Patents

Literature

73results about How to "Solve the problem of falling powder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aerogel composite material with surface subjected to dust-free treatment and preparation method

The invention relates to an aerogel composite material with a surface subjected to dust-free treatment and a preparation method thereof, in particular to a method using an aerogel felt, an aerogel plate, an aerogel cylinder and an aerogel shaped piece as the base material and coating the substrate surface with compact coating so as to avoid shedding of aerogel surface dust. The method is simple and practicable, can effectively solve the problem of easy generation of dust on the aerogel surface, significantly improves the working environment, and can satisfy the use condition of aerogel in clean space. By adopting different ratios, a rigid coating and a flexible coating can be obtained, high temperature and low temperature application can also be achieved, compound proportioning of an inorganic film-forming agent and an organic film-forming agent also can give consideration to flexibility and fire resistance, and significantly improves the adaptability of the coating paste to different types of aerogel materials. The aerogel subjected to dust-free treatment can be applied to heat preservation of various industrial equipment and pipeline, and also can be applied to thermal insulation of high speed rail, vessels, electronics and pharmaceutical workshops and building field.

Owner:浙江圣润纳米科技有限公司

Functional diatomite putty powder and preparation method thereof

InactiveCN105949863AImprove efficiencyShorten the timeFilling pastesInorganic pigmentsMaterials science

The invention relates to putty powder, in particular to functional diatomite putty powder and a preparation method thereof, wherein the putty powder includes in percent by weight: 10-50% of high-temperature activated diatomite, 5-30% of an inorganic binder, 30-70% of an inorganic filler, 0.01-2% of a functional aid, 0.1-5% of an inorganic pigment, 0.5-5% of an organic binder, and 0.5-5% of an organic aid. The functional diatomite putty powder meets the related standard requirements of putty powder and diatomite, and has qualified constructability and functionality, namely having standard-meeting properties such as humidity regulation, formaldehyde clarifying performance, long duration of formaldehyde purifying performance, mold-proof performance, and mold durability.

Owner:CENT SOUTH UNIV +1

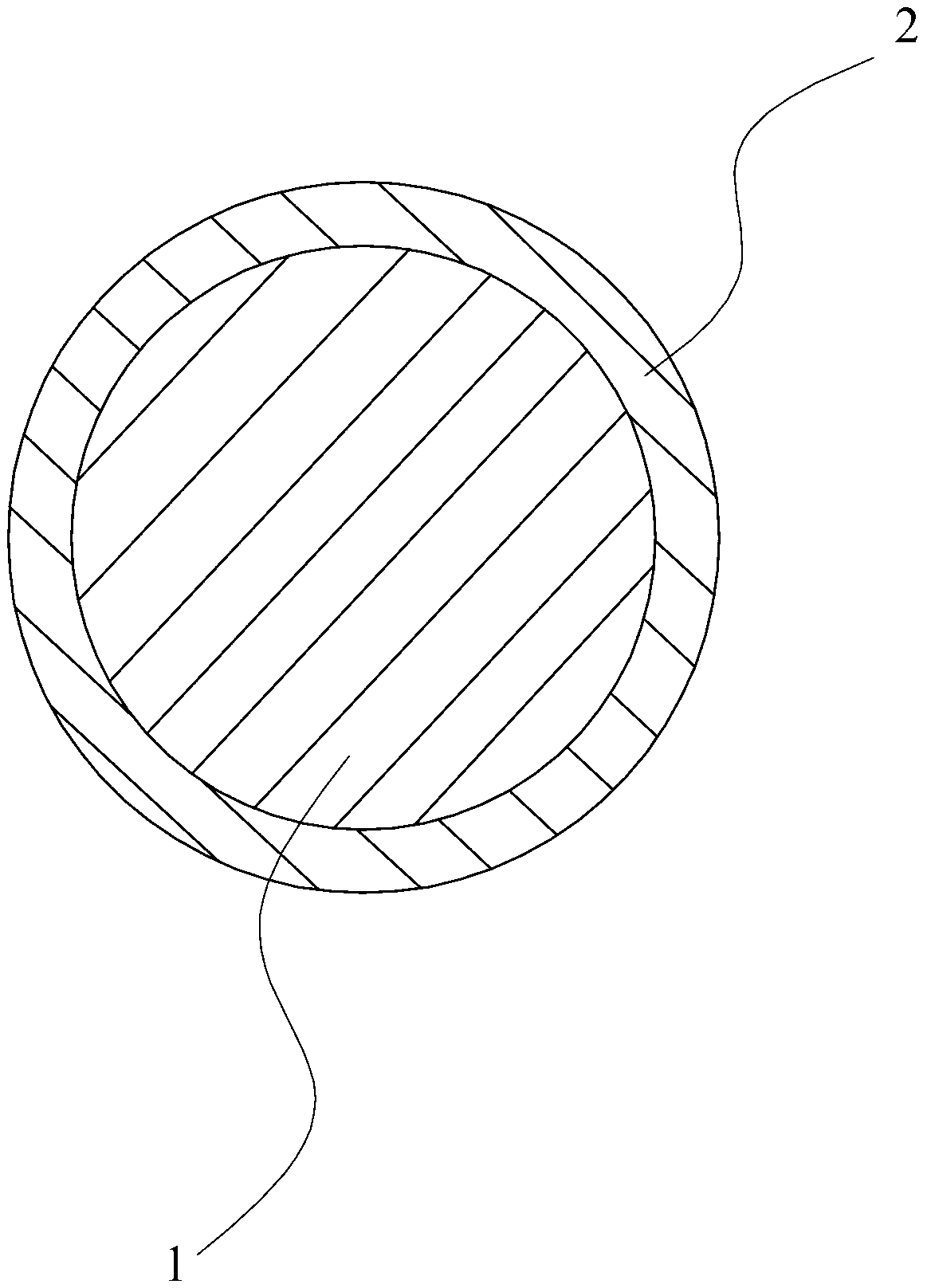

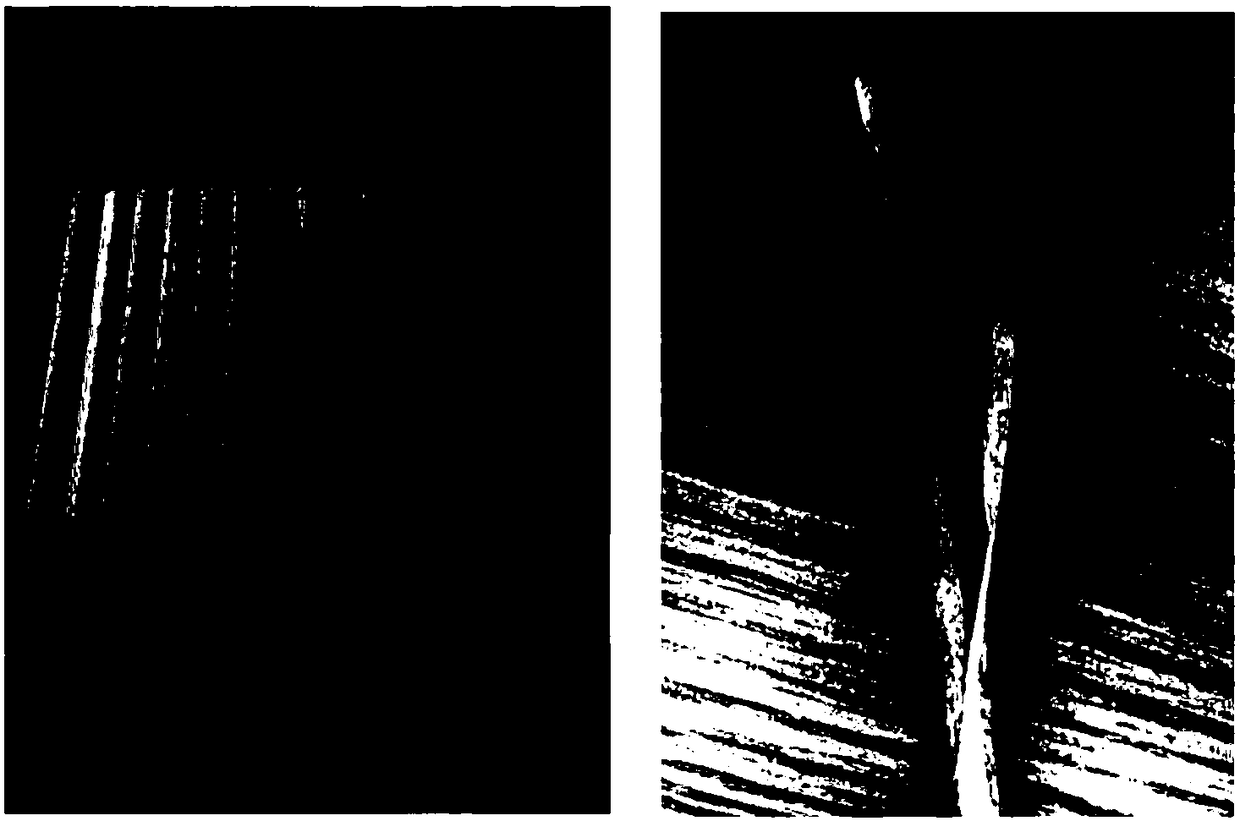

Efficient electrode wire for precision mould cutting and preparing method of efficient electrode wire

ActiveCN103273150AImprove cutting efficiencyLarge discharge energyElectrical-based machining electrodesOperabilityZinc

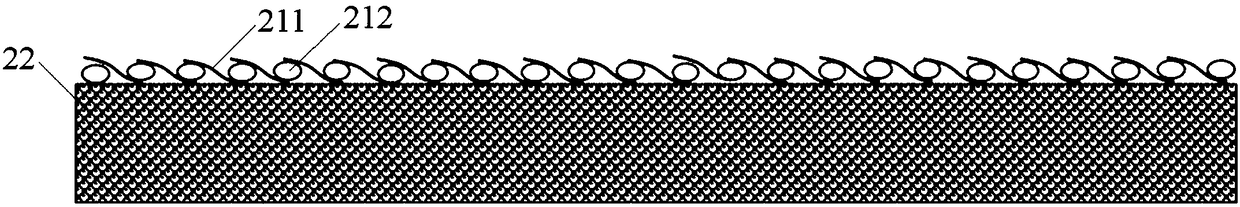

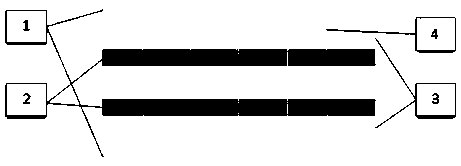

The invention relates to an efficient electrode wire for precision mould cutting. The efficient electrode wire comprises a core material and a shell layer wrapping the surface of the core material, the core material is made of yellow copper from the processes of smelting, casting, stretching and annealing, the shell layer is a discontinuous shell layer formed by heating, continuously drawing and continuously annealing a zinc metal plating layer plated on the yellow copper core material, and the discontinuous shell layer comprises shell particles which radially cover 40-90% of the surface of the core material and are distributed at intervals along an axial direction of the surface of the core material. The invention further relates to a preparation method of the electrode wire. The preparation method is simple in production technology, strong in operability, less in preparation steps, simple in production equipment and easy to prepare satisfactory products and realize large-scale and automated production. The efficient electrode wire is strong in universality and is particularly suitable for precision mould cutting.

Owner:NINGBO BODE HIGHTECH CO LTD

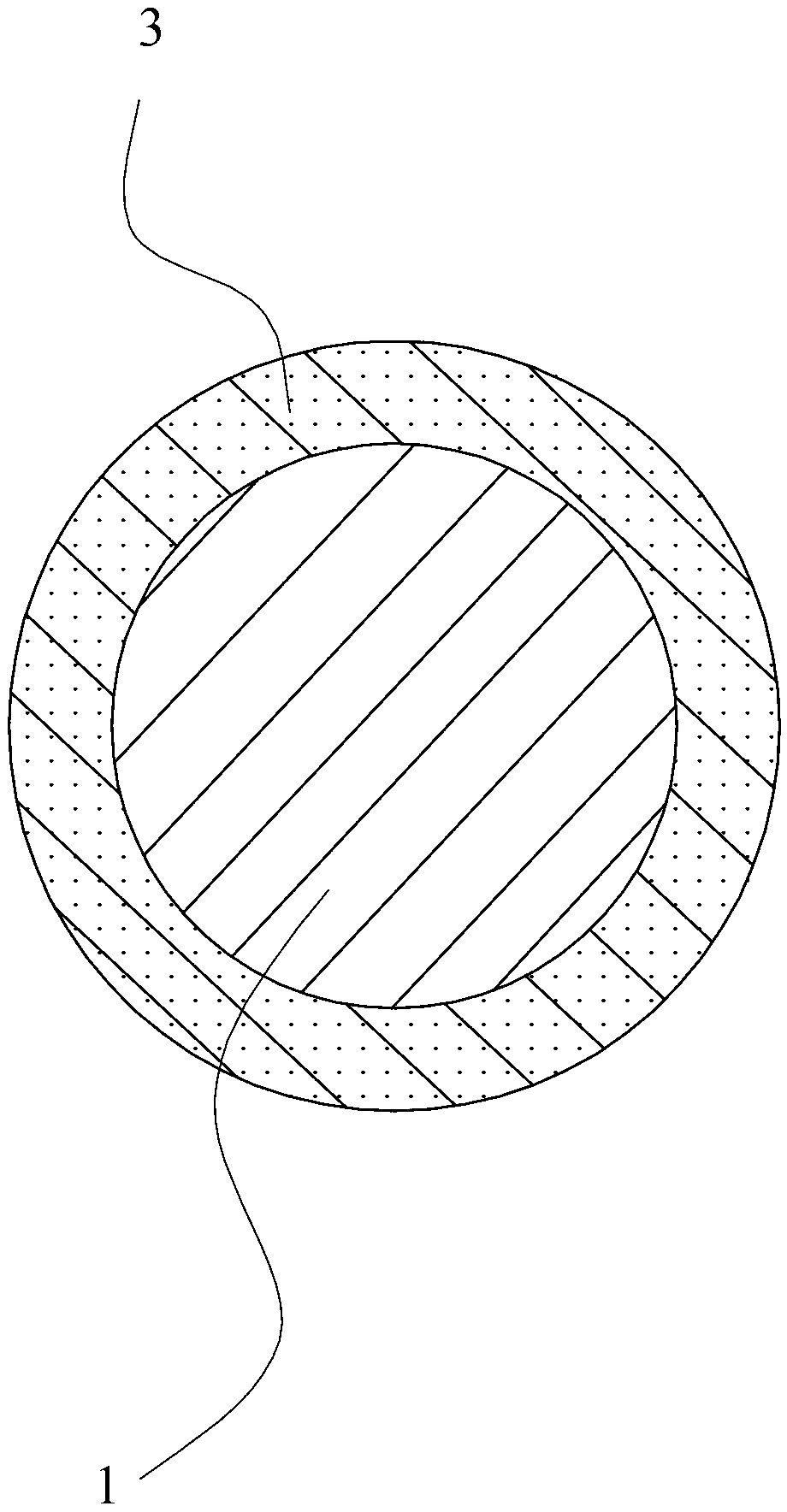

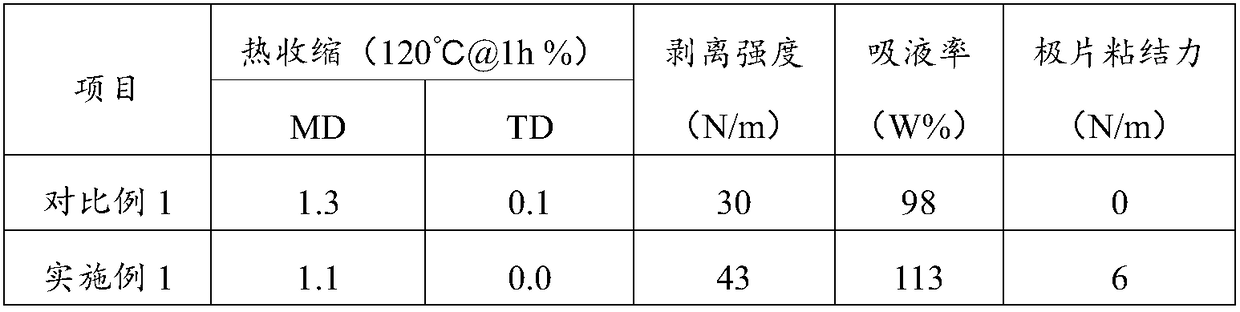

High-temperature resistant composite battery separator and preparation method thereof

ActiveCN108281592AGood thickening effectImprove hydrophilicityCell component detailsInorganic particleInorganic particles

The invention discloses a high-temperature resistant composite battery separator and a preparation method thereof. The high-temperature resistant composite battery separator comprises a base film anda high-temperature resistant coating layer, wherein the high-temperature resistant coating layer is coated on at least one surface of the base film and is formed by coating inorganic particles containing nanometer cellulose as a binding agent. In the composite battery separator, the nanometer cellulose is creatively used as the binding agent to prepare the high-temperature resistant coating layer,the interface bonding force of the coating layer and the base film is improved, the stripping strength of the composite battery separator is further improved, and the problems of falling and powder dropping of the coating layer are solved very well; with the addition of the nanometer cellulose, the inorganic particles are better in dispersion effect in water; moreover, the nanometer cellulose isused as the binding agent to form the coating layer, the high-temperature resistant composite battery separator is rapid in liquid conductivity and high in liquid absorption capability, gel is easilyformed after the electrolyte is absorbed, so that the composite battery separator can be attached onto a surface of an electrode very well, and the integral performance of the lithium ion battery is improved.

