Modification method of aerogel

An airgel and modification technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as complex reaction steps, unsuitable for large-scale industrial production, and poor environmental friendliness, and achieve mechanical properties Poor, wide applicability, good environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0021] Silica airgel was treated at 200°C for 3 hours and then reacted with vinylmethyldichlorosilane vapor at 20°C for 24 hours to graft vinylmethyldichlorosilane on the surface of silica airgel; the grafted silica gas Gel warp strength 100mW / cm 2 The vinyl group on the modifier is cross-linked by ultraviolet irradiation for 30 minutes, and then heat-treated at 200° C. for 24 hours to further cross-link the vinyl group to obtain the modified silica airgel. The density of the modified silica airgel is increased by 50%, the strength is increased by 30 times, the thermal conductivity is increased by 30%, and the water contact angle is 120°.

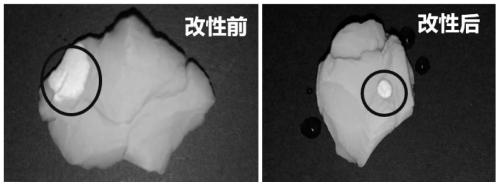

[0022] See attached picture, figure 1 It is a schematic diagram of the hydrophobic performance of the modified silica airgel prepared in Example 1. A macromolecular protective layer is formed on the surface of silica airgel particles through grafting and polymerization crosslinking, which solves the problems of poor mechanical properties ...

example 2

[0024] After the alumina airgel was treated at 250°C for 1 hour, it was reacted with vinyl dimethyl chlorosilane vapor at 40°C for 4 hours to graft vinyl dimethyl chlorosilane on the surface of the alumina airgel; the grafted alumina gas Gel warp strength 200mW / cm 2 The vinyl group on the modifier is cross-linked by ultraviolet irradiation for 10 minutes, and then heat-treated at 250° C. for 4 hours to further cross-link the vinyl group to obtain the modified alumina airgel. The density of the modified alumina airgel is increased by 5%, the strength is increased by 6 times, the thermal conductivity is increased by 15%, and the water contact angle is 120°.

example 3

[0026] Zirconia airgel was treated at 300°C for 1 hour, mixed with vinyl dimethyl chlorosilane and mercaptopropylmethyldimethoxysilane, and reacted at 60°C for 12 hours to make vinyl dimethyl chlorosilane and mercaptopropyl Methyldimethoxysilane is grafted on the surface of zirconia airgel; the strength of grafted zirconia airgel is 100mW / cm 2 The vinyl and mercaptopropyl groups on the modifier were cross-linked by ultraviolet irradiation for 20 minutes, and then heat-treated at 250° C. for 12 hours to further cross-link the vinyl and mercaptopropyl groups to obtain the modified zirconia airgel. The density of the modified zirconia airgel is increased by 30%, the strength is increased by 20 times, the thermal conductivity is increased by 20%, and the water contact angle is 125°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com