Patents

Literature

83results about How to "Solve the brittle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Distributed flexible pressure sensor based on electrically active polymer

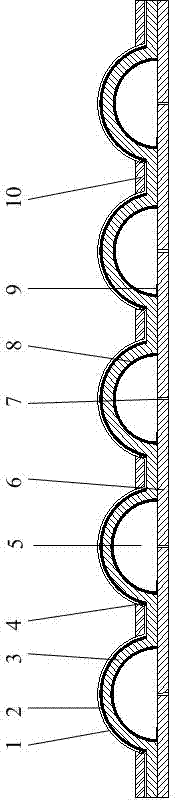

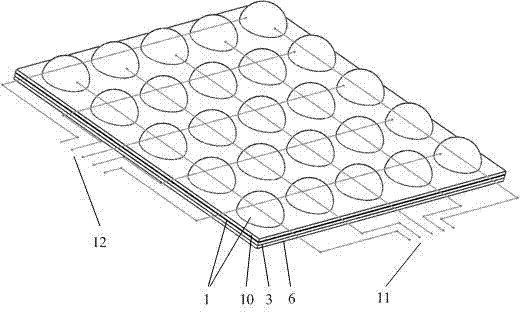

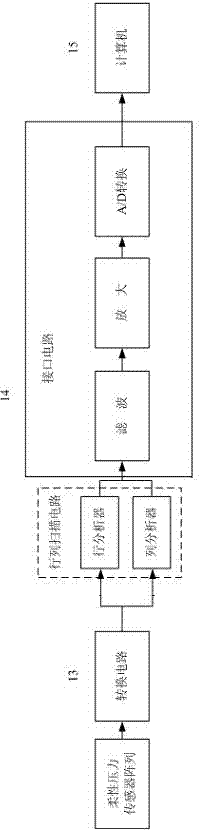

The invention discloses a distributed flexible pressure sensor based on an electrically active polymer. The distributed flexible pressure sensor comprises a sensor array, a switching circuit, an interface circuit and a computer. The sensor array is used for preparing a corresponding array according to the size of a measuring plane and inputting pressure. The switching circuit is used for converting a sensed capacitance value into a voltage value. The interface circuit is used for conducting line-rank scanning, filtering, amplifying and A / D conversion on an input signal and converting an analog voltage signal into a digital voltage signal capable of being read by the computer. The computer is used for collecting, analyzing, processing and displaying the data input by the interface circuit. The flexible pressure sensor can be widely applied to the fields of human health monitoring, physical training, medical rehabilitation, biomechanics and safety monitoring and the like.

Owner:常州柔希电子科技有限公司

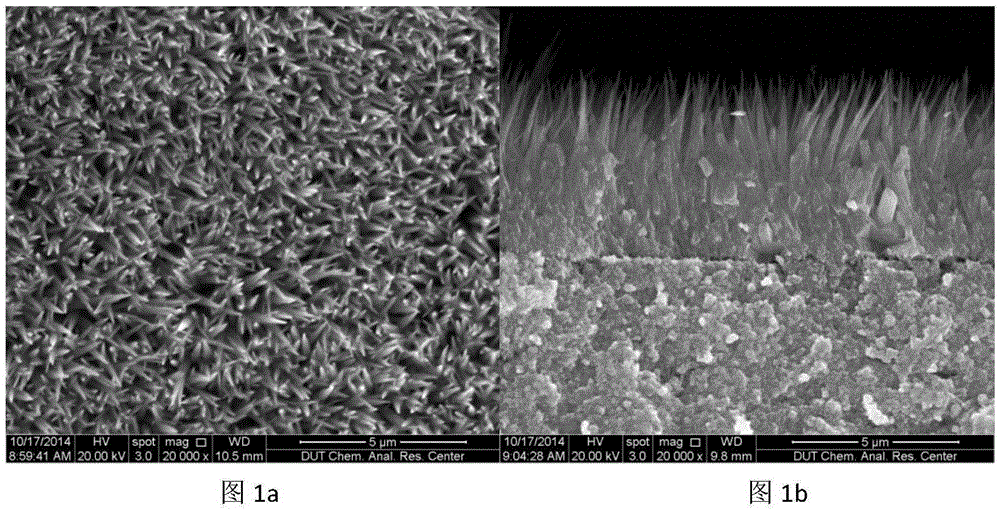

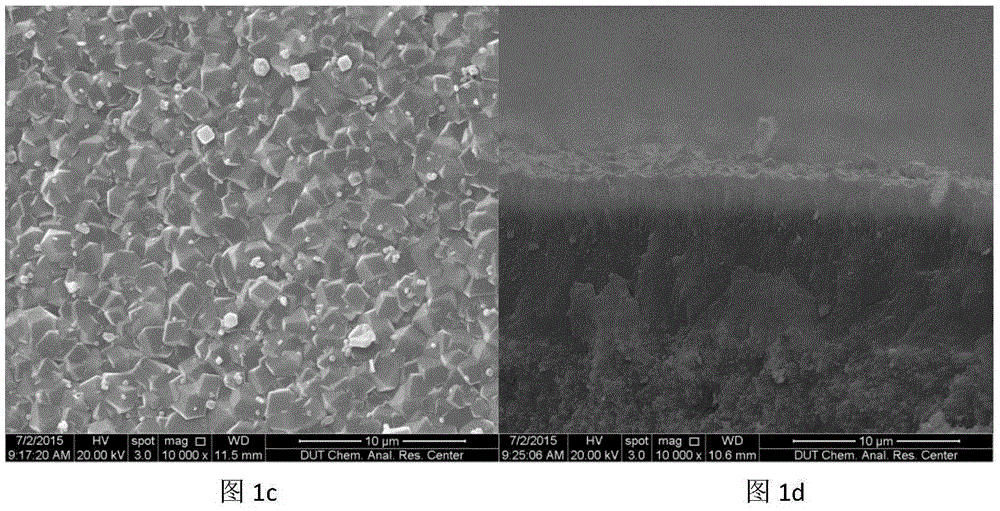

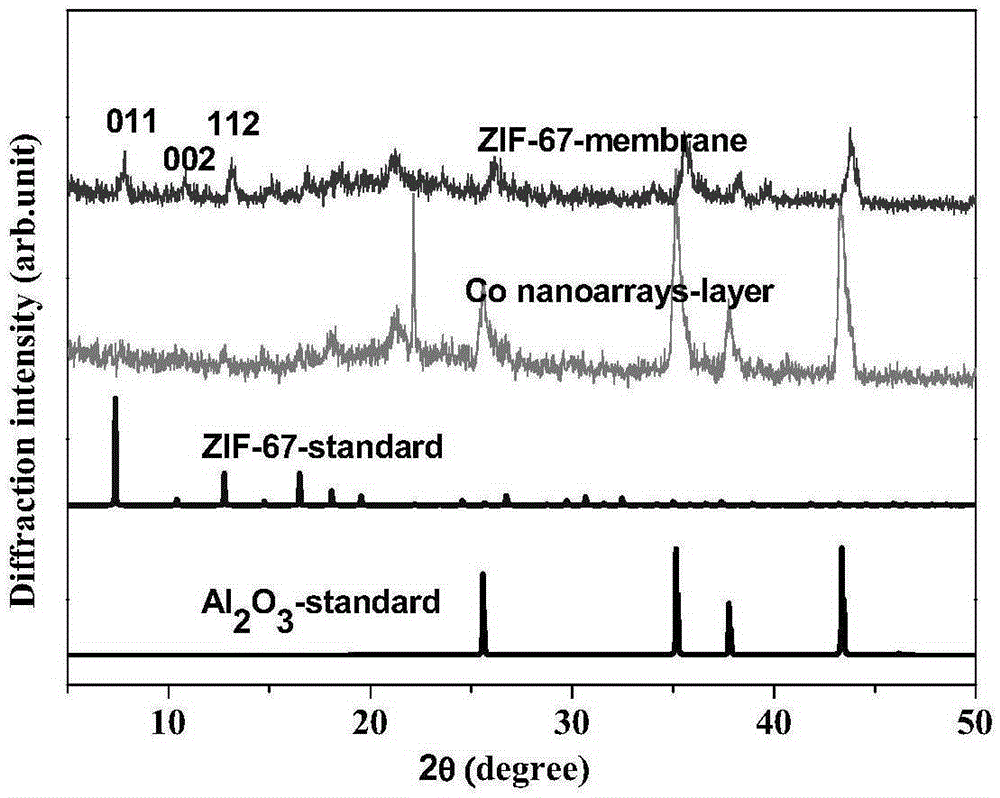

Preparation method for forming metal organic framework ZIF-67 film by utilizing cobalt nano array layer conversion

ActiveCN105233702ASolve the difficulty of heterogeneous nucleationSolve associativitySemi-permeable membranesMetal-organic frameworkSolvent

The invention relates to a preparation method for forming a metal organic framework ZIF-67 film. Through hydrothermal synthesis, first a cobalt nano array layer firmly combined with a carrier is introduced to the carrier, and the carrier with the cobalt nano array layer is obtained; in the aftertreatment process, the cobalt nano array layer provides a metal source for growth of the ZIF-67 film and serves as a growing point and bonding point for forming the film, the continuous and uniform ZIF-67 film is formed by growth. According to the method, the problems that the metal organic framework film has difficulty in heterogeneous nucleation, is weak in binding force with the carrier and is easily subjected to embrittlement are solved. In the cobalt nano array growth process or in the ligand growth process, only water is used as a solvent, and no other organic solvent participates. The environmental pollution is small, and the preparation method conforms to the green chemical development requirements. In the film forming process, the cobalt nano array layer has dual functions of providing a metal cobalt source and enhancing binding force between the carrier and the ZIF-67 film.

Owner:DALIAN UNIV OF TECH

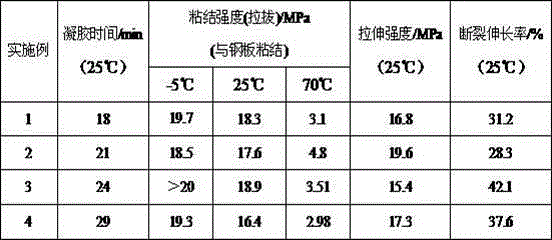

Normal temperature cured flexible epoxy composition for thin layer paving of road and bridge surfaces and preparation method of composition

The invention relates to a normal temperature cured flexible epoxy composition for thin layer paving of road and bridge surfaces. The composition is prepared from a component A and a component B in a mass ratio of (1-2): 1. The component A comprises 10-100 parts by mass of flexible epoxy resin, 0-80 parts by mass of standard epoxy resin, 2-10 parts of a diluent and 5-10 parts by mass of a curing accelerant a; the component B comprises 40-100 parts by mass of a modified amine curing agent, 10-70 parts by mass of a toughening modifier, 1-10 parts by mass of a curing accelerant b, 1-3 parts of a coupling agent and 0.1-1 part of a defoamer. The invention further relates to a preparation method for the normal temperature cured flexible epoxy composition for thin layer paving of road and bridge surfaces. The normal temperature cured flexible epoxy composition for thin layer paving of road and bridge surfaces provided by the invention has the benefits of being good in flexibility, high in ductility, curable at normal temperature, convenient to construct, low in cost and the like.

Owner:WUHAN SHANHU COATINGS CO LTD

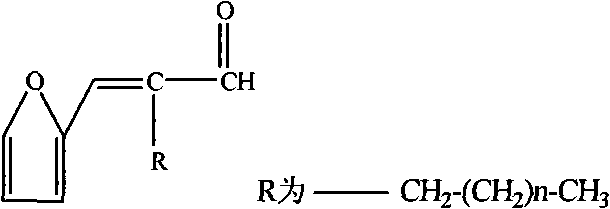

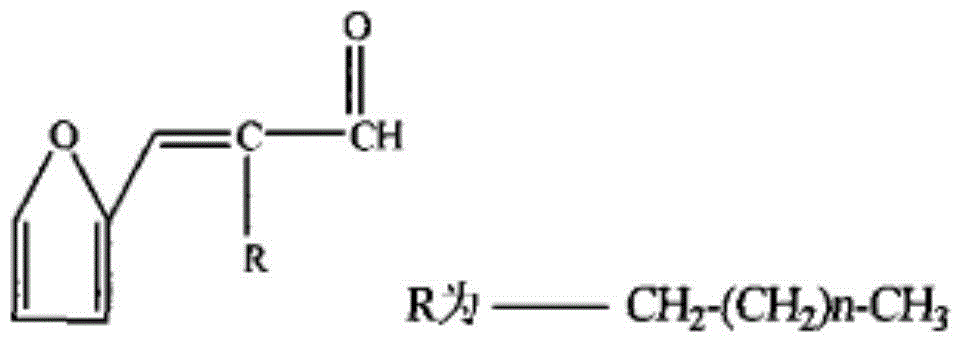

Modified phenolic resin and application thereof in anti-corrosive paint

InactiveCN101899136AImprove brittlenessImprove heat resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyFuran

The invention relates to a new modified phenolic resin and a modified phenolic / epoxy resin anti-corrosive paint prepared by utilizing modified phenolic resin and epoxy resin. The invention solves problems of high formaldehyde toxicity, high volatility, strong irritancy, and the like of raw material of the traditional phenolic resin, and replaces formaldehyde with alpha, beta-furacrolein with high boiling point, low volatility and low toxicity to synthesize the modified phenolic resin with phenol; and therefore, furan rings and flexible side chains are introduced into the modified phenolic resin to form furan resin and improve system brittleness. The modified phenolic resin can be widely used in the fields of plastics, glass reinforced plastic, puddles, adhesives, paints, etc. The modified phenolic / epoxy resin anti-corrosive paint prepared by the modified phenolic resin and the epoxy resin has good performances of the epoxy resin and the furan resin, such as high cohesive force, acid resistance, alkali resistance, high temperature resistance, aging resistance and the like, and can be used for painting ships, oil tanks, pipelines and other structures.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

Preparing method of toughening metlbond foam

The invention discloses a preparing method of toughening metlbond foam, which is prepared by the high-speed mixing and the heating foaming of the following raw materials by weight parts: 100 of A-stage metlbond resin, 5 to 35 of compound toughening agent, 5 to 10 of surface active agent, 8 to 15 of foaming agent and 7 to 20 of solidifying agent. The invention introduces a new compound toughening agent in the technology, develops a solvent with good dissolubility to the compound toughening agent and good mixing performance with the foaming system, compounds a new solidifying agent, solves the defects of easy slag falling, fragile quality, low strength and poor toughness of the metlbond foam, and keeps the traditional advantages of low heat conducting coefficient, less smoke, burning resistance, and the like of the metlbond foam.