Owner:SHENZHEN ZHONGXING NEW MATERIAL TECH CO LTD

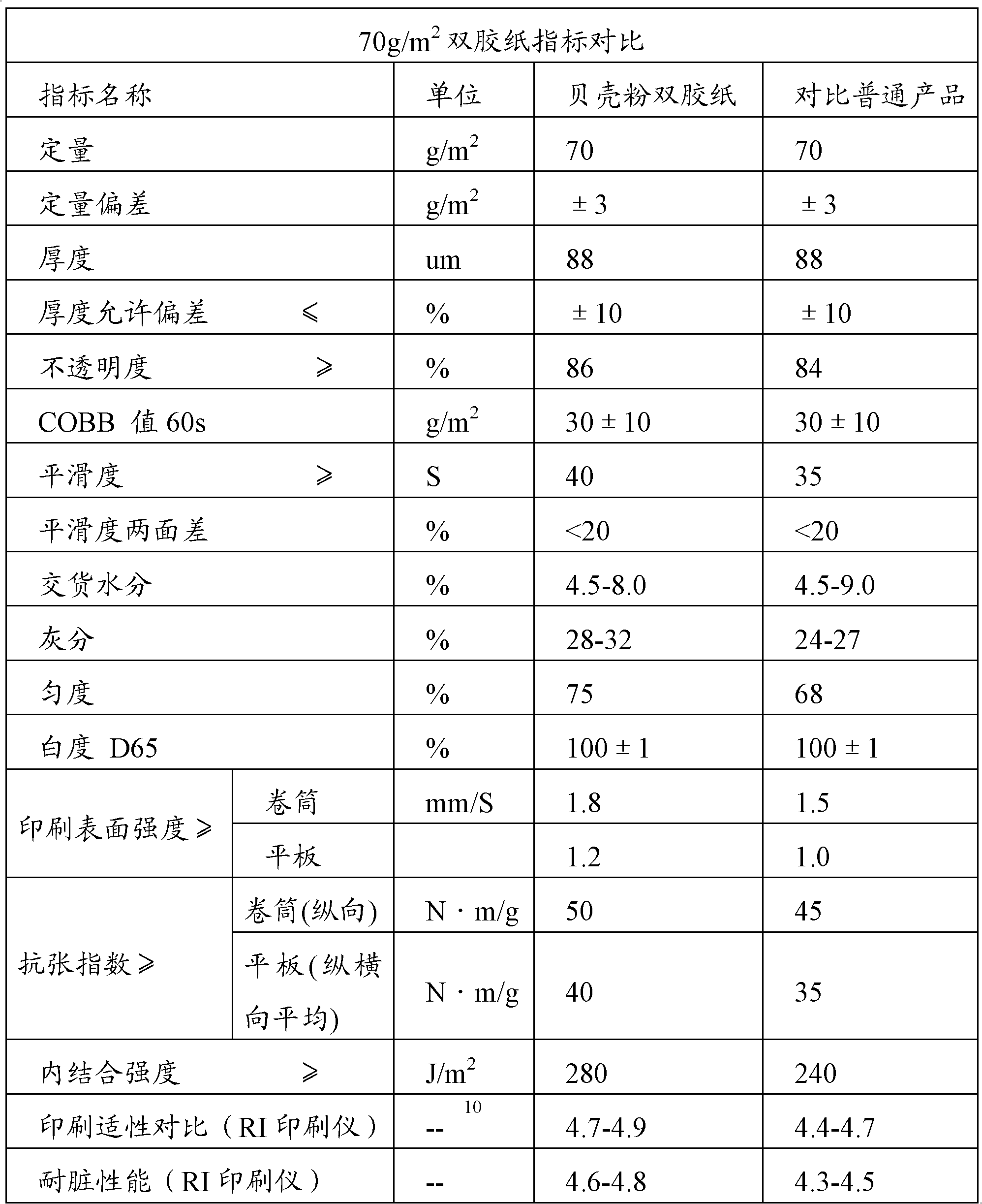

Side offset paper and preparation method thereof

ActiveCN102154927AReduce dosageHigh bonding strengthWater-repelling agents additionPaper coatingPapermakingUltimate tensile strength

The invention relates to the technical field of papermaking, in particular to a side offset paper produced by shell powder and a preparation method thereof. In the side offset paper, high-whiteness hard wood pulp and high-whiteness chemical-mechanical pulp serve as the main material, and meanwhile, shell powder is auxiliary filler for producing the side offset paper; oxidized Cual is added into surface amylopectin to improve the printing surface strength of the side offset paper and avoid the defects of printing hair slip and duslting because of high paper forming ash content; meanwhile, the paper forming printing adaptability and dirty resistance can be obviously improved; and the colorful printing quality of the product is substantially improved.

Owner:ASIA SYMBOL GUANGDONG PAPER

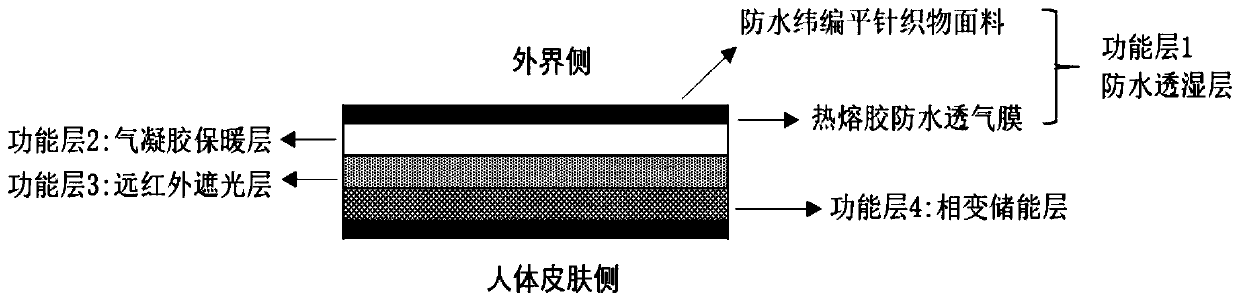

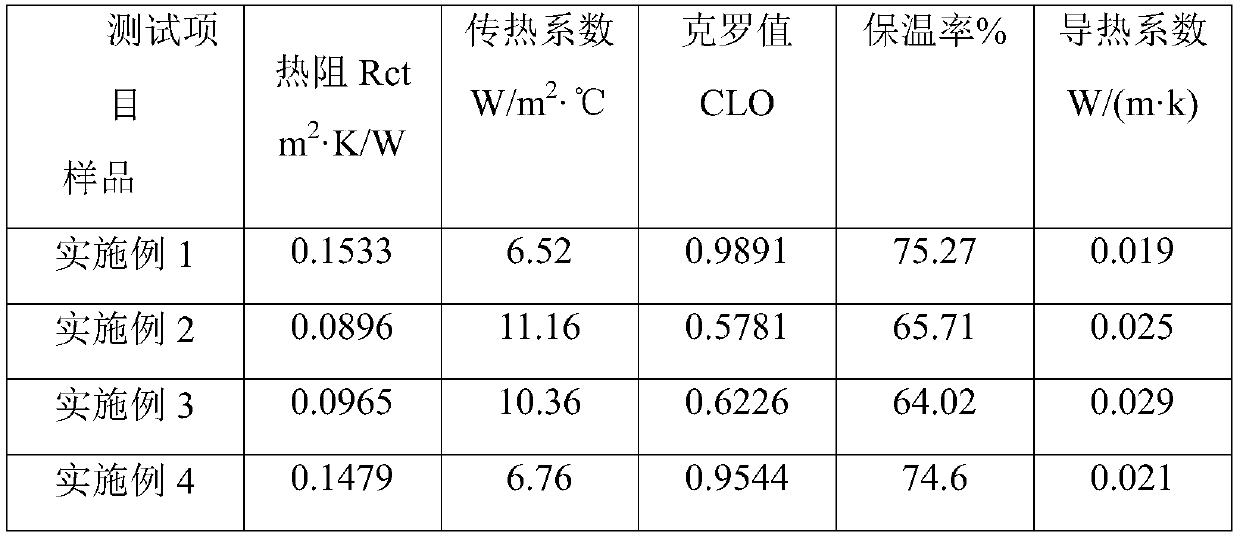

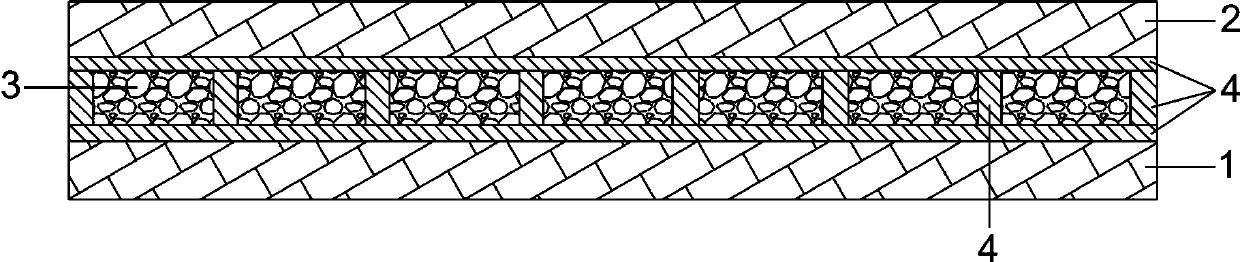

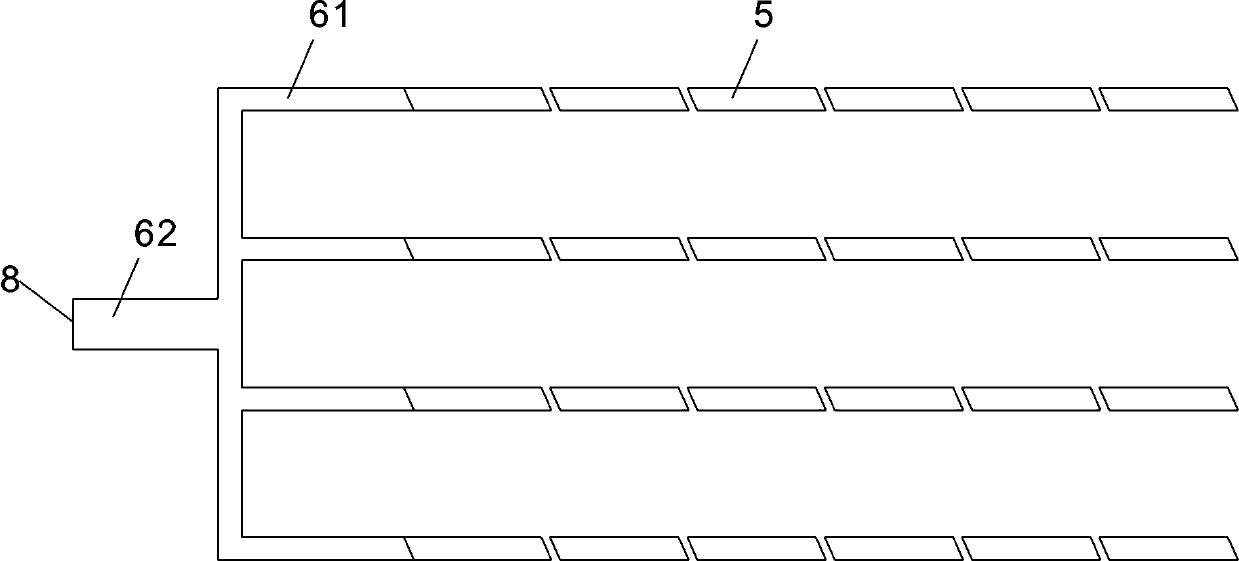

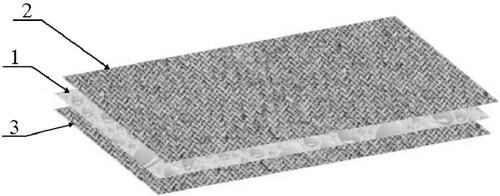

Aerogel based high-heat retention textile composite and preparation method thereof

InactiveCN110077063ASolve the problem of falling powderAvoid destructionMaterial nanotechnologySynthetic resin layered productsInsulation layerThree-dimensional space

The invention relates to an aerogel based high-heat retention textile composite and a preparation method of the aerogel based high-heat retention textile composite, and the aerogel based high-heat retention textile composite sequentially comprises a waterproof and moisture permeable layer, an aerogel heat insulation layer, a far infrared light shielding layer, a phase change energy storage layer and a waterproof and moisture permeable layer from outside to inside. The aerogel based high-heat retention textile composite solves the problem that a powder of an aerogel falls off when the aerogel is used as a heat insulation material, the aerogel is prevented from being dried again in the application process of the aerogel to break the three-dimensional space structure, the advantage of the heat conductivity coefficient is protected against damages, the defect of high loss of the thermal radiation heat of the aerogel, as a main body of the heat insulation material, is improved, the serviceability and the heat retention of the material are further improved, the material achieves the self-temperature regulation function, and the aerogel based high-heat retention textile composite has an excellent market application prospect.

Owner:上海驰纺材料科技有限公司

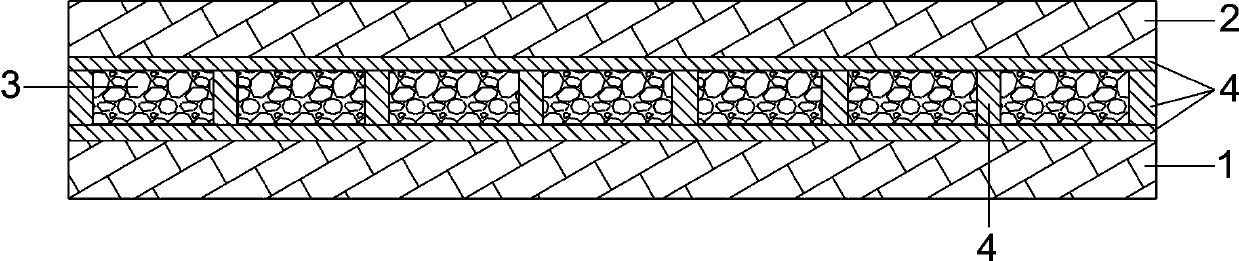

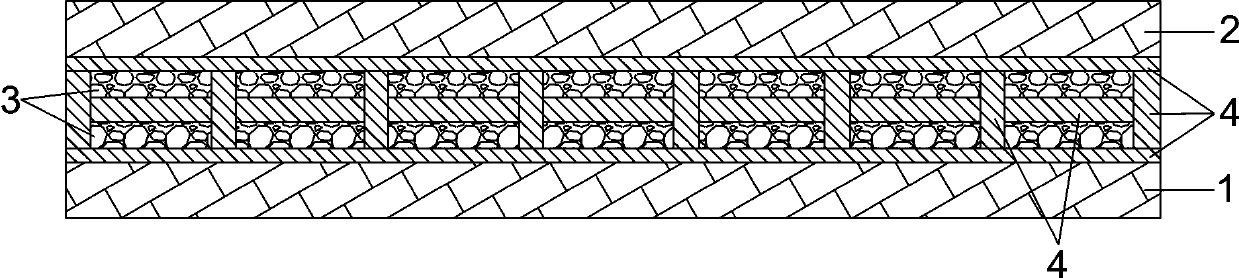

Thermal insulation board and preparation method thereof

ActiveCN111516346AImprove mechanical propertiesSolve the problem of falling powderSynthetic resin layered productsDomestic articlesThermal insulationMold removal

