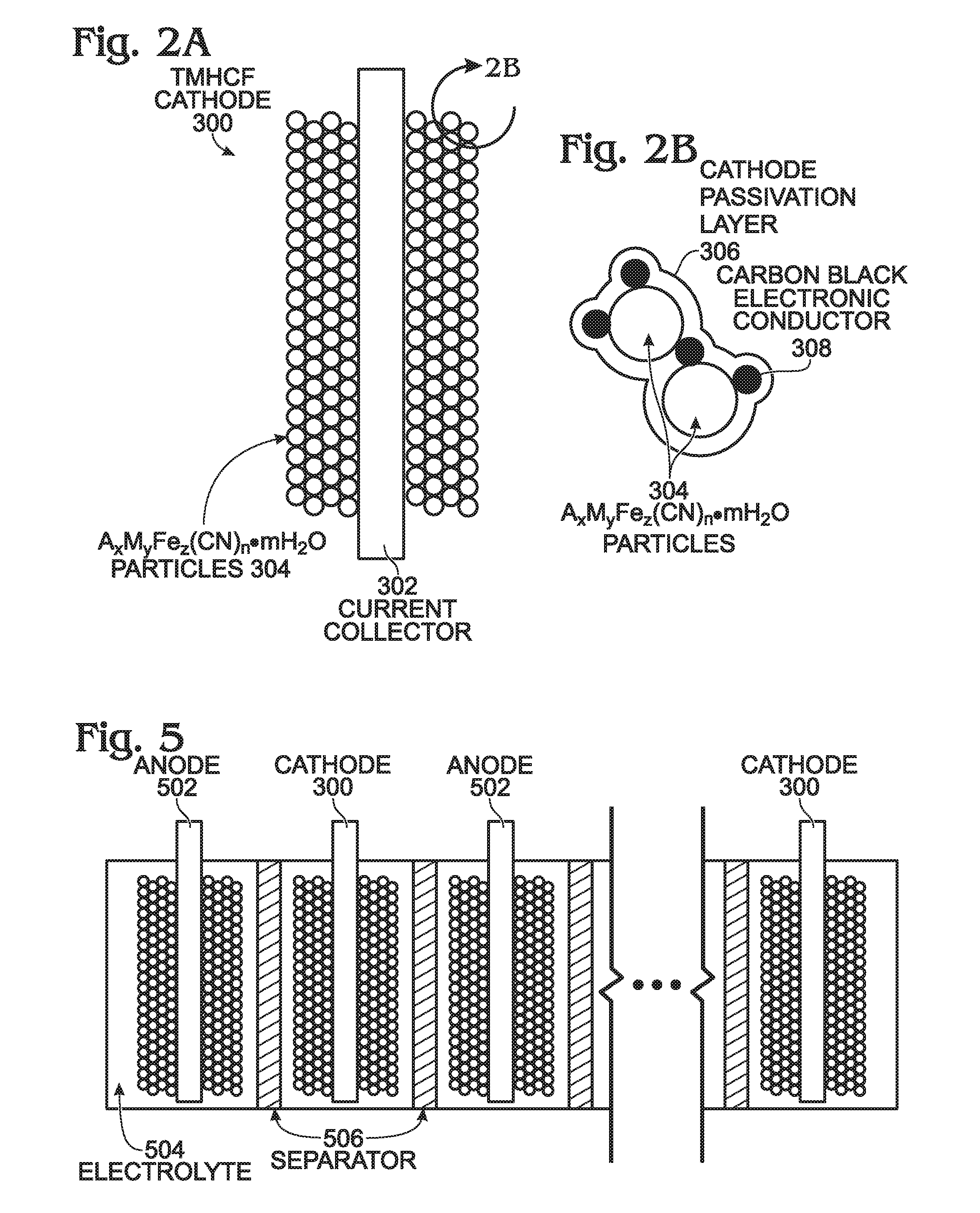

InactiveUS20130260260A1Stable structureStable surface structureOrganic electrolyte cellsPositive electrodesAlkaline earth metalSulfur

A protected transition metal hexacyanoferrate (TMHCF) battery cathode is presented, made from AxMyFez(CN)n.mH2O particles, where the A cations are either alkali or alkaline-earth cations, and M is a transition metal. In one aspect the cathode passivation layer may be materials such as oxides, simple salts, carbonaceous materials, or polymers that form a film overlying the AxMyFez(CN)n.mH2O particles. In another aspect, the cathode passivation layer is a material such as oxygen, nitrogen, sulfur, fluorine, chlorine, or iodine that interacts with the AxMyFez(CN)n.mH2O particles, to cure defects in the AxMyFez(CN)n.mH2O crystal lattice structure. Also presented are TMHCF battery synthesis methods.