Owner:SHANGHAI INST OF TECH

Fireproof insulation board of aerated concrete of B02-level light sand

The invention discloses a fireproof insulation board of aerated concrete of B02-level light sand. The constituents and weight percentages of the fireproof insulation board are as follow: 45-55% of quartz sand, 12-16% of lime, 24-37% of cement, 5% of gypsum, 0.25-0.35% of aluminite powder and 0.2-0.6% of composite admixture, wherein the composite admixture is admixture with composite stabilizing, toughening and waterproof functions, and the constituents and weight percentages are as follow: 25-30% of sodium abietate, 22-26% of chlorinated paraffin, 24-28% of petroleum ether and 20-25% of organo-siloxane. The fireproof insulation board has the advantages that the fireproof insulation board compensates the disadvantages and defects of the prior art, overcomes the production difficulties, andimproves the casting stability when reducing dry density of the aerated concrete product of the sand, so as to conveniently transport and construct the product, and meet huge demands of the construction market and energy conservation and environmental protection requirements of people on building materials in cities.

Owner:天津滨海天筑永利建材有限公司

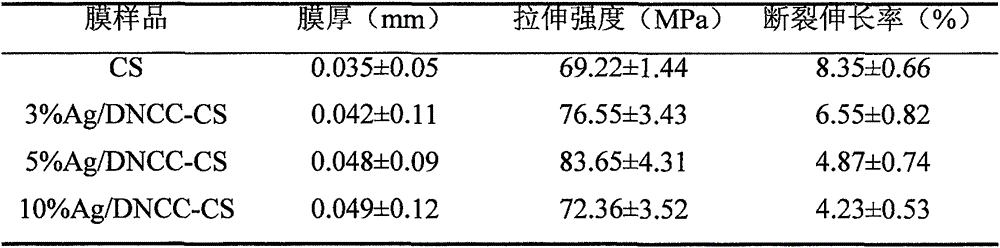

Preparation method of silver-loaded nano cellulose-chitosan composite film

InactiveCN106832437APreparation Process GreenThe preparation process is simple and environmentally friendlyComposite filmWound dressing

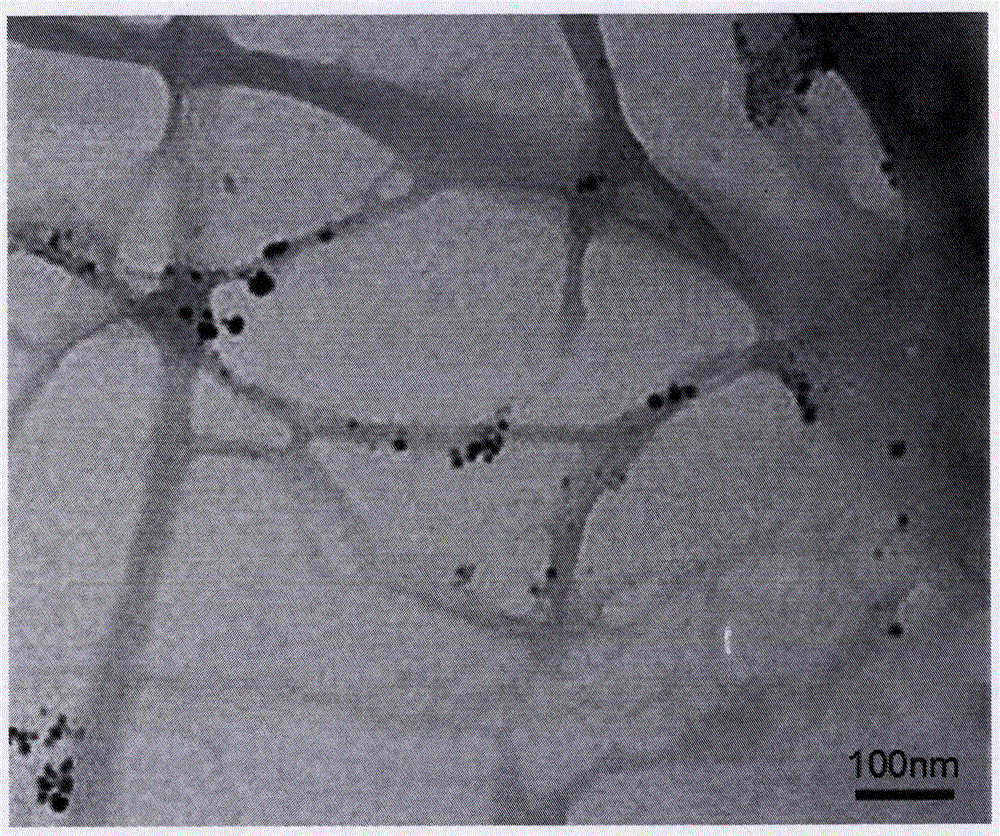

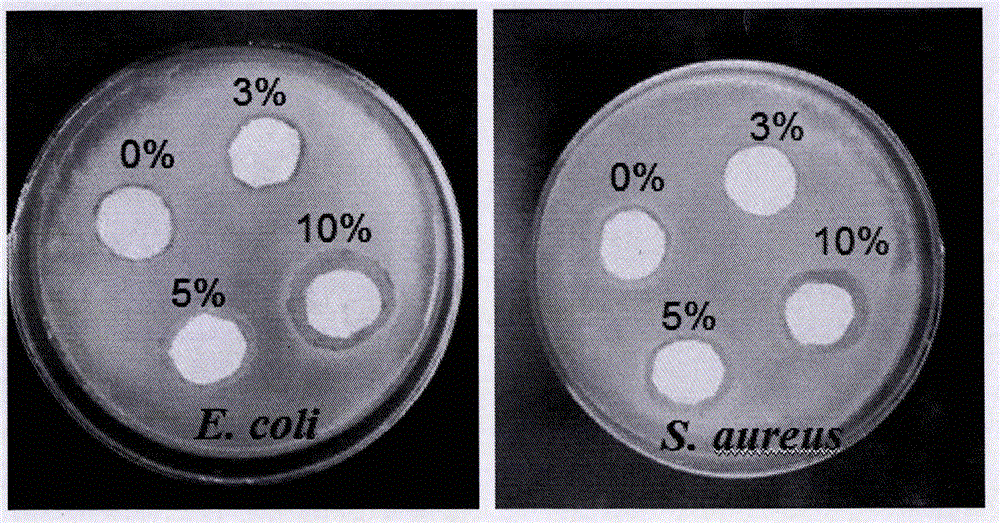

The invention discloses a preparation method of a silver-loaded nano cellulose-chitosan composite film, the preparation method of the silver-loaded nano cellulose-chitosan composite film comprises the following steps: adding sodium periodate into a nano cellulose solution, stirring in a dark place, centrifuging for separation, and washing to obtain dialdehydo nano cellulose; adding a newly-prepared saturated silver ammonia solution for preparation of silver-loaded nano cellulose; mixing the silver-loaded nano cellulose with a chitosan solution to obtain a silver-loaded nano cellulose-chitosan antibacterial film. Nano silver particles prepared in the method are evenly distributed in dialdehydo nano cellulose network structures, the easy agglomeration problem of the nano silver particles can be well solved, the preparation process does not require the use of special instruments, also does not need a chemical reducing agent, and the production cost is reduced. Through use of good mechanical properties of the nano cellulose, the low mechanical strength problem of the chitosan film is improved, and the antibacterial property of the chitosan film is improved by silver loading operation. The silver-loaded nano cellulose-chitosan composite film has broad application prospects in antibacterial wound dressings and food packaging and other industries.

Owner:QIQIHAR UNIVERSITY +1

High-boron cast steel for lining plates

The invention discloses a high-boron cast steel utilizing low-valent boron as a main alloy element and capable of being used for manufacturing ball mill lining plates. The chemical ingredients of the cast steel and the mass percents thereof are as follows: smaller than 0.4% of C, 0.40-0.8% of Si, 0.5-1.2% of Mn, 0.5-1.2% of Cr, 1.2-3.0% of B, smaller than 0.2% of Re, smaller than 0.1% of V, and smaller than 0.1% of Ti; the cast steel is firstly water cooling quenched for 2h at 950-980 DEG C and is air cooling annealed for 4 h at 200-250 DEG C, the hardness thereof is larger than 58 HRC, the impact toughness is larger than 12 J / cm2, and the depth of a through hardening layer thereof is larger than 40 mm.

Owner:ZHANGJIAGANG DINGLI CAST STEEL

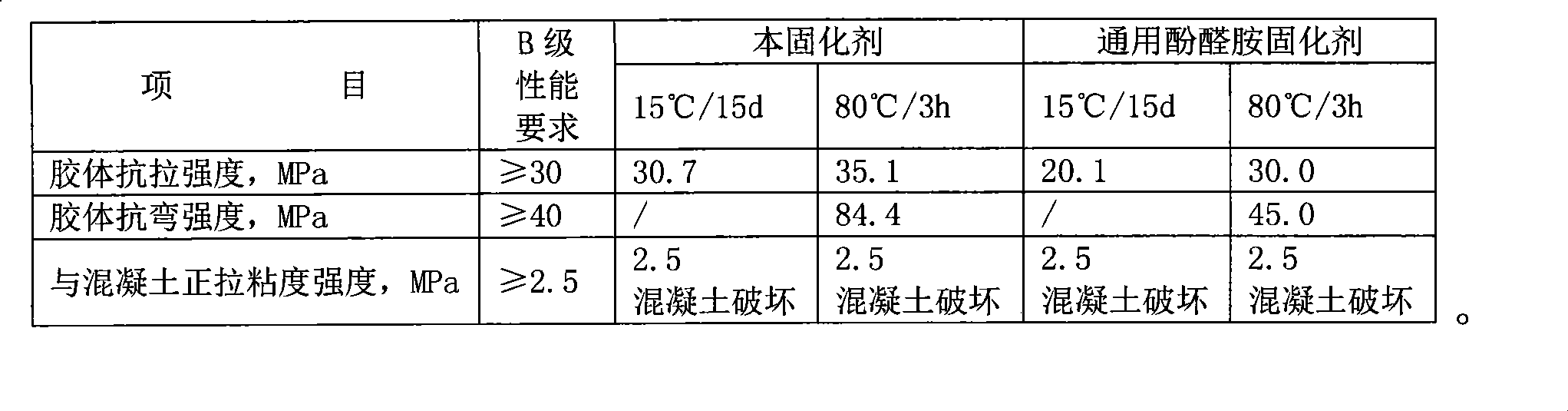

High-performance pnenolic aldehyde amine hardener for epoxy resin and preparation thereof

The invention discloses a high-performance phenol-aldehyde amine curing agent used for epoxy resin and a preparation method thereof and relates to a phenol-aldehyde amine epoxy resin curing agent which is a low-viscosity epoxy resin curing agent applicable to low-temperature damp construction. The curing agent comprises the main components with the weight percentage as follows: 36-45 percent of phenol, 5-8 percent of long-chain phenol, 18-22 percent of formaldehyde solution, 20-25 percent of ethylene polyamine, 3.5-5.5 percent of 4, 4'-diminodiphenyl-methane and 1.5-2.5 percent of polyphenyl polyamine methane. The invention uses a form of normal pressure reaction, thereby avoiding the risk of high temperature and high pressure synthesis; the production method is simple; the curing agent has high activity, low viscosity, good construction and high intensity, so the curing agent can overcome the disadvantages that the epoxy resin is cured slowly under low temperature and has low intensity later. A cured product obtained by curing the epoxy resin with the curing agent overcomes the disadvantage of the brittleness of ordinary phenol-aldehyde amine. The phenol-aldehyde amine epoxy resin curing agent is applicable to the fields of building reinforcing, bridge reinforcing, sealing bonding, water conservancy project, antiseptic paint, etc.

Owner:湖北湖大资产经营有限公司

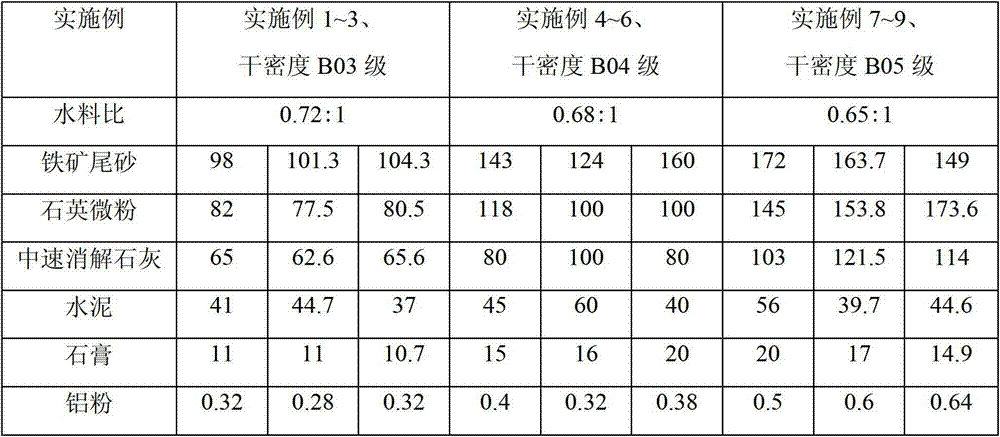

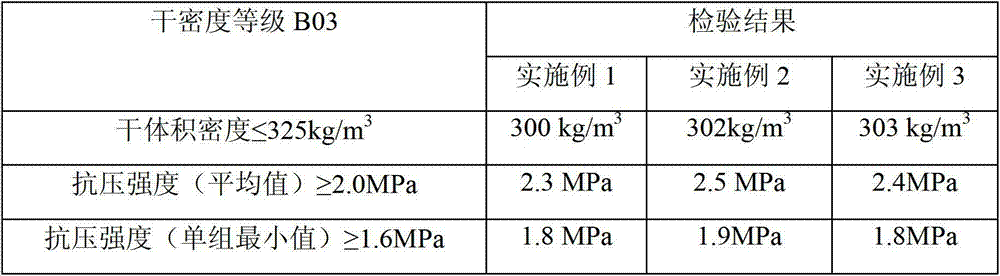

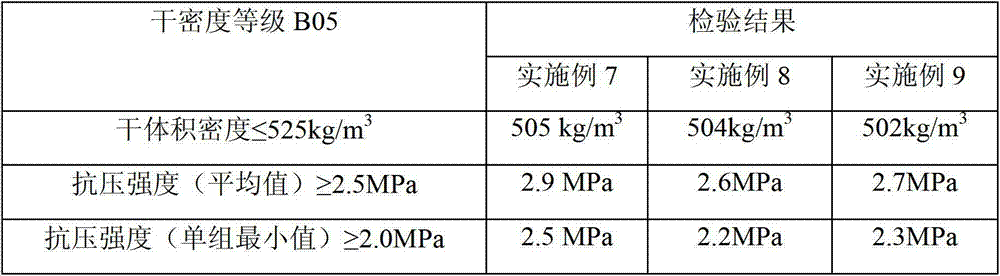

Low-density aerated concrete product and preparation method thereof

The invention discloses a low-density aerated concrete product and a preparation method thereof, and belongs to the technical field of building materials. The preparation method adopting quartz micro powder and iron core tailing, which are respectively 25%-35% and 30%-40% of a dry material, as the primary materials comprises the following steps of: adding cement and lime for cementing; initiating by aluminum powder; and adjusting the component proportion and the steam-curing environment to prepare a light high-strength aerated concrete product with desiccated bulk density of 300kg / m<3>-525kg / m<3> and absolute-dry compressive strength of 2.0 MPa-3.0 MPa. According to the preparation method disclosed by the invention, low-carbon, environment-friendly and energy-saving production concept is adopted, and the quartz micro powder and iron ore tailing, which are discarded after quartz sand ore-dressing, are adopted as the primary materials for producing the low-density autoclaved aerated concrete product as the wall self-insulation material.