The invention belongs to the technical field of thermal insulation materials, and discloses a thermal insulation board and a preparation method thereof. The thermal insulation board comprises a firstpanel layer, a second panel layer, a sandwich layer and framework supporting layers. The sandwich layer is arranged between the first panel layer and the second panel layer; the sandwich layer is formed by splicing a plurality of fiber reinforced aerogel composite felts; the framework supporting layers are integrally formed and fill between the sandwich layer and the first panel layer and betweenthe sandwich layer and the second panel layer, the peripheral edges of the sandwich layer and splicing seams of any two adjacent fiber reinforced aerogel composite felts in the sandwich layer, and theframework supporting layers, the first panel layer and the second panel layer are integrally formed. The preparation method comprises the following steps: laying, sealing, preparing a glue solution,injecting glue, curing and demolding to obtain the thermal insulation board. An integral curing molding method is adopted, the fiber reinforced resin composite panel is obtained, and meanwhile, the framework supporting layers are formed between the fiber reinforced aerogel composite felts so that the prepared thermal insulation board is light in weight, thermal-insulating and greatly improved in mechanical property.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

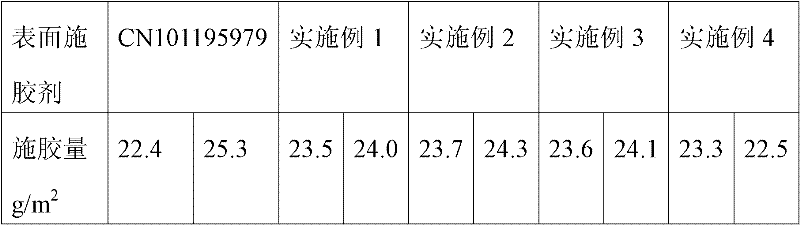

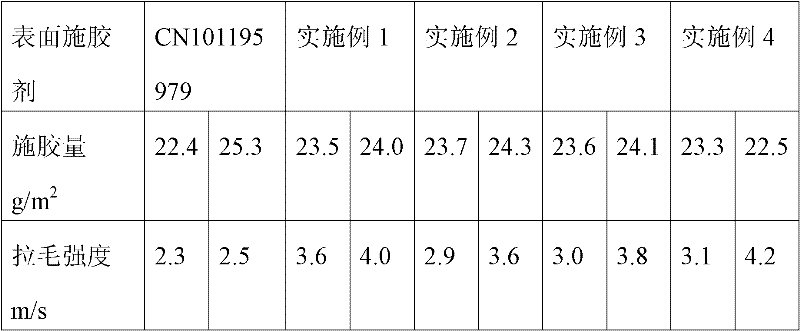

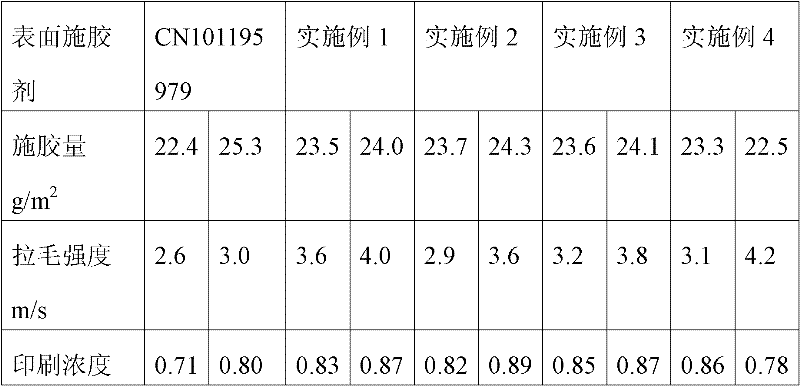

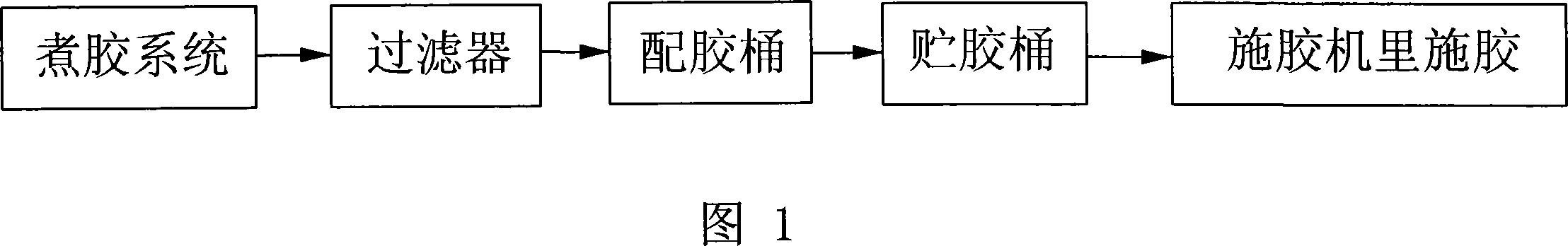

Oxidized starch paper surface sizing agent and preparation method thereof

The invention discloses an oxidized starch paper surface sizing agent and a preparation method thereof. The preparation method comprises the following steps of: (1) adding starch into an alkali solution of which the pH value is 10, soaking, and collecting precipitated starch; (2) adding water, sulfuric acid and an oxidant solution into the precipitating starch, stirring, and standing for 2-5 hours; (3) adding a solid alkali, and stirring for 5-10 minutes; and (4) adding a sodium borate solution, and stirring to obtain the oxidized starch paper surface sizing agent. In the preparation method, oxidized starch is taken as a surface sizing agent, so that the problems of hair falling and powder falling are solved, the paper forming fiber consumption is lowered, a glue making process is simplified, the labor intensity is lowered, and the surface strength and printing suitability of paper can be enhanced.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Fireproof sound-proof heat-insulating aerogel composite material and preparation method thereof

The invention discloses a fireproof sound-proof heat-insulating aerogel composite material and a preparation method thereof. The preparation method comprises the following steps: Step 1, coating fibrofelt with fibre cloth; Step 2, immersing the fibrofelt coated with fibre cloth into a SiO2 sol solution; and Step 3, carrying out sol-gel and drying processes to obtain the fireproof sound-proof heat-insulating aerogel composite material. The product has excellent flame resistance, and the powdery problem of existing aerogel felt is solved; no obvious toxic flue gas is generated by decomposition under the condition of high temperature; and the preparation process is simple and meets the safe and environmental requirements.

Owner:应急管理部四川消防研究所

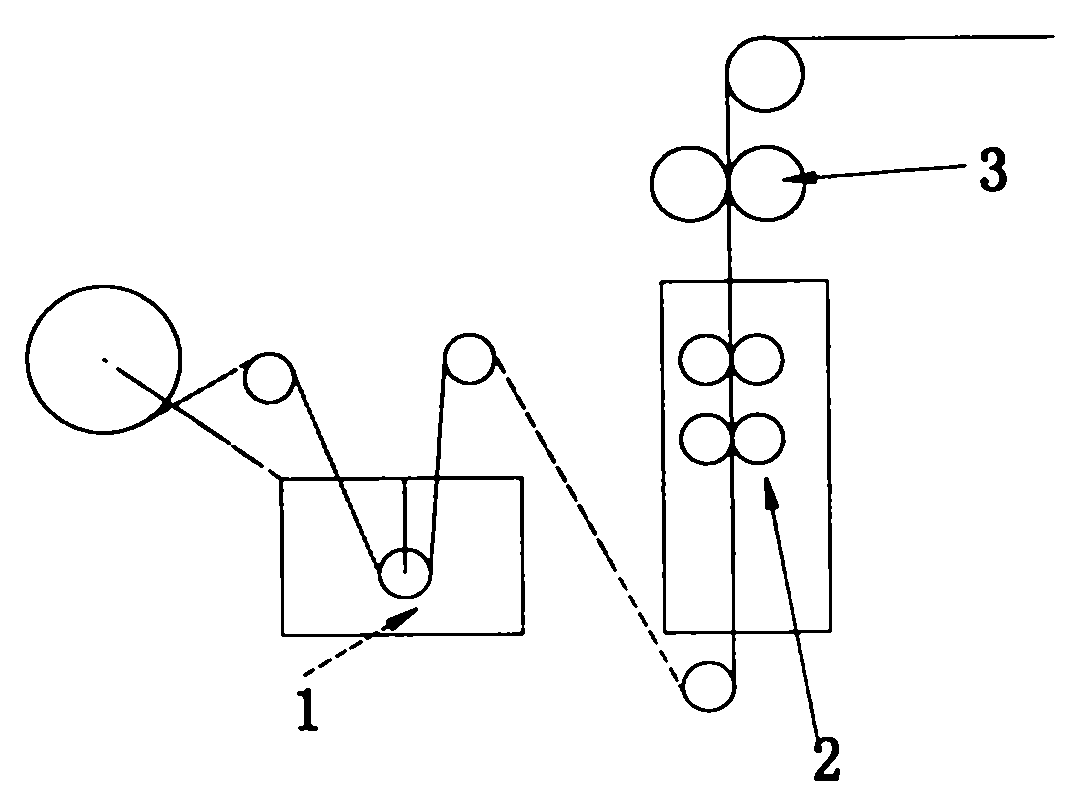

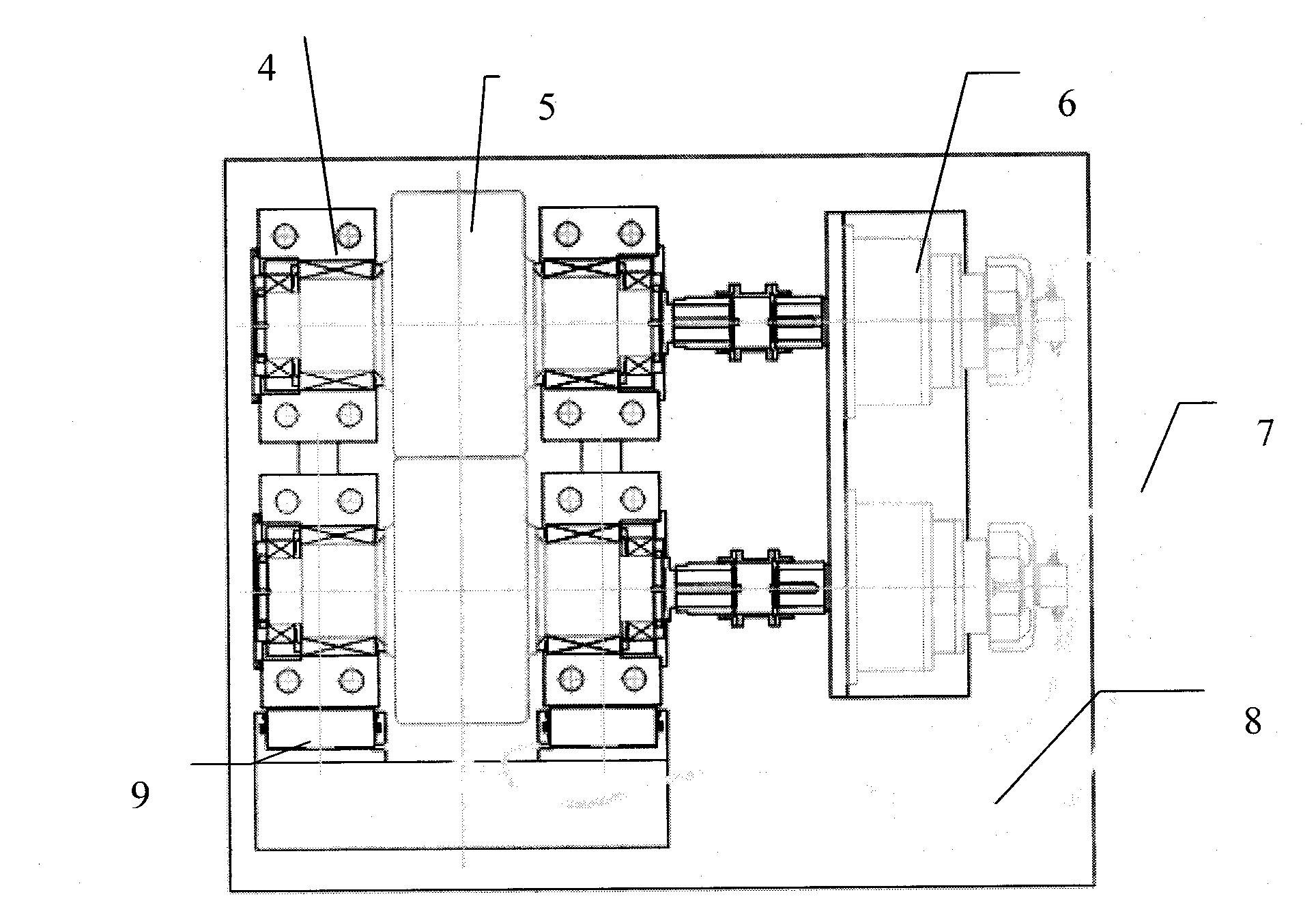

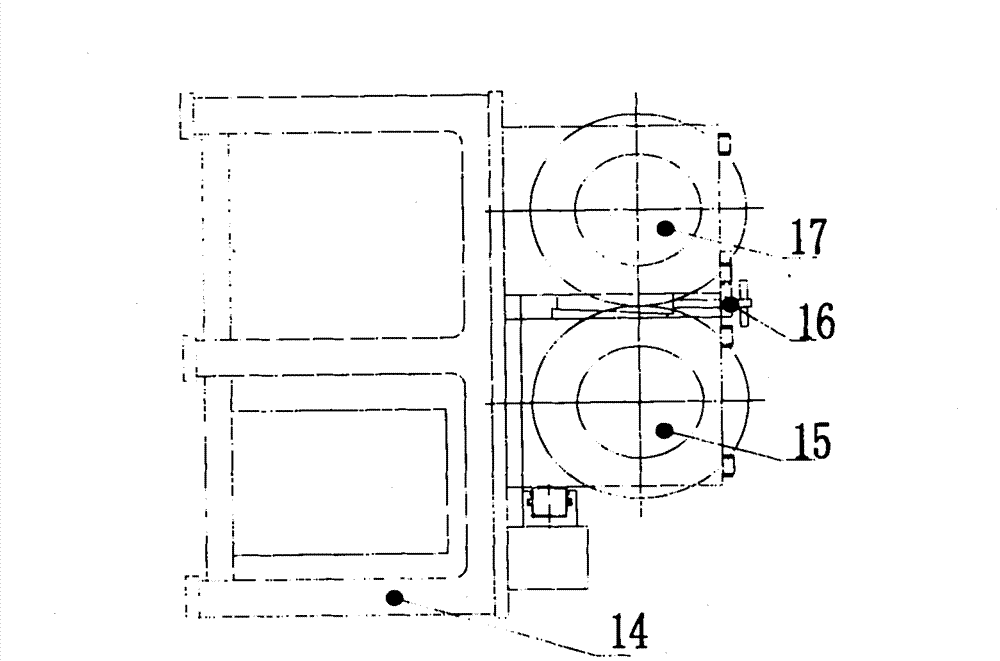

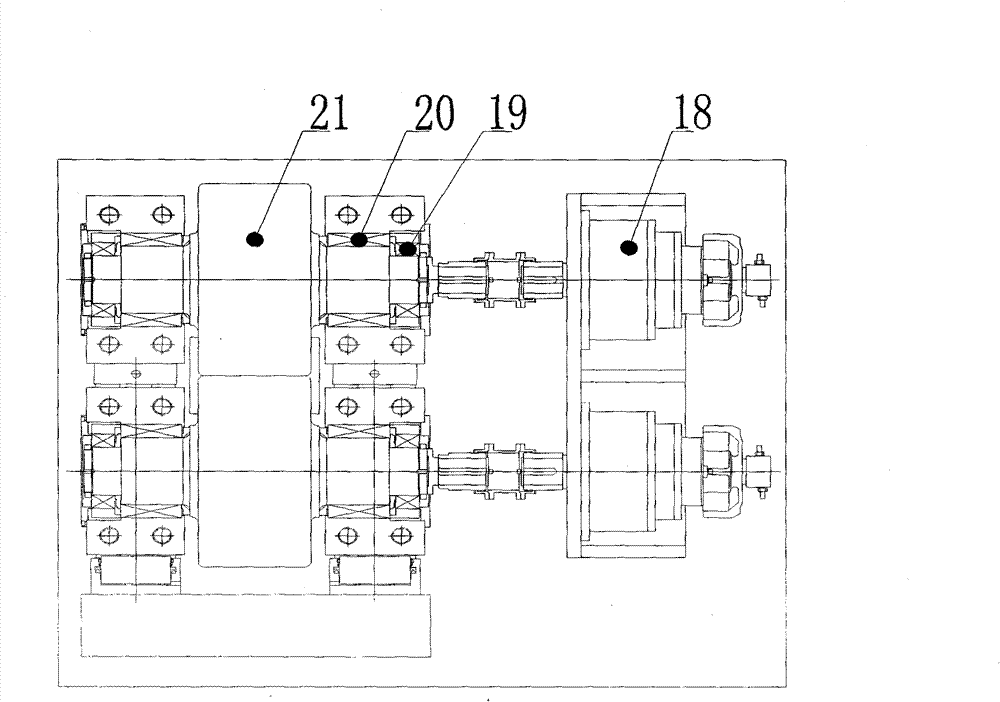

Preparation method of chemical battery pole piece

InactiveCN101867035AImprove uniformityReduce volumeElectrode manufacturing processesEngineeringPole piece

The invention relates to a preparation method of a chemical battery pole piece, which comprises the following steps that: a roll press in production comprises a bearing, a roll body and a driving device, wherein the roll body is a pair of symmetrical rollers, the rollers are placed at left and right and in parallel, and the central axes of the two rollers are positioned on the same horizontal surface. The preparation method of the invention solves the problem of duslting of a traditional press in a traditional process and simultaneously solves the problem of roll cooling due to the temperature reduction of a baseband caused by that the baseband can enter the roll press a certain period of time after powdering. The invention has broad industrial application prospect.