Owner:SHARP KK

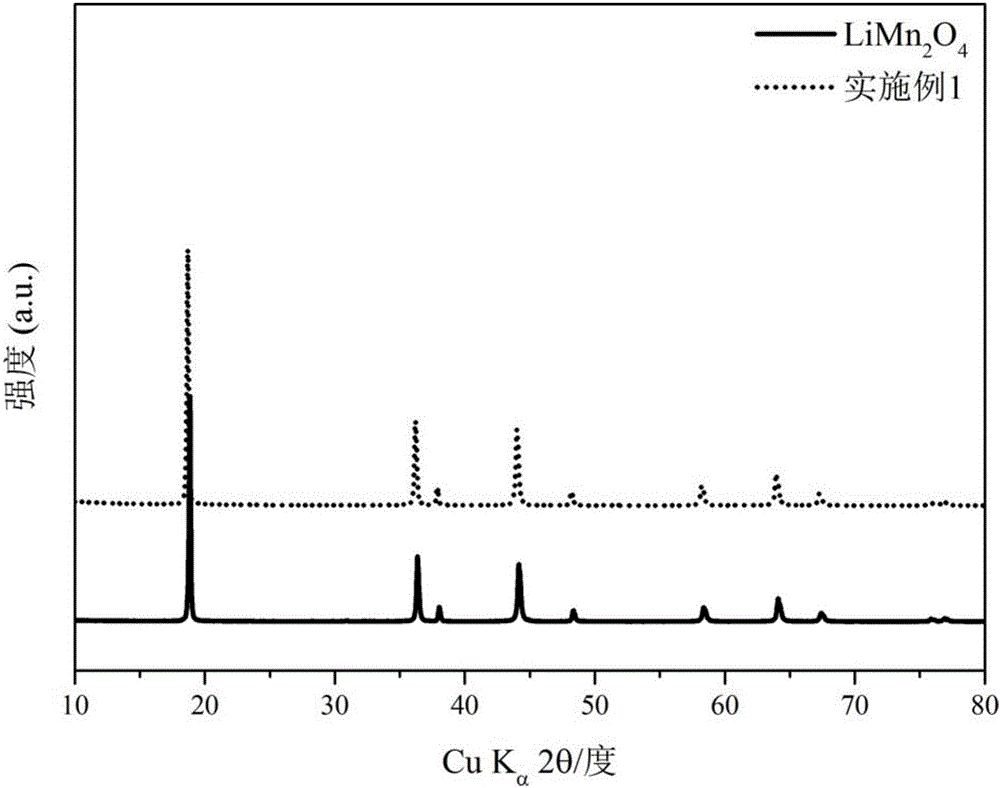

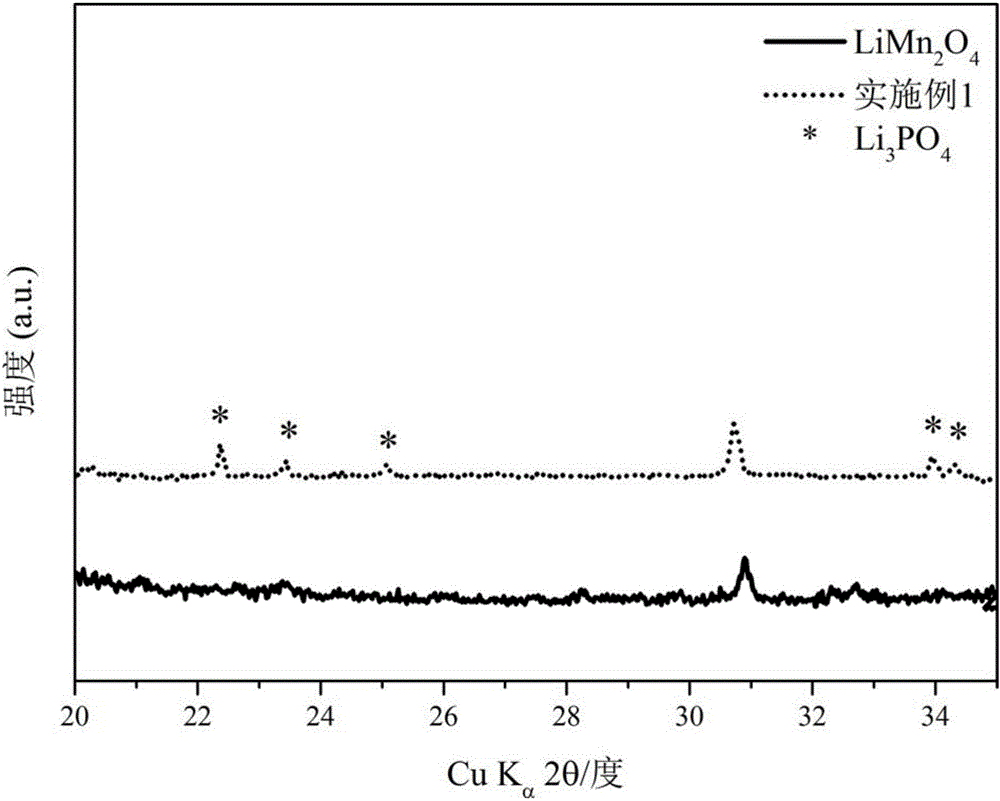

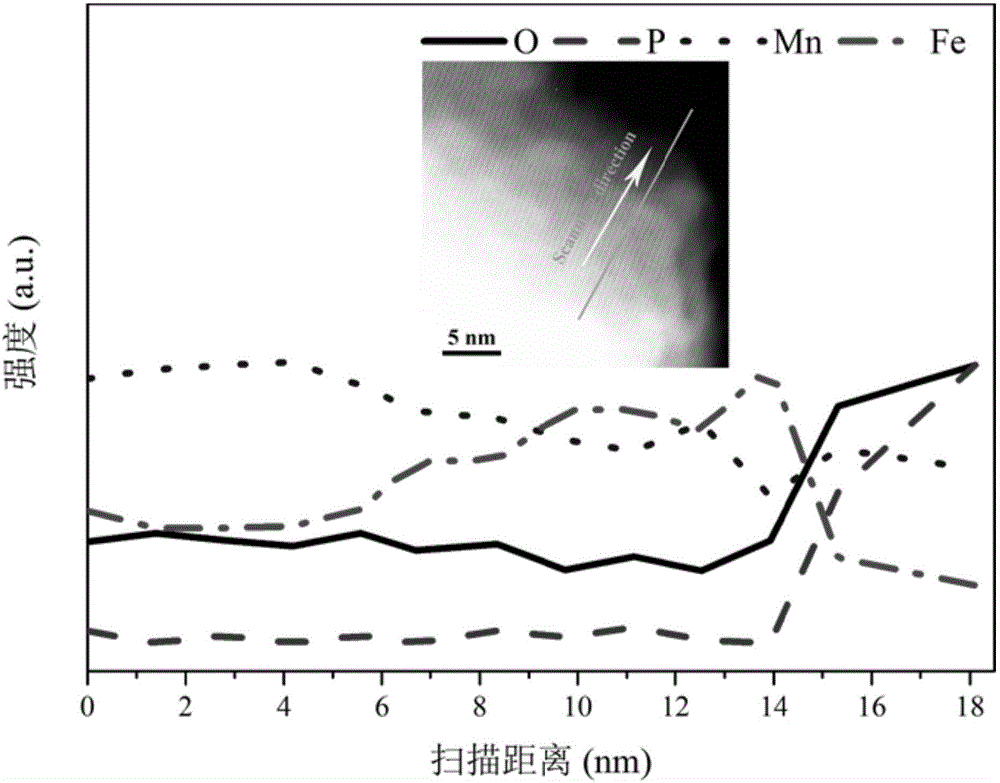

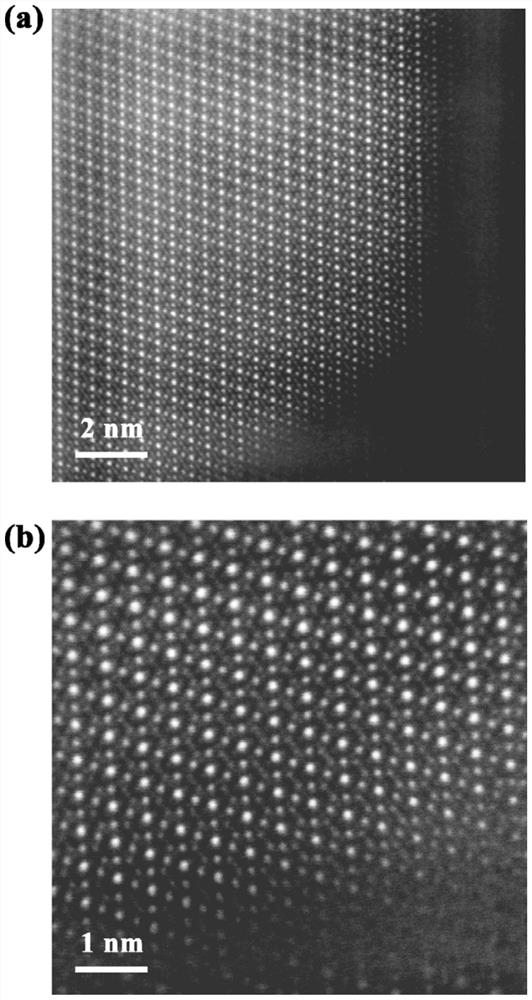

Positive active material with phosphate coated spinel structure as well as preparation method and application of positive active material

ActiveCN107528059AStable surface structureReduce reactivitySecondary cellsPositive electrodesPhosphatePhysical chemistry

The invention provides a positive active material with a phosphate coated spinel structure. The positive active material contains lithium-containing compound particles which have the spinel structure and the chemical formula LiMn(2-x)AxOy and a phosphate coating layer coating the surfaces of lithium-containing compound particles, in the chemical formula LiMn(2-x)AxOy, A is selected from one or more of Ni, Fe, Co, Ti, Y, Sc, Ru, Cu, Mo, Ge, W, Zr, Ca and Sr, x is larger than or equal to 0 and smaller than or equal to 0.7, and y is larger than or equal to 3.8 and smaller than or equal to 4.2; the lithium-containing compound particles have transition layers, and the transition layers contain dispersion elements which are diffused to enter the lithium-containing compound particles through coating and optional calcination. The invention also provides a preparation method of the positive active material and an application of the positive active material in a lithium ion secondary battery. The positive active material has improved circulation stability and coulombic efficiency when used in the lithium ion secondary battery.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Plumbum calcium alloy for starting type accumulators

InactiveCN101294248ASmall and uniform crystal grainsImprove and increase strengthElectrode carriers/collectorsMisch metalElectric-vehicle battery

The invention relates to a lead-calcium alloy used on a starting type storage battery, which is composed of a lead-calcium-tin alloy. The lead-calcium-tin alloy comprises calcium, tin, aluminum, misch metal and lead; the weight percentage of the calcium in the lead-calcium-tin alloy is 0.02 to 0.06 percent; the weight percentage of the tin in the lead-calcium-tin alloy is 0.10 to 1.0 percent; the weight percentage of the aluminum in the lead-calcium-tin alloy is 0.01 to 0.03 percent; the weight percentage of the misch metal in the lead-calcium-tin alloy is 0.01 to 1.00 percent; the other weight percentage is composed of the lead. Compared with prior art, an electric vehicle battery which is assembled by a lead-acid accumulator grid produced by using the lead-calcium alloy has the advantages of corrosion resistance, deep cycle, large-current discharge and long service life.

Owner:上海飞轮有色冶炼厂

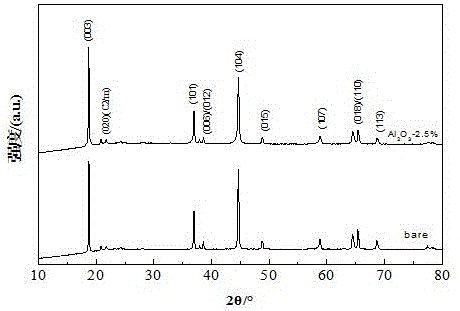

Modifying method by coating surface of lithium-rich positive electrode material with alumina

InactiveCN106684358AImprove electrochemical performanceStable surface structureCell electrodesSecondary cellsCitric acidMaterials science

The invention relates to a modifying method by coating a surface of a lithium-rich positive electrode material with alumina. The method comprises the following steps: carrying out Al2O3 surface modification on a lithium-rich positive electrode material with a sol solution, enabling a Al3+ ion coated salt to react with ammonia water, adding citric acid to form a sol solution, and then adding the lithium-rich positive electrode material to the sol solution, directly evaporating to dryness, and carrying out heat treatment to obtain a modified lithium-rich positive electrode coated with Al2O3 on the surface. The prepared lithium-rich positive electrode material has excellent electrochemical performances, the first discharge specific capacity is 289.69mAh / g and the first coulomb efficiency is 77.01% at the charge and discharge rate of 0.1C, and the capacity retention rate is still 95.45% after 50 cycles at a rate of 1C, showing a good cycle performance.