Owner:山东高阳建材有限公司

Process for preparing high-performance ceramic plate film supporting body

The invention relates to the field of porous ceramic materials in the field of non-metallic inorganic materials and particularly relates to a process for preparing a high-performance ceramic plate film supporting body. The high-performance ceramic plate film supporting body comprises the following raw material ingredients in percentage by weight: 60% to 80% of powdered alumina, 2% to 10% of mica powder, 2% to 10% of binder, 2% to 10% of lubricant, 2% to 10% of plasticizer, 3% to 10% of chopped fibers and 10% to 30% of water, wherein the powdered alumina contains powder of two kinds of particlesizes, i.e., D50: 3 to 10 microns and D50: 20 to 40 microns, and the mica powder is selected from ordinary mica powder and special mica powder and has the particle size of 2 to 5 microns. According to the process, a proper volume of mica powder of small particle size is added into a mixture for preparing the ceramic plate film supporting body, so that a sintering temperature can be lowered, the energy consumption is lowered, and the mechanical strength of the plate film supporting body can be effectively improved; and on the other hand, two kinds of powdered alumina, which is matched in particle size, are selected, so that the increase of degree of uniformity of pores of a ceramic plate film is facilitated, and the ceramic plate film supporting body with high porosity and excellent permeability is prepared.

Owner:江苏埃梯恩膜过滤技术有限公司

Modified phenol-formaldehyde resin and applications thereof in anticorrosion coating

InactiveCN104693390AHigh bonding strengthImprove performanceOrganic chemistryAnti-corrosive paintsEpoxyFuran

The invention relates to novel modified phenol-formaldehyde resin, and preparation of modified phenol-formaldehyde / epoxy resin anticorrosion coating by utilization of the modified phenol-formaldehyde resin and epoxy resin. Aiming at characteristics of traditional phenol-formaldehyde resin raw materials, high toxicity, high volatility, high irritation, and the like of formaldehyde, alpha, beta-furylacrolein which is high in boiling point, low in volatility and low in toxicity in place of formaldehyde is adopted to synthesize the modified phenol-formaldehyde resin with phenol, a furan ring and a flexible side chain are introduced into the modified phenol-formaldehyde resin, furan resin is formed and system brittleness is improved. The modified phenol-formaldehyde resin can be widely applied to the fields of plastic, glass fiber reinforced plastic, amine mud, amine adhesives, coating and the like. The modified phenol-formaldehyde / epoxy resin anticorrosion coating is prepared from the modified phenol-formaldehyde resin and the epoxy resin, has excellent properties of the epoxy resin and the furan resin, such as high adhesion force, acid resistance, alkali resistance, resistance to high temperature and ageing resistance, and can be used as coating for boats, oil tanks, pipes, and other structural objects.

Owner:QINGDAO HUICHENG PETROCHEM TECH

Preparation method and application of mild reaction type aldehyde ketone resin

ActiveCN103333302AReduce volatilityOvercoming the disadvantage of being prone to bumpingBuilding insulationsEpoxyKetone

The invention discloses a preparation method of mild reaction type aldehyde ketone resin. The mild reaction type aldehyde ketone resin is prepared by adding a quantitative superbase catalyst into mixed liquid of aldehyde and ketone compounds under the condition of stirring at normal temperature, wherein the reaction process is mild and stable, so the defect that the traditional furfuraldehyde acetone system is easy to implode is overcome. The invention also discloses an application of the mild reaction type aldehyde ketone resin to preparation of an aldehyde ketone resin modified epoxy grouting material. The prepared grouting material can completely exert the flexibility of the aldehyde ketone resin, solves the problem that epoxy resin has high brittleness, can further improve excellent mechanical properties, adhesive property, ageing resistance and corrosion resistance of the epoxy resin, and also has the characteristics of low toxicity, environmental friendliness and the like. In addition, according to the preparation method, the aldehyde ketone resin is prepared in advance and has higher viscosity and thixotropism when being used together with fillers, so the construction process is simple and the aldehyde ketone resin can be applied to concrete surface corrosion of basic facilities such as bridges and ports, restoration of cultural relic, water and seepage prevention, reinforcement and strengthening of buildings and the like.

Owner:东莞微积分新材料科技有限公司

Heat treating method of carbon graphite material

The invention relates to a carbon graphite composite material, in particular to a heat treatment method for the carbon graphite material. The material to be treated is roasted products, namely carbon graphite roughcast, and the formula of the carbon graphite roughcast comprises the following: the carbon graphite roughcast is prepared by taking ultrafine petroleum coke powder as a main composition, adding proper earthy graphite, abrasion-resistant carbon black and silicon carbide powder into the ultrafine petroleum coke powder, and performing kneading, profiling, asphalt leaching for two times and roasting for three times according to specified technology. After the temperature is raised to be between 850 and 950 DEG C at the speed of 250 to 300 DEG C per hour, the temperature is continuously raised to be between 1,550 and 1,650 DEG C at the speed of 20 to 50 DEG C per hour, and raised to be between 1,900 and 2,100 DEG C at the speed of 200 to 300 DEG C per hour; after the temperature is maintained for 1 to 3 hours, the carbon graphite composite material is cooled to a temperature of less than 50 DEG C along with a furnace and then discharged; and the position of a substrate in the furnace is exchanged, and the technology is repeated. The heat treatment method solves the technical problems of roughcast cracking, large brittleness and difficult processing, reduces the Shore hardness of the material to be approximately 65, and improves the density of the material from approximately 1.70 g / cm<3> to more than 1.80 g / cm<3>.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Fiber-reinforced biological resin adhesive composite material and preparation method thereof

ActiveCN106398119AImprove toughnessThe production process is simple and matureEpoxyWeather resistance

The invention discloses a fiber-reinforced biological resin adhesive composite material and a preparation method thereof. The composite material is prepared from 10-50 parts by weight of a biological resin adhesive and 50-100 parts by weight of fibers. The biological resin adhesive is prepared from 20-100 parts by weight of biomass oil-modified epoxy resin, 2-20 parts by weight of a diluent, 1-4 parts by weight of an emulsifier, 1-3 parts by weight of a coupling agent, 1-5 parts by weight of a release agent, 5-20 parts by weight of a filler, 1-4 parts by weight of a pigment and 10-20 parts by weight of a curing accelerator. The biological resin adhesive is prepared from the biomass oil-modified epoxy resin, then infiltrates fibers and then is cured so that the fiber-reinforced biological resin adhesive composite material with better toughness, better weather resistance and excellent mechanical properties is obtained. The method is used to prepare the composite material, utilizes easily accessible and cheap raw materials, has simple and mature processes and reduces a composite material cost.

Owner:四川景文材料科技有限公司

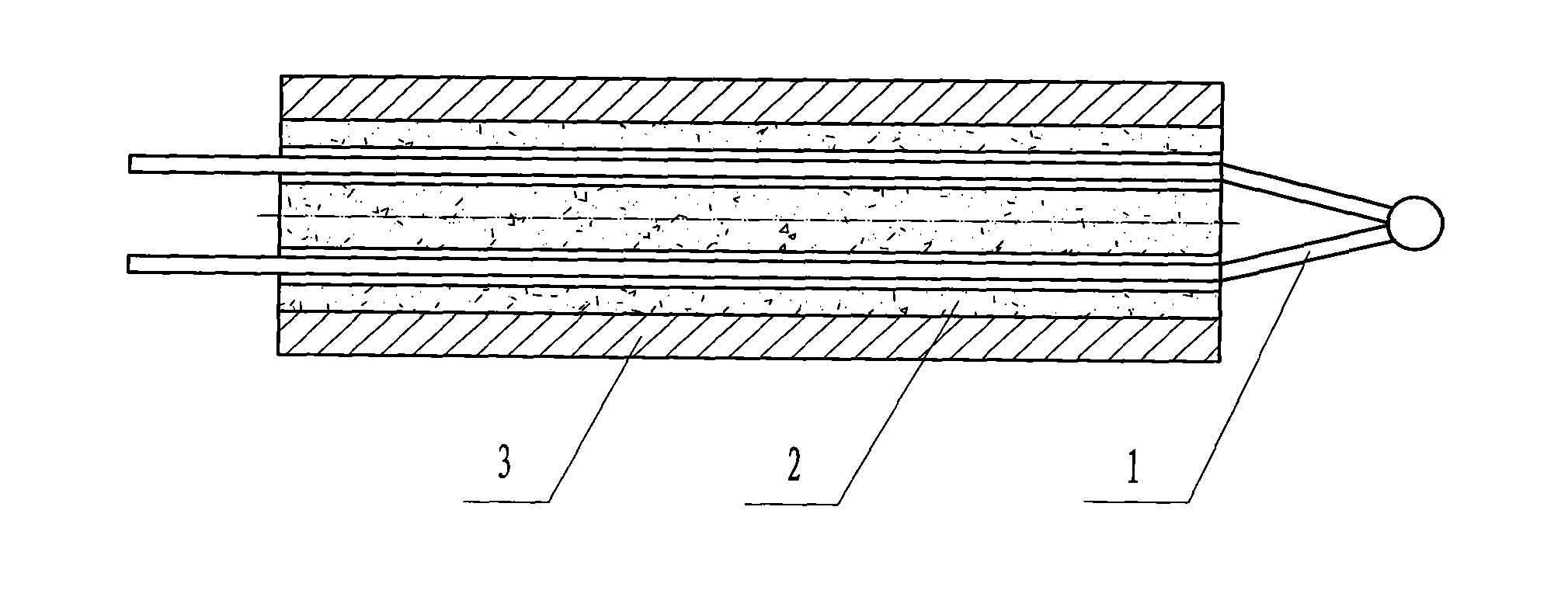

Toughening-type high-temperature iridium rhodium thermocouple

ActiveCN102937486AAvoid coarse grainsSolve the brittleThermometers using electric/magnetic elementsUsing electrical meansIridiumStress relief

The invention relates to a thermocouple for high-temperature measurement, in particular relates to a toughening-type high-temperature iridium rhodium thermocouple for temperature measurement below 2400K, and belongs to the field of temperature testing. The toughening-type high-temperature iridium rhodium thermocouple comprises a thermocouple wire, an insulation procelain tube and a protective outer shell; the thermocouple wire is arranged in the insulation procelain tube; the protective outer shell is wrapped on the outer part of the insulation procelain tube; and high-temperature binders are filled between the thermocouple and the insulation procelain tube and between the insulation procelain tube and the protective outer shell, and are used for fixing and sealing. The toughening-type high-temperature iridium rhodium thermocouple is characterized in that the positive electrode of the thermocouple is made of an IrRh alloy, and the weight percentages of Ir and Rh are respectively 40%-60% and 60%-40%; and the negative electrode of the thermocouple is made of an IrRh alloy, the weight percentages of Ir and Rh are respectively 80%-90% and 20%-10%; the positive electrode and the negative electrode are welded into thermal joint points, and stress relief annealing is required to be carried out after the welding of the thermal joint points and before the assembling of the thermocouple. The problems that traditional thermocouple is high in brittlenss and has a catalytic effect are solved; the negative electrode is prevented from cracking; and the measurement accuracy is improved.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

