High-voltage long-circulation high-nickel single crystal positive electrode material as well as preparation method and application thereof

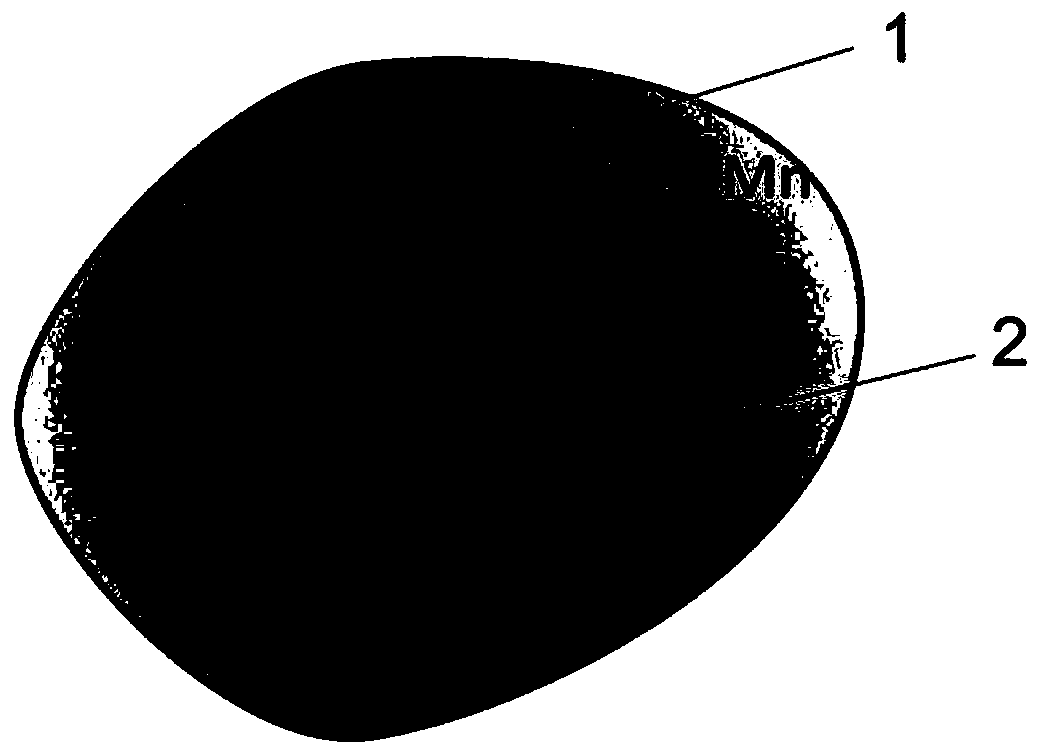

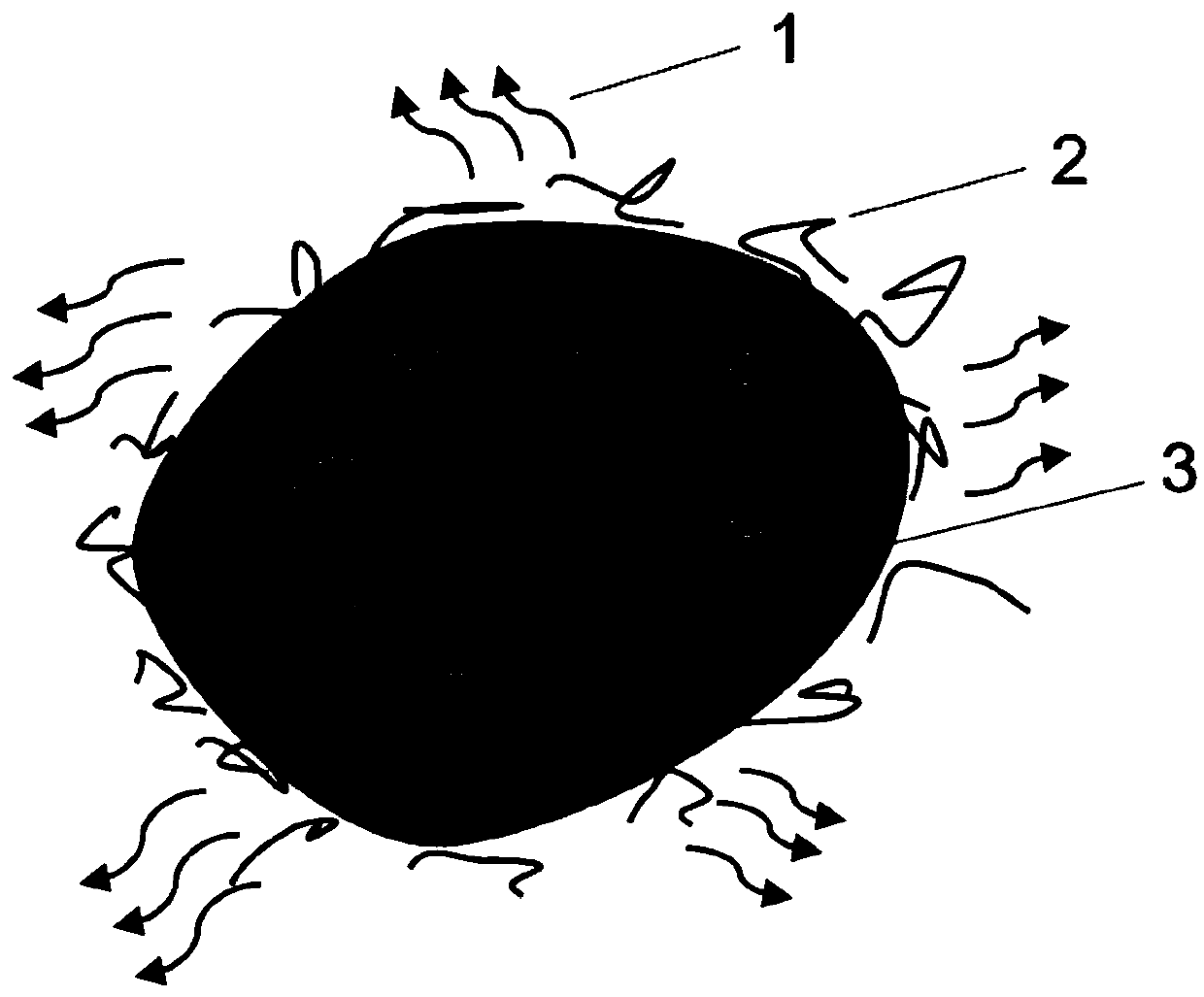

A technology of positive electrode material and single crystal material, which is applied in the field of high voltage long cycle high nickel single crystal positive electrode material and its preparation, can solve the problems of battery capacity and cycle performance degradation, intensified mixing structure, etc. The effect of delaying transition and enhancing high-pressure cycling stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