Owner:GUANGXI UNIV

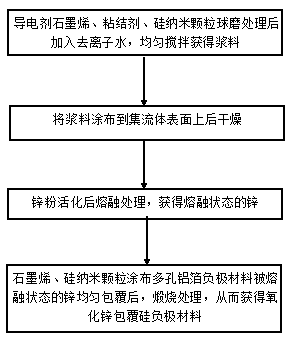

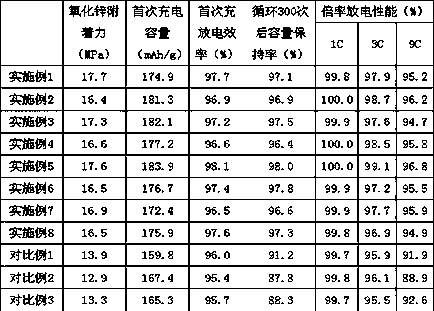

Preparation method of zinc oxide silicon-coated anode material

ActiveCN109560263AInhibition of volume expansionPhenomena that prevent damageSecondary cellsNegative electrodesMolten stateSlurry

The invention relates to the technical field of lithium ion battery anode materials, especially to a preparation method of a zinc oxide silicon-coated anode material. The method comprises the following steps of in order: 1) performing ball milling processing of conductive agent graphene, a binder and silicon nanoparticles, adding deionized water, and uniformly stirring the mixture to obtain slurry; 2) coating the slurry to the surface of a current collector and then performing drying; 3) performing zinc powder activation and then performing melting processing to obtain a zinc in a molten state; and 4) after the graphene and silicon nano-particle coating porous aluminum foil negative electrode materials are uniformly coated with the zinc in the molten state, performing calcination process to obtain the zinc oxide silicon-coated anode material. The preparation process is simple and practicable, simple to operate and low in required cost, and the prepared and obtained zinc oxide silicon-coated anode material can effectively avoid the problem that the expansion and contraction of silicon in the charge-discharge reaction process, can inhibit the secondary reaction of the anode materials, can improve the stability of electrode cycle and the cycle efficiency and can have a high electrical conductivity.

Owner:赵金保 +2

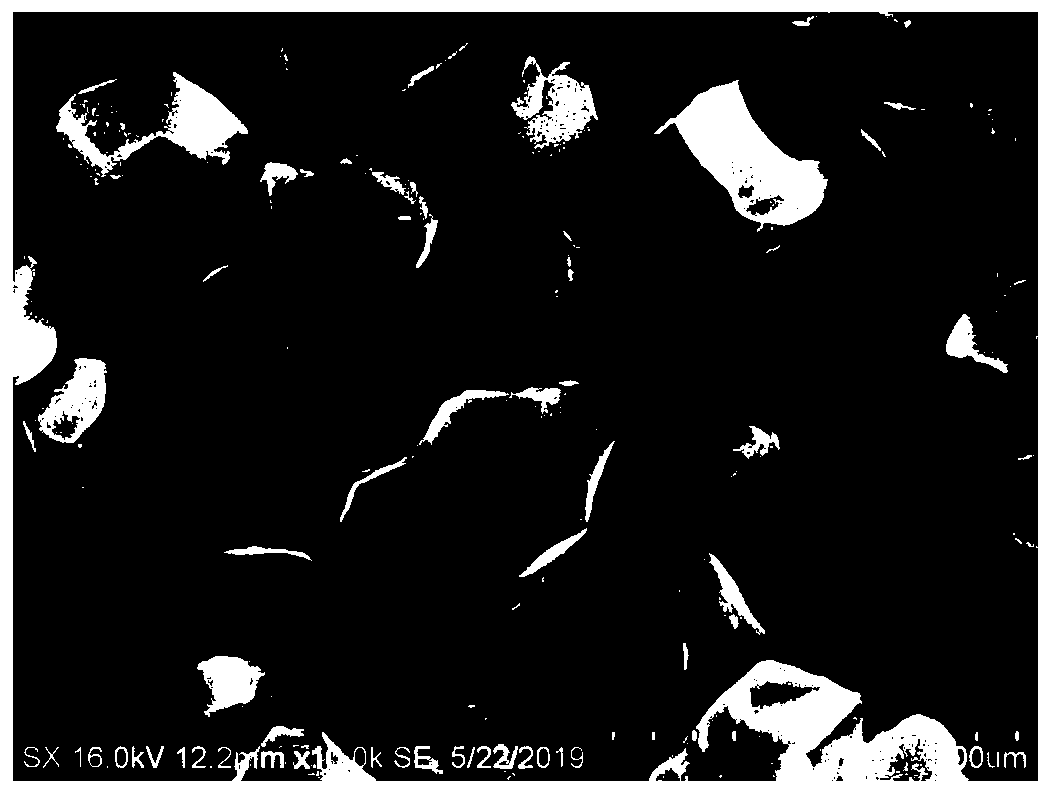

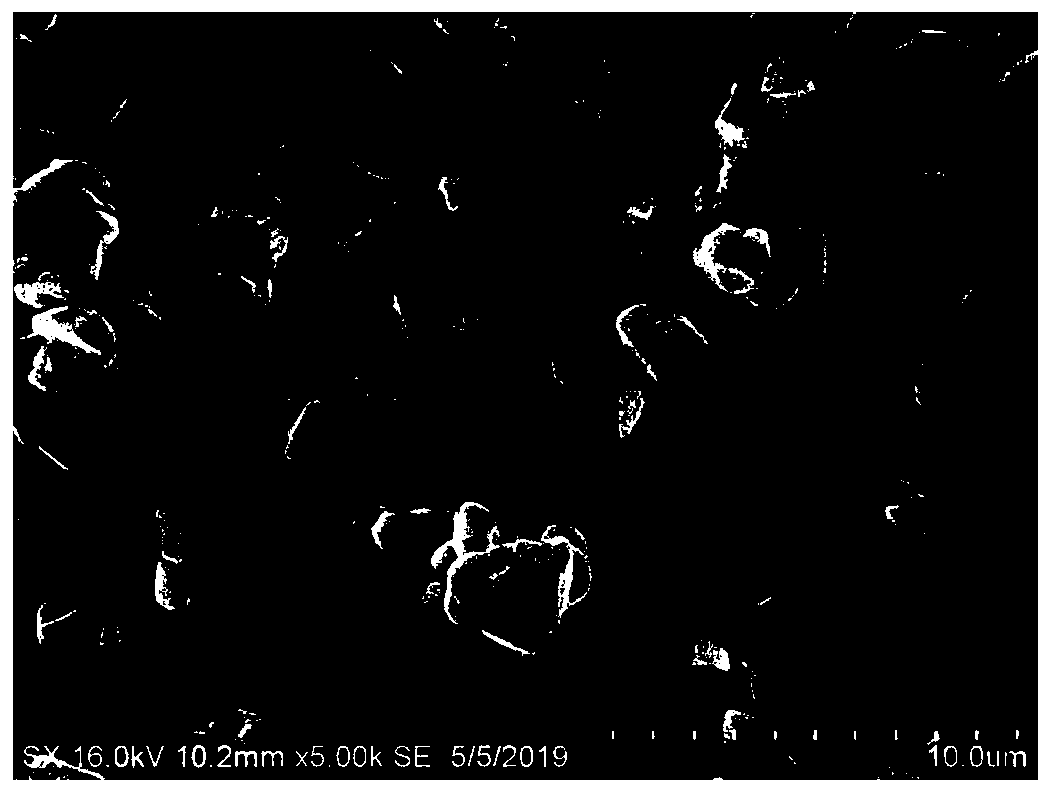

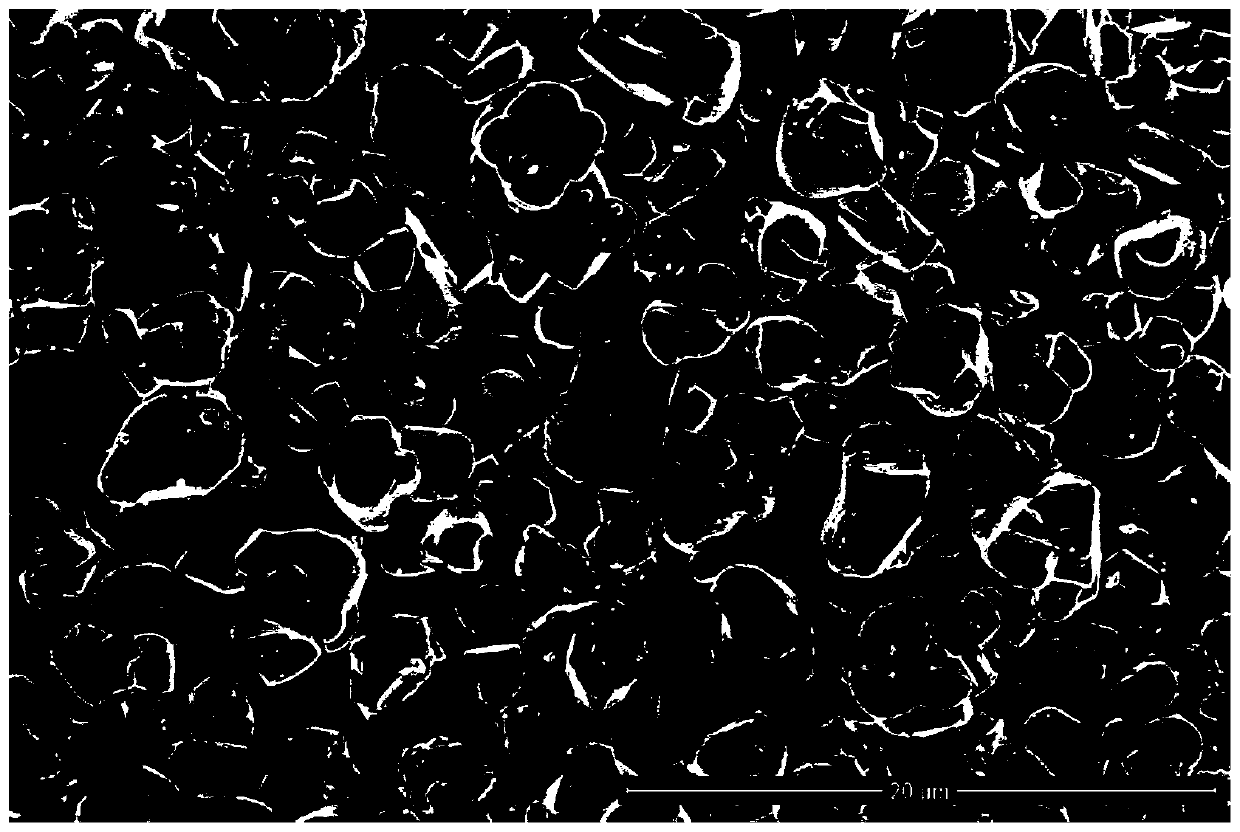

Vertical graphene-copper foil composite current collector based on in-situ growth and preparation method thereof