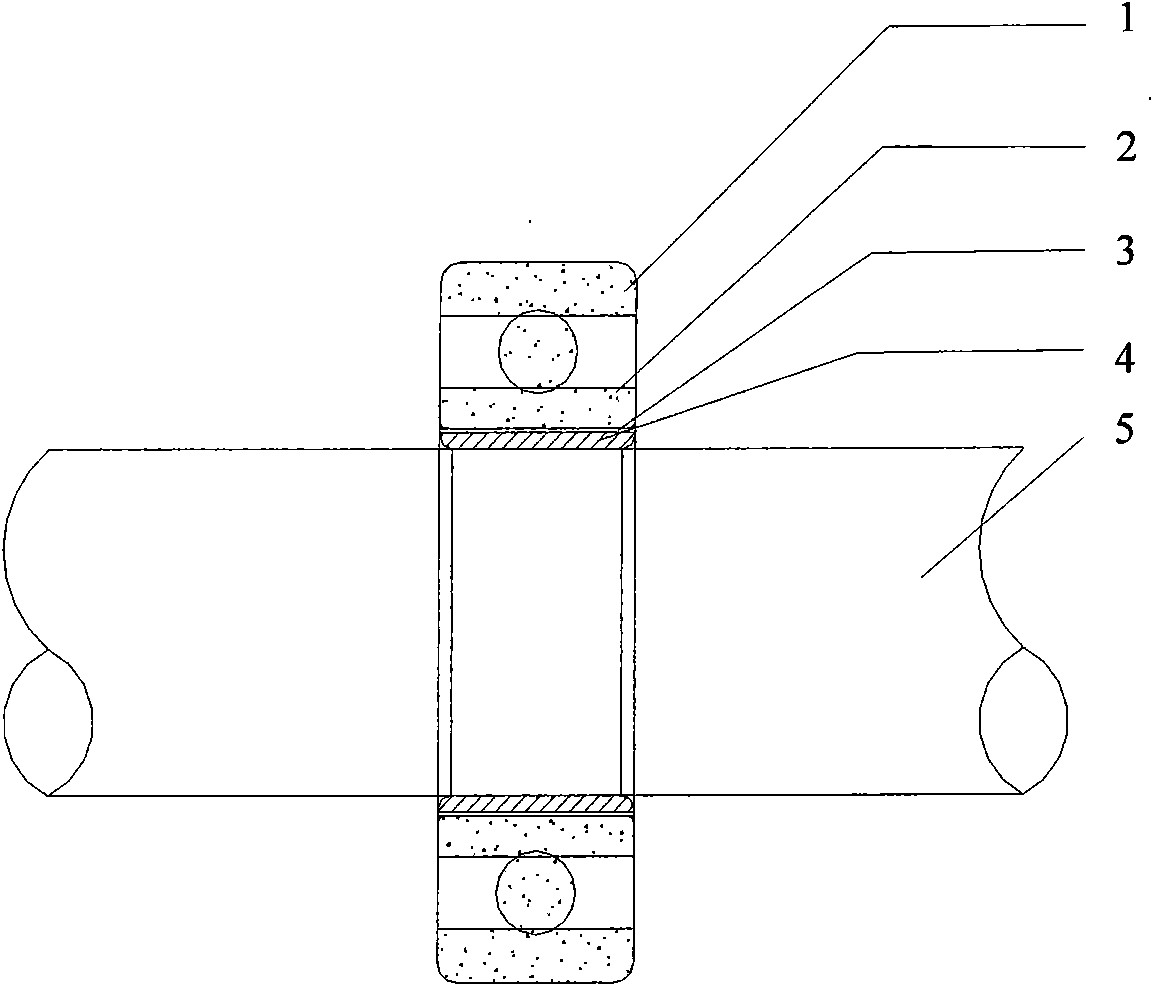

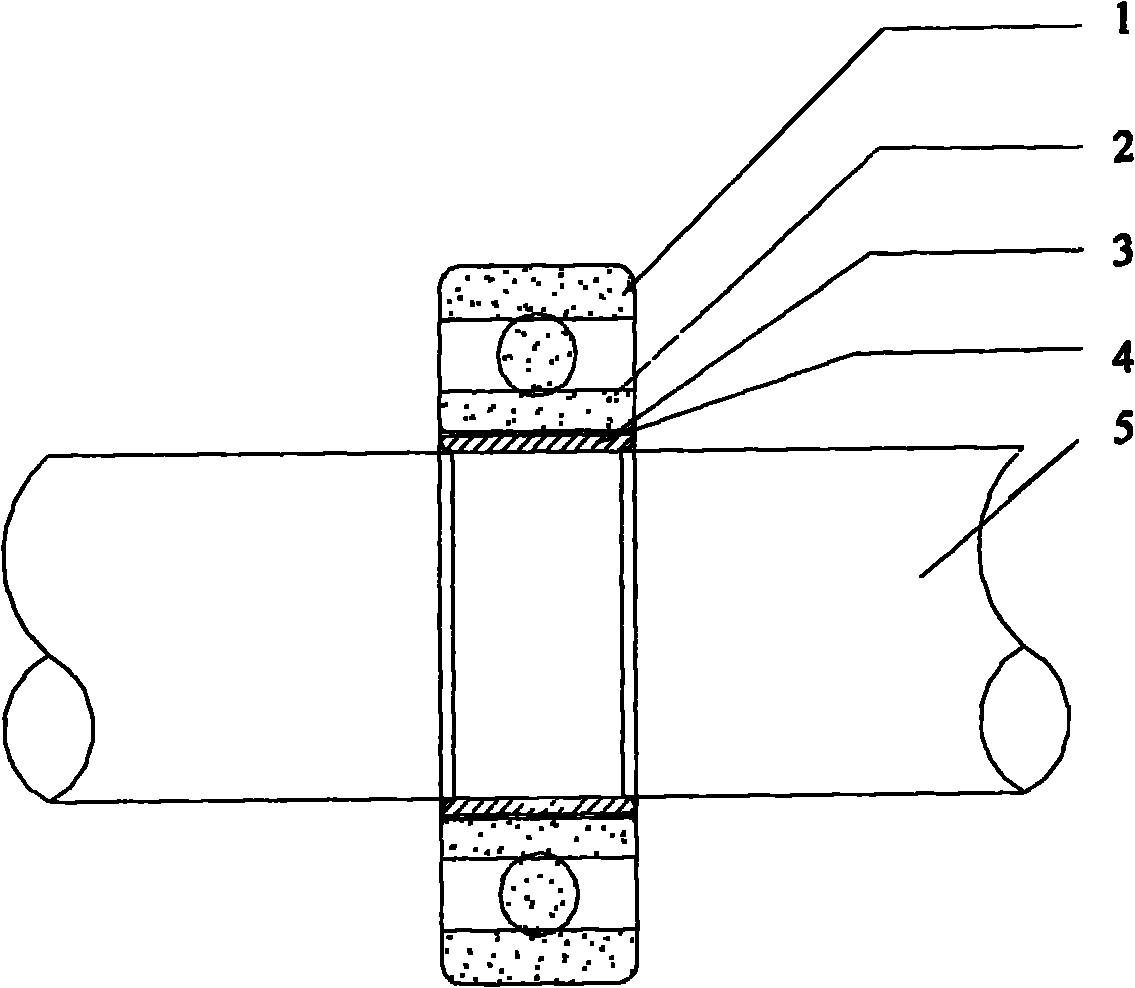

Adhesive for bonding full-ceramic bearing and metal shaft and application method thereof

InactiveCN101885955ASolve the brittleSimple and efficient operationNon-macromolecular adhesive additivesAdhesive processes with surface pretreatmentChemistryNanometre

The invention relates to an adhesive for bonding a full-ceramic bearing and a metal shaft and an application method thereof. The adhesive is an organic and inorganic composite adhesive which takes epoxy resin as the base and phenolic resin as curing agent and is added with nanoscale CaO, wherein 95-100phr of epoxy resin, 59-63phr of phenolic resin and 2.5-3.0phr of nanometer CaO with epoxy resin and phenolic resin as basis are taken. When in use, a metal inner ring is additionally arranged between the inner race of the full-ceramic bearing and the metal shaft, and the metal inner ring and the inner race of the ceramic bearing are bonded by the adhesive provided by the invention. The invention effectively solves the problem of mechanical connection between the full-ceramic bearing and the metal shaft and has simple operation, and simultaneously, the provided composite adhesive overcomes the defects of organic adhesive and inorganic adhesive and improves the bonding property.

