Oxidized starch paper surface sizing agent and preparation method thereof

A technology of surface sizing agent and oxidized starch, which is applied in the direction of water repellent addition, etc., can solve the problems of unstable sizing agent concentration, heavy workload, and complicated preparation process, so as to improve strength and printability and reduce paper-making Effect of fiber consumption and simplification of rubber making process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

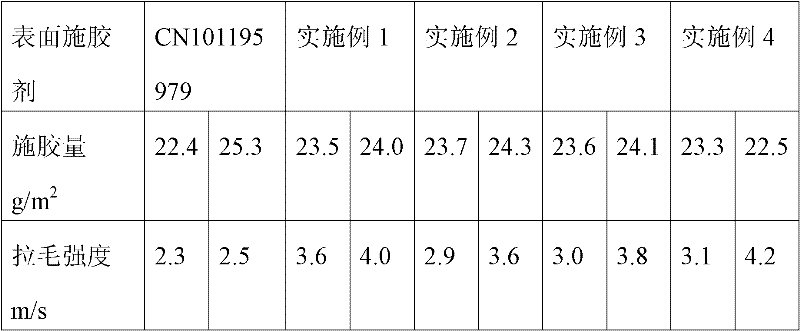

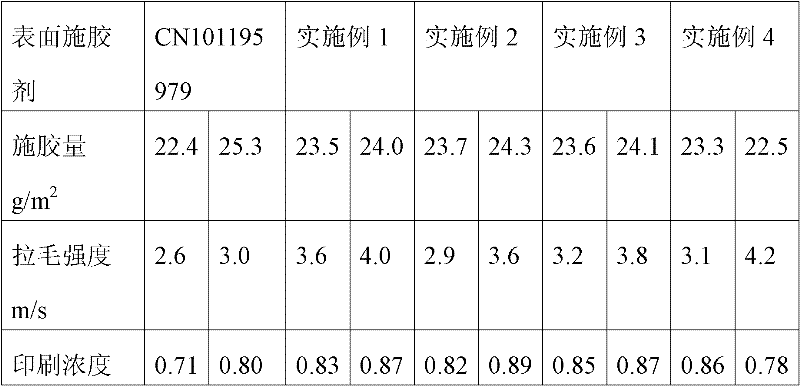

Embodiment 1

[0026] Add 100 parts of cornstarch into 270 parts of sodium hydroxide solution with a pH value of 10 under stirring, soak for 0.5 hours, filter to remove slag, let stand for precipitation, and obtain precipitated starch;

[0027] Take the above-mentioned precipitated starch, add 225 parts of water, 10 parts of sulfuric acid and 2.6 parts of potassium permanganate, stir evenly, the material is brown, and after standing for 5 hours, it turns into white;

[0028] Add 20 parts of sodium hydroxide, and after stirring for 5 minutes, the material is a translucent solution;

[0029] Add 10 parts of sodium borate solution with a weight concentration of 2%, and stir for 15 minutes to obtain the surface sizing agent 1.

Embodiment 2

[0031] Add 100 parts of wheat starch into 300 parts of potassium hydroxide solution with a pH value of 10 under stirring, soak for 1.0 hour, filter to remove slag, let stand for precipitation, and obtain precipitated starch;

[0032] Take the above-mentioned precipitated starch, add 225 parts of water, 20 parts of sulfuric acid and 5.0 parts of potassium permanganate, stir evenly, the material is brown, and after standing for 2 hours, it turns into white;

[0033] Add 15 parts of solid potassium hydroxide, and after stirring for 3 minutes, the material becomes a translucent solution;

[0034] Add 5 parts of sodium borate solution with a weight concentration of 4%, and stir for 10 minutes to obtain surface sizing agent 2.

Embodiment 3

[0036] Add 100 parts of tapioca starch into 280 parts of sodium hydroxide solution with a pH value of 10 under stirring, soak for 0.6 hours, filter to remove slag, let stand for precipitation, and obtain precipitated starch;

[0037] Take the above precipitated starch and add 250 parts of deionized water, 15 parts of sulfuric acid and 3.5 parts of potassium permanganate, stir evenly, the material is brown, and after standing for 4 hours, it turns into white;

[0038] Add 15 parts of solid sodium hydroxide and stir for 4 minutes, the material becomes a translucent solution; add 8 parts of 2.5% sodium borate solution and stir for 12 minutes to obtain the surface sizing agent of the invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com