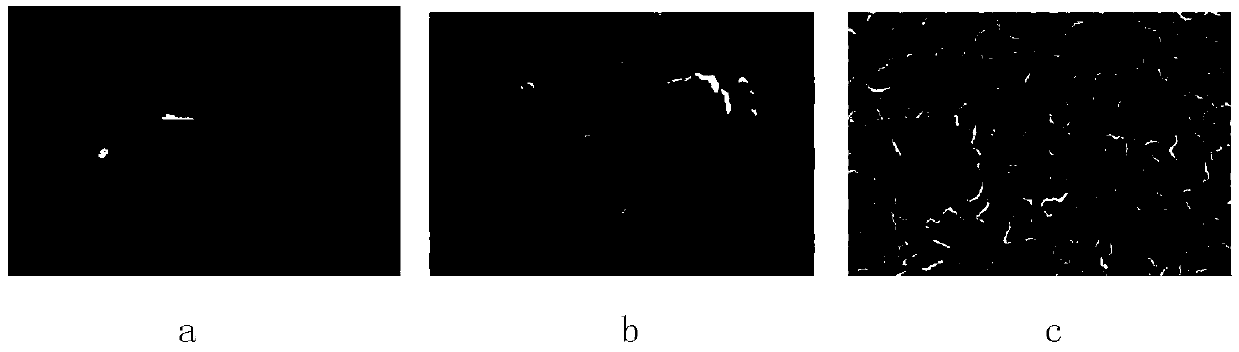

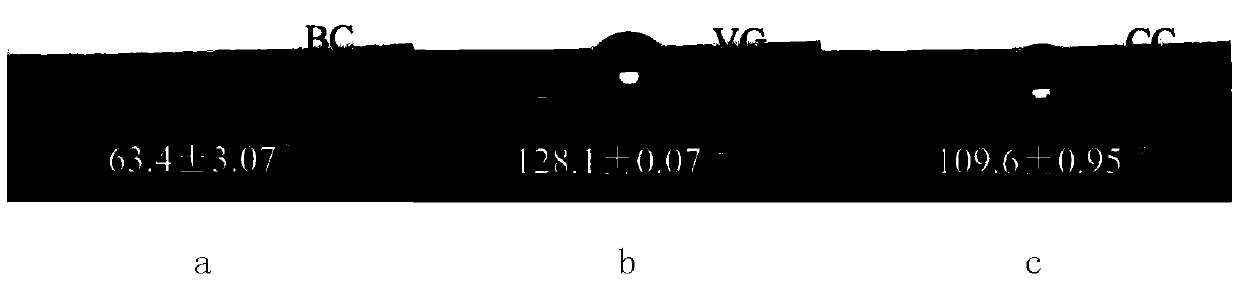

InactiveCN110190286AImprove wettabilityPromote infiltrationElectrode carriers/collectorsNegative electrodesInterface impedanceCopper foil

The invention discloses a vertical graphene-copper foil composite current collector based on in-situ growth and a preparation method thereof and belongs to the technical field of a lithium ion battery. The current collector is advantaged in that the vertical graphene-copper foil composite current collector is prepared in situ by plasma enhanced chemical vapor deposition, the prepared graphene-copper foil composite current collector has a micron-sized petal-like structure with a contact angle range of 125-143.5 DEG, has super hydrophobic and lipophilic properties, can effectively improve infiltration between the current collector and an active material interface, increases the contact surface and increases bonding strength, so the active material is not easy to fall off, and thereby interface impedance is reduced, infiltration of a negative electrode prepared by the current collector and the electrolyte is facilitated, the electrolyte is in sufficient contact with the negative electrodeactive material, the contact area is enhanced, and battery polarization is reduced. The method is advantaged in that operation is simple, cost is relatively low, and the method is suitable for large-scale production.

Owner:JILIN UNIV

Protected transition metal hexacyanoferrate battery electrode

InactiveUS9246164B2Stable structureStable surface structureOrganic electrolyte cellsAlkaline accumulator electrodesAlkaline earth metalSulfur

Owner:SHARP KK

Core-shell high-voltage monocrystal nickel cobalt lithium manganate positive electrode material and preparation method and application thereof

ActiveCN110165192AAvoid breakingIncrease compaction densityMaterial nanotechnologySecondary cellsAir atmosphereManganate

The invention discloses a core-shell high-voltage monocrystal nickel cobalt lithium manganate positive electrode material and a preparation method and application thereof, and the positive electrode material comprises a core layer and a shell layer arranged on the outer surface of the core layer, wherein the core layer and the shell layer form a core-shell structure. The core layer is made of Lia(NixCoyMn<1-x-y>)O2, wherein 1.0 <= a <= 1.15, 0.2 <= x <= 0.6, 0.1 <= y <= 0.5, 1-x-y > 0, and the material of the core layer is of a monocrystal type; the material of the shell layer is LibCokM<1-k>O2, wherein 0.9 <= b <= 1.05, 0.8 <= k <= 0.99, and M is one or more of Mg, Al, Zr, Ti and W. The preparation method comprises the following steps: firstly preparing monocrystal lithium nickel cobaltmanganate, then preparing nano cobaltosic oxide slurry, adding the monocrystal lithium nickel cobalt manganate, lithium salt and an M-containing additive into the slurry, performing mixing, then carrying out spray drying, and performing sintering in an air atmosphere, so as to prepare the nano cobaltosic oxide lithium manganate cathode material. The invention also discloses an application of the positive electrode material in lithium ion batteries. The positive electrode material has excellent first charge-discharge efficiency and high capacity retention rate, and also has excellent cycle performance and safety performance under high voltages of 4.35 V and 4.4 V.