Owner:上海贵池衣车实业有限公司

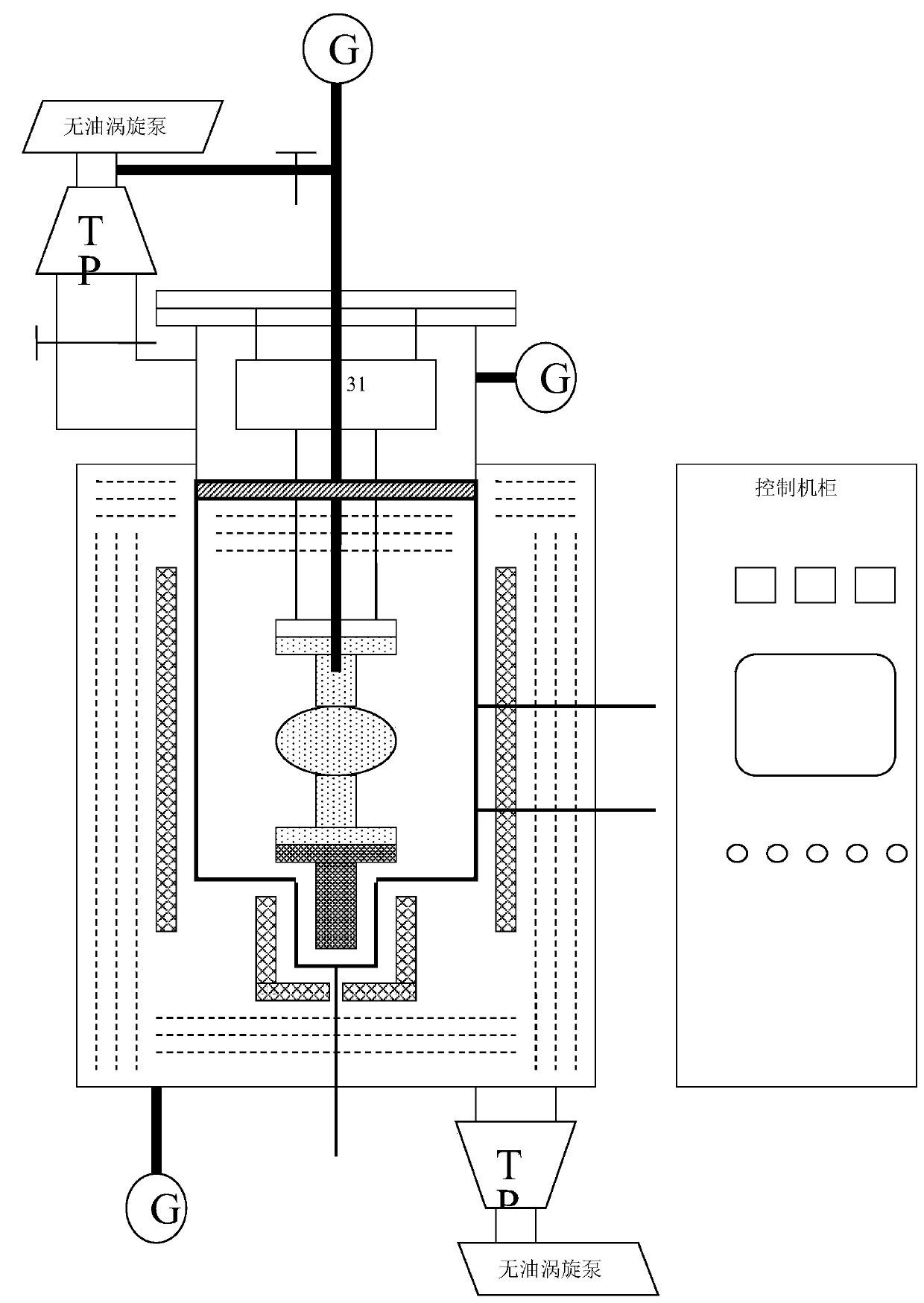

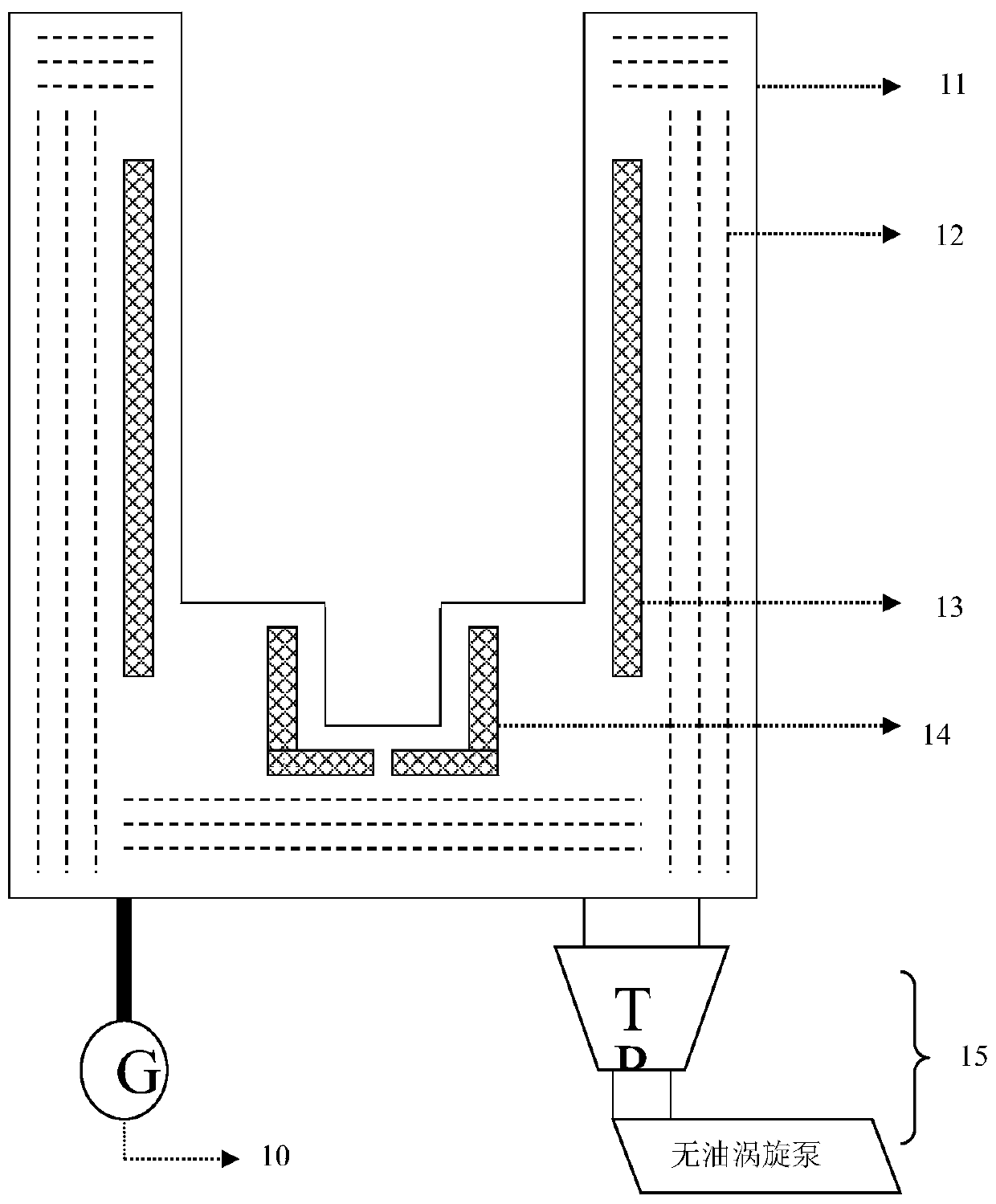

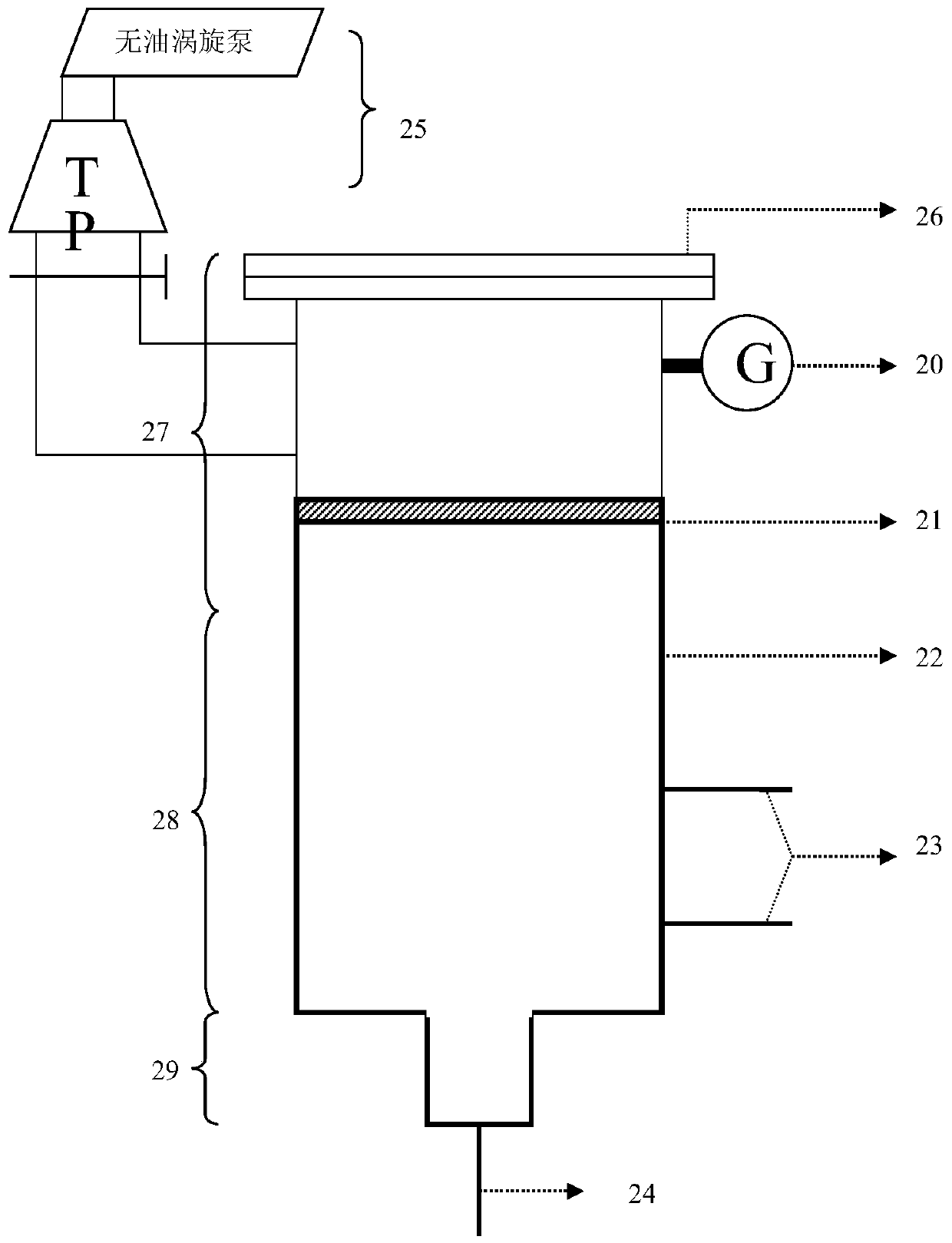

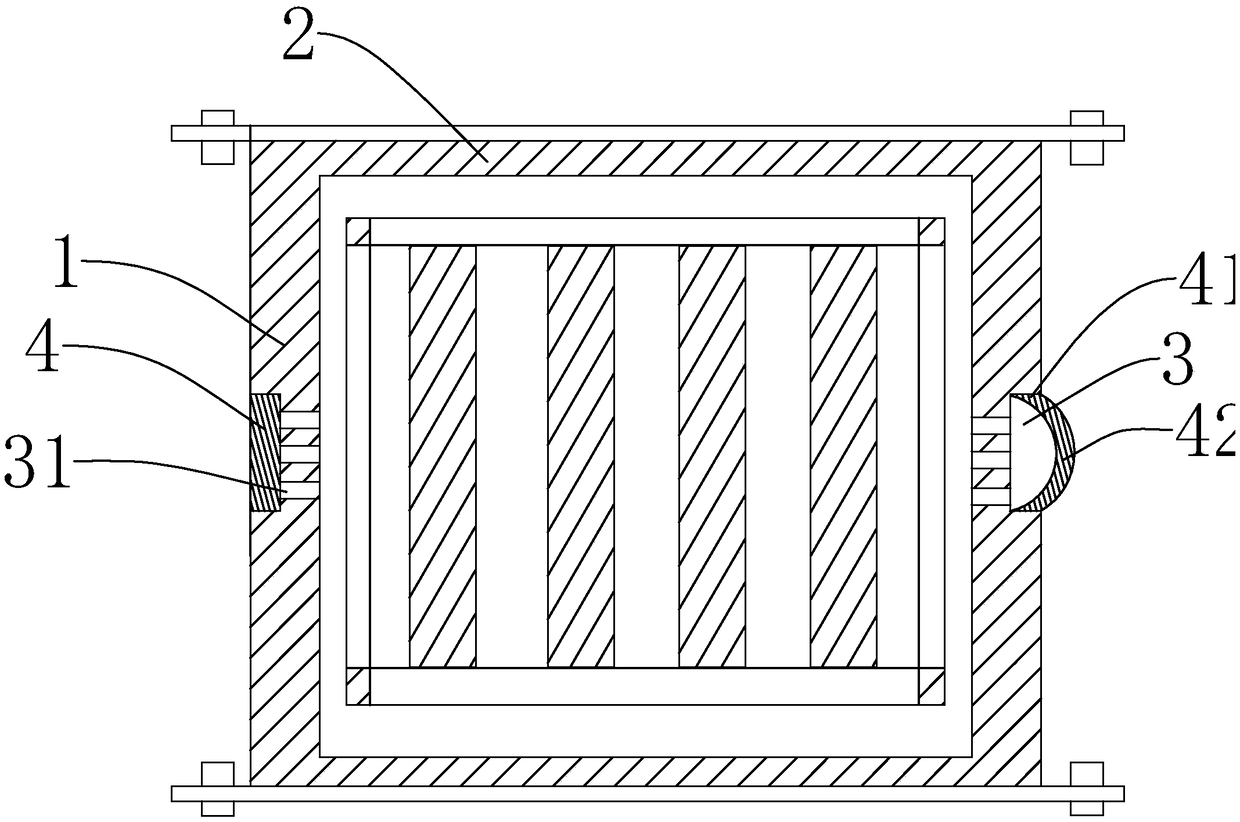

Method for plating triniobium stannide film on inner surface of pure niobium cavity and vacuum furnace

ActiveCN111074208ASolve the brittleSolve usabilityVacuum evaporation coatingSputtering coatingNiobiumCrucible

The invention discloses a method for plating a triniobium stannide film on the inner surface of a pure niobium cavity and a vacuum furnace. The vacuum furnace is characterized by including a double vacuum structure consisting of an external vacuum system and an internal vacuum system, wherein the external vacuum system is internally provided with a heater heating the internal vacuum system and a temperature measuring probe used for measuring the temperature of a set area of the internal vacuum system; and the internal vacuum system is internally provided with a niobium cavity hoisting device,the rotating hoisting device is used for connecting the niobium cavity to be plated with a film and a stannum crucible, and the niobium cavity is rotated circularly through a transmission mechanism. Through the vacuum furnace, the pure niobium cavity can be internally plated with a layer of pure, completely-covering and evenly-distributed triniobium stannide film, and thus application of triniobium stannide to a superconducting cavity is achieved.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI +1

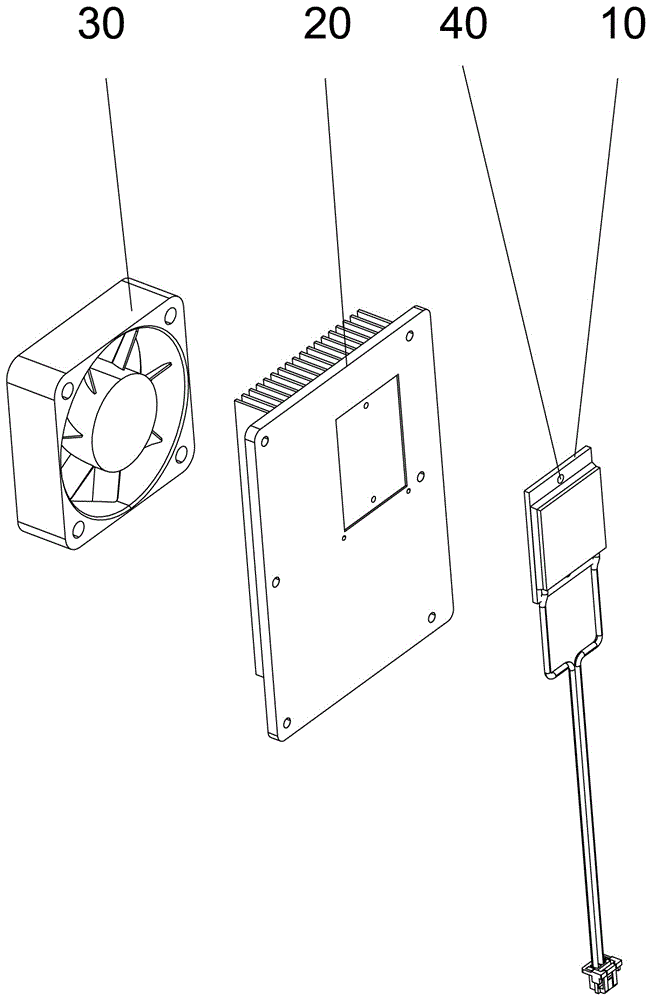

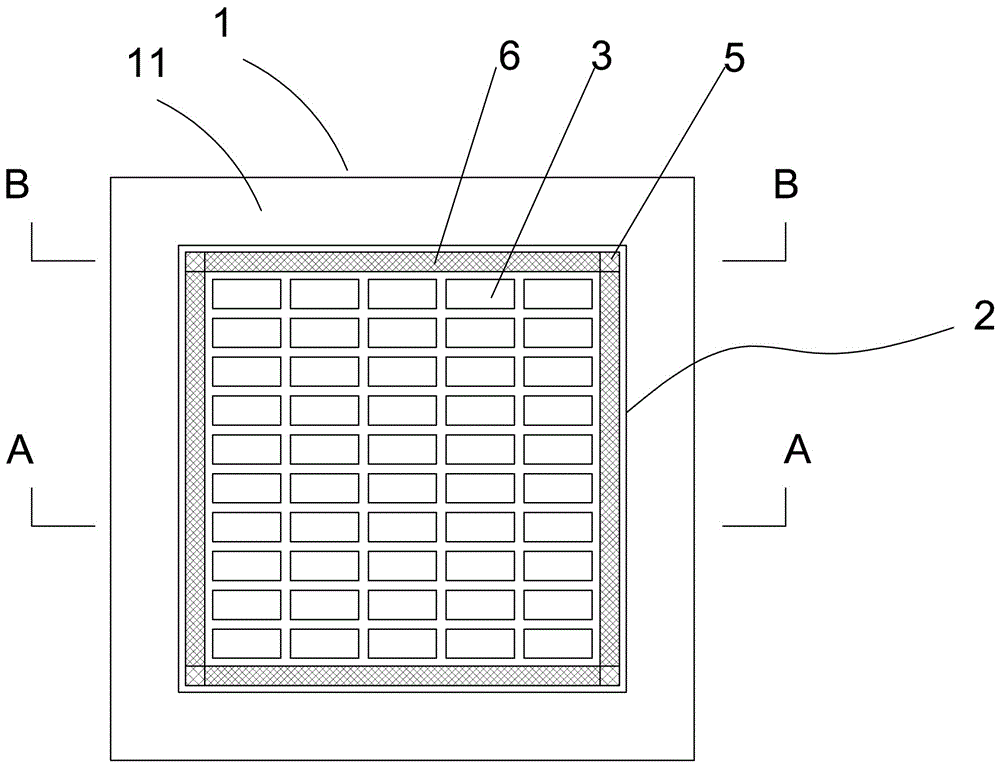

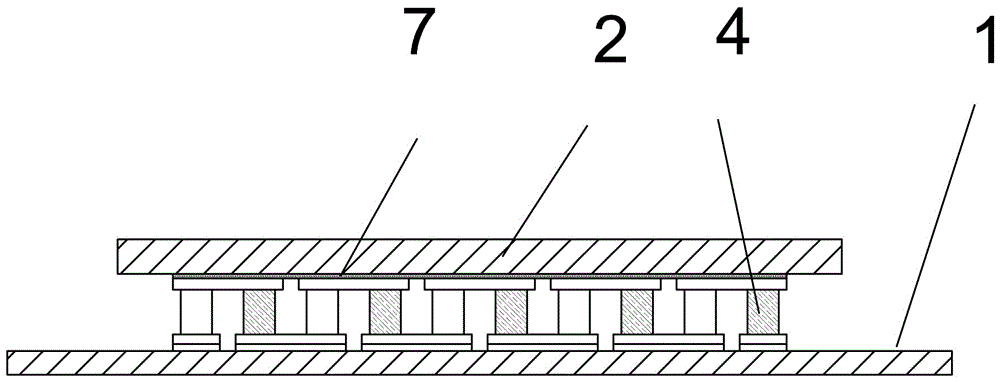

Semiconductor refrigeration system

InactiveCN106152598ASolve the brittleSolve the positioning problemMachines using electric/magnetic effectsRefrigeration componentsEngineeringAluminum substrate

The invention discloses a semiconductor refrigeration system. The semiconductor refrigeration system comprises a refrigeration chip, a heat end radiator and a heat end fan; the refrigeration chip includes a P / N couple pair, an electric conducting electrode, a cold end substrate and a heat end substrate; the cold and heat end substrates adopt aluminum substrates; at least one couple crystal grain in the P / N couple pair is manufactured by a mechanical pressurizing process; the heat end substrate is provided with a mounting part larger than the cold end substrate; and the heat end substrate is joined with the radiator through a fixed bolt. The semiconductor refrigeration system adopts the aluminum substrates to solve the problem of easy brittleness in traditional ceramic. The semiconductor refrigeration system presses the grains, improves the grain rigidity, is more suitable for vehicle-mounted use environments, and improves the pressure resistance of chips through a four-corner stand column structure.

Owner:GUANGDONG FUXIN ELECTRONICS TECH

Preparation method of edible food packaging film

InactiveCN106380867AGrowth inhibitionSolve moisture permeabilityFlexible coversWrappersWhey proteinFood packaging

The invention relates to a preparation method of an edible food packaging film, and belongs to the technical field of food packaging film preparation. The preparation method comprises the following steps: firstly extracting and preparing tung oil from tung seeds; then taking pigskin as a raw material, and carrying out enzymolysis, thus preparing pigskin collagen; then compounding the pigskin collagen with whey protein, chitosan and the like, thus obtaining a packaging film. A collagen film has good gas barrier property, entrance and loss of water can be effectively prevented by utilizing self polarity of the tung oil, the brittleness of the collagen film can be improved through the adding of xanthan gum, and the softness of the edible food packaging film is increased; according to the edible food packaging film prepared by the invention, the problems of poor moisture penetrability, poor gas barrier property, poor antibacterial property and large brittleness are solved, the prepared edible food packaging film is capable of inhibiting growth of food microorganism during a storage process, and the shelf life can also be prolonged by 1 to 2 times.

Owner:TRUSYN CHEM TECH

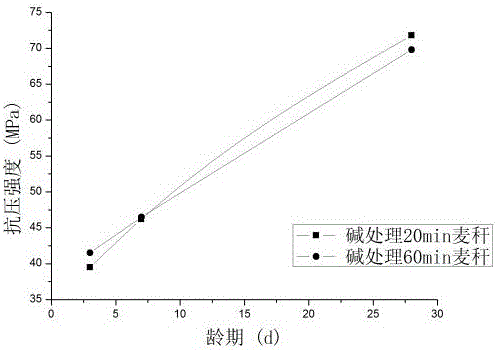

Plant fiber reinforced alkali slag cementing material and preparation method thereof

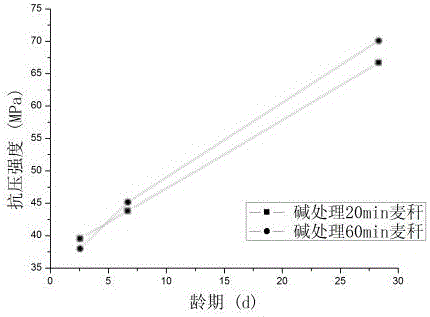

The invention relates to a plant fiber reinforced alkali slag cementing material and a preparation method thereof. To solve the problem of large brittleness of alkali slag cementing material, an adobe wall preparation method for doping certain wheat-straws, rice straws and other plant fibers into adobe of an adobe wall to improve ductility is referred, and plant fibers are added into an alkali slag cementing material in a test to improve the defect of large brittleness. The preparation method comprises the following steps: carrying out alkali treatment on plant fibers, namely soaking the plant fibers with a sodium hydroxide solution having the mass percentage of 10 percent for 20 minutes or 60 minutes; rinsing with clear water, naturally drying the alkali-treated plant fibers in a shadow place until the moisture content is 15 percent for use, and doping the plant fibers into the alkali slag cementing material. The invention is applicable to plant fiber reinforced alkali slag cementing materials and the preparation method thereof.

