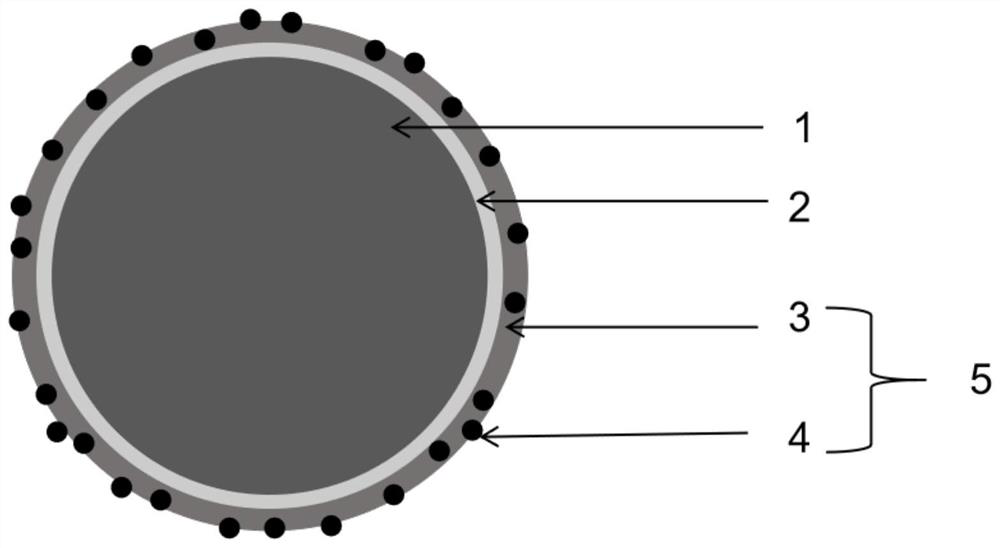

Composite coated nickel-rich positive electrode material as well as preparation method and application thereof

A positive electrode material, nickel-rich technology, applied in the direction of battery electrodes, structural parts, electrical components, etc., can solve the problems of the influence of material rate performance, electrochemical performance of difficult materials, low ion conductivity of aluminum phosphate, etc., to improve efficiency and ion Conductivity, ensure ion transmission characteristics, increase the effect of overall ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

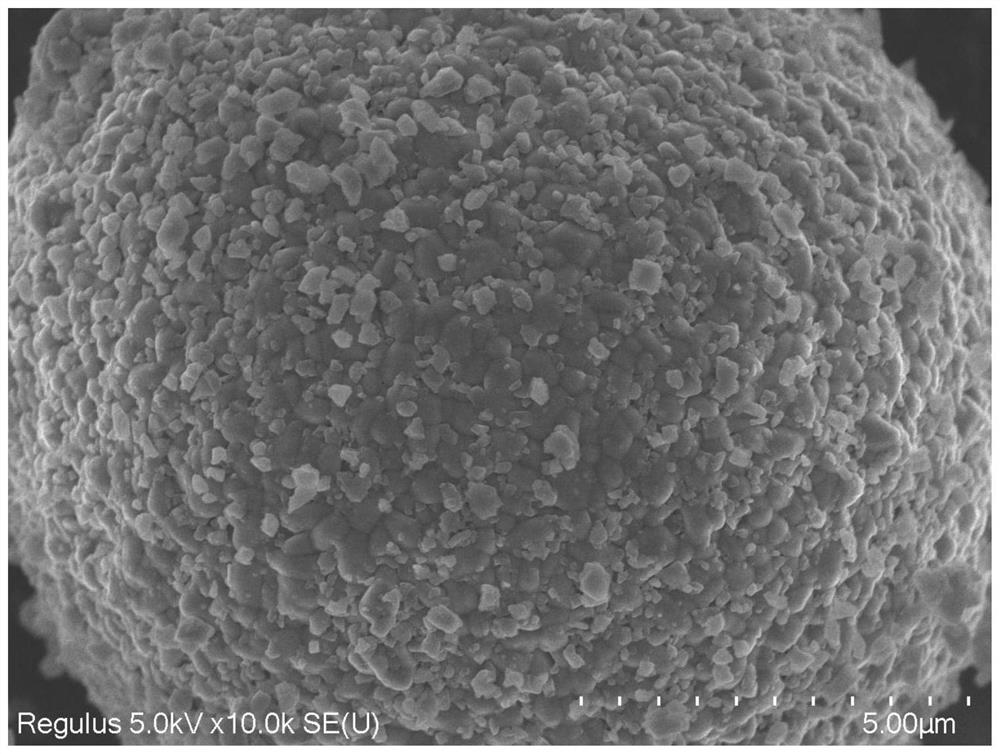

[0040] Put 100 parts of positive electrode matrix raw materials (commercially available NCM880705) and 0.5 parts of boric acid into a mixer for mixing, wherein the speed of the mixer is 1000 rpm and the mixing time is 5min, and then 0.4 parts of composite solid electrolyte (0.9Li 1.4 Al 0.4 Ti 1.6 (PO 4 ) 3 .0.05AlPO 4 .0.05LiTiOPO 4 , 110nm), wherein the speed of the mixer is 1000 rpm, the mixing time is 15min, and then it is transferred to a sintering furnace, and sintered at 290 ° C in an oxygen atmosphere for 15h to obtain a composite-coated nickel-rich cathode material . Scanning electron microscopes such as figure 2 It can be seen that the boron-lithium compound formed by the composite solid electrolyte through low-temperature sintering is uniformly coated on the surface of the positive electrode material, and the composite coating layer formed by the two can effectively improve the electrochemical performance and safety performance of the material.

Embodiment 2

[0042] The difference between Example 2 and Example 1 is that the sintering time of Example 2 is 3h.

Embodiment 3

[0044] The difference between Example 3 and Example 1 is that the sintering temperature of Example 3 is 320°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com