High heat conductivity type graphite film-metal composite material and preparation method thereof

A technology of metal composite materials and high thermal conductivity graphite, which is applied in the field of materials, can solve the problems of easy powder drop, low density, and inability to meet the heat dissipation requirements of portable digital products, etc., to achieve powder drop, good pressure resistance, and good pressure resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

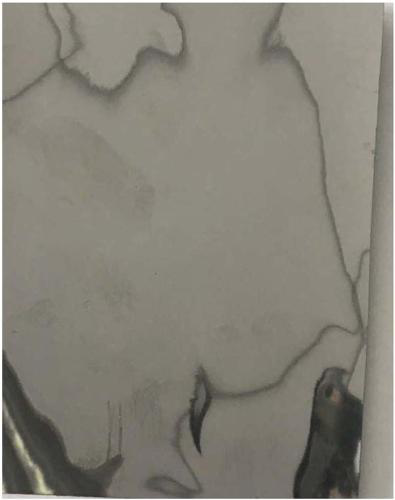

Image

Examples

preparation example Construction

[0019] An embodiment of the present invention provides a method for preparing a high thermal conductivity graphite film-metal composite material, which includes:

[0020] A metal layer is sputtered on the surface of the graphite film by means of vacuum magnetron sputtering.

[0021] Natural graphite film has higher thermal conductivity, lower density, and good material stability, so it has gradually been widely used in the electronics industry. Natural graphite film is made of natural flake graphite or coal tar pitch. After the raw material is acidified, it is heated to expand the interlayer of natural graphite to obtain a worm-like structure. Then, it is calendered with the bonding material under high temperature and high pressure to obtain a film-like graphite sheet. , but the thermal conductivity of natural graphite film generally does not exceed 400W / (m·K), and it is easy to lose powder and other shortcomings, so it is increasingly unable to meet the heat dissipation requi...

Embodiment 1

[0055] The embodiment of the present invention provides a high thermal conductivity graphite film-metal composite material, the preparation method of which is as follows:

[0056] S1. Gradually raise the temperature of the polyimide film to 1300°C to obtain a carbonized film;

[0057] Wherein, the heating process includes multi-stage heating;

[0058] In the first stage, the temperature is raised from room temperature to 300 ° C, and the heating time is 40 minutes;

[0059] In the second stage, the temperature rises from 300°C to 480°C, and the heating time is 50 minutes;

[0060] In the third stage, the temperature is raised from 480°C to 600°C, and the heating time is 420min;

[0061] The fourth stage of heating, from 600°C to 700°C, the heating time is 240min;

[0062] In the fifth stage, the temperature is raised from 700°C to 900°C, and the heating time is 200min;

[0063] In the sixth stage, the temperature is raised from 900°C to 1300°C, and the heating time is 200m...

Embodiment 2

[0080] The embodiment of the present invention provides a high thermal conductivity graphite film-metal composite material, the preparation method of which is as follows:

[0081] S1. Gradually raise the temperature of the polyimide film to 1400°C to obtain a carbonized film;

[0082] Wherein, the heating process includes multi-stage heating;

[0083] In the first stage, the temperature is raised from room temperature to 310°C, and the heating time is 35 minutes;

[0084] In the second stage, the temperature is raised from 310 ° C to 490 ° C, and the heating time is 50 minutes;

[0085] In the third stage, the temperature rises from 490°C to 590°C, and the heating time is 425min;

[0086] In the fourth stage, the temperature is raised from 590°C to 710°C, and the heating time is 245min;

[0087] In the fifth stage, the temperature rises from 710°C to 890°C, and the heating time is 205min;

[0088] The temperature is raised in the sixth stage, from 890°C to 1400°C, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com