Owner:JIANGSU XIANGYING NEW ENERGY TECH CO LTD

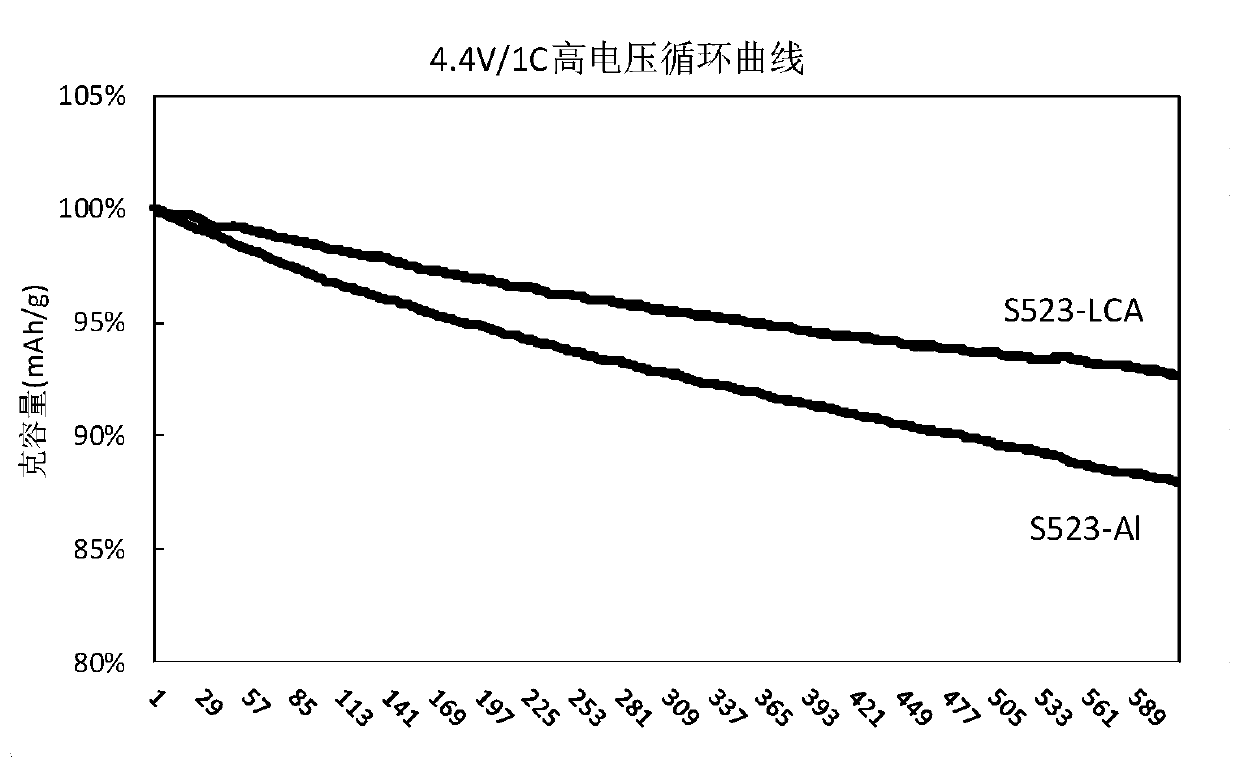

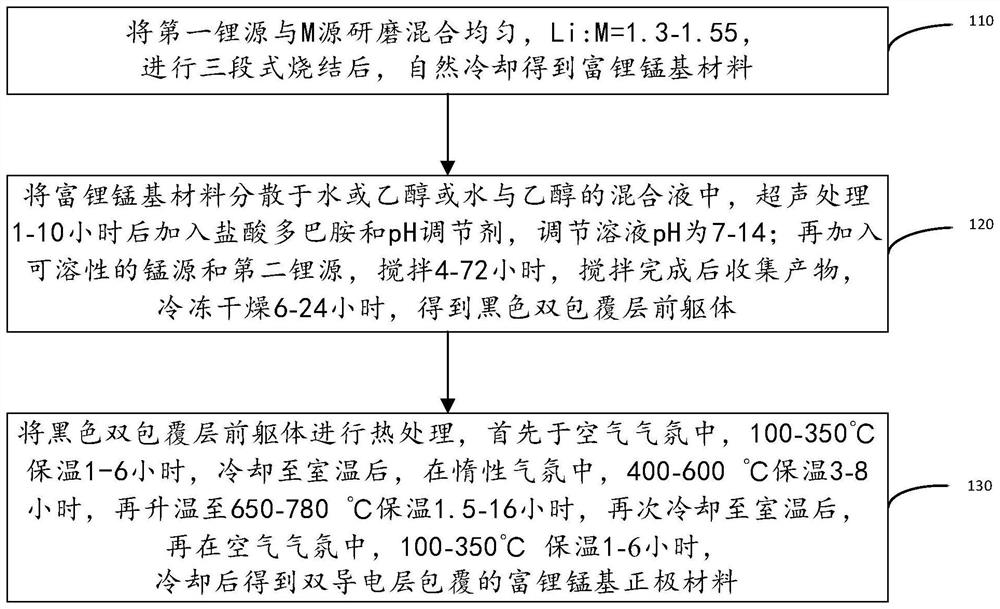

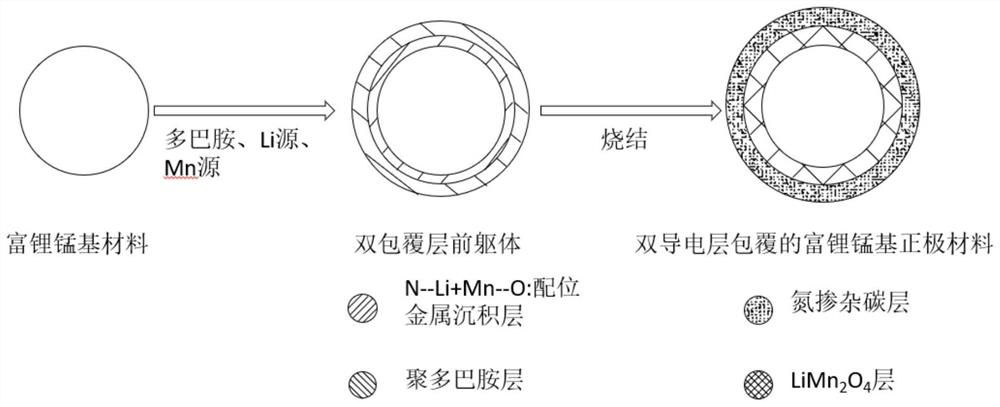

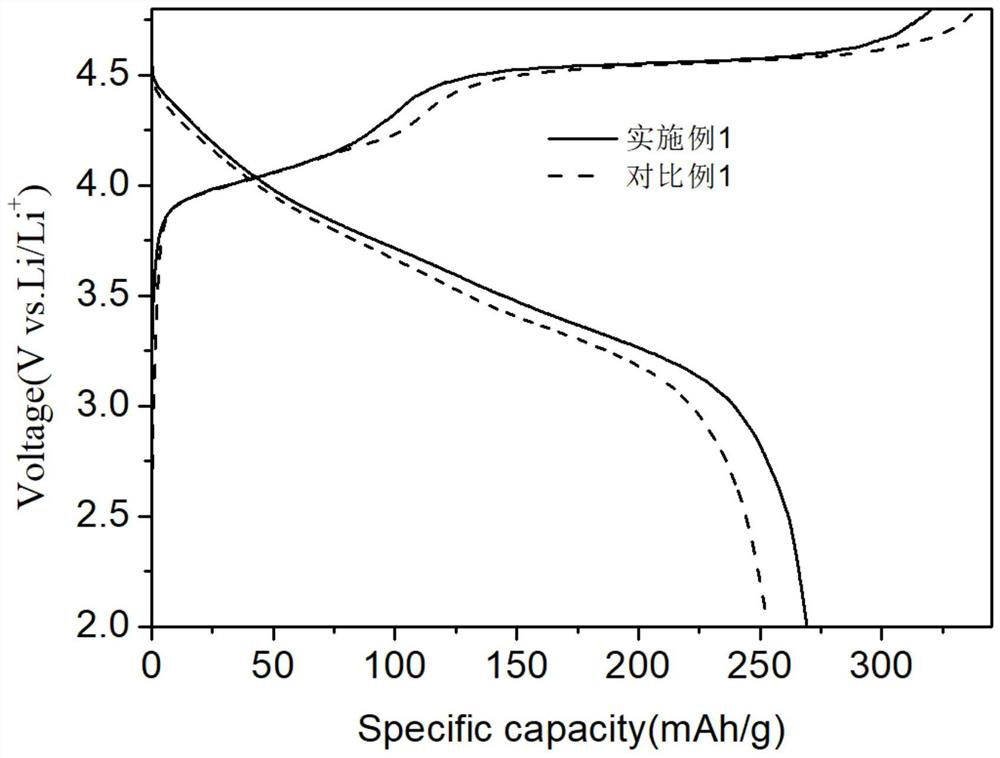

Lithium-rich manganese-based positive electrode material coated with double conductive layers as well as preparation method and application thereof

InactiveCN113078315AIncrease capacityImproved magnification performanceMaterial nanotechnologyCarbon compoundsCarbon coatingManganese

The invention relates to a lithium-rich manganese-based positive electrode material coated with double conductive layers as well as a preparation method and application thereof. The lithium-rich manganese-based positive electrode material structurally comprises a lithium-rich manganese-based material core, a spinel lithium manganate coating layer and a nitrogen-doped graphitized carbon coating layer from inside to outside, an overlapping region exists between the spinel lithium manganate coating layer and the nitrogen-doped graphitized carbon coating layer, and the thickness of the overlapping region is 2-20 nm; the sum of the mass of the spinel lithium manganate coating layer and the nitrogen-doped graphitized carbon coating layer accounts for 1%-10% of the mass of the lithium-rich manganese-based positive electrode material; the chemical expression of the lithium-rich manganese-based positive electrode material is xLi[Li0.33Mn0.67]O2.(1-x)LiMO2@LiMn2O4@C, 0<x<1, wherein M at least comprises two elements of Mn, Ni and Co.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

High heat conductivity type graphite film-metal composite material and preparation method thereof

InactiveCN109234691AStable surface structureSolve the problem of falling powderVacuum evaporation coatingSputtering coatingElectricityHeat conducting

The invention provides a preparation method of a high heat conductivity type graphite film-metal composite material, and relates to the field of materials. The method is characterized in that a vacuummagnetron sputtering mode is used; a metal layer is sputtered on the surface of a graphite film. Therefore, due to the metal layer, the surface structure of the graphite film is stable, and the problem that powder falls off from the graphite film can be solved; moreover, the heat dissipating performance, the flexibility, the longitudinal electricity conductivity, the pressure resistance, and thelike of the graphite film can be improved based on the intrinsic heat conducting performance and electricity conducting performance of metal. The high heat conductivity type graphite film-metal composite material is prepared according to the preparation method and is outstanding in heat dissipating performance, flexibility, longitudinal electricity conductivity, pressure resistance, and the like.