Owner:HUNAN CORUN NEW ENERGY CO LTD

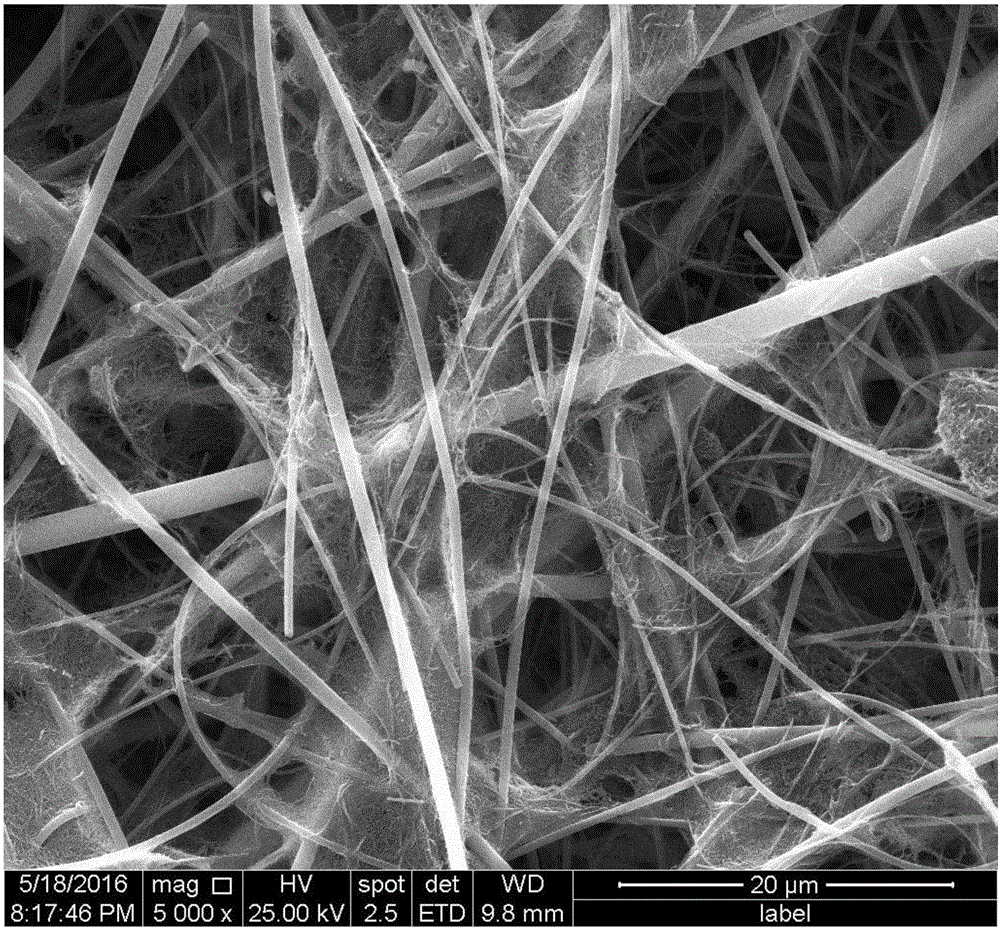

Fiber reinforced flexible silica aerogel

InactiveCN108928057AHigh strengthHigh compressive strengthProtective equipmentGlass/slag layered productsQuartz fiberBonding strength

The invention relates to fiber reinforced flexible silica aerogel, which comprises glass fiber cloth reinforced ceramization phenolic resin sheets, glass fiber cloth reinforced epoxy resin sheets andflexible SiO2 aerogel and interlayer reinforced quartz fiber sewing threads. The inner part of the flexible silica aerogel is reinforced through interlayer overlapping of the glass fiber cloth reinforced epoxy resin sheets and the flexible SiO2 aerogel, the outer surface of the flexible silica aerogel is provided with the glass fiber cloth reinforced ceramization phenolic resin sheets used for strengthening and protecting the flexible SiO2 aerogel, and the quartz fiber sewing threads are used for through sewing the whole structure. The flexible silica aerogel has high strength and certain adhesive properties, the compressive strength of the flexible SiO2 aerogel is significantly improved, the problem of powder dropping of the aerogel is solved, and the interlayer bonding strength of the structure is improved, so that the reliability of aerogel application is greatly improved.

Owner:INNER MONGOLIA AEROSPACE HONGGANG MACHINERY

Preparation method of anti-buffering silicon dioxide aerogel heat insulation sheet

InactiveCN113651592ASolve the problem of falling powderInhibit sheddingSynthetic resin layered productsLaminationFiberSilicon oxide

The invention belongs to the field of heat insulation materials, and discloses a preparation method of an anti-buffering silicon dioxide aerogel heat insulation sheet. The preparation method comprises the following steps: cutting a felt body according to actual application requirements in a fiber felt stage, and combining the felt body with an anti-buffering part silicon rubber frame; and then, finishing the preparation process of the anti-buffering aerogel heat insulation sheet according to the processes of sol-gel, drying and packaging, so that the phenomenon that a large amount of aerogel powder falls off in the processes of cutting aerogel roll felt and packaging functional components in the traditional preparation process is avoided, and the conditions that the heat insulation performance of the aerogel heat insulation component is reduced and the distribution is not uniform are influenced to a certain extent. The anti-buffering aerogel heat insulation sheet obtained through drying is directly packaged, so that the powder falling problem existing in the existing aerogel sheet preparation process is effectively solved, and high packaging efficiency is achieved.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

Full oxidized starch surface sizing technique

InactiveCN101195979AImprove printing effectHigh strengthWater-repelling agents additionPaper coatingFiberSizing

The invention relates to a surface sizing process with full oxidized starch. The starch is selected as raw material. The process steps comprise the production of oxidized starch glue, the preparation of the oxidized starch glue used for sizing, and the sizing of papers in a sizing machine. The invention adopts the full oxidized starch as the sizing agent of the paper surface to solve the problem of dry linting, and to achieve the purposes that the consumption of the paper fiber is decreased, the glue making process is simplified, the labor intensity is lightened, and the printing performance and the printing intensity of the paper surface are enhanced.

Owner:刘烈善 +1

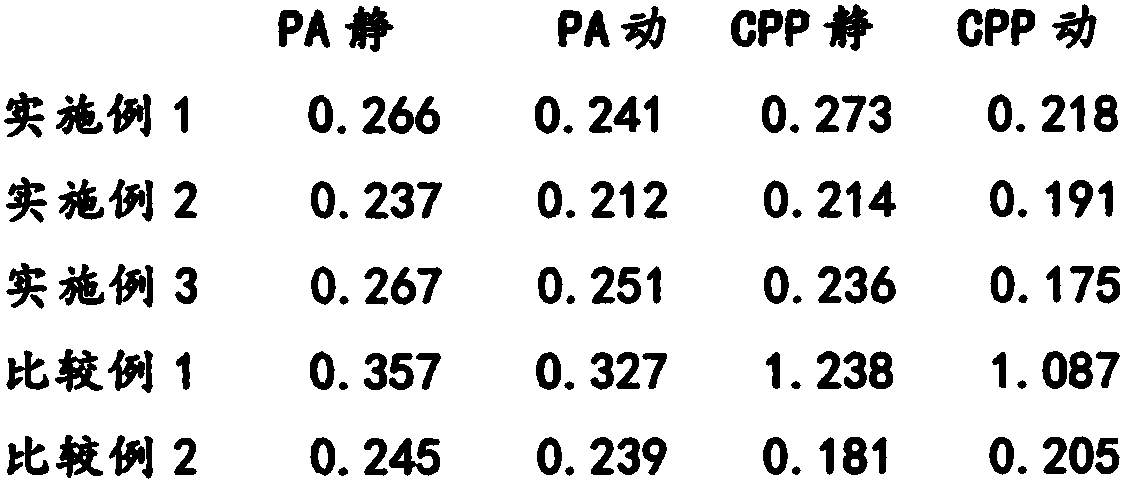

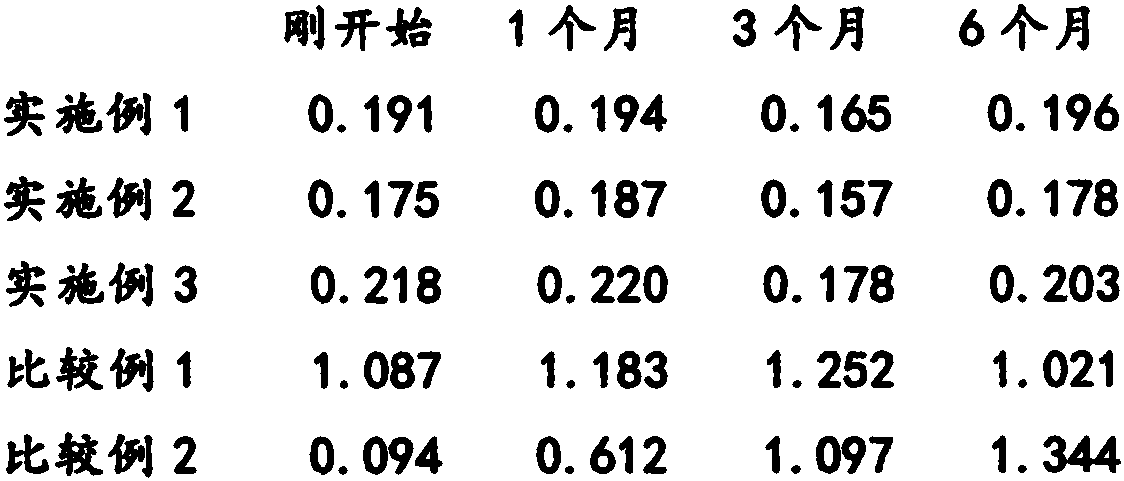

Smooth coating liquid for aluminum plastic thin film and coating process thereof

ActiveCN110760259AGuaranteed stabilityReduced stabilityPolyurea/polyurethane coatingsSpecial surfacesPolyamideOrganosolv

The invention provides smooth coating liquid for an aluminum plastic thin film and a coating process thereof. The coating liquid is prepared from ion-molecular weight organosiloxane, a flatting agent,organic silicon resin, an organic solvent and water. The smooth coating liquid for the aluminum plastic thin film provided by the invention has a favorable effect on remarkably reducing a friction coefficient of a nylon membrane so as to enable a dynamic friction coefficient to be smaller than 0.30; and can be further used for reducing a friction coefficient of a polypropylene thin film so as toenable a dynamic friction coefficient to be smaller than 0.30. The coating process is characterized by coating double surfaces at the same time, and the coating sequence is firstly coating the polypropylene thin film surface and then coating a polyamide thin film surface. The coating process of the smooth coating liquid is simple, no curing is needed, low-temperature drying can be carried out, theproduction efficiency can be effectively improved, and the economic cost can be effectively saved. After an aluminum plastic film product is coated with the smooth coating liquid, a scouring depth performance can be improved, and the stability of the friction coefficient at the high temperature is ensured at the same time.

Owner:广东广麟材耀新能源材料有限公司

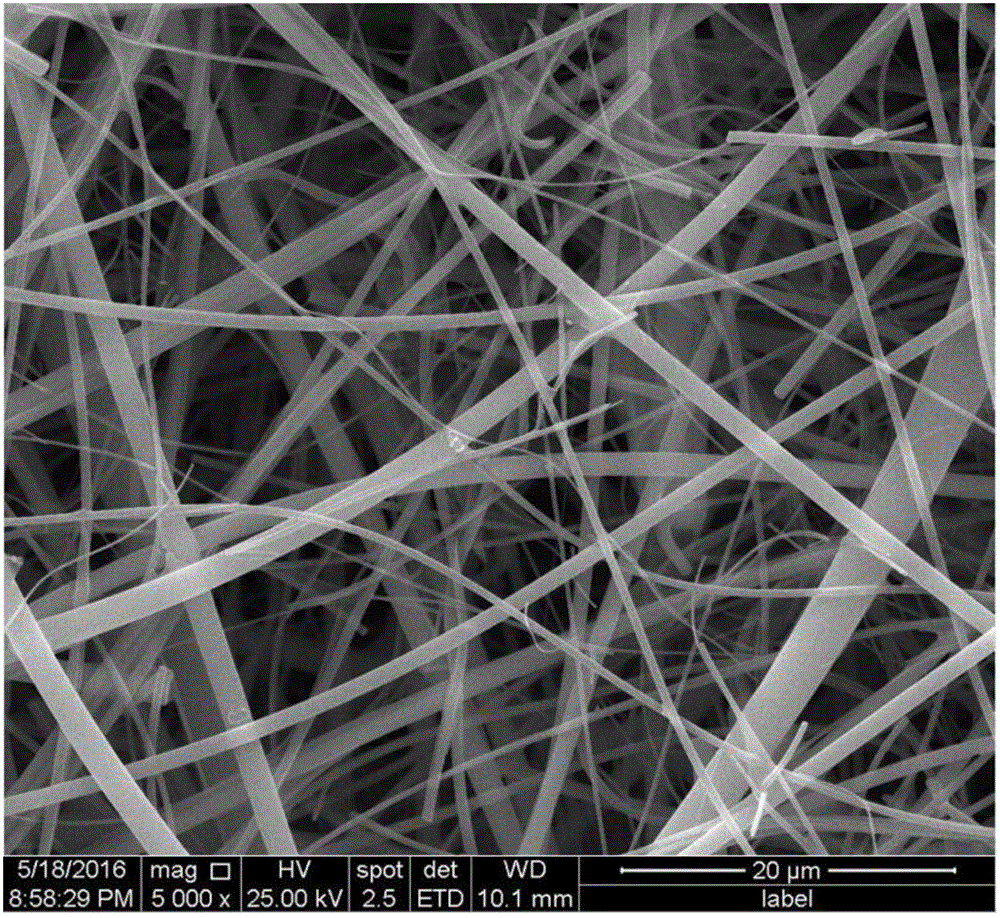

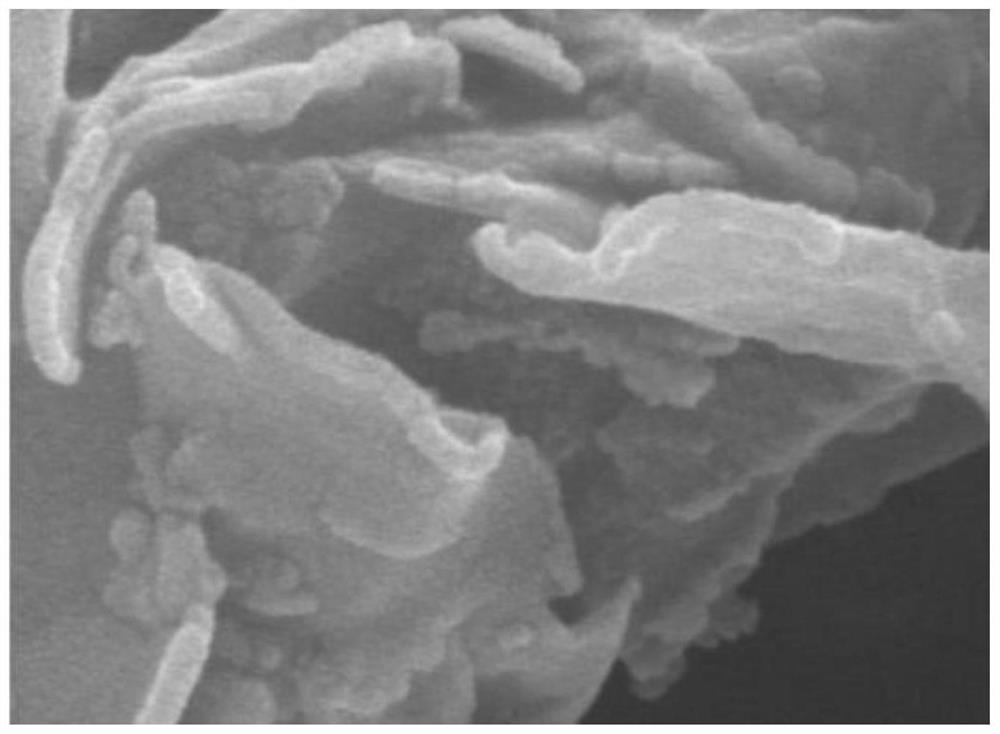

Glass-fiber air filter paper containing carbon nanometer materials and preparing method thereof

ActiveCN105862516AFully contactedSolve the problem of falling powderPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperGlass fiberAir filter

The invention relates to glass-fiber air filter paper containing carbon nanometer materials and a preparing method thereof. The preparing method includes the following steps that 1, the carbon nanometer materials are added into an anion-dispersing-agent water solution, the mixture is subjected to ultrasonic dispersion, and carbon-nanometer-material dispersion liquid is prepared; 2, glass fiber materials are added into water, acid is added, the pH value is adjusted to 2.5 to 3.5, then the mixture is dispersed, then a stabilizer water solution is added, and glass-fiber-material dispersion liquid is prepared; 3, the carbon-nanometer-material dispersion liquid and the glass-fiber-material dispersion liquid are mixed to be even and fed to a forming device to be sucked, then forming wet paper is obtained, sizing and drying are carried out, and the glass-fiber air filter paper is obtained. The glass-fiber air filter paper containing the carbon nanometer materials prepared with the method is of a functional double-layer structure, and is applied to the field of air filter paper, air resistance is small, filter efficiency is high, powder falling is avoided, and the excellent antimicrobial performance is achieved.

