Surface reinforced concrete release agent

A concrete release agent and surface enhancement technology, applied in the direction of additives, ceramic molding machines, manufacturing tools, etc., can solve the problems of no improvement or reduction of concrete surface strength, no attention to the mechanical properties of concrete surface, etc., to reduce the maintenance process in the later stage and cost, the preparation process is simple, and the effect of increasing compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

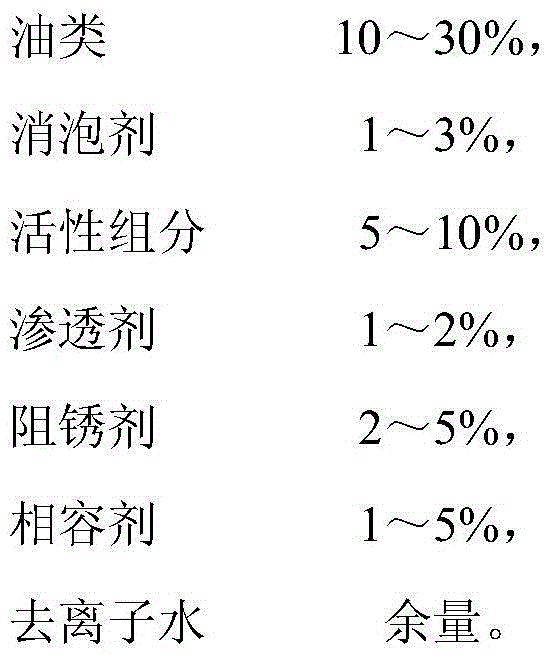

Method used

Image

Examples

Embodiment 1

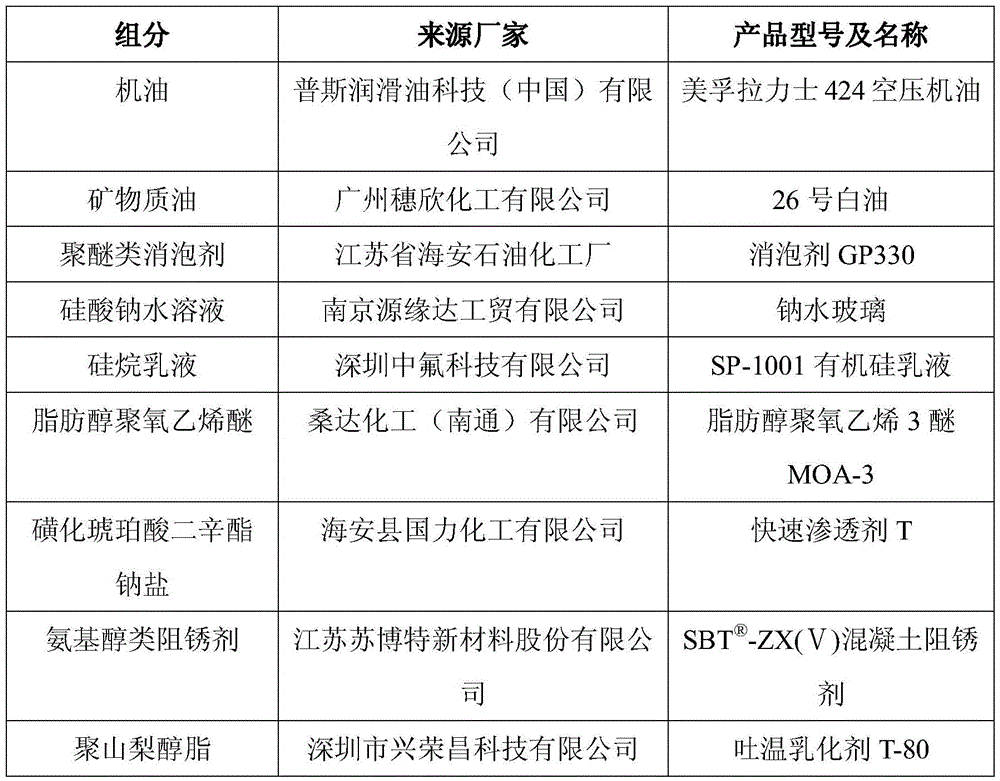

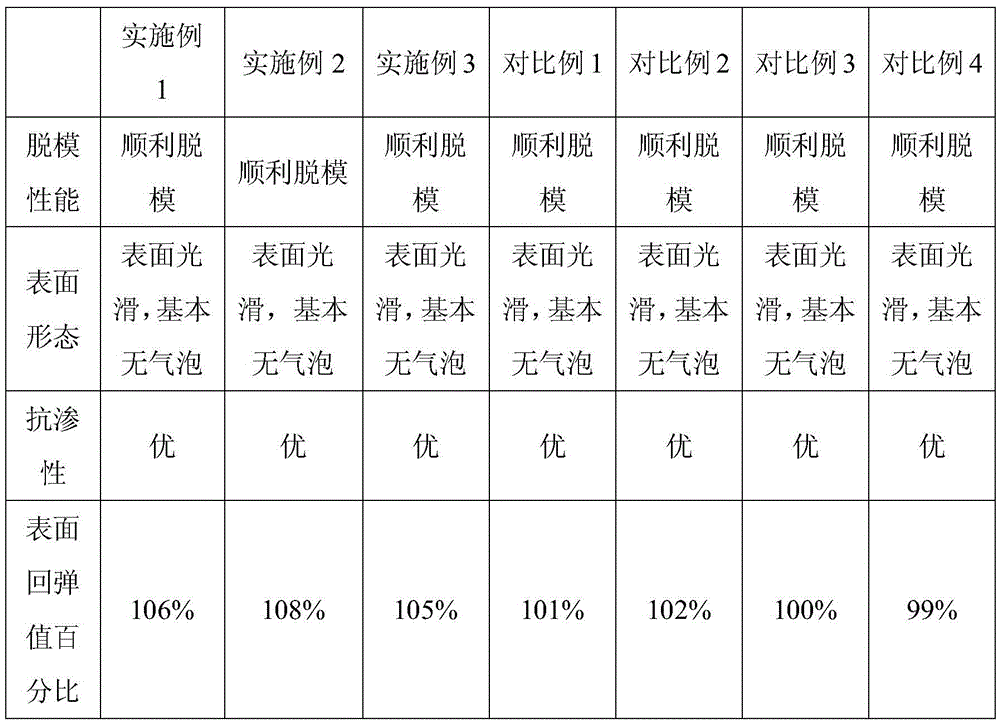

[0025] Take 15 parts of engine oil and 10 parts of mineral oil, heat up to 50°C; then add 2 parts of polyether defoamer, 3 parts of sodium silicate aqueous solution, 2 parts of silane emulsion, 1 part of fatty alcohol polyoxyethylene ether, nitrous acid 3 parts of calcium, 1.5 parts of polysorbate, 62.5 parts of water, after stirring continuously for 1 hour, let it cool naturally and discharge. Use after diluting 3 times with water.

Embodiment 2

[0027] Take 25 parts of mineral oil and heat up to 55°C; then add 2 parts of polyether defoamer, 4 parts of sodium silicate aqueous solution, 1 part of silane emulsion, 1.5 parts of dioctyl sulfosuccinate sodium salt, amino alcohols 3 parts of rust inhibitor, 2 parts of polysorbate, 61.5 parts of water, after stirring continuously for 1.5 hours, let it cool naturally and discharge. Use after diluting 3 times with water.

Embodiment 3

[0029] Take 10 parts of engine oil, 15 parts of mineral oil, heat up to 55°C; then add 2 parts of polyether defoamer, 3 parts of sodium silicate aqueous solution, 2 parts of silane emulsion, 1 part of fatty alcohol polyoxyethylene ether, amino alcohol 3 parts of anti-corrosion agent, 1.5 parts of Span-60, 62.5 parts of water, after stirring continuously for 1 hour, let it cool naturally and discharge. Use after diluting 3 times with water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com