Owner:HARBIN UNIV OF SCI & TECH

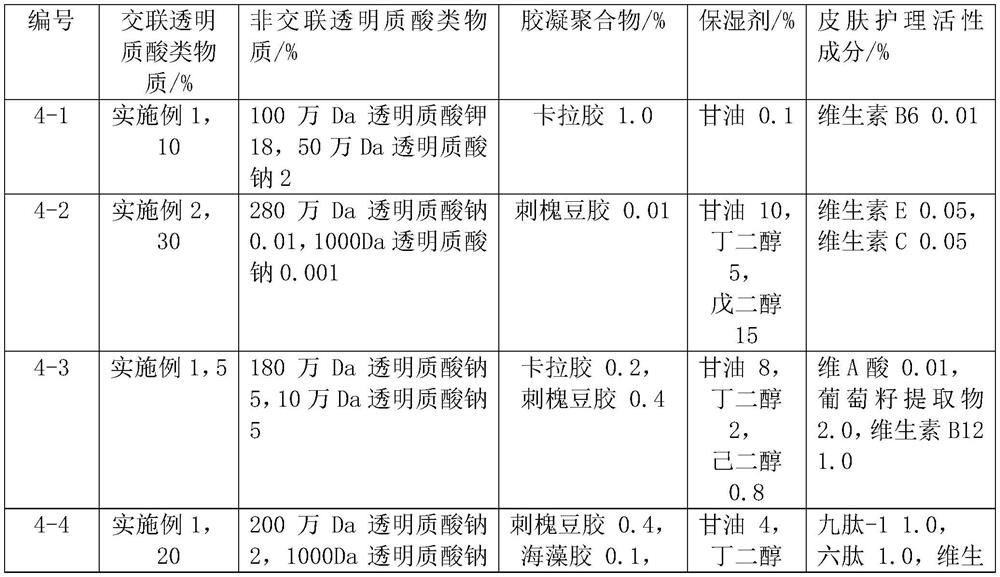

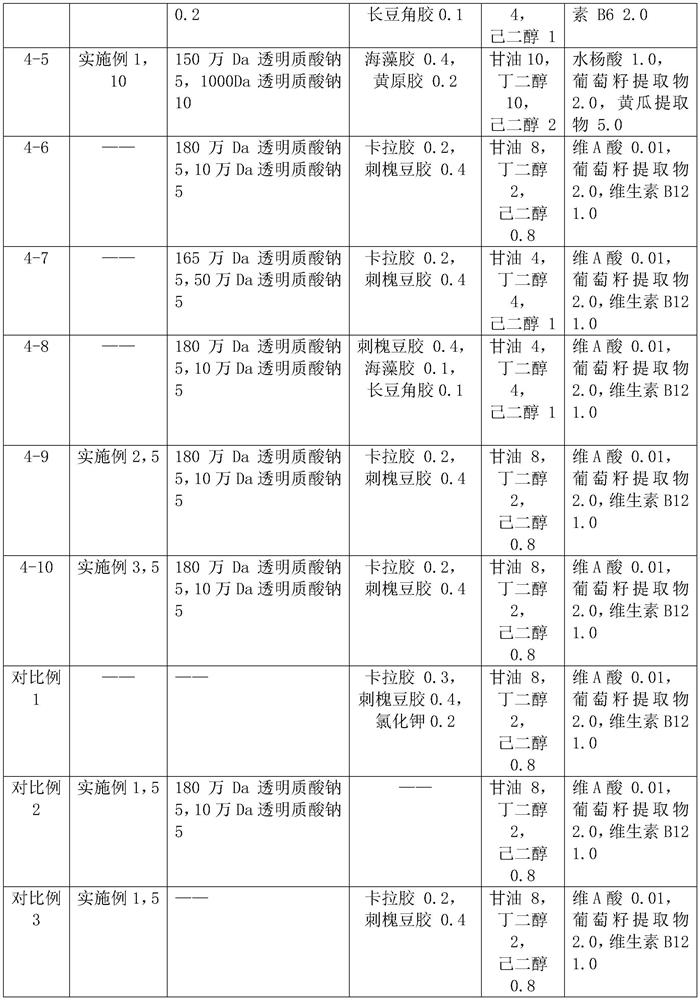

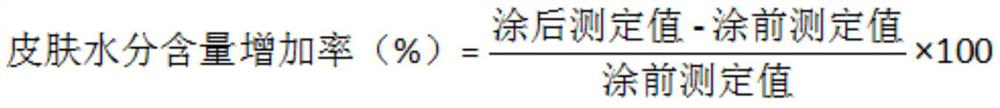

Hydrogel patch for skin care and preparation method thereof

ActiveCN112121032AImprove toughnessHigh strengthCosmetic preparationsToilet preparationsBULK ACTIVE INGREDIENTUlcer care

The invention discloses a hydrogel patch for skin care and a preparation method of the hydrogel patch. A hyaluronic acid substance serves as a main hydrogel matrix to be compounded with a small amountof gel polymers, so that the toughness and the strength of the hydrogel patch are improved. Meanwhile, the hydrogel patch is high in water locking property and low in drainage rate, has the effects of preserving moisture for a long time and promoting percutaneous absorption of active ingredients or medicines, and can be used for skin beauty care, skin trauma and ulcer care and application care ofsoft tissue sprain. Different shapes can be formed by pouring according to different use parts, including the whole face, the nose part, the eyes, the lip, the neck and the body parts such as the abdomen, the hip and the four limbs.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD

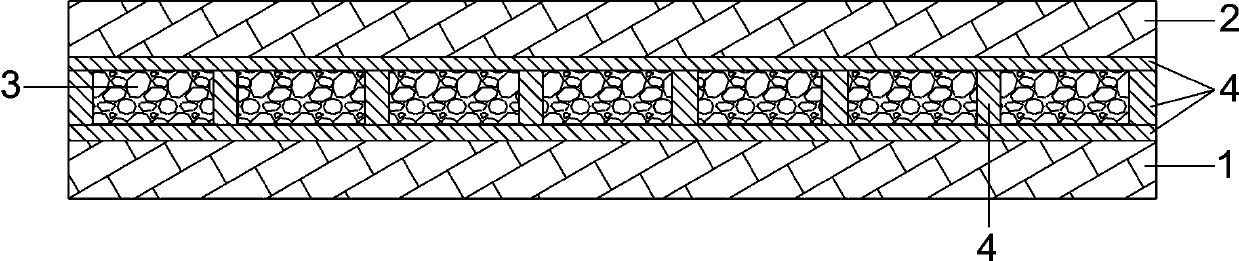

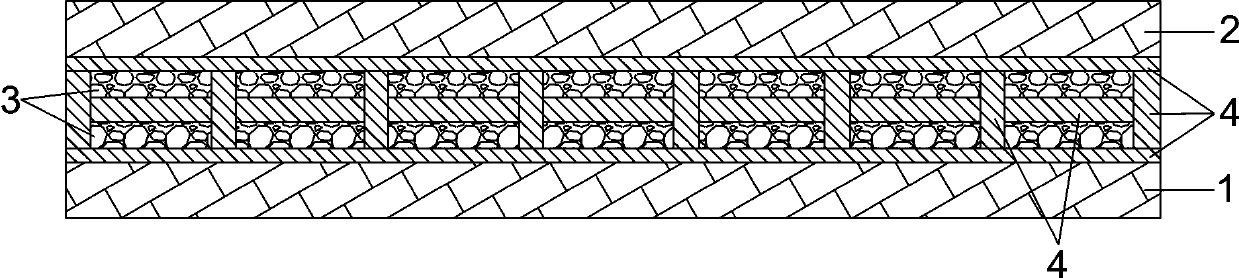

Thermal insulation board and preparation method thereof

InactiveCN111516347AImprove mechanical propertiesSolve the brittleSynthetic resin layered productsDomestic articlesThermal insulationMold removal

The invention belongs to the technical field of thermal insulation materials, and discloses a thermal insulation board and a preparation method thereof. The thermal insulation board comprises a firstpanel layer, a second panel layer, a sandwich layer and framework supporting layers. The sandwich layer is an aerogel felt layer or is formed by stacking two or more aerogel felt layers, and each aerogel felt layer is formed by splicing a plurality of fiber-reinforced aerogel composite felts; the sandwich layer is arranged between the first panel layer and the second panel layer, the lower surfaceof the sandwich layer and the first panel layer, the upper surface of the sandwich layer and the second panel layer, the peripheral edge of the sandwich layer and a splicing seam of any two adjacentfiber reinforced aerogel composite felts in the sandwich layer are integrally formed and filled with the framework supporting layer. The preparation method comprises the following steps: laying, sealing, preparing a glue solution, injecting glue, curing and demolding to obtain the thermal insulation board. An integral curing molding method is adopted, the framework supporting layers are formed while the panel is obtained, and the prepared thermal insulation board has the advantages of light weight, thermal insulation and greatly improved mechanical properties.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

Preparation method for thermosetting phenolic resin tensile sample with high solvent content

PendingCN109228084AImprove bindingImprove mechanical propertiesPreparing sample for investigationAlcoholReaction temperature

The invention relates to a preparation technology for a thermosetting phenolic resin casting matrix with high solvent content and is suitable for mold design of casting matrix tensile samples. A four-frame combined molding chamber structure is adopted for reasonably designing a phenolic resin tensile sample mold. Reaction temperature and reaction time are strictly controlled by controlling a curing reaction process; the phenolic resin is subjected to pre-gelling treatment under the conditions of certain temperature and certain time till the resin is under a semi-gel state; most micro-molecules, such as water and formaldehyde, generated from condensation polymerization are removed from the resin under the semi-gel state, and meanwhile, the ethyl alcohol solvent contained in the phenolic resin is removed and an excellent binding force between resin and resin is kept; the phenolic resin under the semi-gel state is put into a mold for further curing, so as to finally acquire a transparentphenolic resin tensile sample. According to the invention, the problems of more defects, easiness in breaking while de-molding and the like of phenolic resin tensile sample can be solved, and the tensile sample with high success rate and few defects can be acquired.

Owner:TIANJIN POLYTECHNIC UNIV

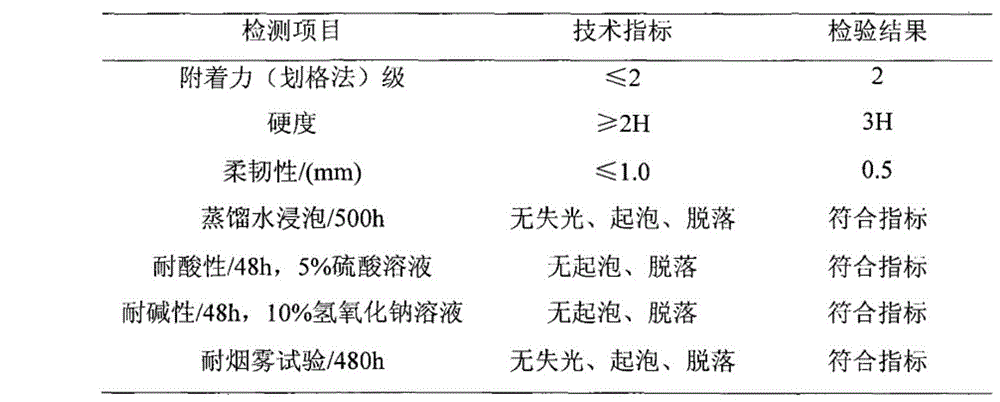

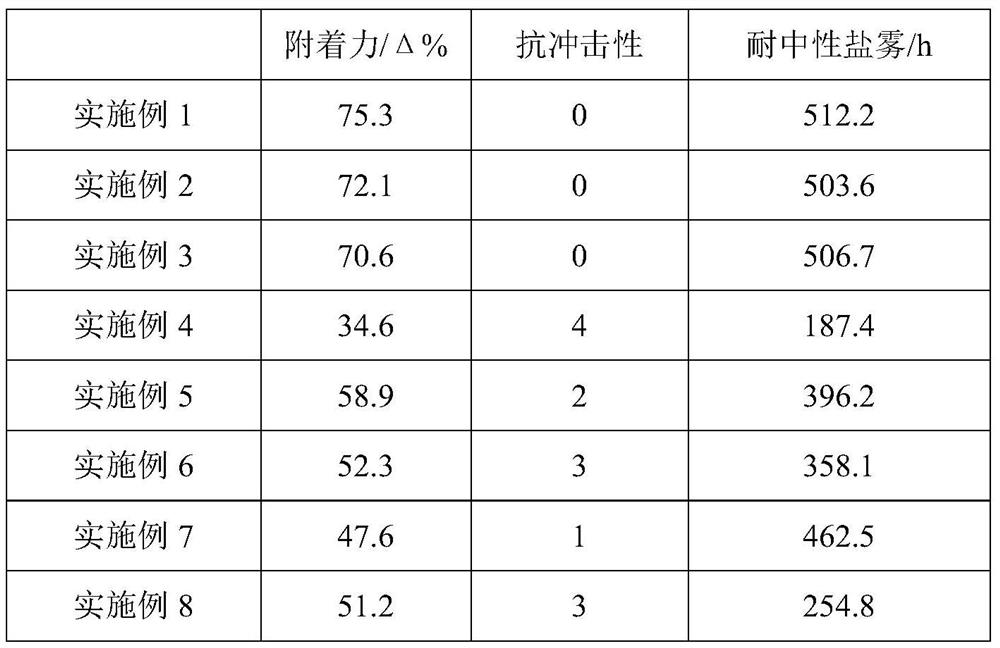

Water-based heavy anti-corrosion coating containing water-based modified chlorinated polyether emulsion and preparation method of coating

The invention relates to the field of heavy anti-corrosion coatings, in particular to a water-based heavy anti-corrosion coating containing water-based modified chlorinated polyether emulsion and a preparation method of the water-based heavy anti-corrosion coating. In percentage by weight, a component A of coating comprises the following raw materials: 52-59% of water-based modified epichlorohydrin emulsion, 4-8% of superfine barium sulfate, 3-6% of mica powder, 2-6% of zinc phosphate, 1-3% of aluminum zinc orthophosphate, 0.1-0.5% of a thickening agent, 0.1-0.2% of a wetting agent, 0.3-0.5% of a defoaming agent, 0.1-0.4% of a dispersing agent, 0.01-0.05% of a flash rust inhibitor, 0.05-0.1% of an anti-settling agent, 0.05-0.1% of a flatting agent, 1-5% of a coalescing agent, 4-8% of filler 1-3% of silica powder, and with the remainder of water ; a component B comprises 50% of a curing agent and 50% of water; and the weight ratio of the component A to the component B is 1: (1-1.5). The water-based heavy anti-corrosion coating containing the water-based modified chlorinated polyether emulsion is prepared, the prepared water-based heavy anti-corrosion coating is high in flexibility and impact resistance, can be rapidly cured at normal temperature, is high in adhesive force with a base material, can keep a lasting salt spray resistance protection effect, and has a wide application prospect.