Owner:KUNMING NATAI TECH CO LTD

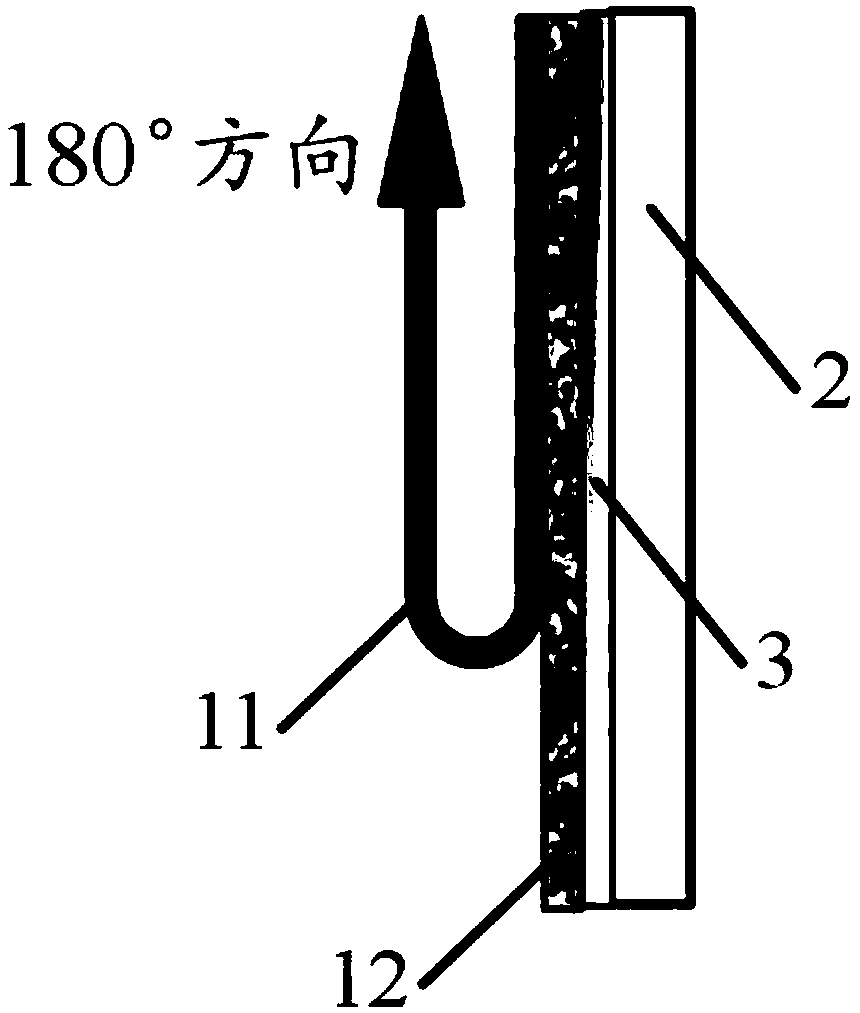

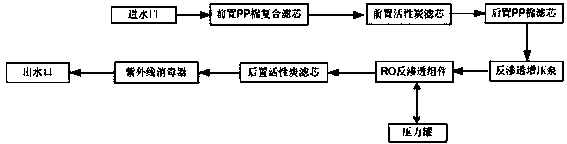

Anti-clogging environment-friendly water dispenser with polyethylene film activated carbon filter elements

InactiveCN103663603AIncrease water fluxHigh compressive strengthMultistage water/sewage treatmentWater/sewage treatment by sorptionActivated carbonEnvironmental resistance

The invention provides an anti-clogging environment-friendly water dispenser with polyethylene film activated carbon filter elements. The water dispenser comprises a front-end activated carbon filter element, a PP (polypropylene) cotton composite filter element, an RO (reverse osmosis) booster pump, an RO component, a rear-end activated carbon filter element, an ultraviolet sterilizer and a water outlet which are connected in sequence, wherein the front-end activated carbon filter element adopts a hollow structure and comprises a 2-micron PP cotton filter layer with the thickness of 8 mm, an activated carbon filter layer with the thickness of 9 mm and a 9- micron PP cotton filter layer with the thickness of 8 mm from inside to outside, an upper end cover and a lower end cover are arranged at two ends of the front-end activated carbon filter element and the rear-end activated carbon filter element, a water outlet is formed in the upper end cover, and the lower end cover is sealed; and the PP cotton composite filter element comprises a casing, a cylindrical PP cotton layer and a cylindrical carbon rod layer are arranged in the casing, the carbon rod layer is arranged on the inner wall of the PP cotton layer which is bonded with the carbon rod layer, a water inlet is formed in the casing, and a liquid enters the casing from the water inlet, passes through the PP cotton layer and passes through the carbon rod layer.

Owner:CHENGDU JETCOM TECH

High heat conductivity type graphite film-metal composite material and preparation method thereof

InactiveCN109234691AStable surface structureSolve the problem of falling powderVacuum evaporation coatingSputtering coatingElectricityHeat conducting

The invention provides a preparation method of a high heat conductivity type graphite film-metal composite material, and relates to the field of materials. The method is characterized in that a vacuummagnetron sputtering mode is used; a metal layer is sputtered on the surface of a graphite film. Therefore, due to the metal layer, the surface structure of the graphite film is stable, and the problem that powder falls off from the graphite film can be solved; moreover, the heat dissipating performance, the flexibility, the longitudinal electricity conductivity, the pressure resistance, and thelike of the graphite film can be improved based on the intrinsic heat conducting performance and electricity conducting performance of metal. The high heat conductivity type graphite film-metal composite material is prepared according to the preparation method and is outstanding in heat dissipating performance, flexibility, longitudinal electricity conductivity, pressure resistance, and the like.

Owner:江苏墨泰新材料有限公司

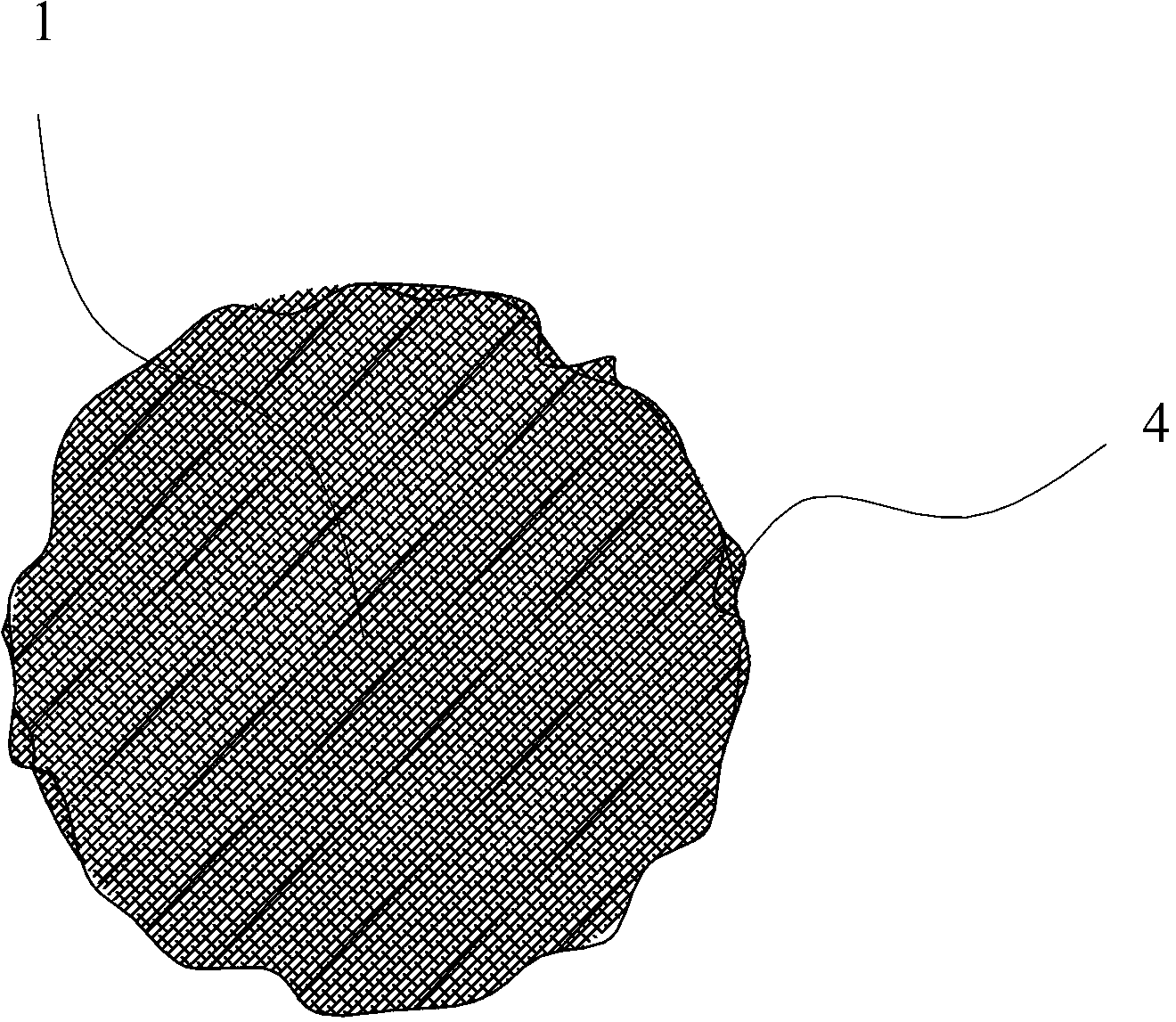

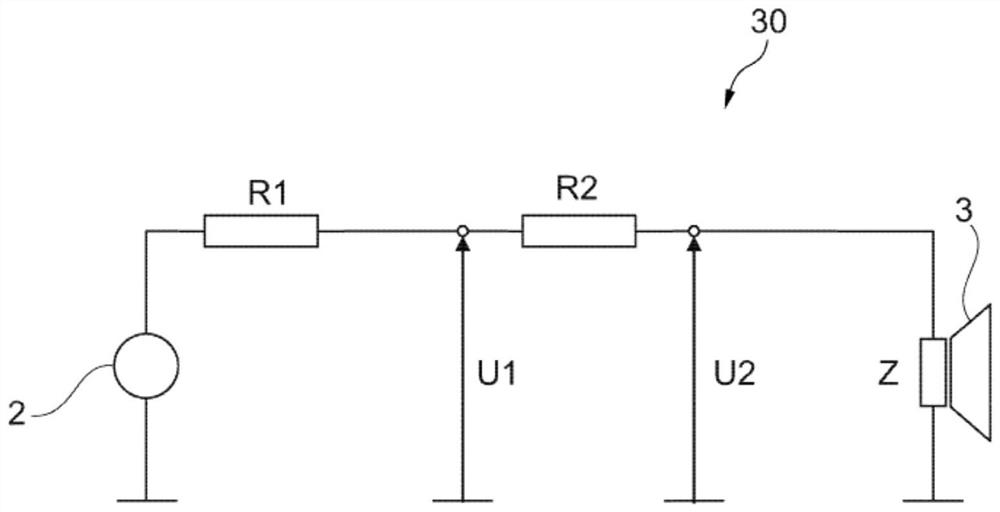

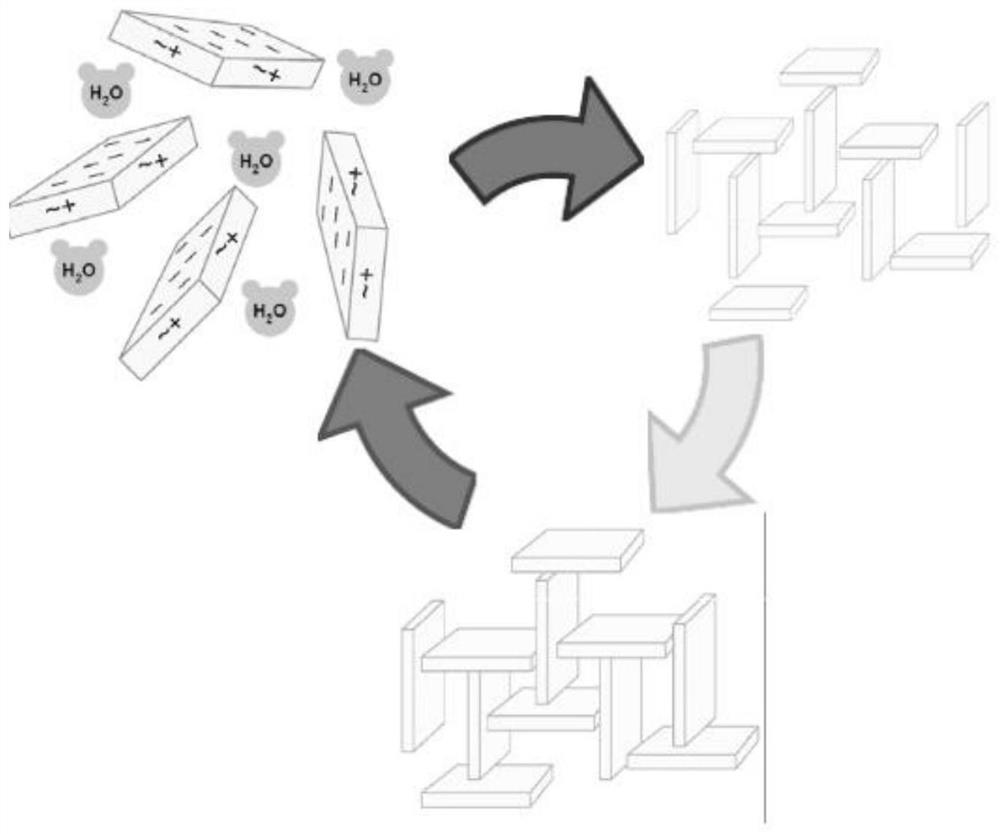

Zeolite spherical porous sound absorption particle, and application thereof in mobile phone loudspeaker system

PendingCN113041993ARaise the resonant frequencyLower resonant frequencyOther chemical processesSound producing devicesBass (sound)Loudspeaker

The invention provides a zeolite spherical porous sound absorption particle, and application thereof in a mobile phone loudspeaker system. The zeolite spherical porous sound absorption particle comprises zeolite porous particles and an adhesive; the zeolite porous particles are bonded together by the adhesive to form the porous spherical particle with abundant macroporous channels; and the main elements of the zeolite porous particles are silicon, oxygen and aluminum, and the mass ratio of silicon to aluminum is at least 150. As a sound absorption material, the zeolite spherical porous sound absorption particle can effectively solve the powder falling problem and the irreversible aging problem caused by high-temperature and high-humidity conditions, the reduction amplitude of the resonant frequency of the mobile phone loudspeaker is increased towards the lower frequency, and the bass effect is obviously improved; and the resonant space is virtually increased, and the resonant frequency of the loudspeaker can be reduced by 100 Hz or above.

