Doped lithium cobaltate having composite cladding layer and preparation method and application thereof

A technology of lithium cobalt oxide and lithium cobalt oxide is applied in the field of lithium ion battery materials, which can solve the problems of poor lithium ion transmission ability and insignificant effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

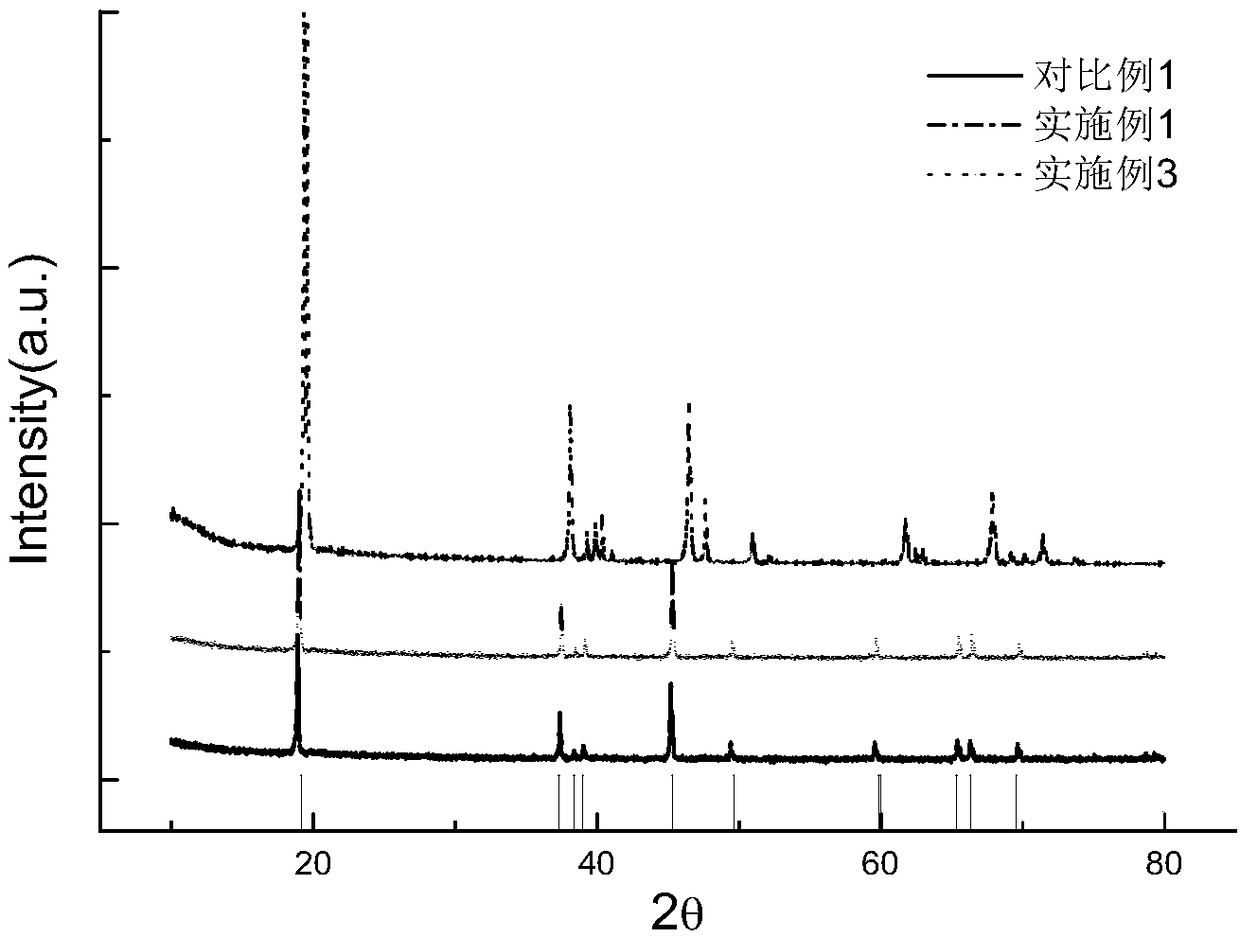

[0136] Example 1 Gradient doped lithium cobalt oxide sample 1 # preparation of

[0137] Weigh Co 3 o 4 49.15g, add 200mL water, stir to form a dispersion. Prepare 1mol / L ammonia solution. Weigh 2.71g magnesium acetate tetrahydrate, add 13mL water to dissolve; weigh 2.63g cobalt acetate tetrahydrate, add 13mL water to dissolve; prepare 2mol / L LiOH solution and 1mol / L ammonia water mixed solution.

[0138] Continuously input the magnesium acetate solution into the cobalt acetate solution, and stir evenly, and continuously input the formed mixed solution into Co 3 o 4Add 26mL of 2mol / L LiOH solution and 1mol / L ammonia solution to the dispersion at the same time. After the addition, adjust the pH to 11.5 with ammonia water, stir for 4 hours, filter, wash with water three times, and dry at 100°C to obtain the surface concentration gradient package. Coated Mg(OH) 2 The precursor Q1.

[0139] Weigh 10g of the above-mentioned Q1 precursor, and mix the lithium salt and the pre...

Embodiment 2

[0140] Example 2 Gradient doped lithium cobalt oxide sample 2 with transition layer (intermediate layer) # preparation of

[0141] Weigh 50 g of the precursor Q1 in the example, add 200 mL of water, and stir to form a dispersion. Weigh 13.88g of yttrium acetate tetrahydrate and dissolve it in 30mL of water. Prepare 5mol / L LiOH solution and 1mol / L ammonia solution.

[0142] Add yttrium acetate solution and 30mL 5mol / L LiOH solution and 1mol / L ammonia water mixed solution to the dispersion liquid of precursor simultaneously, Y(OH) 5 It settles on the surface of precursor Q1, and the pH of the precipitation is controlled at 12. Stir for 4 hours, filter and wash with water, and dry at 100° C. to obtain composite precursor Q2.

[0143] Weigh 10g of the above-mentioned Q2 precursor, and mix the lithium salt with the precursor at a molar ratio of 1.05:1; weigh LiOH·H 2 O 5.20g, mixed with the precursor Q2 evenly, sintered at 600°C for 6 hours in the air atmosphere, then raised t...

Embodiment 3

[0144] Embodiment 3 Gradient doped lithium cobalt oxide sample 3 with transition layer (intermediate layer) and shell layer # preparation of

[0145] Weigh 50g of precursor Q2, add 200mL of water, and stir to form a dispersion. Weigh 16.07g of manganese acetate tetrahydrate and dissolve it in 30mL of water. Prepare 2mol / L LiOH solution and 1mol / L ammonia solution.

[0146] Manganese acetate solution and 30mL 2mol / L LiOH solution and 1mol / L ammonia water mixed solution are added to the dispersion of precursor Q2 at the same time, Mn(OH) 2 It settles on the surface of the precursor Q2, and the pH of the precipitation is controlled at 10.5. Stir for 4 hours, filter and wash with water, and dry at 100° C. to obtain composite precursor Q3.

[0147] Weigh 10g of the above-mentioned Q3 precursor, mix the lithium salt and the precursor at a molar ratio of 1.05:1, weigh LiOH·H 2 O 5.29g, mixed with precursor Q3 evenly, sintered at 600°C for 6 hours in air atmosphere, then raised t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com