Owner:杭州电化新材料有限公司

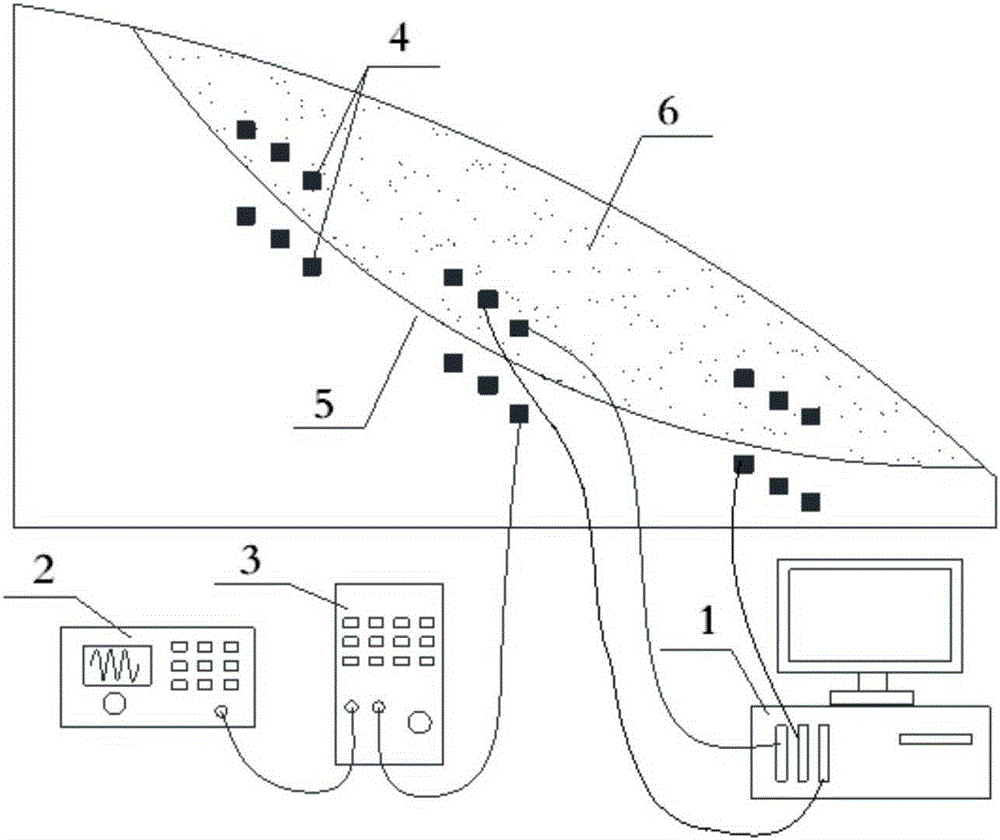

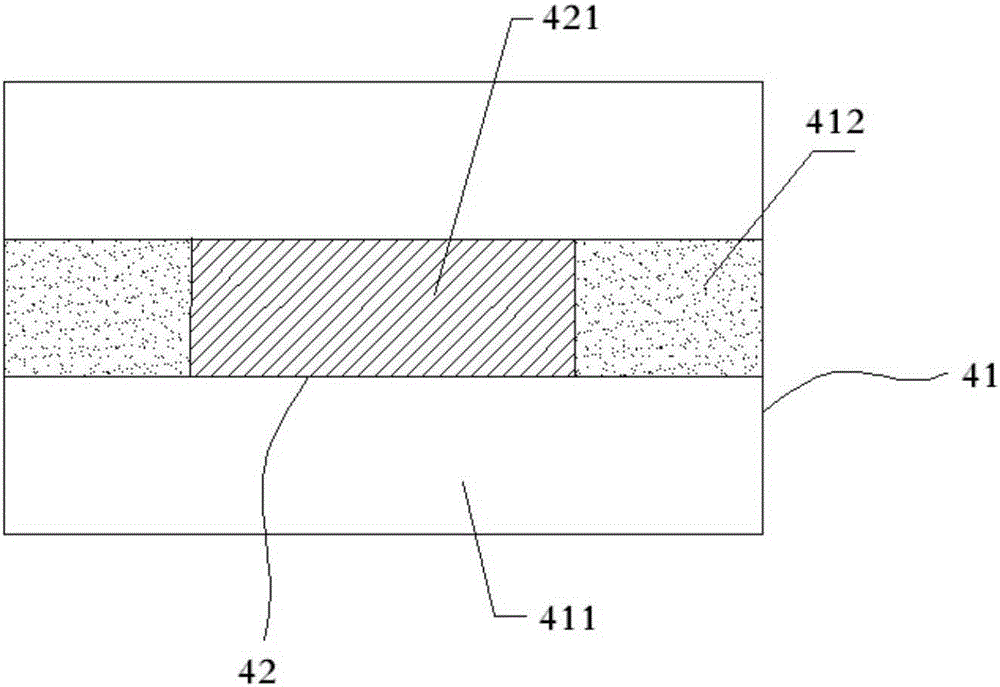

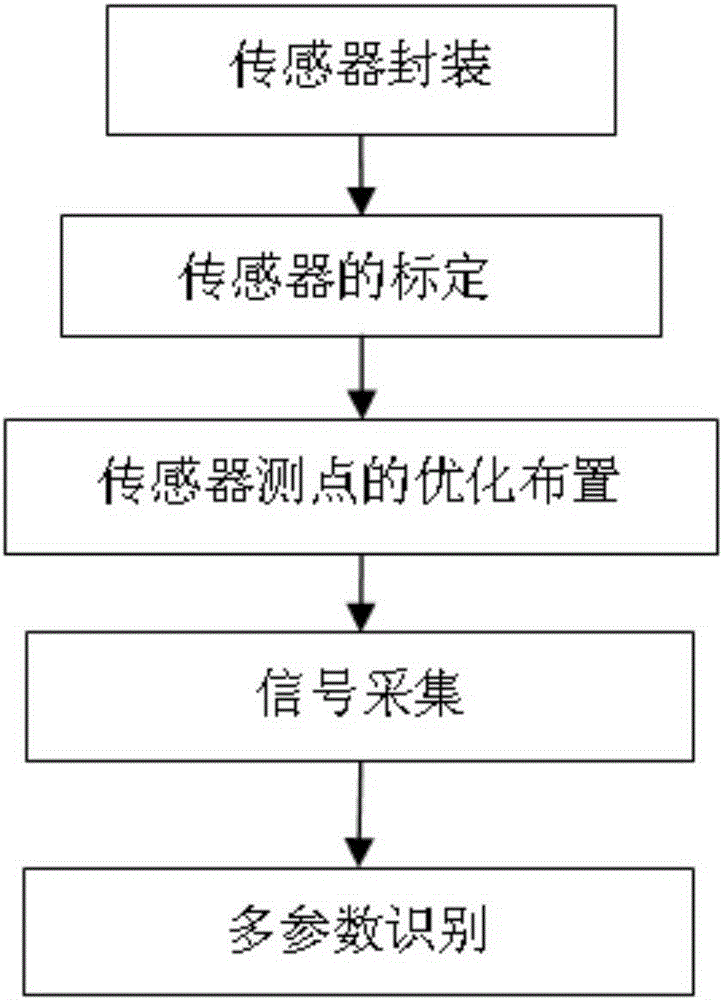

Multi-parameter monitoring system and method for geotechnical material in landslide area

ActiveCN105203736AReduce landslide accidents and casualtiesSolve the brittleEarth material testingWater contentSensor array

The invention discloses a multi-parameter monitoring system and method for a geotechnical material in a landslide area. According to the method, a piezoelectric ceramic sensor array is embedded in an area prone to a landslide, by means of the inverse piezoelectric effect of piezoelectric ceramic sensors, voltage is applied to any piezoelectric ceramic sensor, stress waves are generated and emitted to the periphery, then the stress waves are received by the aid of the direct piezoelectric effect of the piezoelectric ceramic sensors, voltage signals can be output, and the modulus of elasticity of soil media can be calculated through the time difference between voltage signal emitting and voltage signal receiving and the arrangement distance; the change of the water content of the soil and whether crack damage happens can be determined through change of the amplitude values of the voltage signals. The property parameters of the geotechnical material in the landslide area can be known in real time, the method can be used for early warning of the landslide, and landslide accidents and casualties are reduced effectively; compared with other monitoring methods, the method is reliable, stable, low in cost and easy to implement and is applicable to engineering in the landslide area with high capacity and wide range.

Owner:西安电子科技大学昆山创新研究院

High-strength bus duct and manufacturing method thereof

ActiveCN108963926AQuick repairAvoid accidentsCooling bus-bar installationsTotally enclosed bus-bar installationsEngineeringMetal

The invention discloses a high-strength bus duct and a manufacturing method thereof and relates to the technical field of a bus duct. The bus duct comprises a casing composed of a side board and a cover board, wherein an outer side of the side board is provided with multiple grooves, the grooves are internally provided with dual-metal pieces, the dual-metal pieces respectively comprise a deformation portion arranged at the middle and connection portions arranged at two ends, the connection portions are hinged with side walls of the grooves, in a normal temperature state, the dual-metal piecesare completely in the grooves, when the temperature of the side board reaches the preset value, the deformation portions are outside the grooves. The bus duct is advantaged in that the dual-metal pieces can be used to remind the staff that the temperature in the bus duct is too high, so timely measures are taken, and accidents are avoided.

