Positive active material with phosphate coated spinel structure as well as preparation method and application of positive active material

A technology of positive active material and spinel structure, applied in the direction of positive electrode, structural parts, active material electrode, etc., can solve the problem of difficult distribution of lattice lithium phosphate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] 10.52g of LiMn 2 o 4 Material (particle size is 200nm) joins in 20ml water and stirs constantly, thus obtains LiMn 2 o 4 decentralized system. 10ml concentration of 0.2mol / L FeSO 4 Aqueous solution, 10ml of NH with a concentration of 0.2mol / L 4 h 2 PO 4 The aqueous solution and 10 ml of LiOH aqueous solution with a concentration of 0.6 mol / L were added to the above dispersion system, and kept stirring. The resulting mixture was transferred to a 100ml polytetrafluoroethylene reactor and kept at 180°C for 10 hours. After the reaction, the powder in the product was collected, washed with water for three times, and then washed with absolute ethanol once, and dried at 80° C. for 3 hours to obtain a positive electrode active material.

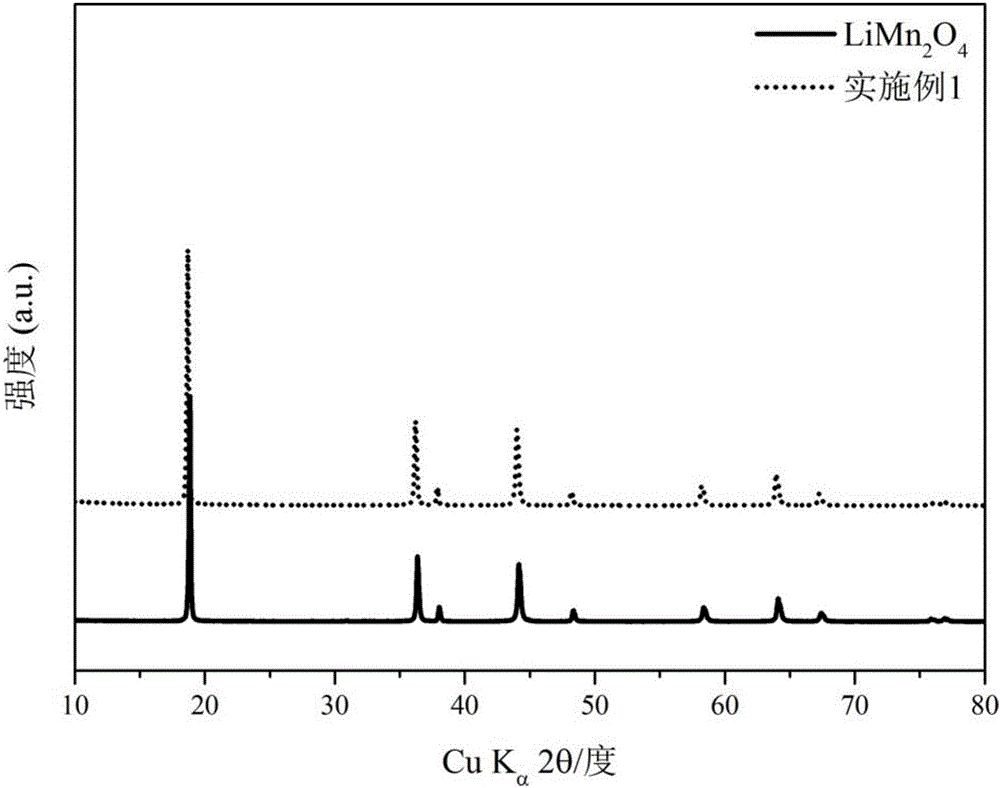

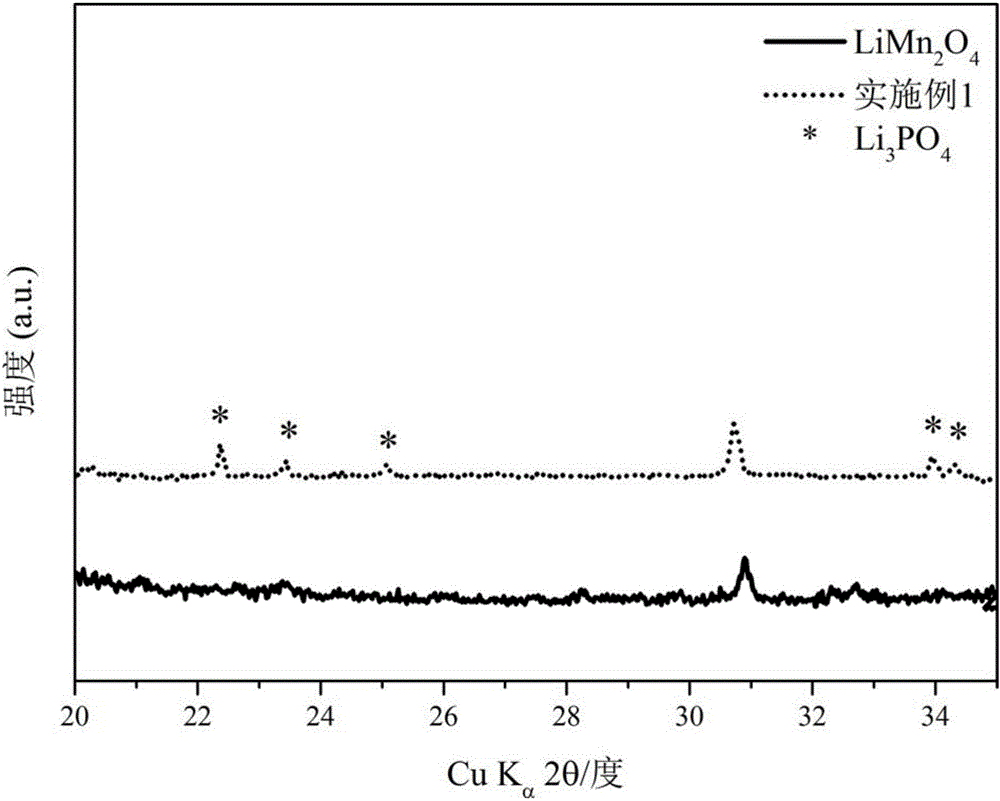

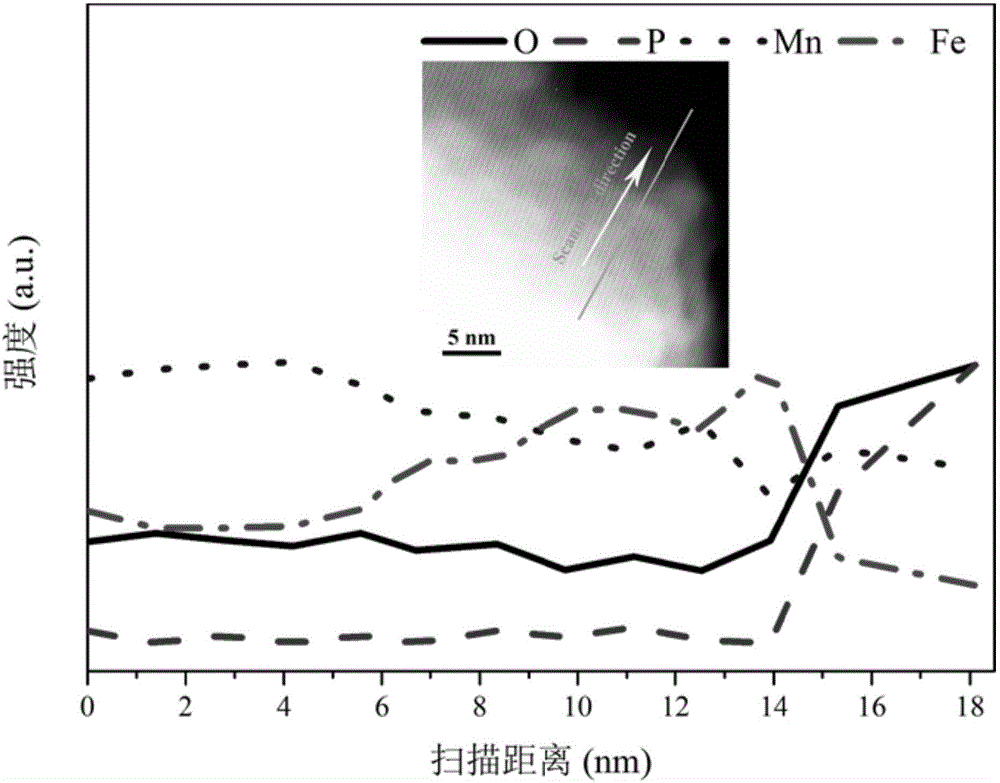

[0090] figure 1 LiMn is shown 2 o 4 and the XRD fast-scan pattern of the cathode active material prepared in Example 1 at 10° to 80°. From figure 1 It can be seen that LiMn 2 o 4 There is almost no difference from the XRD patter...

Embodiment 2