Owner:SSI NEW MATERIAL (ZHENJIANG) CO LTD

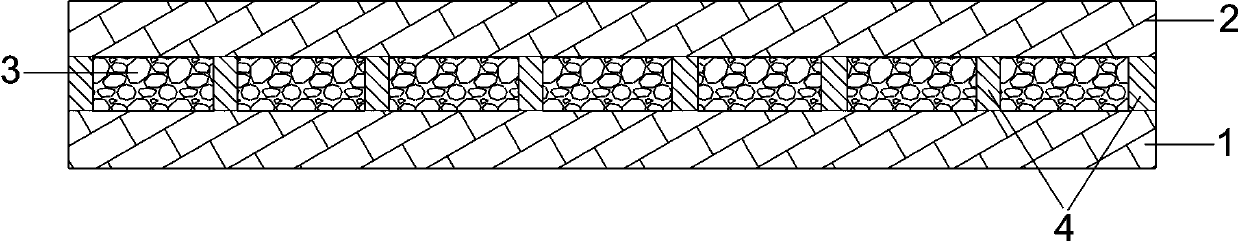

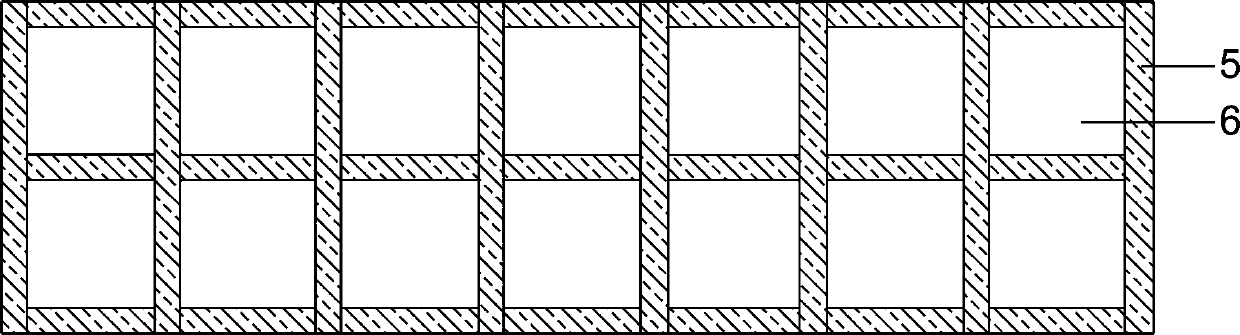

Composite insulation board and preparation method thereof

InactiveCN111516326AHas lightweight insulationImprove mechanical propertiesSynthetic resin layered productsLaminationPolymer sciencePolymer chemistry

The invention belongs to the technical field of preparation of insulation boards, and discloses a composite insulation board and a preparation method thereof. The composite insulation board comprisesa first panel layer, a second panel layer, a sandwich layer and a framework supporting layer. The sandwich layer comprises a plurality of fiber-reinforced aerogel composite felts, the framework supporting layer is in a grid shape, the framework supporting layer is arranged between the first panel layer and the second panel layer, and grids of the framework supporting layer are filled with the fiber-reinforced aerogel composite felts. The preparation method comprises the following steps: sequentially laying a release film, first demolding cloth, a first fiber reinforced resin prepreg tape and alatticed fiber reinforced resin prepreg tape frame from bottom to top; laying the fiber reinforced aerogel composite felt into a latticed fiber reinforced resin prepreg tape frame; laying a second fiber reinforced resin prepreg tape-second demolding cloth; and performing hot-pressing curing molding and demolding treatment to obtain the product. The mechanical property of the composite insulationboard is greatly improved.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

Thermal insulation board and preparation method thereof

InactiveCN111516347AImprove mechanical propertiesSolve the brittleSynthetic resin layered productsDomestic articlesThermal insulationMold removal

The invention belongs to the technical field of thermal insulation materials, and discloses a thermal insulation board and a preparation method thereof. The thermal insulation board comprises a firstpanel layer, a second panel layer, a sandwich layer and framework supporting layers. The sandwich layer is an aerogel felt layer or is formed by stacking two or more aerogel felt layers, and each aerogel felt layer is formed by splicing a plurality of fiber-reinforced aerogel composite felts; the sandwich layer is arranged between the first panel layer and the second panel layer, the lower surfaceof the sandwich layer and the first panel layer, the upper surface of the sandwich layer and the second panel layer, the peripheral edge of the sandwich layer and a splicing seam of any two adjacentfiber reinforced aerogel composite felts in the sandwich layer are integrally formed and filled with the framework supporting layer. The preparation method comprises the following steps: laying, sealing, preparing a glue solution, injecting glue, curing and demolding to obtain the thermal insulation board. An integral curing molding method is adopted, the framework supporting layers are formed while the panel is obtained, and the prepared thermal insulation board has the advantages of light weight, thermal insulation and greatly improved mechanical properties.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

Method for preparing positive plate of nickel hydrogen battery

ActiveCN101867045BImprove consistencyImprove performanceAlkaline accumulator electrodesBiochemical engineeringKey factors

The invention relates to a method for full-automatically preparing a positive plate of a nickel hydrogen battery, which comprises the processes of automatically discharging, automatically feeding and welding a nickel plate, prepressing, gluing, feeding powder, rolling, detecting thickness, softening, automatically welding a nickel wire, automatically rubberizing, automatically splitting, and automatically weighing. The whole process of manufacturing and processing the positive plate is full-automatic, so that the consistency of the positive plate, which is a key factor influencing the consistency of the battery, can be improved; and the method has the advantages of shortening the manufacturing time, saving labor cost, reducing the influence of personal factors, contributing to tracing theproblems of products, along with wide industrial application prospect.

Owner:先进储能材料国家工程研究中心有限责任公司

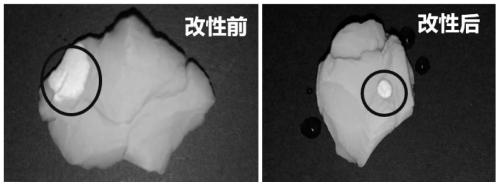

Modification method of aerogel

The invention belongs to the field of preparation of novel materials, and particularly relates to a modification method of aerogel. According to the method, organic steam is adopted to be chemically grafted with hydroxyl on the surface of aerogel; groups in the modifier are crosslinked on the surface of the aerogel through ultraviolet irradiation and high-temperature heat treatment to form macromolecules so as to protect the network structure of the aerogel, so that the mechanical property and the hydrophobic property of the aerogel are improved, and the method is flexible, free, wide in applicability, good in environmental friendliness and suitable for industrial production.

Owner:NANJING UNIV OF TECH

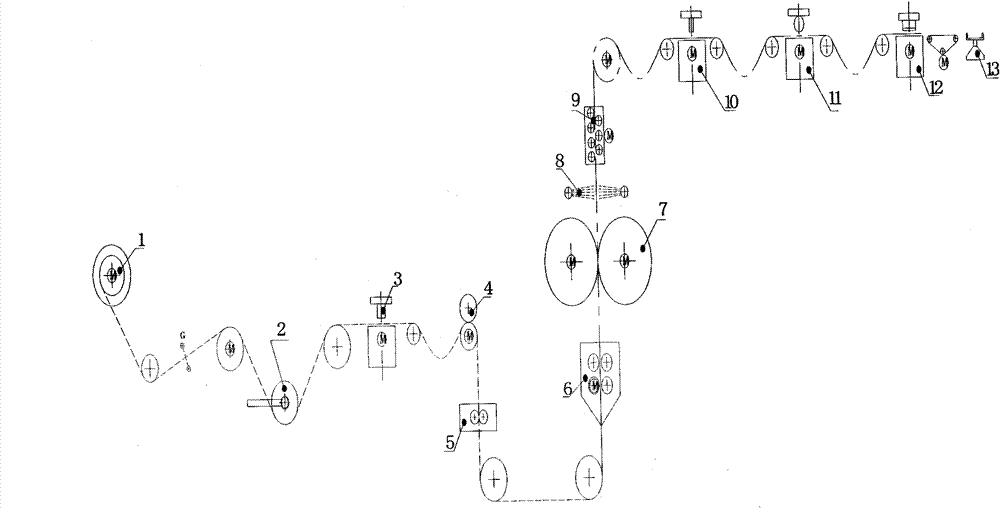

Aerogel heat insulation sheet for electronic product and preparation method thereof

InactiveCN110712408ASolve the problem of falling powderEasy to operateSynthetic resin layered productsLaminationInsulation layerAlcohol

The invention belongs to the technical field of heat insulation of electronic products, and discloses an aerogel heat insulation sheet for an electronic product and a preparation method of the aerogelheat insulation sheet. The aerogel heat insulation sheet comprises an upper layer felt body, a lower layer felt body and an aerogel heat insulation layer integrally formed between the two felt bodies. The preparation method comprises the following steps: (1) dispersing aerogel powder into a water-based polymer coating to obtain a mixed coating; (2) adding industrial alcohol or absolute ethyl alcohol accounting for 5-20% of the mass of the mixed coating into the mixed coating, and uniformly stirring and mixing the coating; (3) placing the felt body on a coating machine, coating the felt body with the mixed coating obtained in the step (2), and paving another felt body on the surface of the coating layer after the coating is completed, so as to obtain a composite layer; and (4) carrying outhot press molding on the composite layer obtained in the step (3) on a hot press to obtain the aerogel heat insulation sheet for the electronic product. According to the invention, the felt body is prevented from falling off from the network structure and scattering on the surface of the packaging film when the aerogel is packaged by the felt body, so that the thermal insulation effect of the thermal insulation sheet is greatly reduced.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

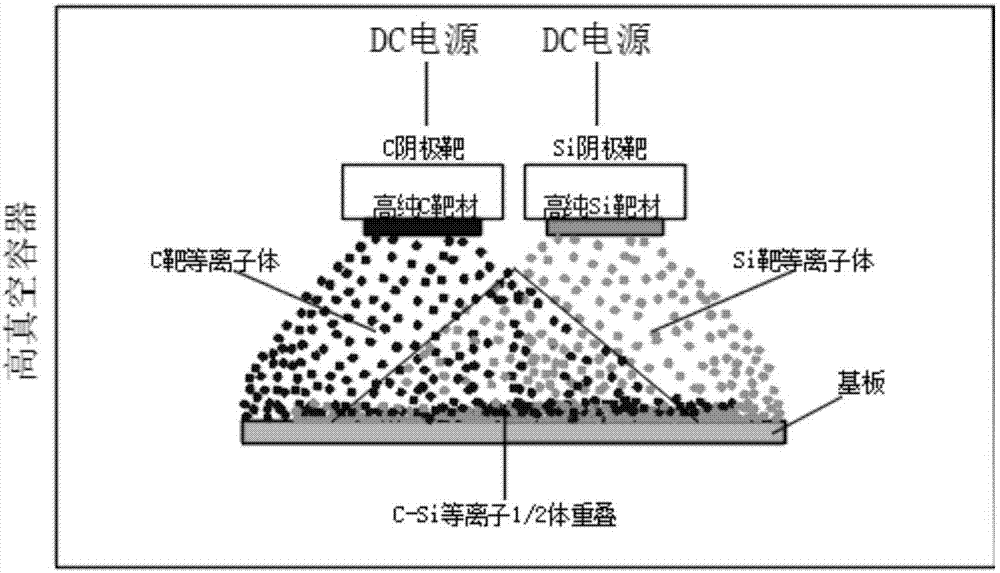

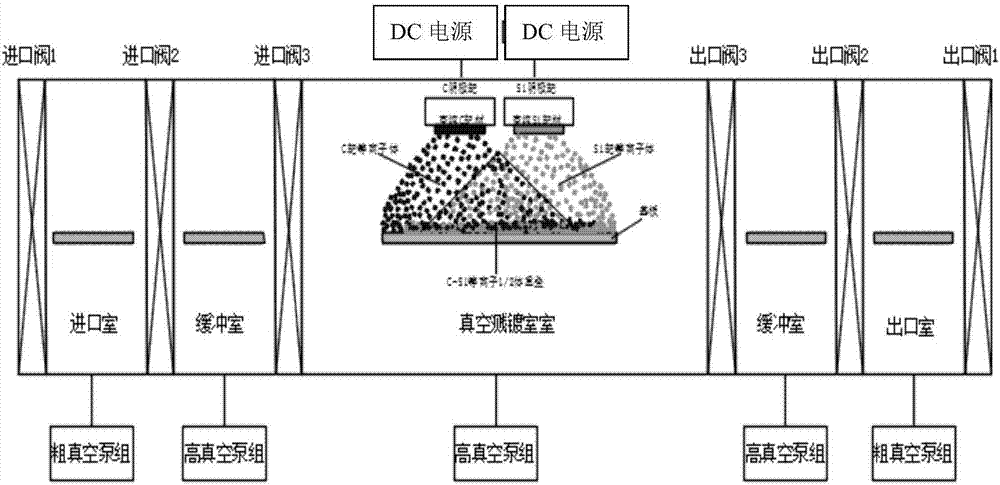

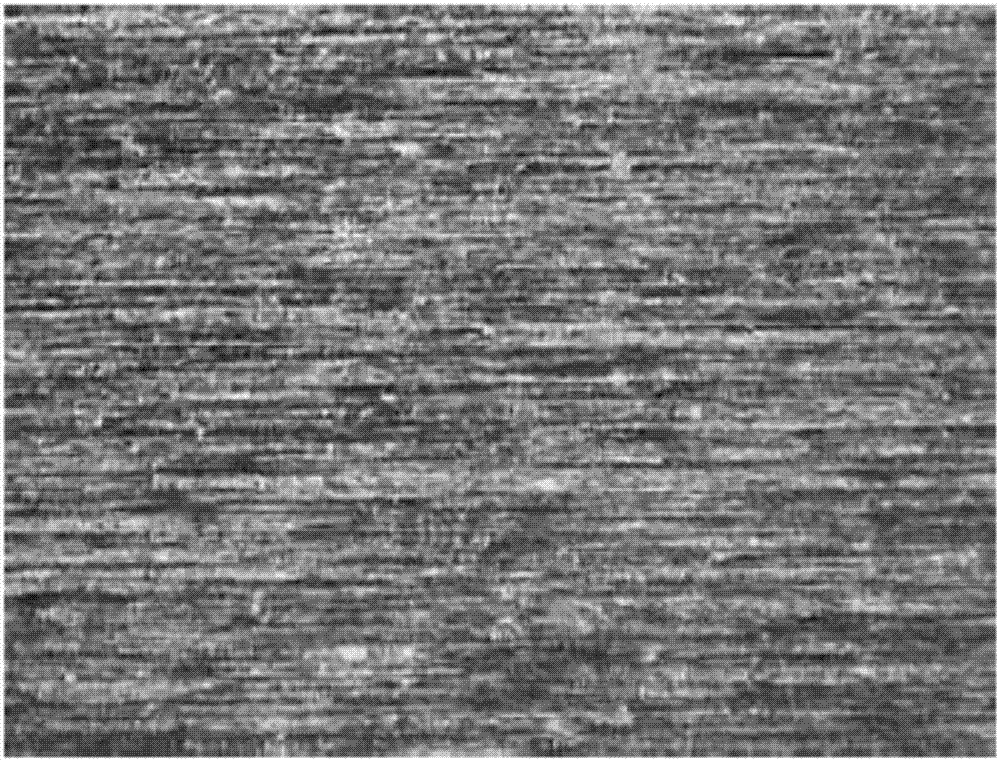

Method for preparing C-Si anode coating of lithium battery with vacuum magnetron sputtering coating technology

InactiveCN107482160AThe doping ratio is flexible and adjustableHigh crystallinityVacuum evaporation coatingSecondary cellsSputteringMetallurgy

The invention discloses a method for preparing a C-Si anode coating of a lithium battery with a vacuum magnetron sputtering coating technology. The method comprises the following steps: selecting shiny copper foil and slitting the copper foil according to loading size of used vacuum magnetron sputtering coating equipment; setting mounting positions of a Si cathode target and a C cathode target of the vacuum magnetron sputtering coating equipment, and enabling Si plasma sputtered by the Si cathode target and C plasma sputtered by the C cathode target to perform doped sputtering coating to realize 1 / 2 volume overlap; setting process conditions of vacuum magnetron sputtering coating; forming a doped C-Si coating through vacuum direct-current magnetron sputtering coating in a vacuum environment to realize doping of Si plasma and C plasma and thickness of 200-500 nm; drying the coated copper foil in a vacuum drying box and sealing the copper foil in a vacuum bag for storage. A C-Si composite anode film is deposited on anode copper foil of the lithium battery with the vacuum magnetron sputtering coating technology, so that the electrical performance of the anode is improved.

