Thermal insulation board and preparation method thereof

A heat insulation and panel layer technology, applied in chemical instruments and methods, other household appliances, household components, etc., can solve the problems of airgel powder dropping, poor flexibility, airgel brittleness, etc., and achieve excellent impact resistance Compressive properties, expanding the scope of application, and improving the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

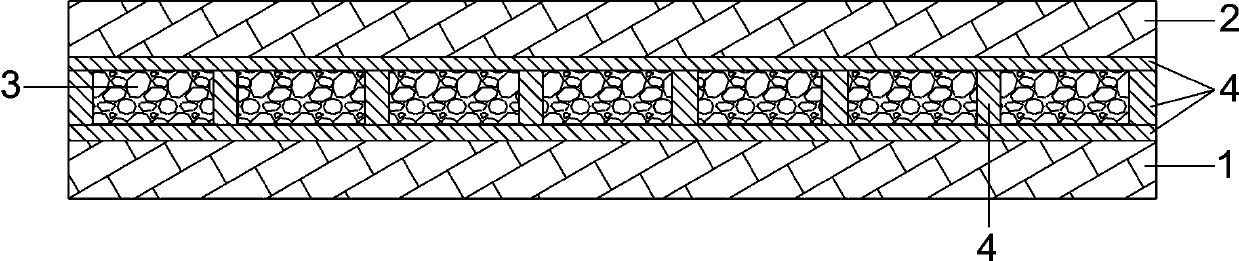

[0043] like figure 1 , image 3 and Figure 4 As shown, a heat insulation board comprises a first panel layer 1, a second panel layer 2, a sandwich layer, and a skeleton support layer 4. The sandwich layer is an airgel felt layer, and the airgel felt The layer is formed by splicing several cuboid fiber-reinforced airgel composite mats 3; the sandwich layer is arranged between the first panel layer 1 and the second panel layer 2, and the lower surface of the sandwich layer and the first panel layer 1 between the upper surface of the sandwich layer and the second panel layer 2, the surrounding (front, back, left, and right) edges of the sandwich layer, and any two adjacent fiber-reinforced airgel composite felts 3 in the sandwich layer. The molding is filled with a skeleton support layer 4, and the skeleton support layer 4 is integrally cured with the first panel layer 1 and the second panel layer 2;

[0044] The first panel layer 1, the second panel layer 2 and the skeleton ...

Embodiment 2

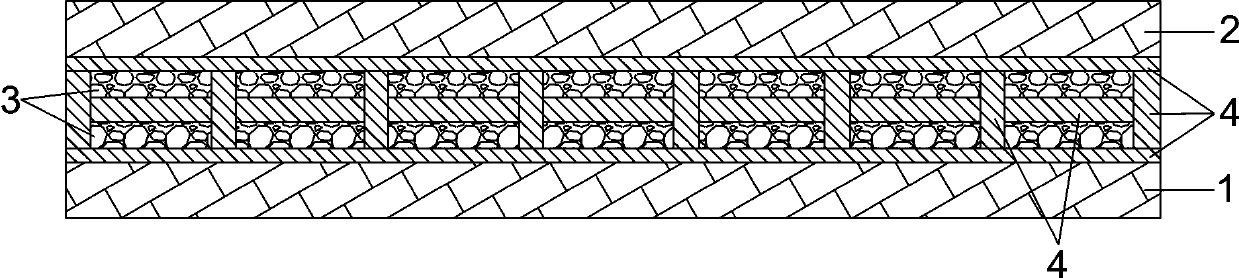

[0054] A kind of thermal insulation board, structure such as figure 2 , image 3 and Figure 4 As shown, that is, the difference from Example 1 is that the sandwich layer is formed by superimposing two layers of airgel felt layers, and each layer of airgel felt layer is formed by splicing several cuboid fiber-reinforced airgel composite felts 3. The thickness of each airgel felt layer is 1 mm; correspondingly, in the step (1) of the preparation step, the fiber-reinforced airgel composite felt 3 wrapped in the third fiber cloth is spliced together to form two spliced layers , the two spliced layers are aligned up and down and stacked to form a spliced body; others are the same as in Embodiment 1.

[0055] The density of the thermal insulation board prepared in this embodiment is 0.33 g / cm 3 , the compressive strength is 4.0 Mpa.

Embodiment 3

[0057] A kind of thermal insulation board, structure such as figure 1 , image 3 and Figure 5 As shown, that is, the difference from Example 1 is: the implementation of the flow guide and the injection part is shown in Figure 5 , the injection part also includes a main injection tube 62, all branch injection tubes 61 are connected to the main injection tube 62, and the other end of the main injection tube 62 is used as the injection port 8; the preparation steps are the same as in Example 1.

[0058] The density of the thermal insulation board prepared in this embodiment is 0.28 g / cm 3 , the compressive strength is 3.8 Mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com