Owner:江苏墨泰新材料有限公司

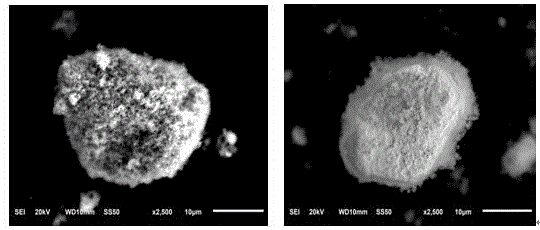

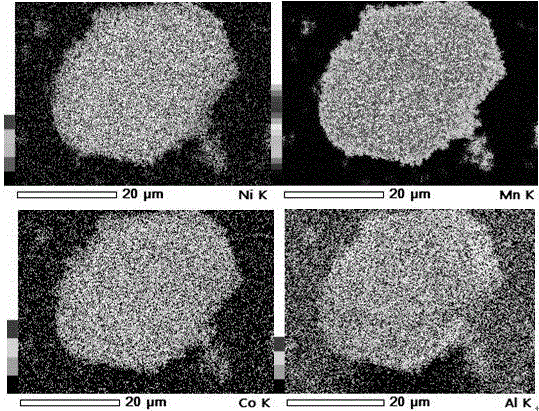

Nanometer silicon carbide coated lithium nickel manganese cobalt cathode material and preparation method thereof

InactiveCN106410137AImprove conductivityReduce surface polarizationMaterial nanotechnologyCell electrodesManganeseCobalt

The invention relates to a nanometer silicon carbide coated lithium nickel manganese cobalt cathode material and preparation method thereof. The nanometer silicon carbide coated lithium nickel manganese cobalt cathode material is prepared through the coating of the nanometer silicon carbide on the surface of a lithium nickel manganese cobalt cathode material; the mass ratio of the lithium nickel manganese cobalt cathode material to the nanometer silicon carbide is 1: 0.002-0.02; the chemical general formula of the lithium nickel manganese cobalt cathode material is LiaNixCoyMnzO2, wherein a is not less than 0.9 and not more than 1.2, and x+y+1=1; and the grain size of the nanometer silicon carbide is 10-500nm. The nanometer silicon carbide is coated on the surface of the lithium nickel manganese cobalt cathode material to prepare the nanometer silicon carbide coated lithium nickel manganese cobalt cathode material, so that the conductivity of the cathode material is increased, the surface polarization of the material in the charging / discharging process is effectively lowered, thereby improving the rate performance and the cycle performance of the material.

Owner:JIANGSU XIANGYING NEW ENERGY TECH CO LTD

Protected Transition Metal Hexacyanoferrate Battery Electrode Synthesis Method

ActiveUS20160087260A1Stable structureStable surface structureElectrode carriers/collectorsPositive electrodesSynthesis methodsPolymer

