Toughened phenol-formaldehyde foam insulation board and preparation method thereof

A technology of phenolic foam and thermal insulation board, which is applied in the field of building exterior wall materials, can solve the problems of high thermal conductivity of phenolic foam board, high strength and oxygen index of thermal insulation board, low thermal conductivity, etc., and achieve the effect of improving strength, toughness and toughening Significant, solve the effect of brittleness and powder loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

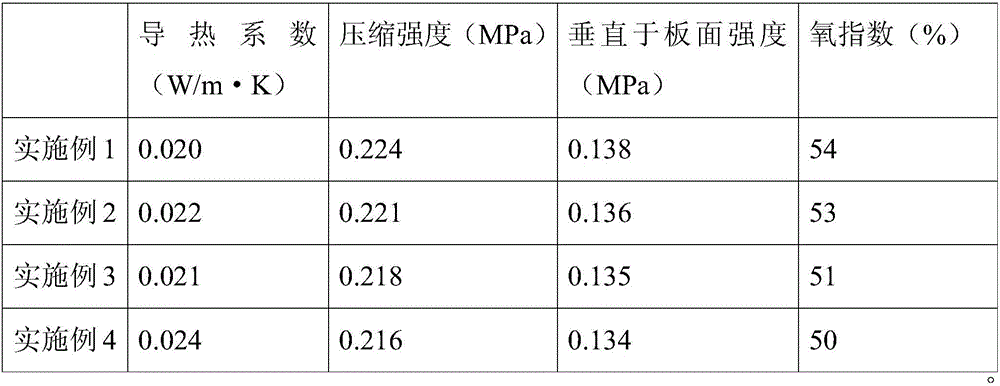

Examples

Embodiment 1

[0022] A toughened phenolic foam insulation board, calculated in parts by weight, comprising the following raw materials:

[0023] 65 parts of phenolic resin, 12 parts of silane coupling agent KH550, 5 parts of silica sol, 4 parts of Tween 80, 7 parts of cyclopentane, 12 parts of p-toluenesulfonic acid and 4 parts of toughening agent. The following components of the toughening agent: 30 parts of acrylic acid styrene copolymer emulsion, 5 parts of polyacrylic acid and 13 parts of modified wollastonite fiber, the modified wollastonite fiber is wollastonite coated with methyl methacrylate.

[0024] The preparation method comprises the following steps:

[0025] 1) Mix phenolic resin, silane coupling agent KH550, silica sol, phosphoric acid and toughening agent uniformly at 70°C to obtain mixture A;

[0026] 2) Mix and stir the mixture A, Tween 80 and cyclopentane evenly, quickly pour it into a mold preheated at 45°C to foam, and then solidify.

Embodiment 2

[0028] A toughened phenolic foam insulation board, calculated in parts by weight, comprising the following raw materials:

[0029] 60 parts of phenolic resin, 10 parts of silane coupling agent KH560, 4 parts of silica sol, 3 parts of Tween 80, 5 parts of n-pentane, 11 parts of hydrochloric acid and 3 parts of toughening agent. The toughening agent includes the following components: 25 parts of acrylic acid styrene copolymer emulsion, 6 parts of polyacrylic acid and 10 parts of modified wollastonite fiber.

[0030] The preparation method comprises the following steps:

[0031] 1) Mix phenolic resin, hydrochloric acid, silane coupling agent KH560, silica sol and toughening agent uniformly at 60°C to obtain mixture A;

[0032] 2) Mix and stir the mixture A, Tween 80 and n-pentane evenly, quickly pour it into a mold preheated at 40°C to foam, and then solidify.

Embodiment 3

[0034] A toughened phenolic foam insulation board, calculated in parts by weight, comprising the following raw materials:

[0035] 68 parts of phenolic resin, 13 parts of silane coupling agent KH560, 6 parts of silica sol, 5 parts of Tween 80, 8 parts of n-pentane, 10 parts of phosphoric acid and 5 parts of toughening agent. The toughening agent is 32 parts of acrylic styrene copolymer emulsion, 3 parts of polyacrylic acid and 14 parts of modified wollastonite fiber.

[0036] The preparation method comprises the following steps:

[0037] 1) Mix phenolic resin, silane coupling agent KH560, silica sol, a mixed acid of phosphoric acid and p-toluenesulfonic acid, and a toughening agent at 62°C to obtain mixture A;

[0038] 2) Mix and stir the mixture A, Tween 80 and n-pentane evenly, quickly pour it into a mold preheated at 42°C to foam, and then solidify.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com