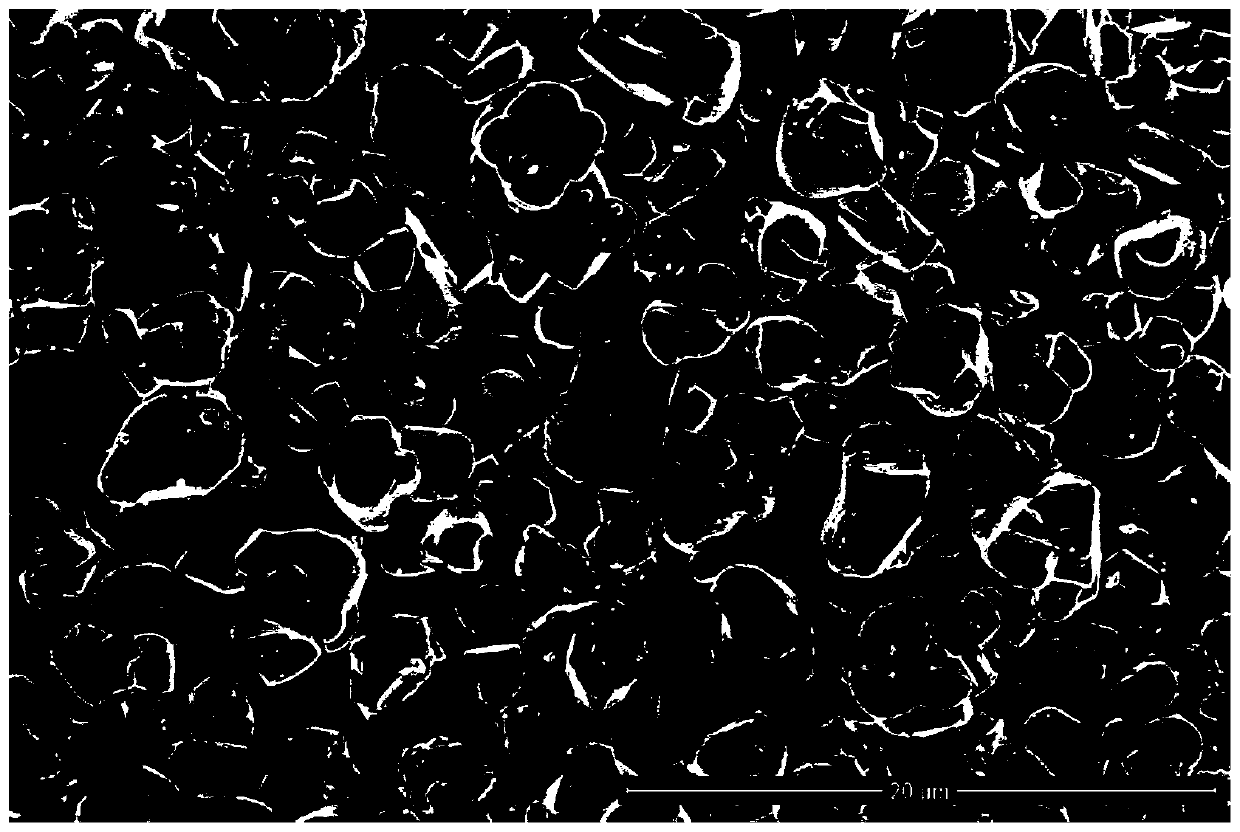

[0044] The preparation method of the high-voltage long-cycle high-nickel single crystal positive electrode material in this embodiment is as follows:

[0045] 1) Weigh lithium hydroxide, urea and water respectively according to the mass ratio of 5%, 15%, and 80%. Specifically, add 33.19g of lithium hydroxide and 99.56g of urea into 530.98g of deionized water, stir until dissolved and place Cool down to -12°C in the refrigerator. Lithium source solution A is obtained.

[0046] 2) Solution A was stirred at high speed, and 26.55 g of α-cellulose powder (length less than 25 μm) was added at the same time, and the mass of α-cellulose powder accounted for 4% of the total mass of solution A. Continue stirring until dissolved to obtain carbon source sol B.

[0047] 3) According to the ratio of precursor to lithium hydroxide molar ratio of 1:1.05, add Ni with particle size D50 of 4.5 μm to sol B 0.8 co 0.1 mn 0.1 (OH) 2 Precursor 70g, high-speed stirring to disperse, then turn to l...

Embodiment 2

[0058] The preparation method of the high-voltage long-cycle high-nickel single crystal positive electrode material in this embodiment is as follows:

[0059] 1) Weigh lithium hydroxide, thiourea and water according to the mass ratio of 4%, 12%, and 84%, respectively, specifically add 32.86g of lithium hydroxide and 98.58g of thiourea to 690.0g of deionized water, and stir until dissolved Then place in the refrigerator to cool down to -15°C. Lithium source solution A is obtained.

[0060] 2) Solution A was stirred at high speed, and 28.75 g of β-cellulose powder (length less than 25 μm) was added at the same time, and the mass of β-cellulose accounted for 3.5% of the total mass of solution A. Continue stirring until dissolved to obtain carbon source sol B.

[0061] 3) According to the ratio of precursor to lithium hydroxide molar ratio of 1:1.05, add Ni with particle size D50 of 4.5 μm to sol B 0.6 co 0.2 mn 0.2 (OH) 2 Precursor 70g, high-speed stirring to disperse, then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com