[0099] 10.52g of LiMn 2 o 4 Material (particle size is 200nm) is added in the water of 20ml and is constantly stirred, thereby obtains LiMn 2 o 4 decentralized system. 10ml of NH with a concentration of 0.2mol / L 4 h 2 PO 4 The aqueous solution and 10 ml of LiOH aqueous solution with a concentration of 0.6 mol / L were added to the above dispersion system, and stirred continuously. The resulting mixture was transferred to a 100ml polytetrafluoroethylene reactor and kept at 180°C for 10 hours. After the reaction, the powder in the product was collected, washed three times with water, then once with absolute ethanol, and dried at 80°C for 3 hours to obtain lithium phosphate and LiMn 2 o 4 mixture.

[0100] Figure 7 A representative SEM image of the cathode material prepared in Example 2 is shown. From Figure 7 It can be seen that without adding FeSO 4 In the case of LiMn 2 o 4 The surface of the material is smooth. However, combined with XRD fast scan and slow sca...

Embodiment 3

[0102] 10.52g of LiMn 2 o 4 Material (particle size is 200nm) joins in 20ml water and stirs constantly, thus obtains LiMn 2 o 4 decentralized system. 10ml concentration of 0.2mol / L FeSO 4 Aqueous solution, 10ml of NH with a concentration of 0.2mol / L 4 h 2 PO 4 The aqueous solution and 10 ml of LiOH aqueous solution with a concentration of 0.6 mol / L were added to the above dispersion system, and stirred continuously. The resulting mixture was transferred to a 100ml polytetrafluoroethylene reactor and kept at 180°C for 10 hours. After the reaction, the powder in the product was collected, washed with water for 3 times, and then with absolute ethanol once, and dried at 80° C. for 3 hours. The dried powder was calcined in air at 450° C. for 3 hours to obtain a positive electrode active material.

[0103] The XRD fast-scan pattern and slow-scan pattern of embodiment 3 show that, after hydrothermal coating and calcination in air, LiMn 2 o 4 The bulk crystal structure of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com