Core-shell high-nickel monocrystal nickel cobalt lithium manganate positive electrode material and preparation method and application thereof

A technology of nickel-cobalt-lithium-manganese-manganese oxide and positive electrode materials, which is applied in nanotechnology for materials and surface science, battery electrodes, electrical components, etc., and can solve the problems of easy side reactions, low initial charge and discharge efficiency, and increased processing difficulty, etc. problems, to achieve the effects of improving ion and electronic conductivity and rate performance, excellent first charge and discharge efficiency, and avoiding material fragmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

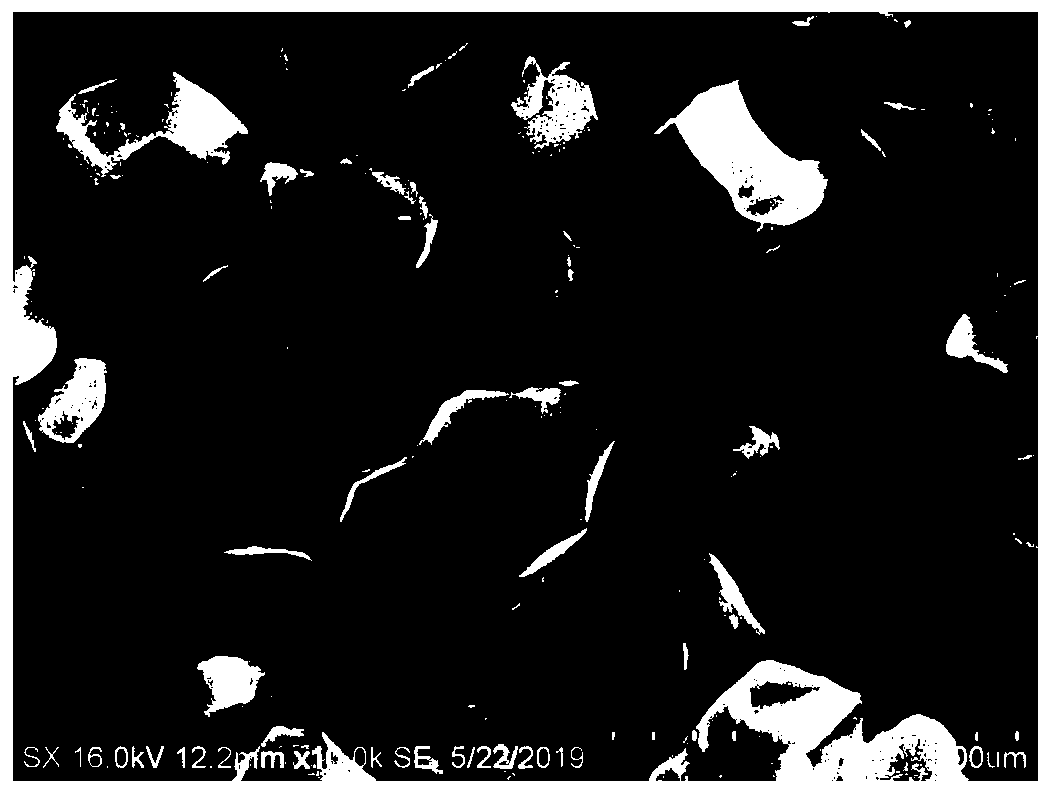

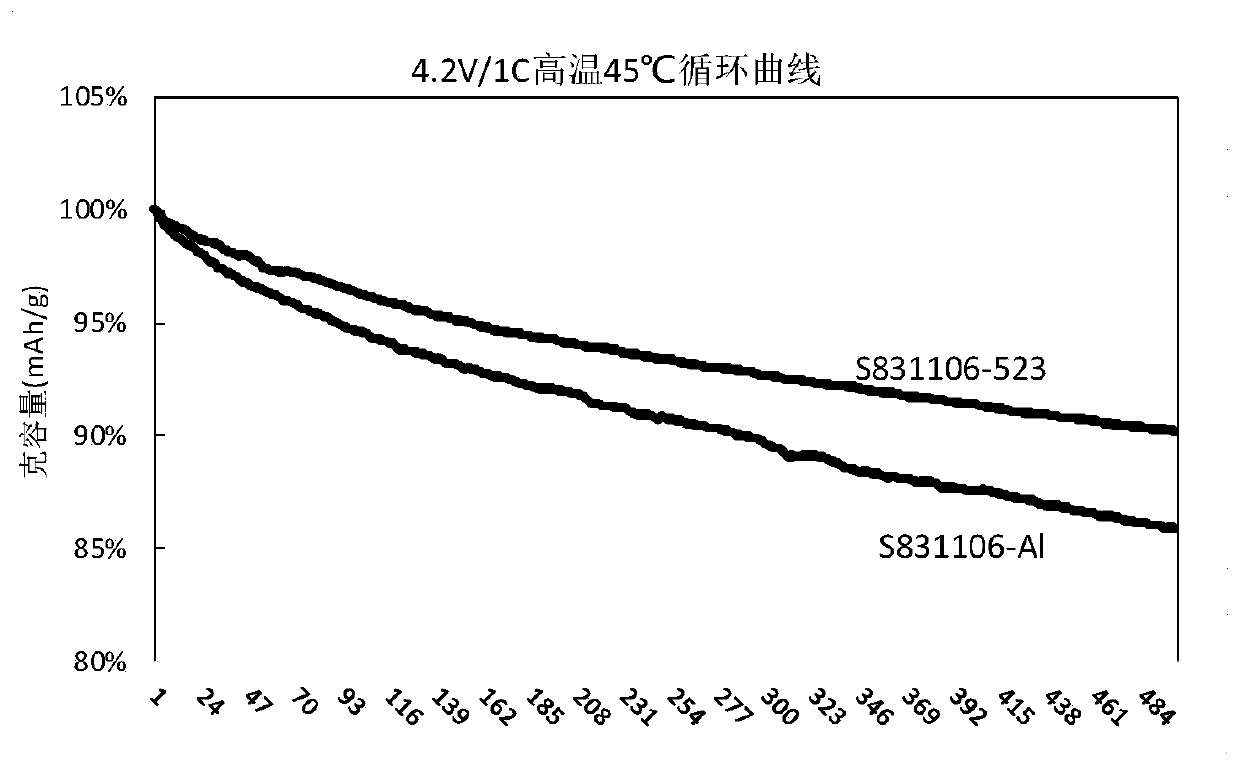

Embodiment 1

[0052] This embodiment provides a core-shell type high-nickel single crystal nickel-cobalt lithium manganese oxide positive electrode material, which includes a core layer and a shell layer arranged on the outer surface of the core layer, and the core layer and the shell layer form a core-shell structure; the material of the core layer is a compound shown in the following formula: LiNi 0.83 co 0.11 mn 0.06 o 2 , the material of the core layer is a single crystal; the material of the shell layer is a compound shown in the following formula: LiNi 0.49 co 0.196 mn 0.294 al 0.02 o 2 ; 0.83 co 0.11 mn 0.06 o 2 @LiNi 0.49 co 0.196 mn 0.294 al 0.02 o 2 Represents a core-shell type high nickel single crystal nickel cobalt lithium manganate positive electrode material, and its preparation method comprises the following steps:

[0053] (1) Preparation of granular high-nickel single-crystal nickel-cobalt lithium manganese oxide LiNi 0.83 co 0.11 mn 0.06 o 2

[0054] ...