Owner:荣马电器有限公司

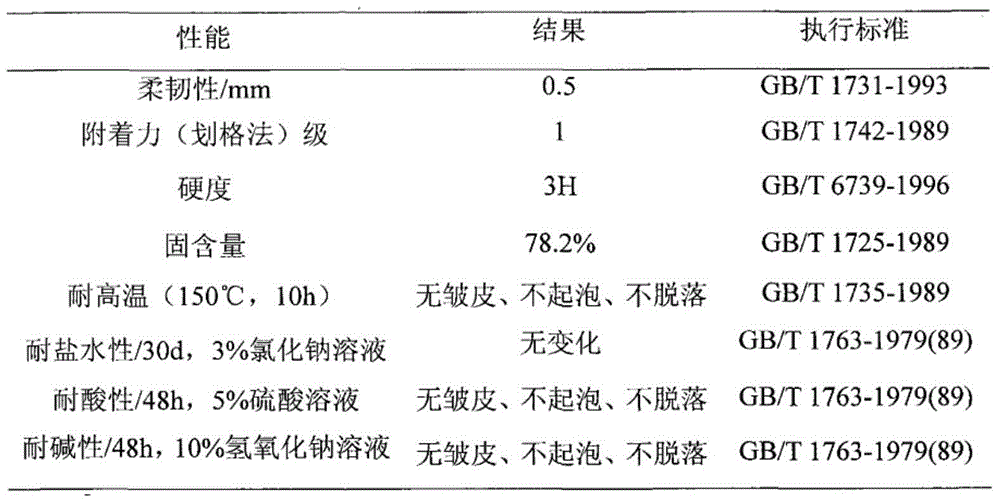

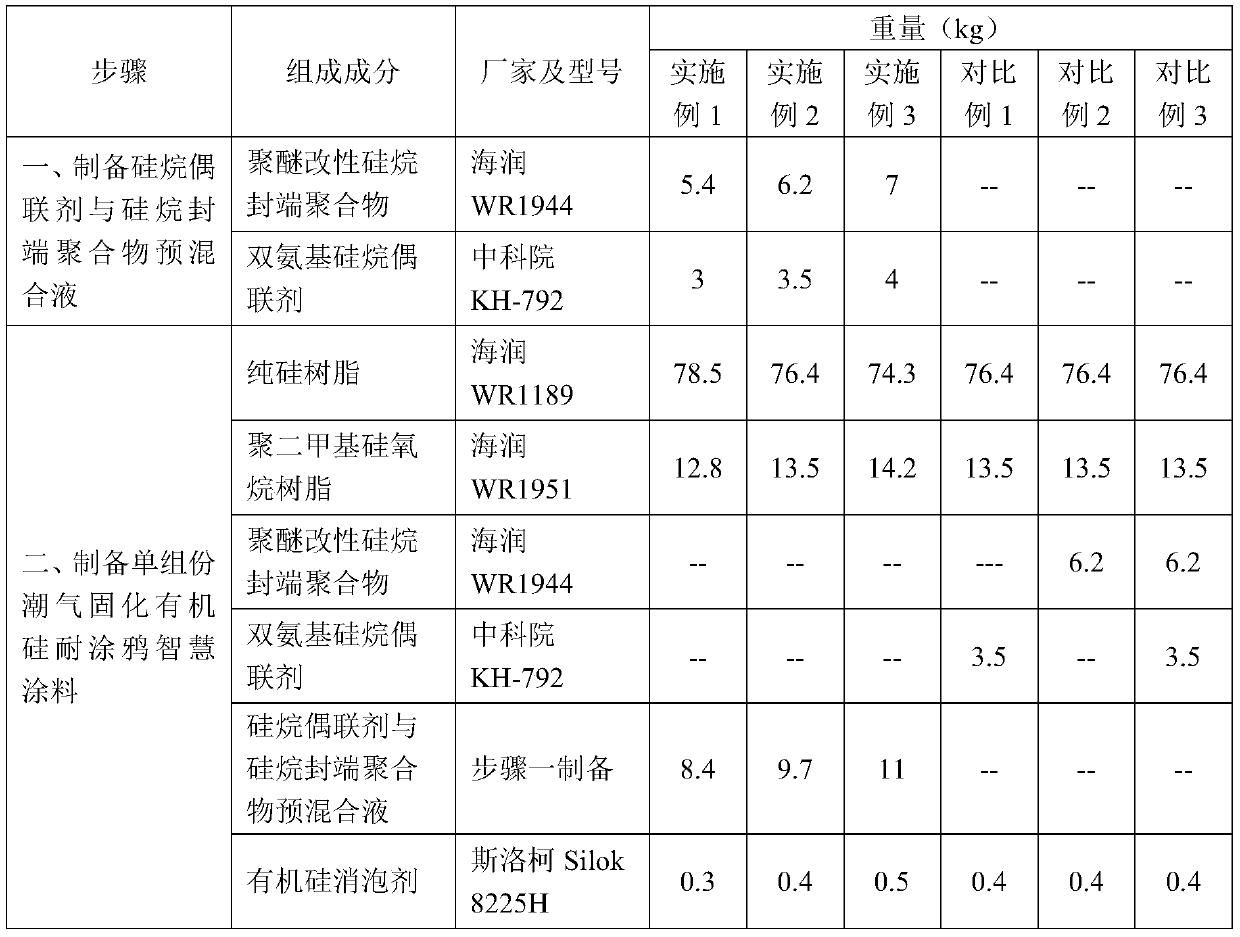

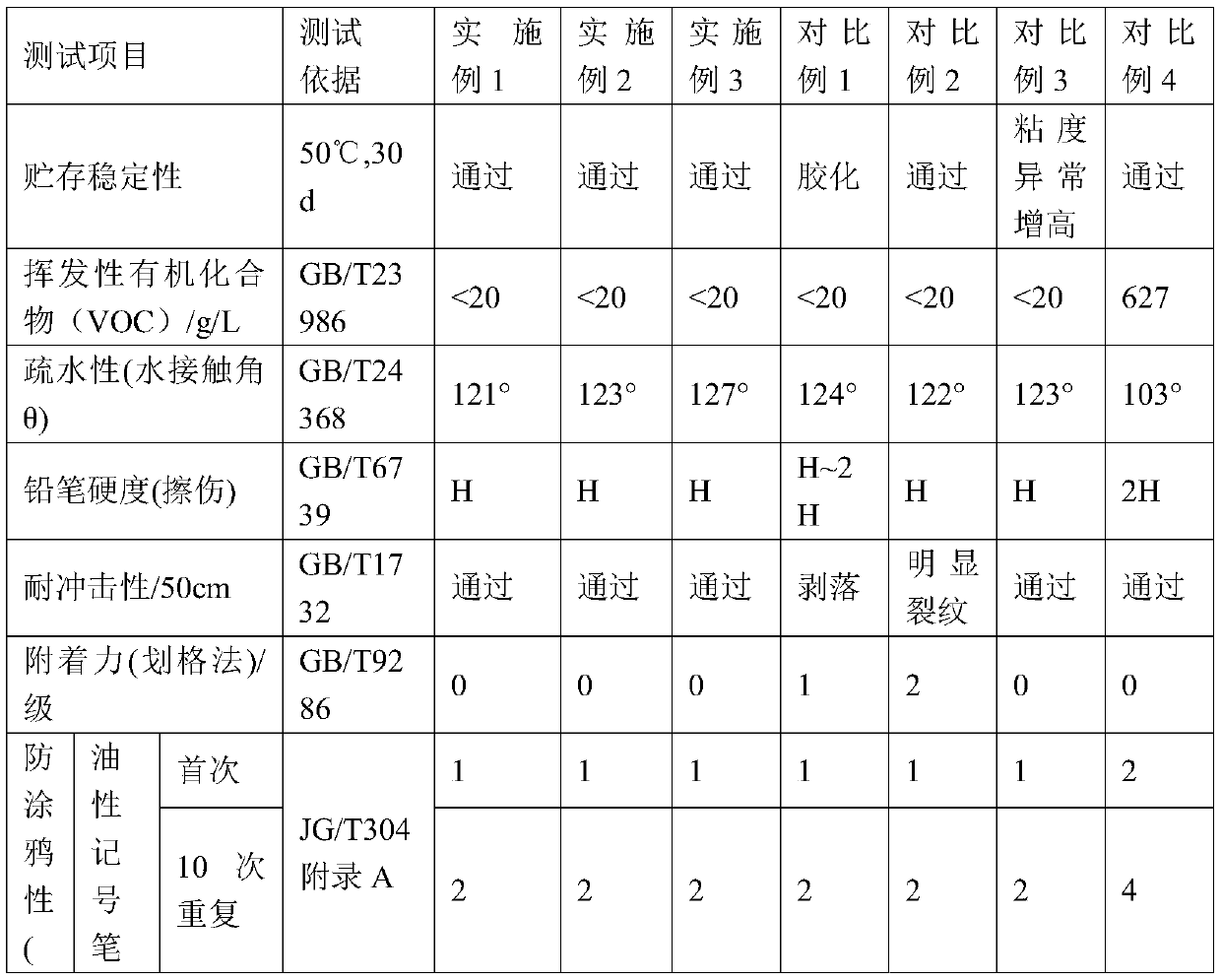

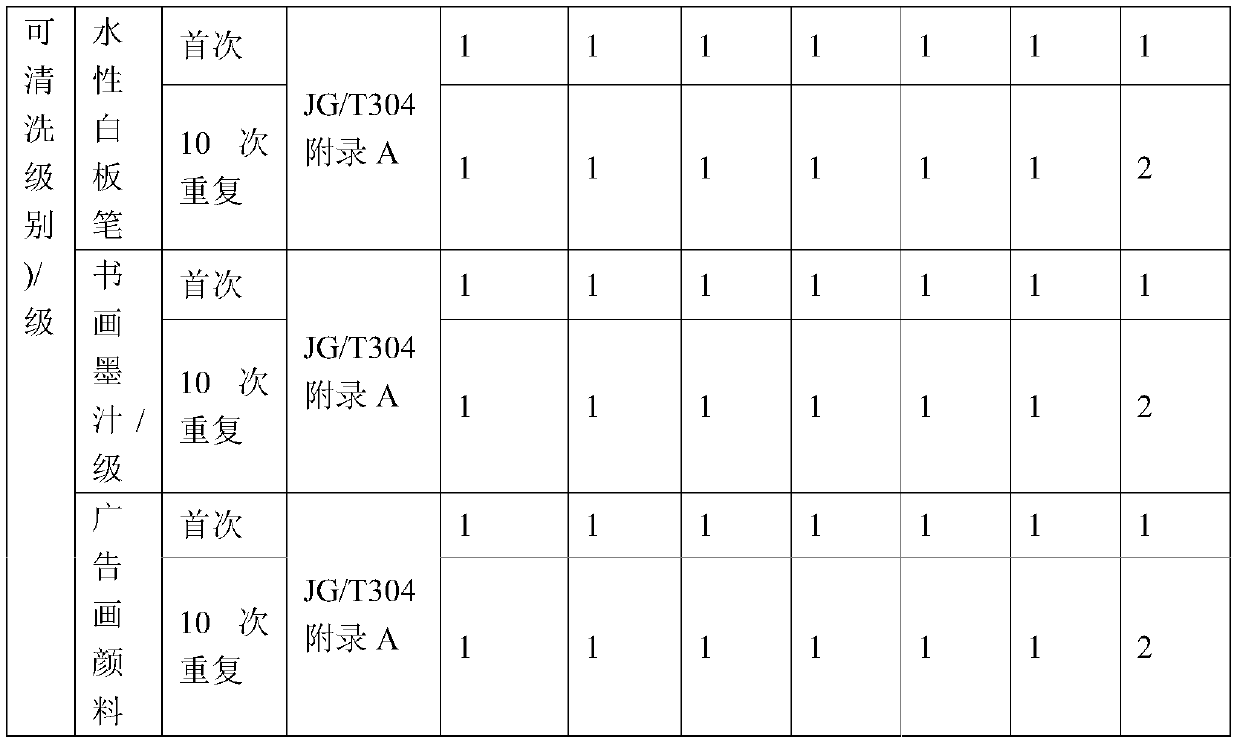

One-component moisture-curable organosilicon graffito-resistant intelligent coating material and preparation method thereof

ActiveCN110467877ALower surface energyStrong water and oil repellencyCoatingsSilanesTherapeutic effect

The invention provides a one-component moisture-curable organosilicon graffito-resistant intelligent coating material and a preparation method thereof, wherein the one-component moisture-curable organosilicon graffito-resistant intelligent coating material is obtained by mixing and blending the following components by weight: 74.3-78.5 parts of a pure silicon resin, 12.8-14.2 parts of a polydimethylsiloxane resin, 8.4-11.0 parts of a pre-mixed solution of a silane coupling agent and a silane-terminated polymer, and 0.3-0.5 part of an organosilicon defoamer, wherein the pre-mixed solution of the silane coupling agent and the silane-terminated polymer is obtained by mixing and blending the following components by weight: 5.4-7.0 parts of a polyether-modified silane-terminated polymer and 3.0-4.0 parts of a diaminosilane coupling agent. According to the present invention, the prepared one-component moisture-curable organosilicon graffito-resistant intelligent coating material can solve the problems of not lasting effect and incomplete protection of the graffito-resistant coating material, and further has the following characteristics that the hydrophobicity of the graffito-resistant product coating is strong, and the prevention and treatment effect on oily marking pens is good and long-lasting.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

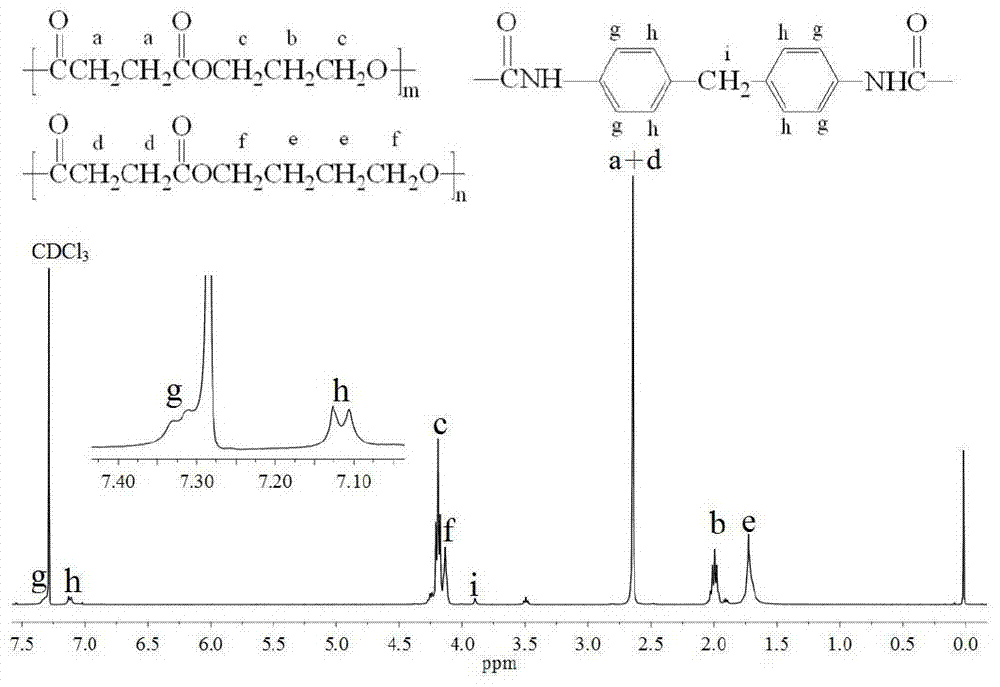

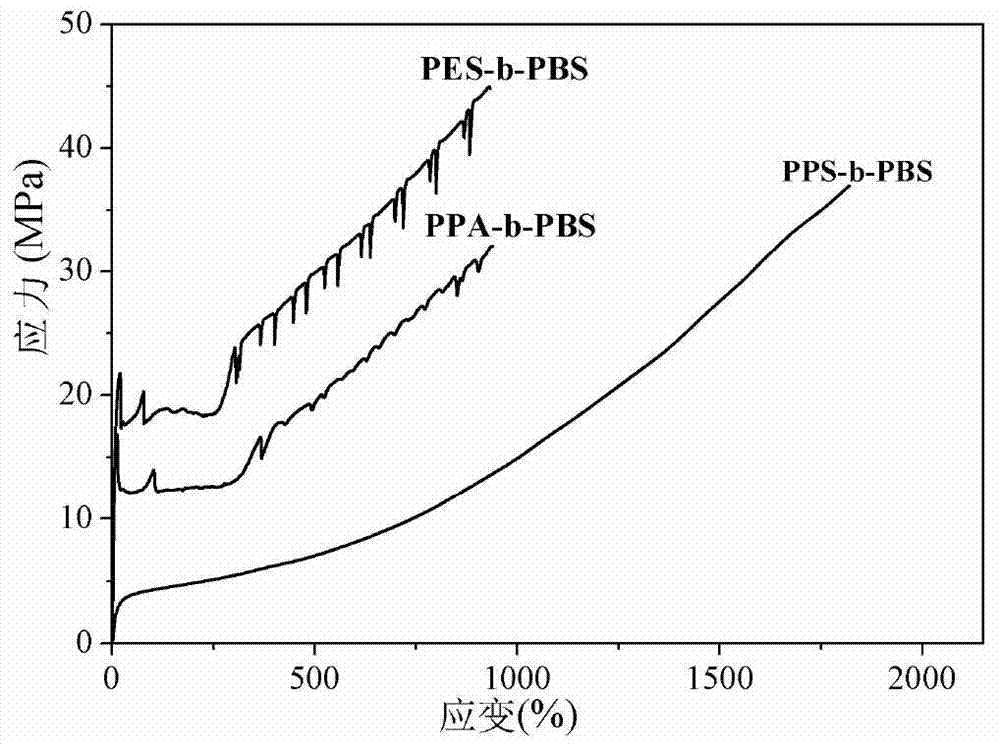

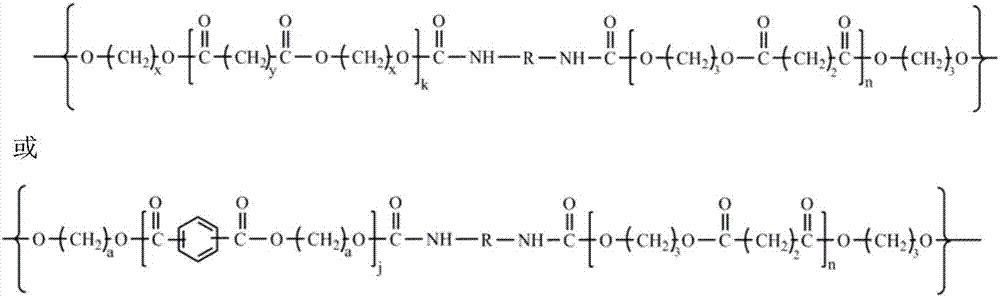

A kind of high tenacity multi-block copolyester elastomer and preparation method thereof

The invention discloses a high-toughness multiblock copolyester elastomer. The high-toughness multiblock copolyester elastomer has the structural general formula shown in descriptions, wherein R represents an alkyl part of diisocyanate, each of j, k and n is an integer greater than 6, each of x and a is an integer between 2 and 10, y is an integer between 0 and 8, y is not equal to 2 when x is equal to 3, and x is not equal to 3 when y is equal to 2. The high-toughness multiblock copolyester elastomer has the limiting viscosity number of 1.0-3.2dL / g, the melting point of 40-240 DEG C, the tensile strength of 10-50MPa and the elongation at break of 1,112-2,200%. The invention further discloses a preparation method of the high-toughness multiblock copolyester elastomer. According to the high-toughness multiblock copolyester elastomer prepared by the preparation method, the melting point and molecular weight are high, the mechanical properties are excellent, and the controllability and repeatability are good, so that the range of application of the high-toughness multiblock copolyester elastomer prepared by the preparation method can be wider.

Owner:SICHUAN UNIV

Fireproof insulation board of aerated concrete of B02-level light sand

The invention discloses a fireproof insulation board of aerated concrete of B02-level light sand. The constituents and weight percentages of the fireproof insulation board are as follow: 45-55% of quartz sand, 12-16% of lime, 24-37% of cement, 5% of gypsum, 0.25-0.35% of aluminite powder and 0.2-0.6% of composite admixture, wherein the composite admixture is admixture with composite stabilizing, toughening and waterproof functions, and the constituents and weight percentages are as follow: 25-30% of sodium abietate, 22-26% of chlorinated paraffin, 24-28% of petroleum ether and 20-25% of organo-siloxane. The fireproof insulation board has the advantages that the fireproof insulation board compensates the disadvantages and defects of the prior art, overcomes the production difficulties, and improves the casting stability when reducing dry density of the aerated concrete product of the sand, so as to conveniently transport and construct the product, and meet huge demands of the construction market and energy conservation and environmental protection requirements of people on building materials in cities.

Owner:天津滨海天筑永利建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com