Owner:惠州市烯谷新能源产业技术研究院有限公司

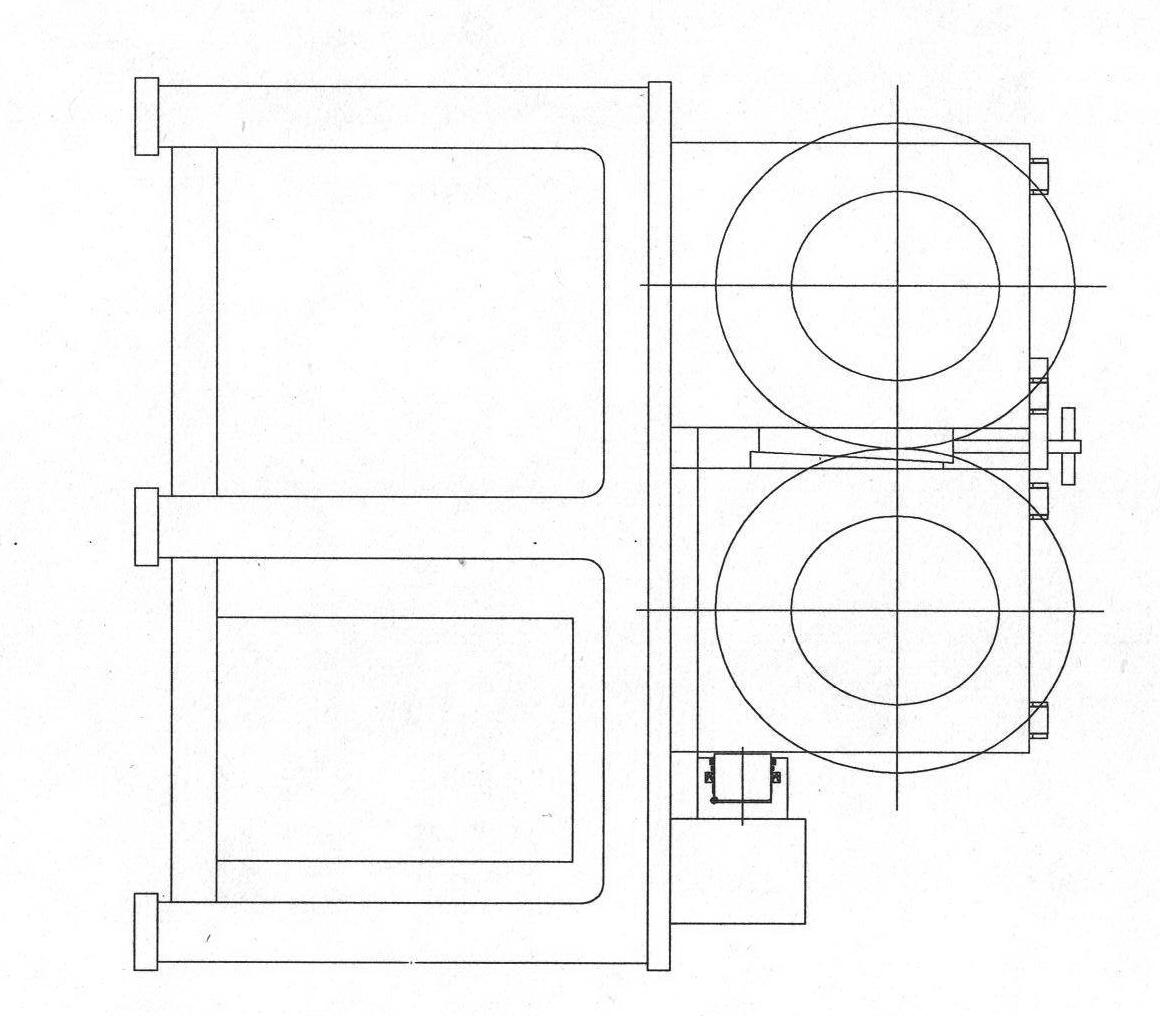

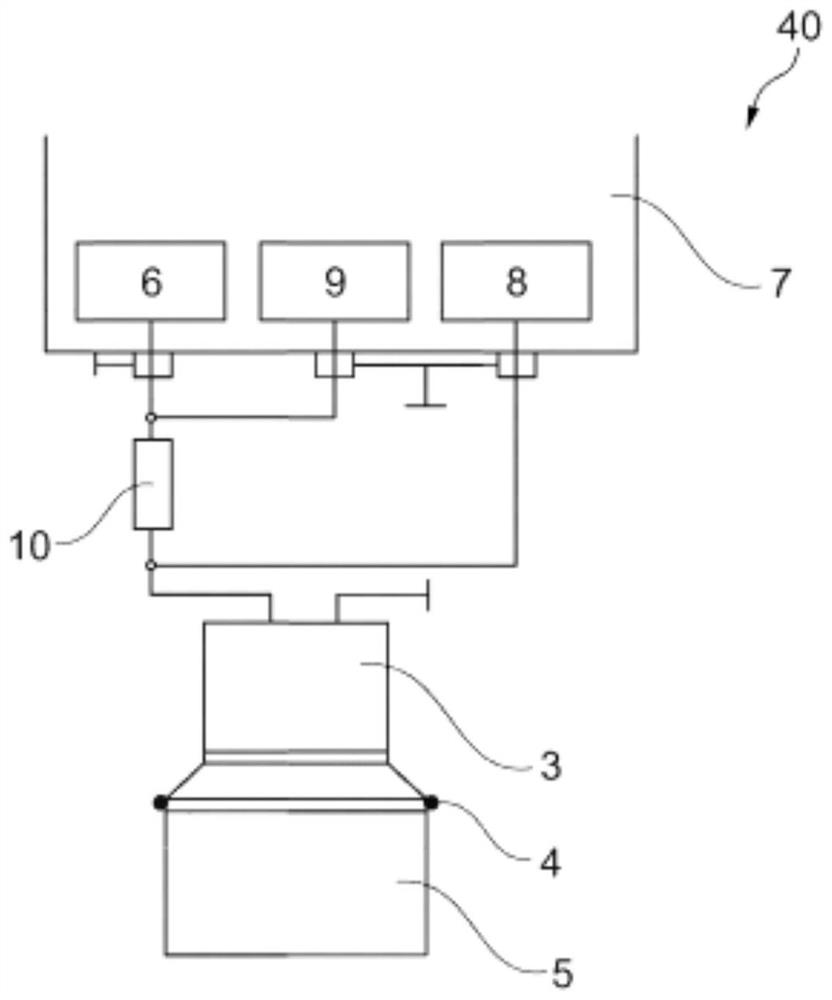

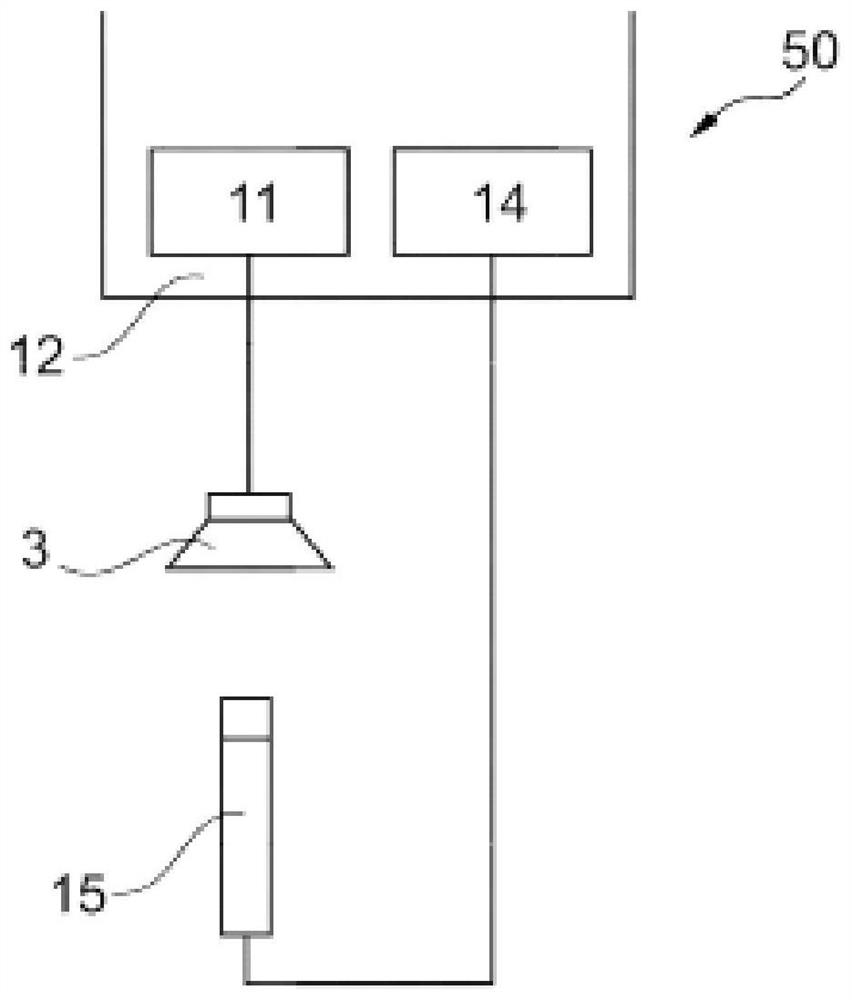

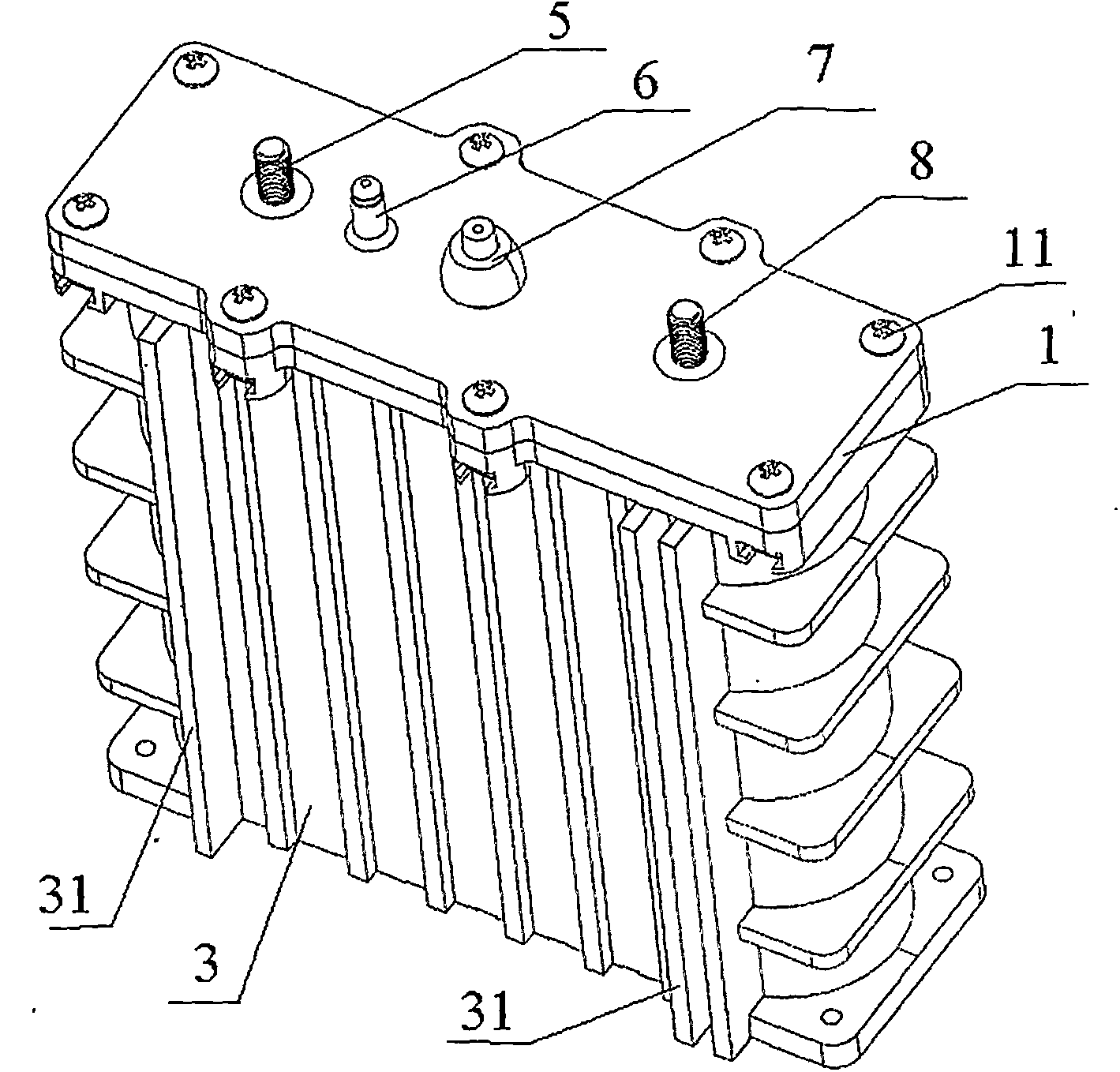

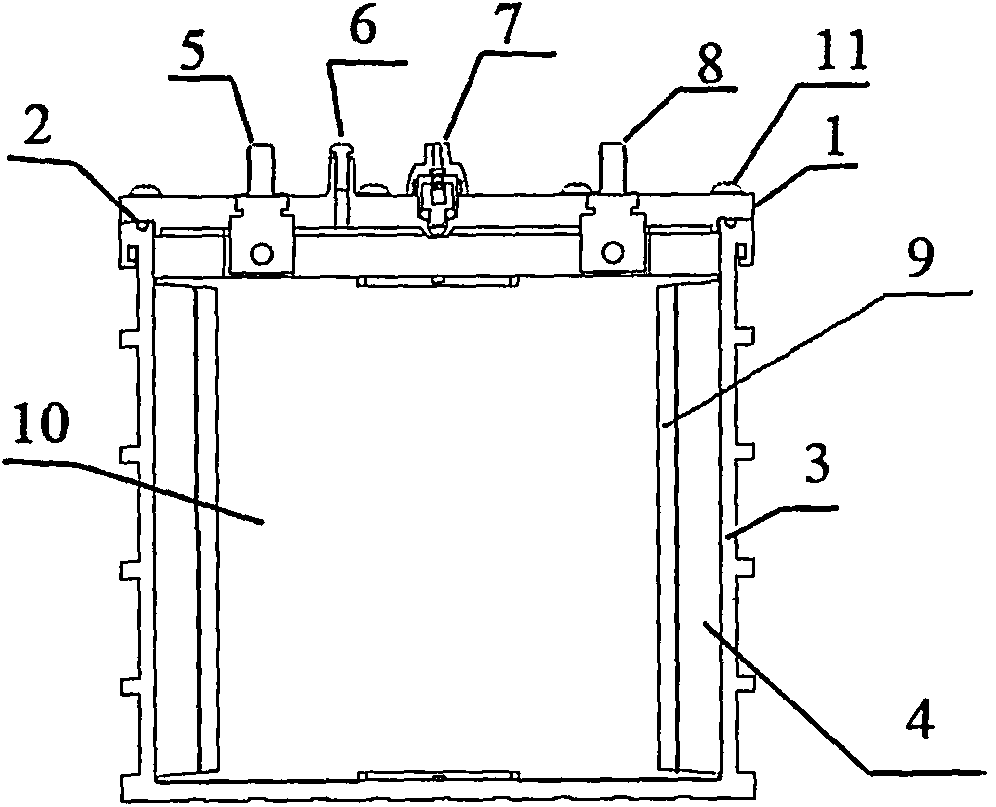

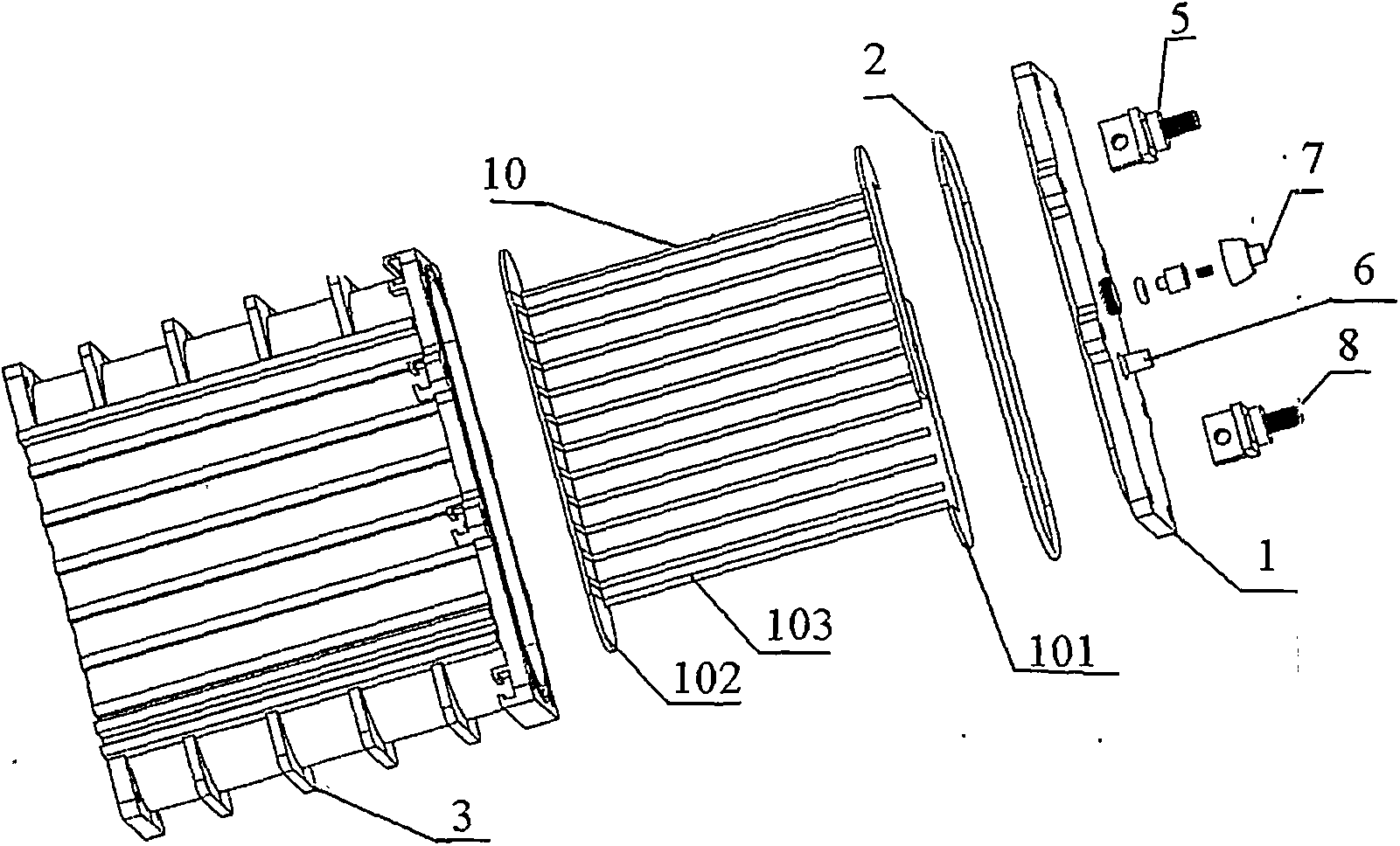

Novel lithium battery structure

InactiveCN103825054ASolve the problem of falling powderGuaranteed stabilityFinal product manufactureVent arrangementsEngineeringBattery capacity