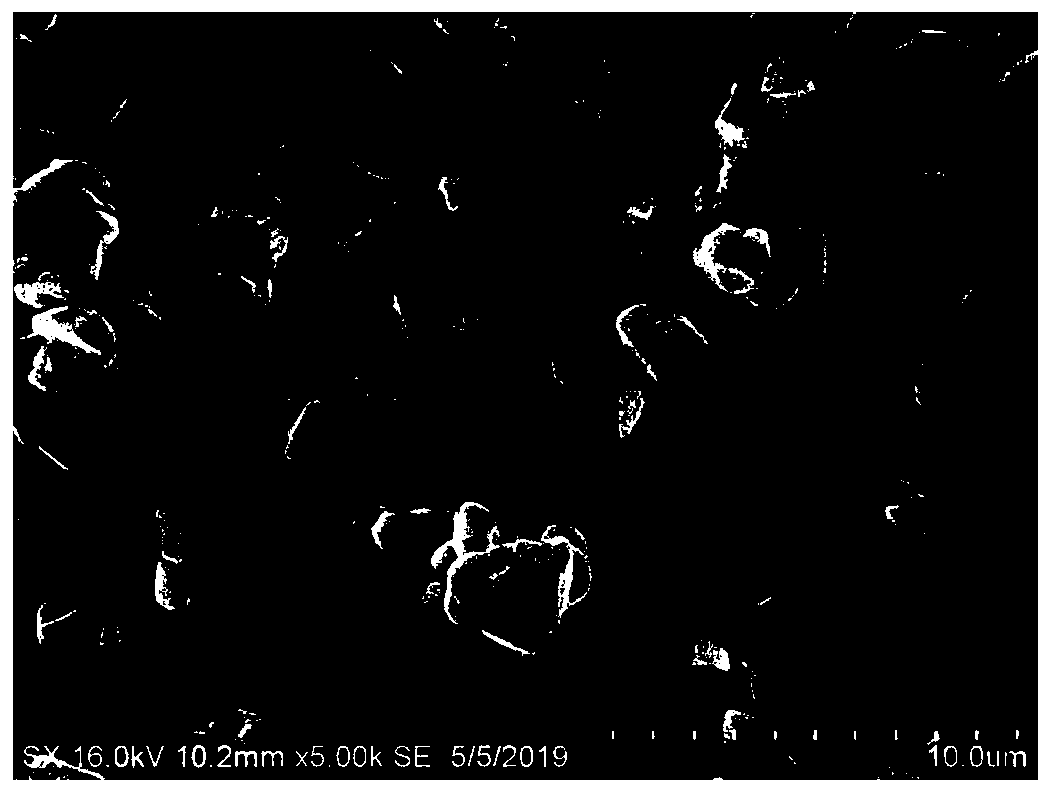

Embodiment 2

[0060] This embodiment provides a core-shell type high-nickel single crystal nickel-cobalt lithium manganese oxide positive electrode material, which includes a core layer and a shell layer arranged on the outer surface of the core layer, and the core layer and the shell layer form a core-shell structure; the material of the core layer is a compound shown in the following formula: LiNi 0.88 co 0.06 mn 0.06 o 2 , the material of the core layer is a single crystal; the material of the shell layer is a compound shown in the following formula: LiNi 0.49 co 0.196 mn 0.294 al 0.02 o 2 ; 0.88 co 0.06 mn 0.06 o 2 @LiNi 0.49 co 0.196 mn 0.294 al 0.02 o 2 Represents a core-shell type high nickel single crystal nickel cobalt lithium manganate positive electrode material, and its preparation method comprises the following steps:

[0061] (1) Preparation of granular high-nickel single-crystal nickel-cobalt lithium manganese oxide LiNi 0.88 co 0.06 mn 0.06 o 2

[0062] ...

Embodiment 3

[0068] This embodiment provides a core-shell type high-nickel single crystal nickel-cobalt lithium manganese oxide positive electrode material, which includes a core layer and a shell layer arranged on the outer surface of the core layer, and the core layer and the shell layer form a core-shell structure; the material of the core layer is a compound shown in the following formula: LiNi 0.65 co 0.15 mn 0.20 o 2 , the material of the core layer is a single crystal; the material of the shell layer is a compound shown in the following formula: LiNi 0.327 co 0.327 mn 0.326 al 0.02 o 2 ; 0.65 co 0.15 mn 0.20 o 2 @LiNi 0.327 co 0.327 mn 0.326 al 0.02 o 2 Represents a core-shell type high nickel single crystal nickel cobalt lithium manganate positive electrode material, and its preparation method comprises the following steps:

[0069] (1) Preparation of granular high-nickel single-crystal nickel-cobalt lithium manganese oxide LiNi 0.65 co 0.15 mn 0.20 o 2

[0070...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com