Owner:SHARP KK

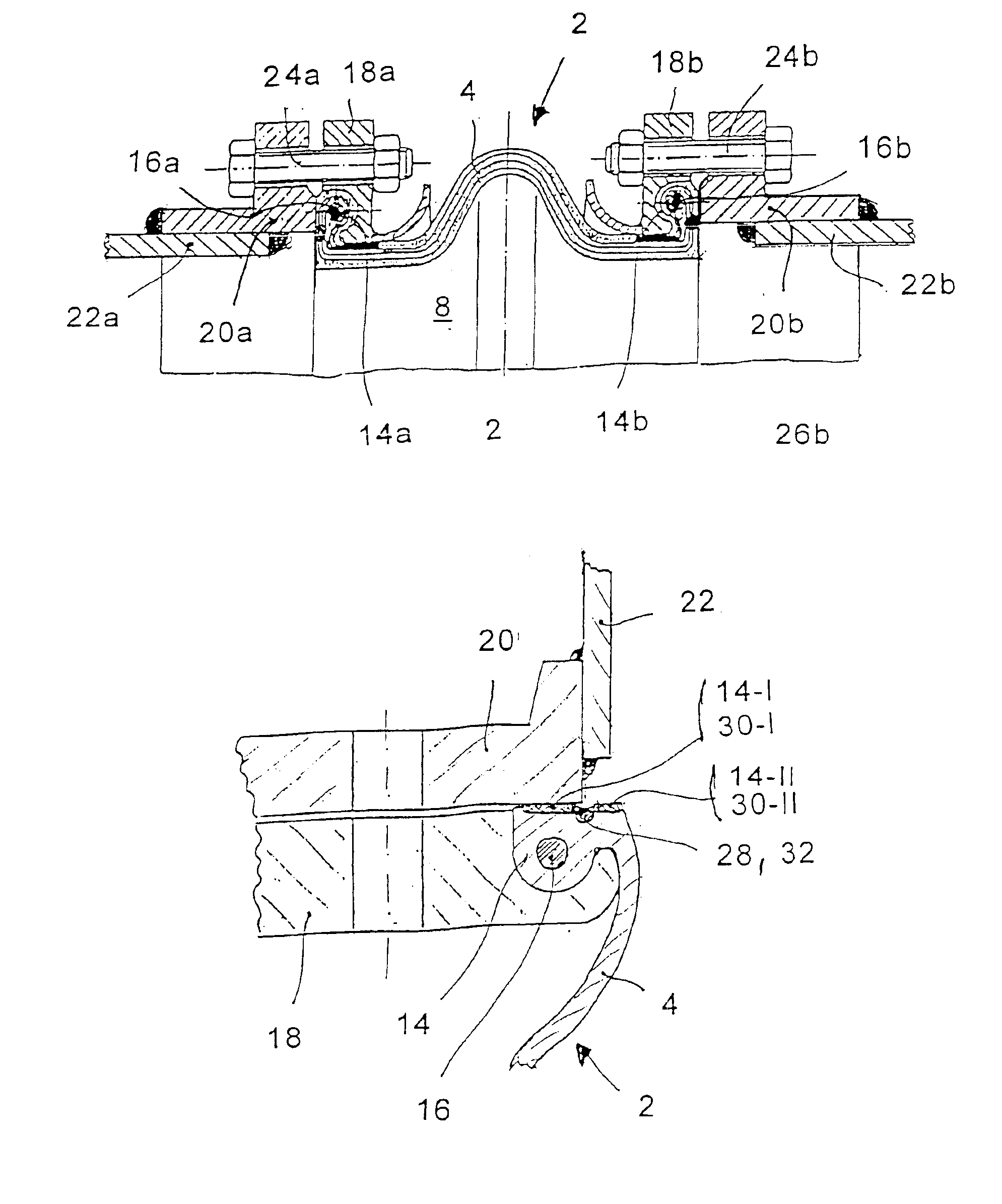

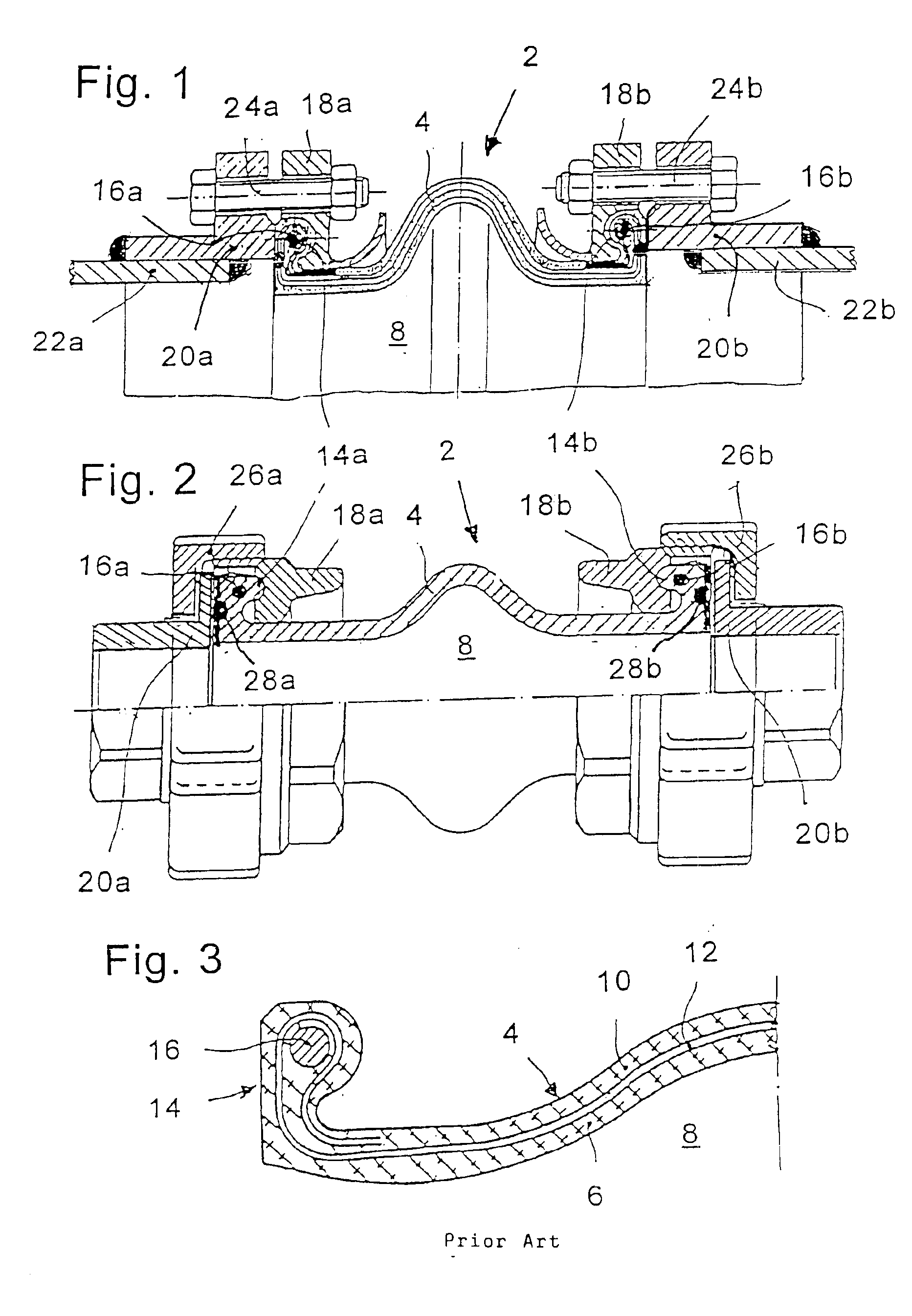

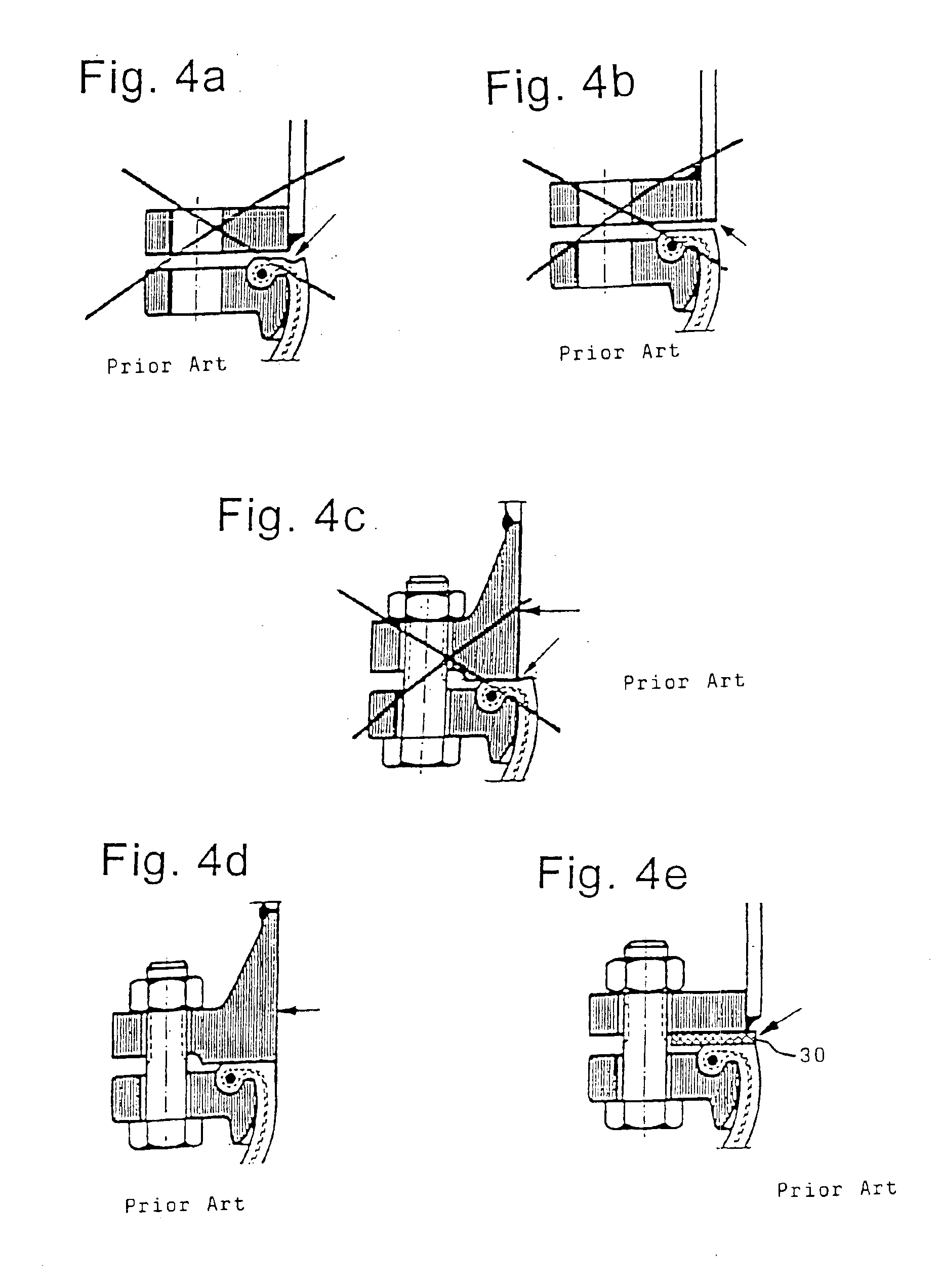

Flexible pipe connecting unit

InactiveUS6945567B2Stable surface structureAvoid flowSleeve/socket jointsFlanged jointsWave shapeEngineering

The invention is directed to a flexible pipe connecting unit which includes a part made of elastic workable material. The pipe connecting unit includes a wave-shaped or hose-shaped bellows (4) made of elastomeric material. The bellows (4) has respective projecting flange collars (14; 14 a, 14b) at its respective ends. The flange collars (14; 14a, 14b) preferably are provided with a reinforcement insert (16; 16a, 16b) and annularly-shaped pipe connecting pieces (flanges 18; 18a, 16b) are disposed behind corresponding ones of the flange collars. The pipe connecting unit (2) coacts directly with weld-on flanges as counter flanges (20; 20a, 20b) without additional seals or corresponding joining locations. For this purpose, the end sealing faces of the flange collars (14; 14a, 14b) are partitioned in the radial direction by a peripherally extending slot (28; 28a, 28b). In this way, at least two coaxial concentric annularly-shaped sealing surfaces (14-I, 14-II) are formed. With outer weld-on or slip-on flanges (20; 20a, 20b), only corresponding ones of the outer annular sealing Surfaces (14-I) are in contact engagement and, when the counter flange (20; 20a, 20b) is a welding-neck flange, at least the outer sealing annular surface (14-I) comes into contact engagement. A stabilization ring (32) can be implanted in the slot (28; 28a, 28b) of the flange collar (14; 14a, 14b) between the outer annular sealing surface (14-I) and the inner annular sealing surface (14-II).

Owner:CONTITECH LUFTFEDERSYST

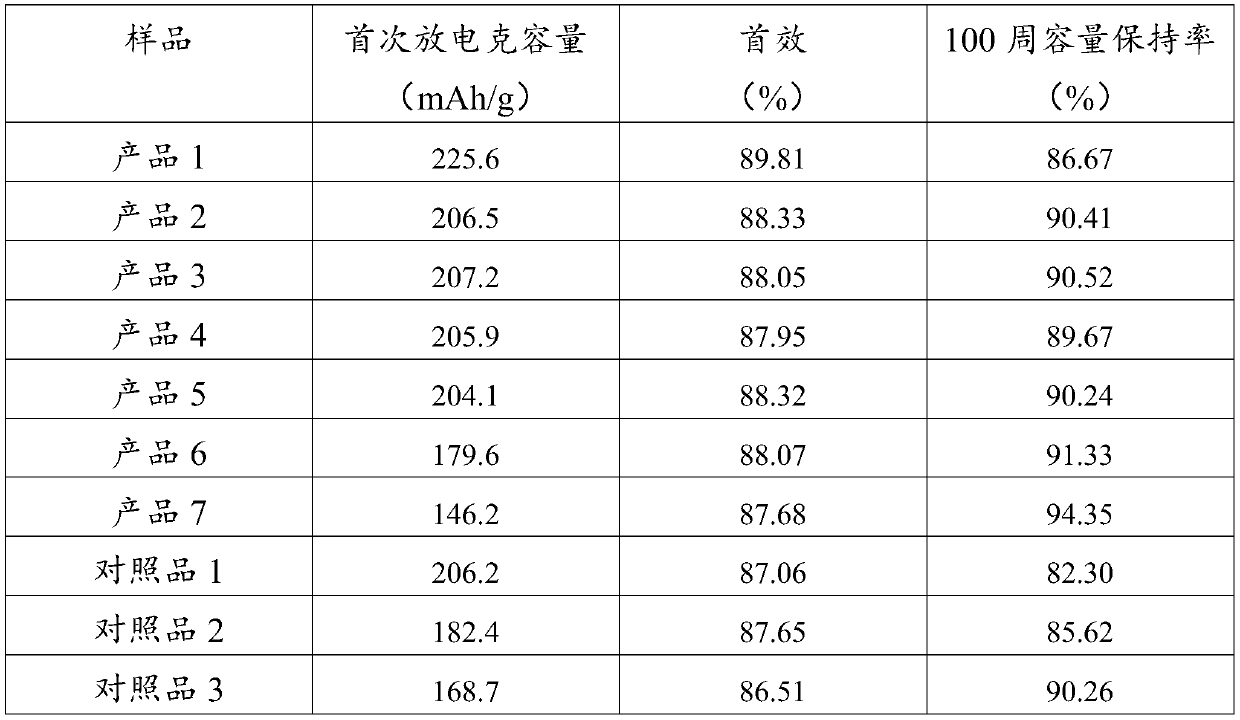

Composition, preparation method and application of composition to ion battery positive electrode material

InactiveCN109904414ARaw materials are easy to getThe process is simple and reliableCell electrodesLi-accumulatorsManganateCharge discharge

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a composition, a preparation method and an application of the composition to an ion battery positiveelectrode material. The composition comprises nickel cobalt lithium manganate, nano-sol and a liquid-phase solvent, wherein the nano-sol is selected from one or more of nano-aluminum sol, nano-titanium sol, nano-silicon sol, nano-yttrium sol, nano-silicon aluminum sol and nano-silicon zirconium sol; and the pH value of the nano-sol is less than 7. The invention also provides the preparation methodof the composition, and an application of the composition or a product obtained by the preparation method to the lithium ion battery positive electrode material. The preparation method is simple andconvenient, and the raw materials are low in price and easy to obtain; after the battery is prepared, a charge-discharge cycle test is carried out, and the first effect and the 100-cycle capacity retention rate are both superior to those of a reference substance; and the technical defects that in the prior art, a coating technology of the nickel cobalt lithium manganate positive electrode materialis complex in process and high in cost are overcome.