The invention discloses a novel lithium battery structure. The novel lithium battery structure comprises an upper cover (1), a sealing ring (2) and a shell (3), wherein the upper cover (1), the sealing ring (2) and the shell (3) form an enclosed cavity (4) for containing electrolyte, a negative terminal (5), a charging hole (6), a vent valve (7) and a positive terminal (8) are arranged at the top part of the upper cover in a protruding manner, a battery cell (13) is arranged in the enclosed cavity (4) and comprises a battery cell skeleton (10), a battery pole core (9) and a heat shrinkage tube (12), and the vent valve comprises a venting cavity (102) penetrating through the upper cover (1) and a valve cover (103) covering the venting cavity. According to the novel lithium battery structure, the powder falling-off problem of the positive electrode and the negative electrode of the lithium battery is solved, the battery cell skeleton is additionally arranged inside the battery to ensure the stability of the battery capacity; moreover, the lithium battery structure is provided with the vent valve to be capable of venting and reducing pressure automatically, therefore, the safety performance is improved, and electrolyte cannot flow out of the shell when the novel lithium battery structure is upside down.

Owner:SHANGHAI LEHU HUADE ELECTRIC SWITCH

Regenerated waterproof putty powder and application method thereof

The invention provides regenerated waterproof putty powder and an application method thereof, which belong to the technical field of building materials. The regenerated waterproof putty powder is prepared from the following components in parts by weight: 220 to 350 parts of Portland cement, 400 to 680 parts of waste aerated concrete micro powder, 50 to 150 parts of ash calcium powder, 50 to 150 parts of heavy calcium carbonate powder, 50 to 120 parts of talcum powder, 2 to 7 parts of hydroxypropyl methyl cellulose, 3 to 8 parts of dispersible latex powder, 3 to 7 parts of magnesium aluminum silicate and 2 to 8 parts of dry powder polycarboxylate superplasticizer. Waste aerated concrete micro powder is used as a main filler, heavy calcium carbonate powder and talcum powder are used as secondary fillers, white cement and ash calcium powder are used as main film-forming substances, hydroxypropyl methyl cellulose, dispersible latex powder, magnesium aluminum silicate and a dry powder polycarboxylate superplasticizer are used as functional aids, and the putty powder has the characteristics of good crack resistance, high bonding strength, favorable water resistance and favorable decorative effects.

Owner:SHENZHEN HUAWEI ENVIRONMENTAL PROTECTION BUILDINGMATERIAL

Tobacco shredding technique

InactiveCN108477664AIncrease throughputGood sensory quality and experienceTobacco treatmentCigar manufactureWater contentEngineering

The invention discloses a tobacco shredding technique. Tobacco is divided into strips and shredded such that the tobacco is transversely half cut and longitudinally continuous. The invention also discloses a processing technique of single heat-not-burn cigarette core rods based on the shredding technique. The finished single heat-not-burn cigarette core rod processed via the shredding technique has certain gaps; more air passes through a heat-not-burn cigarette during smoking; the problem is also solved that dry reconstituted tobacco in the traditional paper filter rod opening technique experiences picking. In addition, the parameters, such as single rod weight, shred depth and product water content, are optimized, and the product with suitable smoking resistance and hardness, as well as good sensory quality and experience, is acquired.

Owner:CHINA TOBACCO GUANGDONG IND +1

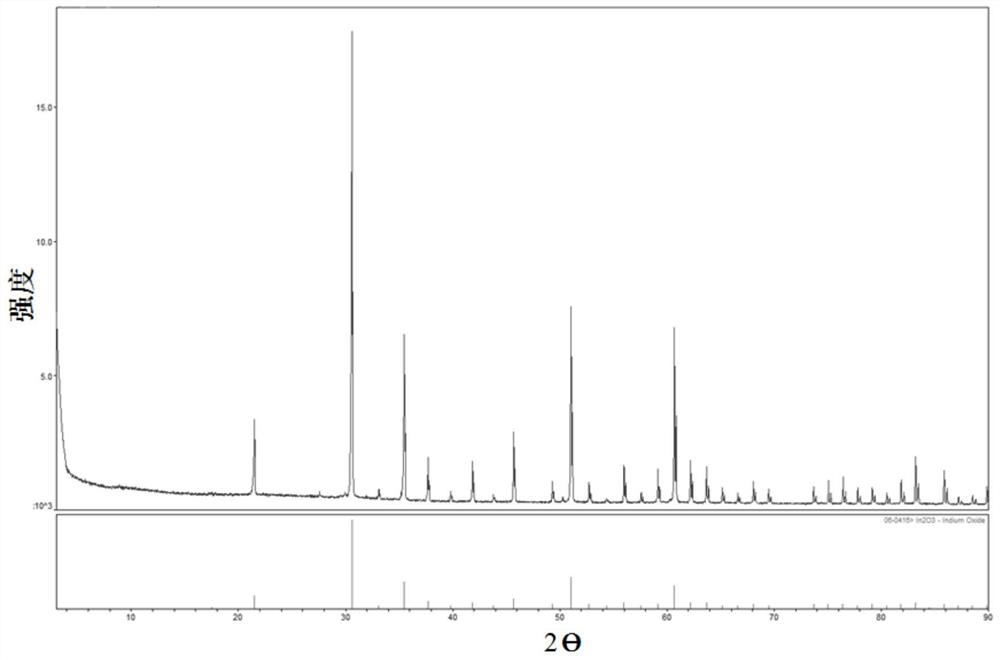

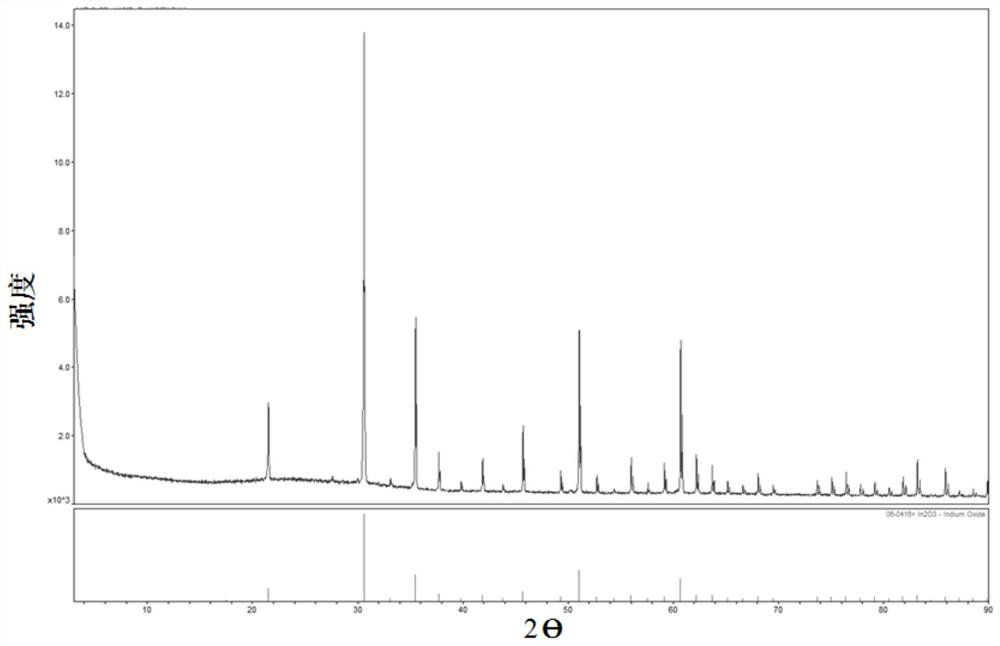

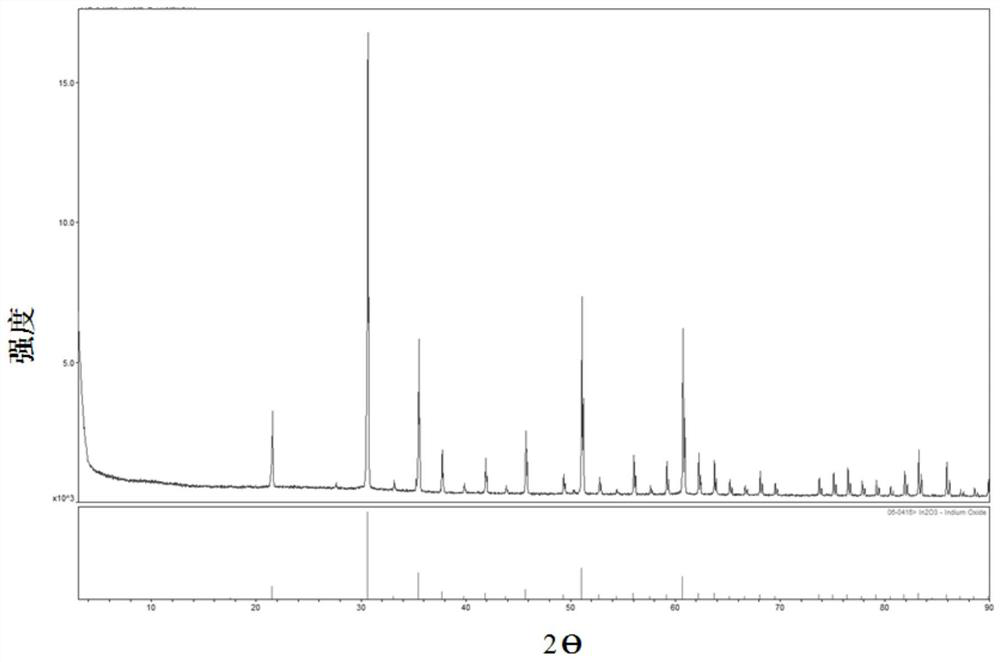

Sintered body for vapor deposition and preparation method thereof

ActiveCN111943649ASmall distortionImprove mobilityFinal product manufactureVacuum evaporation coatingNano siliconSingle crystal

The invention provides a sintered body for vapor deposition and a preparation method thereof. The sintered body is prepared from indium oxide, a doping element x and a silicon element, the content ofthe doping element x accounts for 0.2-5.0% of the weight ratio of x oxide to (indium oxide + x oxide), the content of the silicon element in the sintered body is 5-600 ppm, and the silicon element isat least one of nano silicon oxide powder and silicon dioxide sol. Indium oxide and the oxide mixture doped with the element x are mixed at a high temperature to obtain indium oxide single crystal phase powder which is of a bixbyite structure and contains the element x in a solid solution mode, then the indium oxide single crystal phase powder is mixed with the silicon element to be pressed into ablank in required size, and then sintering is conducted to obtain a sintered body. During RPD coating with the sintered body, high mobility can be obtained, meanwhile, the problem that due to the fact that the density of the sintered body is low, powder falling in the using process affects continuous operation of the coating process, and consequently the production efficiency is reduced is solved, and shutdown is not needed for cleaning the powder falling problem any more, continuous production is achieved, and the production efficiency is improved.

Owner:长沙壹纳光电材料有限公司

Guar gum surface sizing agent and preparation method thereof

ActiveCN102363939AImprove printing effectHigh strengthWater-repelling agents additionPaper coatingFiberOrganic solvent

The invention provides a guar gum surface sizing agent and a preparation method thereof. The preparation method comprises the following steps of: (1) dropwise adding an oxidant aqueous solution into an organic solvent containing guar gum raw powder, controlling the pH of a system to 2-4 after dropwise adding, and reacting to obtain guar gum oxide; and (2) adding a viscosity stabilizer into the guar gum oxide obtained in the step (1) with the amount which is 0.1-3 percent based on the oven dry weight of guar gum, adjusting the pH of the system to 6-8, reacting, and collecting the guar gum surface sizing agent from a reaction product. Due to the adoption of a paper surface sizing agent, the consumption of papermaking fiber can be lowered, the glue making process is simplified, the labor intensity is lowered, and the printing performance and the printing strength of the paper surface sizing can be improved; and the guar gum surface sizing agent has the advantages of small impurity content and convenience for applying during preparation of a glue solution.

Owner:SHANGHAI CHANGFA NEW MATERIAL CO LTD

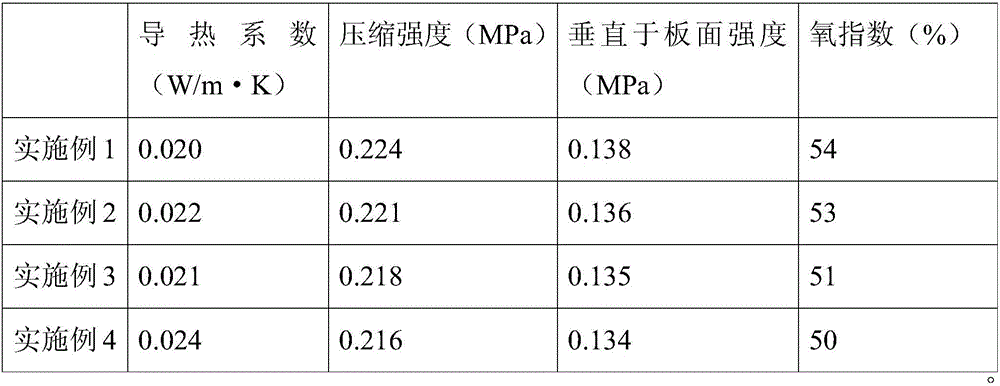

Toughened phenol-formaldehyde foam insulation board and preparation method thereof

The invention provides a toughened phenol-formaldehyde foam insulation board and a preparation method thereof. The toughened phenol-formaldehyde foam insulation board contains the following raw materials in parts by weight: 60-70 parts of phenol-formaldehyde resin, 10-15 parts of silane coupling agent, 4-6 parts of silica sol, 3-6 parts of surfactant, 5-10 parts of foamer, 10-15 parts of curing agent and 3-6 parts of toughening agent, wherein the toughening agent is prepared from an acrylic-styrene copolymer emulsion, polyacrylic acid and modified wollastonite fibers. The preparation method comprises the following steps: (1) uniformly mixing the phenol-formaldehyde resin, the silane coupling agent, the silica sol, the curing agent and the toughening agent at the temperature of 60 DEG C to 80 DEG C, so as to obtain a mixture A; (2) uniformly mixing and stirring the mixture A, the surfactant and the foamer, rapidly pouring the mixture into a preheated mold for foaming, and carrying out curing, thereby preparing the toughened phenol-formaldehyde foam insulation board. The insulation board is high in strength and oxygen index and small in coefficient of thermal conductivity.

Owner:合肥广能新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com