Owner:深圳新恒业电池科技有限公司

Positive electrode active material, preparation method thereof and lithium battery

ActiveCN112151773AStable surface structureReduce reactivityFinal product manufactureCell electrodesPhysical chemistryLithium compound

The present invention provides a positive electrode active material having a spinel structure. The positive electrode active material comprises lithium-containing compound particles having a chemicalformula of Li1+xNi0.5-yMn1.5-zOu, wherein -0.2< / =x< / = 0.2, -0.2< / = y< / = 0.2, -0.2< / = z< / =0.2, and 3.8 < / = u < / = 4.2, the positive electrode active material is characterized in that surfaces of the lithium-containing compound particles have a rock salt phase surface layer having a gradient phosphorus distribution, and contains a metal element that occupies the 16c or 8a position of the spinel octahedron. Compared with the prior art, the surface gradient phosphorus-doped spinel positive electrode active material for the lithium ion battery provided by the invention is advantaged in that (1) thepreparation method is simple in process and low in cost; (2) the comprehensive performance of the spinel positive electrode active material can be greatly improved, and the spinel positive electrode active material has an excellent development prospect.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

High-voltage long-circulation high-nickel single crystal positive electrode material as well as preparation method and application thereof

ActiveCN109817904AStable structureImprove high pressure cycle stabilityCell electrodesSecondary cellsLithiumSingle crystal

The invention discloses a high-voltage long-circulation high-nickel single crystal positive electrode material as well as a preparation method and application thereof. A high-voltage long-circulationhigh-nickel single crystal positive electrode material has a chemical formula of LiNixCoyMn1-x-yO2. In the formula, x is greater than or equal to 0.6 and less than 1, and y is greater than 0 and lessthan or equal to 0.4; wherein a nickel-lithium mixed shell layer is arranged on the surface of the high-nickel single crystal positive electrode material, and the concentration of metal elements in the high-nickel single crystal positive electrode material is in gradient distribution. The invention also discloses a preparation method of the high-voltage long-circulation high-nickel single crystalpositive electrode material and an application of the high-voltage long-circulation high-nickel single crystal positive electrode material. A nickel-lithium premixing row layer is formed on the surface of the high-nickel single crystal positive electrode material, so that the structure of the material is stabilized, electrolyte erosion is prevented, and further transformation of the material structure is delayed. Metal elements in the material are distributed in a gradient concentration mode, and the high-pressure cycling stability of the material is enhanced through the gradient distributionstructure.

Owner:GUANGDONG BRUNP RECYCLING TECH +3

TiB<2>-coated lithium nickel cobalt manganate positive electrode material and preparation method therefor

InactiveCN107799731AImprove conductivityReduce surface polarizationCell electrodesSecondary cellsManganateCharge discharge

The invention discloses a TiB<2>-coated lithium nickel cobalt manganate positive electrode material and a preparation method therefor. The positive electrode material has the chemical formula of LiNi<x>Co<y>Mn<z>O<2>, wherein a is greater than or equal to 0.9 and less than or equal to 1.2; x+y+z is equal to 1; the TiB<2> granules are 20-2,000nm in dimensions; and the mass ratio of TiB<2> to thelithium nickel cobalt manganate positive electrode material is (0.002-0.02) to 1. The conductivity of the positive electrode material is improved, and surface polarization effect of the material in the charging-discharging process of the material is lowered effectively, thereby improving rate capability and cycle performance of the material.

Owner:CHANGZHOU POWERGENIE MATERIALS

Composite coated nickel-rich positive electrode material as well as preparation method and application thereof

ActiveCN114678500AEasy to storeImprove efficiencySolid electrolytesCell electrodesSolid state electrolyteLithium-ion battery

The invention discloses a composite coated nickel-rich positive electrode material as well as a preparation method and application thereof, and belongs to the technical field of lithium ion battery positive electrode materials. The composite coated positive electrode material comprises a nickel-rich positive electrode base material, a transition layer and a composite coating layer coated on the surface of the base material. The composite coating layer is composed of the composite solid electrolyte and the lithium-boron compound, the positive electrode material can be effectively protected through the combined action of the composite solid electrolyte and the lithium-boron compound, the safety performance of the material is improved, and the rate capability of the material can be further improved.

Owner:BEIJING WELION NEW ENERGY TECH CO LTD

Anode material with core-shell structure and manufacture method thereof

InactiveCN109860579AImprove conductivityExcellent rate performanceCell electrodesSecondary cellsCore shellLarge capacity

The invention provides an anode material with a core-shell structure and a manufacture method thereof. The anode material has the core-shell structure, wherein SiO and / or Si serves as a center core, acarbon material serves as a buffer layer, and an aluminum oxide material serves as a shell. The invention further provides a preparation method of the anode material. The anode material has high capacity retaining rate and good cyclic performance.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

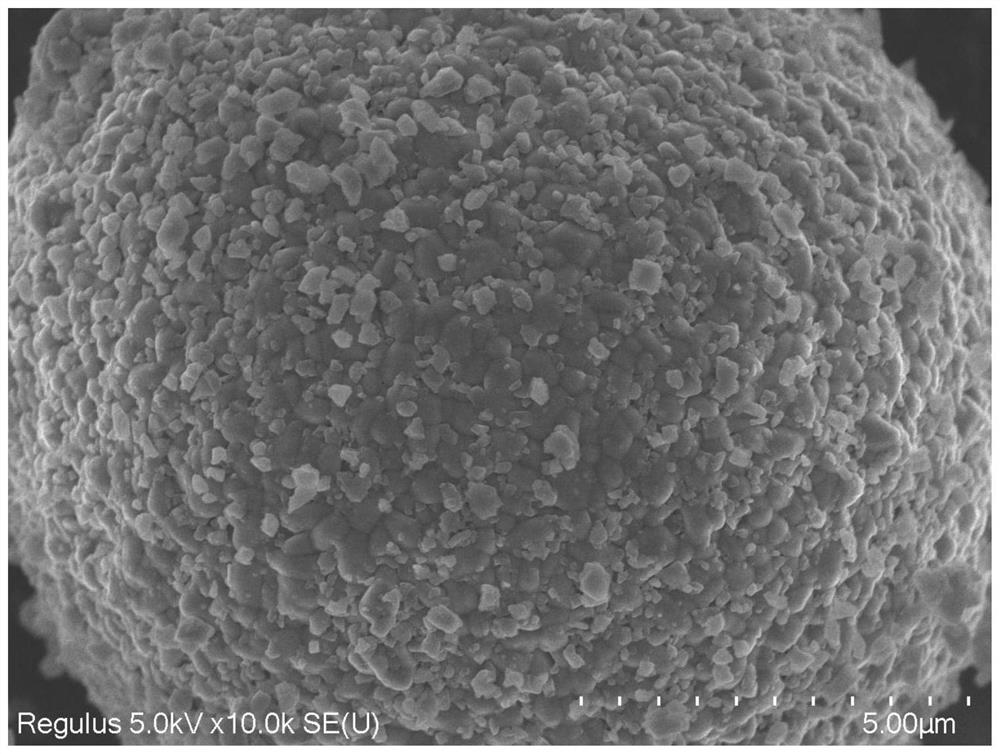

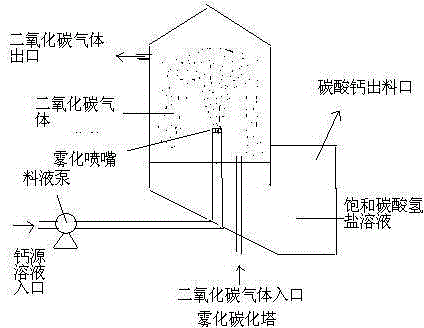

Preparation method of low-density hollow calcium carbonate

ActiveCN104016392AStable surface structureGood mechanical propertiesCalcium/strontium/barium carbonatesCalcium carbonateOil in water

The invention relates to a preparation method of low-density hollow calcium carbonate. The method comprises the following specific steps: emulsifying a calcium source solution by an emulsifier, wherein the calcium source solution wraps an oil core material to form liquid globules in an oil in water structure; atomizing the emulsion by means of an atomizing nozzle in carbon dioxide gas to be carbonized; carbonizing the calcium source solution outside the liquid globules to form calcium carbonate to wrap the oil core material so as to form particles; finally, drying to form calcium carbonate particles with hollow structures. The hollow calcium carbonate is low in density, stable in structure and good in mechanical property, and the particle diameter and the hollowness can be finely adjusted according to demands, so that the low-density hollow calcium carbonate is convenient and practical and has market application value.

Owner:涟源市正铭新型建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com